Advances in PLA Decomposition Rates in Soil Conditions

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Biodegradation Background and Objectives

Polylactic acid (PLA) has emerged as a promising biodegradable polymer, gaining significant attention in recent years due to its potential to address environmental concerns associated with conventional plastics. The biodegradation of PLA in soil conditions represents a critical area of research, as it directly impacts the material's end-of-life management and its overall environmental footprint.

The evolution of PLA technology can be traced back to the 1930s when it was first synthesized by Wallace Carothers. However, it wasn't until the late 20th century that PLA gained traction as a viable alternative to petroleum-based plastics. The increasing focus on sustainable materials and circular economy principles has further accelerated research and development efforts in PLA biodegradation.

The primary objective of advancing PLA decomposition rates in soil conditions is to enhance the material's environmental compatibility while maintaining its functional properties during use. This goal aligns with broader sustainability initiatives and regulatory pressures to reduce plastic waste and its environmental impact. Researchers aim to optimize PLA formulations and develop strategies to control and accelerate its degradation process in various soil environments.

Key technological trends in this field include the development of PLA blends and composites with enhanced biodegradability, the incorporation of pro-degradant additives, and the exploration of microbial strains capable of efficiently breaking down PLA. Additionally, there is a growing interest in understanding the influence of soil characteristics, such as pH, temperature, and microbial activity, on PLA decomposition rates.

The advancement of PLA biodegradation technology is expected to have far-reaching implications across multiple industries, including packaging, agriculture, and biomedical applications. Improved decomposition rates could expand PLA's applicability in single-use products and agricultural mulch films, where rapid biodegradation is crucial for environmental protection and soil health.

As research progresses, scientists are also focusing on developing standardized testing methods to accurately assess PLA biodegradation in various soil conditions. This standardization is essential for comparing different PLA formulations and ensuring consistent performance across diverse environmental settings.

The pursuit of enhanced PLA decomposition rates in soil conditions represents a multidisciplinary effort, involving polymer science, microbiology, soil science, and environmental engineering. By addressing the challenges associated with PLA biodegradation, researchers aim to unlock the full potential of this sustainable material and contribute to the global effort in reducing plastic pollution and promoting circular economy principles.

The evolution of PLA technology can be traced back to the 1930s when it was first synthesized by Wallace Carothers. However, it wasn't until the late 20th century that PLA gained traction as a viable alternative to petroleum-based plastics. The increasing focus on sustainable materials and circular economy principles has further accelerated research and development efforts in PLA biodegradation.

The primary objective of advancing PLA decomposition rates in soil conditions is to enhance the material's environmental compatibility while maintaining its functional properties during use. This goal aligns with broader sustainability initiatives and regulatory pressures to reduce plastic waste and its environmental impact. Researchers aim to optimize PLA formulations and develop strategies to control and accelerate its degradation process in various soil environments.

Key technological trends in this field include the development of PLA blends and composites with enhanced biodegradability, the incorporation of pro-degradant additives, and the exploration of microbial strains capable of efficiently breaking down PLA. Additionally, there is a growing interest in understanding the influence of soil characteristics, such as pH, temperature, and microbial activity, on PLA decomposition rates.

The advancement of PLA biodegradation technology is expected to have far-reaching implications across multiple industries, including packaging, agriculture, and biomedical applications. Improved decomposition rates could expand PLA's applicability in single-use products and agricultural mulch films, where rapid biodegradation is crucial for environmental protection and soil health.

As research progresses, scientists are also focusing on developing standardized testing methods to accurately assess PLA biodegradation in various soil conditions. This standardization is essential for comparing different PLA formulations and ensuring consistent performance across diverse environmental settings.

The pursuit of enhanced PLA decomposition rates in soil conditions represents a multidisciplinary effort, involving polymer science, microbiology, soil science, and environmental engineering. By addressing the challenges associated with PLA biodegradation, researchers aim to unlock the full potential of this sustainable material and contribute to the global effort in reducing plastic pollution and promoting circular economy principles.

Market Analysis for Biodegradable Plastics

The biodegradable plastics market has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. The global market for biodegradable plastics was valued at approximately $4.2 billion in 2020 and is projected to reach $7.8 billion by 2025, growing at a CAGR of 13.3% during the forecast period.

Polylactic acid (PLA), a key biodegradable plastic derived from renewable resources such as corn starch or sugarcane, has emerged as a prominent player in this market. The PLA market specifically is expected to grow from $786 million in 2020 to $1.8 billion by 2025, with a CAGR of 18.1%.

The packaging industry remains the largest consumer of biodegradable plastics, accounting for over 60% of the total market share. This is followed by the agriculture and horticulture sector, which utilizes biodegradable mulch films and plant pots. The textile industry is also showing increased interest in biodegradable fibers, particularly for disposable applications.

Geographically, Europe leads the biodegradable plastics market, driven by stringent regulations and high consumer awareness. North America follows closely, with the United States being a major contributor due to its large agricultural sector and growing demand for sustainable packaging solutions. The Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth in the coming years.

Consumer demand for environmentally friendly products is a key driver of market growth. A survey conducted in 2020 revealed that 74% of consumers are willing to pay more for sustainable packaging. This shift in consumer behavior has prompted major brands and retailers to commit to using biodegradable or compostable packaging materials.

However, the market faces challenges such as higher production costs compared to conventional plastics and limited industrial composting facilities. The average cost of biodegradable plastics is still 20-100% higher than traditional plastics, depending on the specific material and application.

Recent advancements in PLA decomposition rates in soil conditions have the potential to address some of these challenges and further boost market growth. Improved biodegradability in natural environments could expand the range of applications for PLA and increase its attractiveness to both consumers and industries seeking more sustainable material options.

Polylactic acid (PLA), a key biodegradable plastic derived from renewable resources such as corn starch or sugarcane, has emerged as a prominent player in this market. The PLA market specifically is expected to grow from $786 million in 2020 to $1.8 billion by 2025, with a CAGR of 18.1%.

The packaging industry remains the largest consumer of biodegradable plastics, accounting for over 60% of the total market share. This is followed by the agriculture and horticulture sector, which utilizes biodegradable mulch films and plant pots. The textile industry is also showing increased interest in biodegradable fibers, particularly for disposable applications.

Geographically, Europe leads the biodegradable plastics market, driven by stringent regulations and high consumer awareness. North America follows closely, with the United States being a major contributor due to its large agricultural sector and growing demand for sustainable packaging solutions. The Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth in the coming years.

Consumer demand for environmentally friendly products is a key driver of market growth. A survey conducted in 2020 revealed that 74% of consumers are willing to pay more for sustainable packaging. This shift in consumer behavior has prompted major brands and retailers to commit to using biodegradable or compostable packaging materials.

However, the market faces challenges such as higher production costs compared to conventional plastics and limited industrial composting facilities. The average cost of biodegradable plastics is still 20-100% higher than traditional plastics, depending on the specific material and application.

Recent advancements in PLA decomposition rates in soil conditions have the potential to address some of these challenges and further boost market growth. Improved biodegradability in natural environments could expand the range of applications for PLA and increase its attractiveness to both consumers and industries seeking more sustainable material options.

Current PLA Decomposition Challenges

Polylactic acid (PLA) decomposition in soil conditions presents several significant challenges that hinder its widespread adoption as a sustainable alternative to conventional plastics. One of the primary issues is the variability in decomposition rates across different soil environments. Factors such as temperature, moisture content, pH levels, and microbial activity can greatly influence the rate at which PLA breaks down, leading to inconsistent performance in real-world applications.

The slow decomposition rate of PLA in ambient soil conditions is another major concern. While PLA is biodegradable, it often requires specific industrial composting conditions to degrade efficiently. In natural soil environments, PLA can persist for extended periods, sometimes taking several years to fully decompose. This prolonged presence in the environment can lead to accumulation and potential ecological impacts, undermining the material's eco-friendly credentials.

Furthermore, the incomplete degradation of PLA poses a challenge. In some cases, PLA may fragment into smaller particles rather than fully biodegrading. These microplastics can persist in the environment and potentially enter food chains, raising concerns about long-term ecological and health effects. The formation of these persistent fragments highlights the need for more comprehensive degradation processes.

The impact of additives and blends on PLA decomposition is another area of concern. Many PLA products contain additives or are blended with other materials to enhance their properties. These additions can significantly alter the decomposition behavior of PLA, often slowing down the process or introducing new environmental challenges. Balancing the desired material properties with optimal decomposition characteristics remains a complex challenge for manufacturers and researchers.

Temperature sensitivity is a critical factor affecting PLA decomposition. The material typically requires temperatures above 58°C for efficient breakdown, which are rarely achieved in natural soil conditions. This temperature requirement limits the effectiveness of PLA as a biodegradable solution in many real-world scenarios, particularly in colder climates or during winter months.

Lastly, the lack of standardized testing methods for PLA decomposition in soil conditions hampers progress in this field. Current testing protocols often fail to accurately simulate real-world conditions, leading to discrepancies between laboratory results and actual environmental performance. This inconsistency makes it challenging to assess and compare different PLA formulations and to develop effective strategies for enhancing decomposition rates in diverse soil environments.

The slow decomposition rate of PLA in ambient soil conditions is another major concern. While PLA is biodegradable, it often requires specific industrial composting conditions to degrade efficiently. In natural soil environments, PLA can persist for extended periods, sometimes taking several years to fully decompose. This prolonged presence in the environment can lead to accumulation and potential ecological impacts, undermining the material's eco-friendly credentials.

Furthermore, the incomplete degradation of PLA poses a challenge. In some cases, PLA may fragment into smaller particles rather than fully biodegrading. These microplastics can persist in the environment and potentially enter food chains, raising concerns about long-term ecological and health effects. The formation of these persistent fragments highlights the need for more comprehensive degradation processes.

The impact of additives and blends on PLA decomposition is another area of concern. Many PLA products contain additives or are blended with other materials to enhance their properties. These additions can significantly alter the decomposition behavior of PLA, often slowing down the process or introducing new environmental challenges. Balancing the desired material properties with optimal decomposition characteristics remains a complex challenge for manufacturers and researchers.

Temperature sensitivity is a critical factor affecting PLA decomposition. The material typically requires temperatures above 58°C for efficient breakdown, which are rarely achieved in natural soil conditions. This temperature requirement limits the effectiveness of PLA as a biodegradable solution in many real-world scenarios, particularly in colder climates or during winter months.

Lastly, the lack of standardized testing methods for PLA decomposition in soil conditions hampers progress in this field. Current testing protocols often fail to accurately simulate real-world conditions, leading to discrepancies between laboratory results and actual environmental performance. This inconsistency makes it challenging to assess and compare different PLA formulations and to develop effective strategies for enhancing decomposition rates in diverse soil environments.

Existing PLA Decomposition Enhancement Methods

01 Environmental factors affecting PLA decomposition

The decomposition rate of PLA is influenced by various environmental factors such as temperature, humidity, pH, and the presence of microorganisms. Higher temperatures and moisture levels generally accelerate the decomposition process. The pH of the surrounding environment can also impact the rate of hydrolysis, which is a key mechanism in PLA breakdown.- Environmental factors affecting PLA decomposition: Various environmental factors influence the decomposition rate of PLA, including temperature, humidity, pH, and the presence of microorganisms. Higher temperatures and moisture levels generally accelerate the breakdown process, while acidic or alkaline conditions can also impact the rate of decomposition. The presence of specific microorganisms in the environment can significantly enhance PLA degradation.

- Additives to control PLA decomposition rate: Incorporating certain additives into PLA can modify its decomposition rate. These additives may include plasticizers, compatibilizers, or biodegradation promoters. By carefully selecting and adjusting the concentration of these additives, manufacturers can tailor the decomposition rate of PLA-based products to suit specific applications or environmental conditions.

- PLA blends and composites for controlled decomposition: Blending PLA with other biodegradable polymers or creating PLA-based composites can alter its decomposition characteristics. These blends or composites may exhibit different decomposition rates compared to pure PLA, allowing for more precise control over the material's lifespan in various environments. Natural fibers or inorganic fillers can also be incorporated to influence the decomposition process.

- Surface modifications to influence PLA decomposition: Modifying the surface of PLA materials can affect their decomposition rate. Techniques such as plasma treatment, chemical etching, or coating applications can alter the surface properties of PLA, potentially accelerating or decelerating its breakdown. These modifications can enhance or inhibit the material's interaction with environmental factors that drive decomposition.

- Enzymatic degradation of PLA: Specific enzymes can be used to enhance the decomposition rate of PLA. These enzymes, often derived from microorganisms, can catalyze the hydrolysis of PLA polymer chains, leading to faster breakdown of the material. Research into enzymatic degradation of PLA focuses on identifying effective enzymes and optimizing their application for controlled biodegradation in various environments.

02 Additives to control PLA decomposition rate

Various additives can be incorporated into PLA to modify its decomposition rate. These may include plasticizers, compatibilizers, or specific enzymes that can either accelerate or slow down the degradation process. By carefully selecting and adjusting the concentration of these additives, the decomposition rate of PLA can be tailored for specific applications.Expand Specific Solutions03 PLA blends and composites for controlled decomposition

Blending PLA with other biodegradable polymers or creating composites with natural fibers can significantly affect its decomposition rate. These blends and composites can be designed to achieve specific degradation profiles, allowing for customized decomposition rates suitable for various applications, from packaging to medical devices.Expand Specific Solutions04 Surface modifications to alter PLA decomposition

Surface treatments and modifications can be applied to PLA to alter its decomposition rate. These may include physical treatments like plasma or corona discharge, or chemical modifications such as grafting or coating. Such modifications can enhance or inhibit the initial stages of decomposition, thereby controlling the overall degradation process.Expand Specific Solutions05 Molecular weight and crystallinity effects on PLA decomposition

The molecular weight and degree of crystallinity of PLA play crucial roles in determining its decomposition rate. Higher molecular weight and increased crystallinity generally lead to slower decomposition rates. By controlling these parameters during the manufacturing process, the degradation profile of PLA can be fine-tuned for specific applications.Expand Specific Solutions

Key Players in PLA Biodegradation Research

The field of PLA decomposition in soil conditions is in a growth phase, with increasing market size driven by sustainability concerns. The technology maturity varies, with ongoing research to enhance decomposition rates. Companies like Total Research Corp, Tongji University, and Clemson University are at the forefront of academic research, while industrial players such as Wanhua Chemical Group and LG Chem Ltd. are developing commercial applications. The market is characterized by a mix of academic institutions, research organizations, and industrial companies, indicating a collaborative approach to advancing PLA decomposition technology. The involvement of diverse players suggests a competitive landscape with potential for significant breakthroughs in improving decomposition rates and expanding PLA's eco-friendly applications.

Council of Scientific & Industrial Research

Technical Solution: CSIR has developed a novel approach to enhance PLA decomposition rates in soil conditions. Their method involves the incorporation of specific enzymes and microorganisms into the PLA matrix during the manufacturing process. These additives are designed to activate under soil conditions, catalyzing the breakdown of PLA molecules. Additionally, they have engineered a surface treatment that increases the material's hydrophilicity, allowing for better water penetration and accelerated microbial activity.

Strengths: Highly effective in increasing decomposition rates, customizable for different soil types. Weaknesses: Potential increased production costs, may affect the material's initial properties.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical has developed a proprietary blend of PLA with bio-based additives that significantly enhance its decomposition rate in soil. Their technology focuses on creating a more porous structure within the PLA material, allowing for increased microbial access. They have also incorporated specific organic compounds that act as nutrient sources for soil microorganisms, encouraging their growth and activity around the PLA. This approach not only accelerates decomposition but also enriches the soil with beneficial organic matter.

Strengths: Dual benefit of faster decomposition and soil enrichment. Weaknesses: May have limitations in certain soil conditions, potential for higher material costs.

Innovative PLA Degradation Mechanisms

Degradable recycling material

PatentPendingHK1214287A

Innovation

- Controlled degradation rate of PLA through altering the proportion of L and D forms, molecular weight, and degree of crystallization.

- Accelerated decomposition of PLA using large quantities of readily available microorganisms from compost.

- Production of more amorphous PLA polymers through the addition of enzymes and microorganisms during the melting process.

Biodegradable chemical delivery system

PatentActiveUS20110275520A1

Innovation

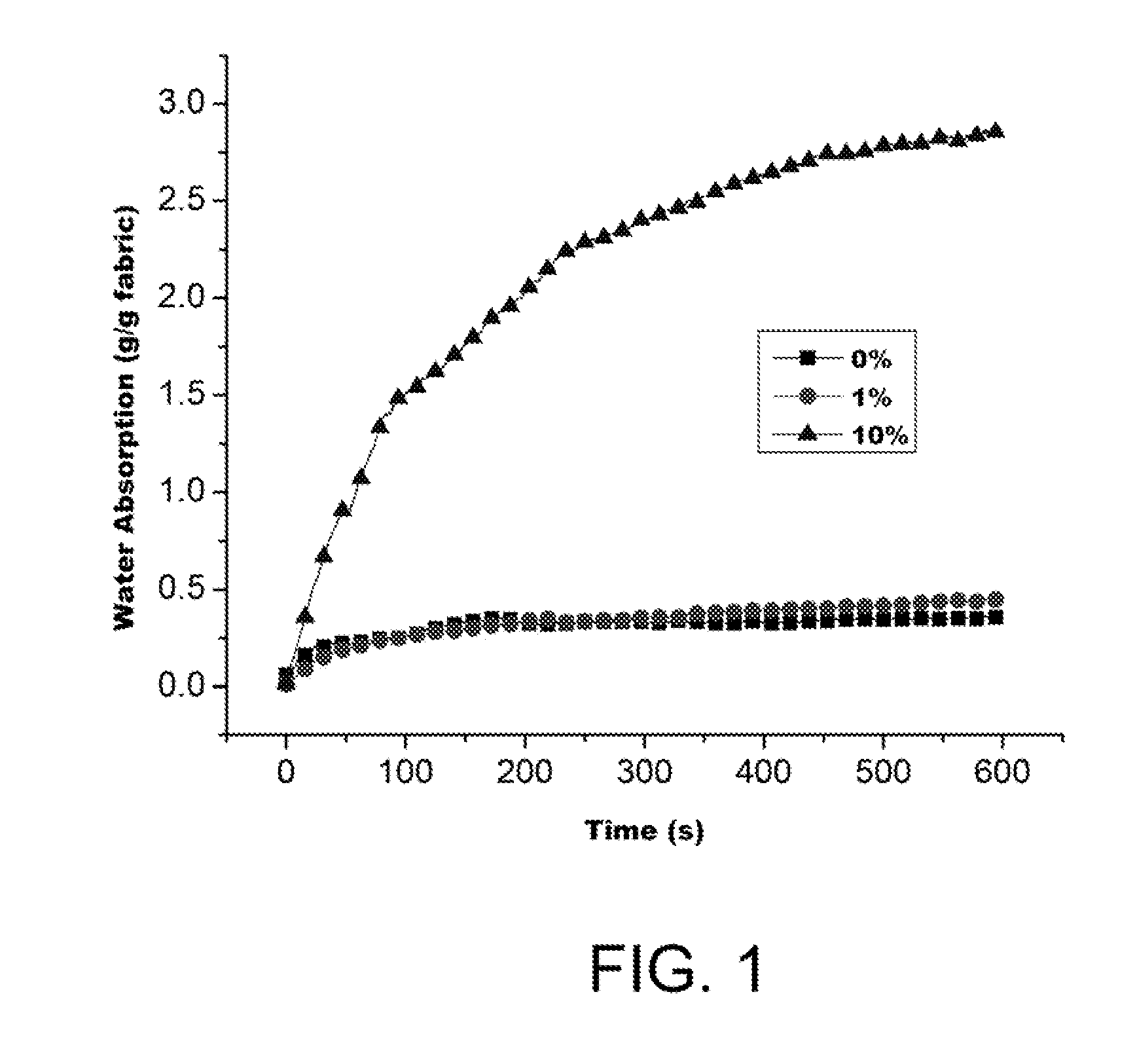

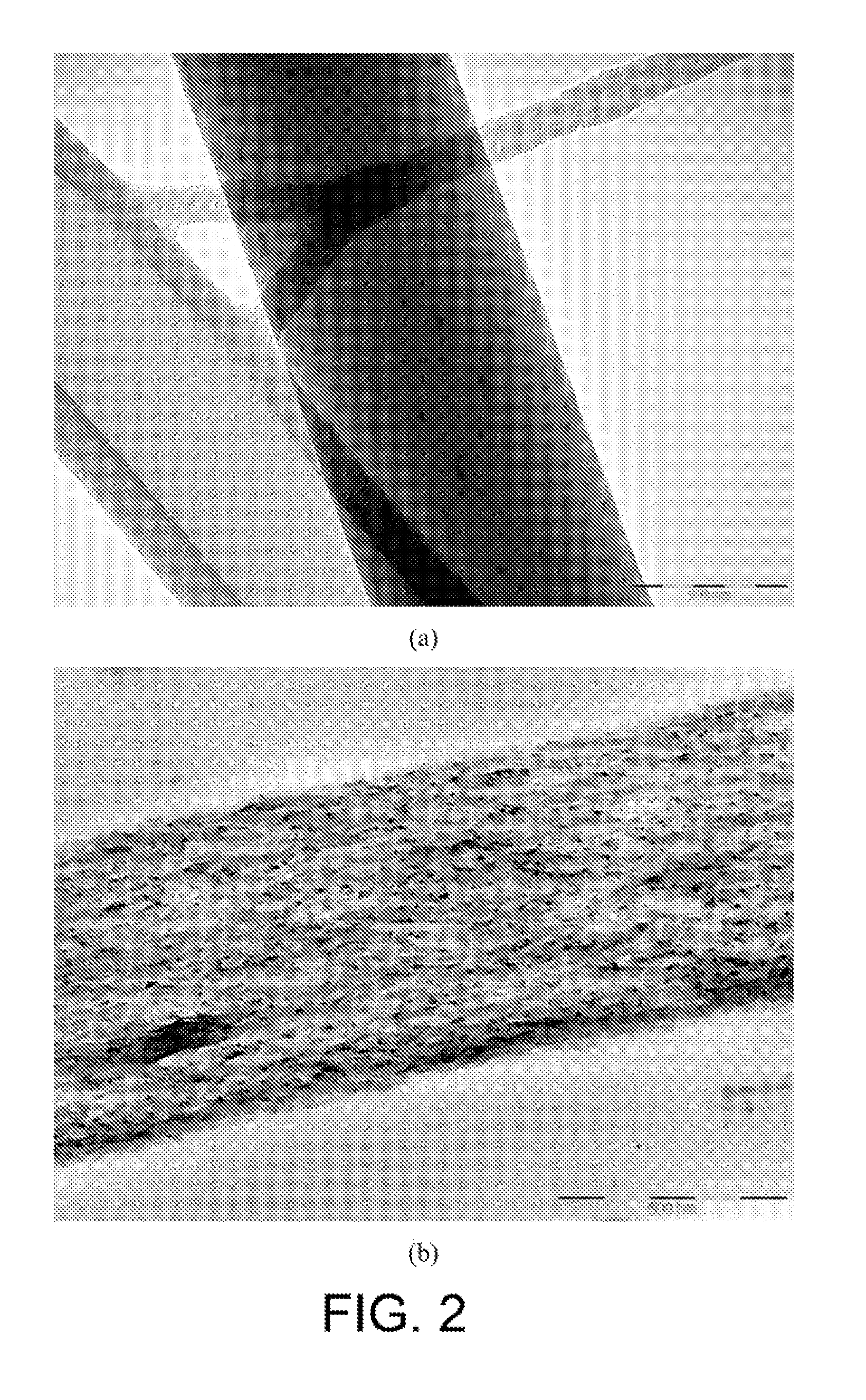

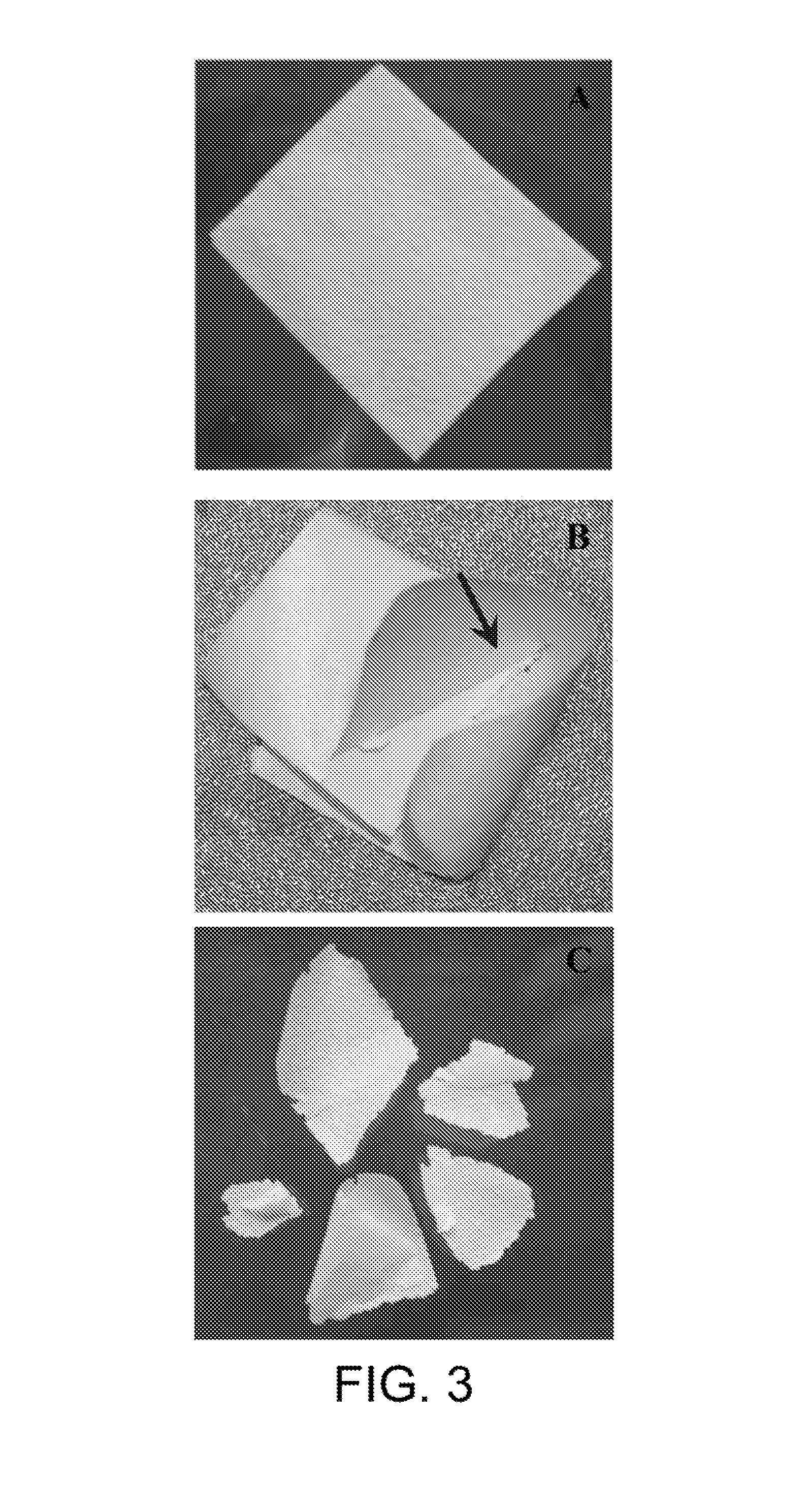

- A polymeric material system comprising a hydrophobic polymeric matrix and a hydrophilic second polymeric material, where the latter forms nanocomposite fibers with PLA, enhancing degradation rates and allowing controlled release of compounds like pesticides through varying the composition and form of the polymeric material.

Environmental Impact Assessment

The environmental impact assessment of advances in PLA decomposition rates in soil conditions is a critical aspect of evaluating the sustainability and ecological footprint of this biodegradable polymer. PLA, or polylactic acid, has gained significant attention as an eco-friendly alternative to traditional plastics due to its biodegradability. However, its decomposition rate in soil conditions has been a subject of ongoing research and improvement.

Recent advancements in PLA decomposition rates have shown promising results in terms of reducing the polymer's persistence in the environment. These improvements have been achieved through various methods, including the development of new PLA formulations, the use of additives to enhance degradation, and the optimization of soil conditions to promote microbial activity.

One of the primary environmental benefits of faster PLA decomposition is the reduction of plastic pollution in soil ecosystems. As PLA breaks down more rapidly, it minimizes the accumulation of plastic particles in the soil, which can negatively impact soil structure, water retention, and nutrient cycling. This faster degradation also reduces the risk of microplastic formation, a growing concern in environmental science.

The accelerated decomposition of PLA in soil conditions also contributes to improved carbon cycling. As PLA breaks down, it releases carbon dioxide and water, which can be readily assimilated by plants and soil microorganisms. This process aligns more closely with natural carbon cycles compared to the long-term sequestration of carbon in non-biodegradable plastics.

However, it is essential to consider potential drawbacks of faster PLA decomposition. Rapid breakdown may lead to a sudden release of lactic acid, which could temporarily alter soil pH levels. This pH fluctuation might affect soil microbial communities and plant growth in the immediate vicinity. Long-term studies are needed to fully understand these impacts and develop mitigation strategies if necessary.

The environmental impact assessment must also consider the broader life cycle of PLA products. While faster decomposition is generally beneficial, it is crucial to evaluate the energy and resources required to produce PLA materials with enhanced degradation properties. A comprehensive analysis should weigh the environmental costs of production against the benefits of improved biodegradability.

Furthermore, the assessment should examine the potential for PLA decomposition to contribute to soil fertility. As PLA breaks down, it may release nutrients that can be beneficial for plant growth. However, this nutrient release must be carefully managed to prevent over-fertilization or nutrient imbalances in soil ecosystems.

Recent advancements in PLA decomposition rates have shown promising results in terms of reducing the polymer's persistence in the environment. These improvements have been achieved through various methods, including the development of new PLA formulations, the use of additives to enhance degradation, and the optimization of soil conditions to promote microbial activity.

One of the primary environmental benefits of faster PLA decomposition is the reduction of plastic pollution in soil ecosystems. As PLA breaks down more rapidly, it minimizes the accumulation of plastic particles in the soil, which can negatively impact soil structure, water retention, and nutrient cycling. This faster degradation also reduces the risk of microplastic formation, a growing concern in environmental science.

The accelerated decomposition of PLA in soil conditions also contributes to improved carbon cycling. As PLA breaks down, it releases carbon dioxide and water, which can be readily assimilated by plants and soil microorganisms. This process aligns more closely with natural carbon cycles compared to the long-term sequestration of carbon in non-biodegradable plastics.

However, it is essential to consider potential drawbacks of faster PLA decomposition. Rapid breakdown may lead to a sudden release of lactic acid, which could temporarily alter soil pH levels. This pH fluctuation might affect soil microbial communities and plant growth in the immediate vicinity. Long-term studies are needed to fully understand these impacts and develop mitigation strategies if necessary.

The environmental impact assessment must also consider the broader life cycle of PLA products. While faster decomposition is generally beneficial, it is crucial to evaluate the energy and resources required to produce PLA materials with enhanced degradation properties. A comprehensive analysis should weigh the environmental costs of production against the benefits of improved biodegradability.

Furthermore, the assessment should examine the potential for PLA decomposition to contribute to soil fertility. As PLA breaks down, it may release nutrients that can be beneficial for plant growth. However, this nutrient release must be carefully managed to prevent over-fertilization or nutrient imbalances in soil ecosystems.

Regulatory Framework for Biodegradable Materials

The regulatory framework for biodegradable materials plays a crucial role in advancing PLA decomposition rates in soil conditions. As governments and environmental agencies worldwide recognize the importance of sustainable materials, they have implemented various policies and standards to govern the production, use, and disposal of biodegradable plastics like PLA.

In the United States, the Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims, ensuring that consumers are not misled by false or exaggerated statements.

The European Union has taken a more comprehensive approach with its EN 13432 standard, which specifies requirements for packaging recoverable through composting and biodegradation. This standard sets strict criteria for the biodegradation rate, disintegration, and ecotoxicity of materials, providing a benchmark for PLA and other biodegradable plastics.

Internationally, the International Organization for Standardization (ISO) has developed several standards related to biodegradable plastics, including ISO 17088 for compostable plastics and ISO 14855 for determining the ultimate aerobic biodegradability of plastic materials in soil conditions. These standards provide a global framework for assessing and certifying biodegradable materials.

Many countries have also implemented extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. These programs incentivize the development of more easily biodegradable materials like PLA and encourage research into improving decomposition rates in various soil conditions.

Regulatory bodies are increasingly focusing on the end-of-life management of biodegradable plastics. For instance, the European Commission's Circular Economy Action Plan includes measures to address biodegradable and compostable plastics, aiming to ensure that they are used in a way that maximizes their benefits without causing harm to the environment.

As research into PLA decomposition rates advances, regulatory frameworks are evolving to incorporate new scientific findings. This includes updating standards to reflect more accurate testing methods for soil biodegradation and considering the impact of different environmental factors on decomposition rates.

The regulatory landscape also influences funding and research priorities in the field of biodegradable materials. Government grants and incentives often target areas aligned with regulatory goals, such as improving the biodegradation rates of PLA in various soil conditions or developing more environmentally friendly additives to enhance decomposition.

In the United States, the Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims, ensuring that consumers are not misled by false or exaggerated statements.

The European Union has taken a more comprehensive approach with its EN 13432 standard, which specifies requirements for packaging recoverable through composting and biodegradation. This standard sets strict criteria for the biodegradation rate, disintegration, and ecotoxicity of materials, providing a benchmark for PLA and other biodegradable plastics.

Internationally, the International Organization for Standardization (ISO) has developed several standards related to biodegradable plastics, including ISO 17088 for compostable plastics and ISO 14855 for determining the ultimate aerobic biodegradability of plastic materials in soil conditions. These standards provide a global framework for assessing and certifying biodegradable materials.

Many countries have also implemented extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. These programs incentivize the development of more easily biodegradable materials like PLA and encourage research into improving decomposition rates in various soil conditions.

Regulatory bodies are increasingly focusing on the end-of-life management of biodegradable plastics. For instance, the European Commission's Circular Economy Action Plan includes measures to address biodegradable and compostable plastics, aiming to ensure that they are used in a way that maximizes their benefits without causing harm to the environment.

As research into PLA decomposition rates advances, regulatory frameworks are evolving to incorporate new scientific findings. This includes updating standards to reflect more accurate testing methods for soil biodegradation and considering the impact of different environmental factors on decomposition rates.

The regulatory landscape also influences funding and research priorities in the field of biodegradable materials. Government grants and incentives often target areas aligned with regulatory goals, such as improving the biodegradation rates of PLA in various soil conditions or developing more environmentally friendly additives to enhance decomposition.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!