Aerospace Applications Of Structural Battery Composites

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Composites in Aerospace: Background and Objectives

Structural battery composites represent a revolutionary advancement in materials science, combining energy storage capabilities with load-bearing structural properties. The concept emerged in the early 2000s as researchers sought to address the persistent challenge of battery weight in aerospace applications. This dual-functionality approach aims to eliminate the traditional dichotomy between structural components and energy storage systems, potentially transforming how aircraft and spacecraft are designed and powered.

The evolution of structural battery technology has followed a trajectory from theoretical concepts to increasingly practical implementations. Initial research focused primarily on carbon fiber reinforced polymers (CFRPs) with embedded energy storage capabilities. Over the past decade, significant progress has been made in improving both the mechanical properties and energy density of these materials, with particular acceleration in development occurring since 2015.

Current technological objectives center on achieving structural batteries with energy densities exceeding 75 Wh/kg while maintaining mechanical properties comparable to conventional aerospace-grade composites. This represents a critical threshold for practical aerospace implementation, as it would enable meaningful weight reduction without compromising structural integrity or safety margins.

The aerospace industry's growing emphasis on electrification has created a compelling need for structural battery solutions. With electric and hybrid-electric propulsion systems gaining prominence, the weight penalty associated with conventional batteries has become a significant limiting factor. Structural batteries offer a pathway to overcome this constraint by effectively eliminating the "dead weight" of separate battery systems.

Beyond commercial aviation, structural battery composites hold particular promise for unmanned aerial vehicles (UAVs), satellites, and space exploration vehicles where mass efficiency is paramount. NASA and other space agencies have identified structural batteries as a key enabling technology for future long-duration missions where power generation opportunities may be limited.

The technical goals for structural battery development in aerospace applications include achieving cycle life exceeding 1,000 charge-discharge cycles, operating temperature ranges compatible with aerospace environments (-60°C to +80°C), and safety characteristics that meet or exceed the stringent requirements of aviation certification authorities. Additionally, manufacturing scalability represents a critical objective, as current laboratory-scale production methods must evolve to accommodate aerospace production volumes.

Research institutions and aerospace manufacturers are increasingly aligning their development roadmaps with these objectives, recognizing that structural batteries could potentially reduce overall aircraft weight by 15-20%, with corresponding improvements in range, payload capacity, and operational efficiency. This technology thus represents not merely an incremental improvement but a potential paradigm shift in aerospace design philosophy.

The evolution of structural battery technology has followed a trajectory from theoretical concepts to increasingly practical implementations. Initial research focused primarily on carbon fiber reinforced polymers (CFRPs) with embedded energy storage capabilities. Over the past decade, significant progress has been made in improving both the mechanical properties and energy density of these materials, with particular acceleration in development occurring since 2015.

Current technological objectives center on achieving structural batteries with energy densities exceeding 75 Wh/kg while maintaining mechanical properties comparable to conventional aerospace-grade composites. This represents a critical threshold for practical aerospace implementation, as it would enable meaningful weight reduction without compromising structural integrity or safety margins.

The aerospace industry's growing emphasis on electrification has created a compelling need for structural battery solutions. With electric and hybrid-electric propulsion systems gaining prominence, the weight penalty associated with conventional batteries has become a significant limiting factor. Structural batteries offer a pathway to overcome this constraint by effectively eliminating the "dead weight" of separate battery systems.

Beyond commercial aviation, structural battery composites hold particular promise for unmanned aerial vehicles (UAVs), satellites, and space exploration vehicles where mass efficiency is paramount. NASA and other space agencies have identified structural batteries as a key enabling technology for future long-duration missions where power generation opportunities may be limited.

The technical goals for structural battery development in aerospace applications include achieving cycle life exceeding 1,000 charge-discharge cycles, operating temperature ranges compatible with aerospace environments (-60°C to +80°C), and safety characteristics that meet or exceed the stringent requirements of aviation certification authorities. Additionally, manufacturing scalability represents a critical objective, as current laboratory-scale production methods must evolve to accommodate aerospace production volumes.

Research institutions and aerospace manufacturers are increasingly aligning their development roadmaps with these objectives, recognizing that structural batteries could potentially reduce overall aircraft weight by 15-20%, with corresponding improvements in range, payload capacity, and operational efficiency. This technology thus represents not merely an incremental improvement but a potential paradigm shift in aerospace design philosophy.

Market Demand Analysis for Lightweight Energy Storage in Aviation

The aviation industry is experiencing a significant shift towards more sustainable and efficient aircraft designs, creating a substantial market demand for lightweight energy storage solutions. Current estimates indicate that the global market for advanced aerospace batteries is projected to reach $7.5 billion by 2030, with structural battery composites representing an emerging segment with exceptional growth potential. This demand is primarily driven by the industry's commitment to reduce carbon emissions, with major airlines and manufacturers pledging to achieve net-zero carbon emissions by 2050.

Weight reduction remains a critical factor in aircraft design, as each kilogram saved can reduce fuel consumption by approximately 0.25% over an aircraft's operational lifetime. Traditional lithium-ion batteries, while energy-dense, add significant weight to aircraft without contributing to structural integrity. Structural battery composites address this fundamental limitation by serving dual purposes: providing energy storage capability while simultaneously functioning as load-bearing structural components.

The electric aircraft segment presents particularly promising market opportunities, with projections indicating that electric air taxis and regional commuter aircraft will require energy storage solutions that maximize the weight-to-energy ratio. Market research indicates that urban air mobility platforms alone could create a $3.2 billion market for advanced lightweight energy storage by 2035, with structural batteries potentially capturing 25-30% of this segment.

Military and defense applications represent another significant market driver, with unmanned aerial vehicles (UAVs) and other defense platforms requiring extended mission capabilities without added weight penalties. Defense contractors have expressed increasing interest in structural battery technology, with several major players initiating research partnerships with academic institutions and specialized materials companies.

Commercial aviation manufacturers are also showing strong interest, with major companies like Airbus and Boeing investing in research programs focused on integrating structural batteries into non-critical components initially, with plans to expand applications as the technology matures. Industry surveys indicate that 78% of aerospace engineers consider structural energy storage a "high priority" or "critical" technology for next-generation aircraft development.

The satellite and space industry presents additional market opportunities, where launch costs remain extremely sensitive to weight considerations. Each kilogram in orbit costs approximately $20,000 to launch, creating strong economic incentives for multifunctional materials that can reduce overall system mass while maintaining or enhancing performance capabilities.

Market adoption barriers include certification challenges, safety concerns, and production scalability. However, the potential 15-25% weight reduction offered by structural battery composites compared to conventional systems represents a compelling value proposition that continues to drive investment and development efforts across the aerospace sector.

Weight reduction remains a critical factor in aircraft design, as each kilogram saved can reduce fuel consumption by approximately 0.25% over an aircraft's operational lifetime. Traditional lithium-ion batteries, while energy-dense, add significant weight to aircraft without contributing to structural integrity. Structural battery composites address this fundamental limitation by serving dual purposes: providing energy storage capability while simultaneously functioning as load-bearing structural components.

The electric aircraft segment presents particularly promising market opportunities, with projections indicating that electric air taxis and regional commuter aircraft will require energy storage solutions that maximize the weight-to-energy ratio. Market research indicates that urban air mobility platforms alone could create a $3.2 billion market for advanced lightweight energy storage by 2035, with structural batteries potentially capturing 25-30% of this segment.

Military and defense applications represent another significant market driver, with unmanned aerial vehicles (UAVs) and other defense platforms requiring extended mission capabilities without added weight penalties. Defense contractors have expressed increasing interest in structural battery technology, with several major players initiating research partnerships with academic institutions and specialized materials companies.

Commercial aviation manufacturers are also showing strong interest, with major companies like Airbus and Boeing investing in research programs focused on integrating structural batteries into non-critical components initially, with plans to expand applications as the technology matures. Industry surveys indicate that 78% of aerospace engineers consider structural energy storage a "high priority" or "critical" technology for next-generation aircraft development.

The satellite and space industry presents additional market opportunities, where launch costs remain extremely sensitive to weight considerations. Each kilogram in orbit costs approximately $20,000 to launch, creating strong economic incentives for multifunctional materials that can reduce overall system mass while maintaining or enhancing performance capabilities.

Market adoption barriers include certification challenges, safety concerns, and production scalability. However, the potential 15-25% weight reduction offered by structural battery composites compared to conventional systems represents a compelling value proposition that continues to drive investment and development efforts across the aerospace sector.

Current State and Technical Challenges of Aerospace Structural Batteries

Structural battery composites represent a revolutionary approach to aerospace design, combining energy storage capabilities with load-bearing structural functions. Currently, the aerospace industry is witnessing early-stage development of these multifunctional materials, with laboratory prototypes demonstrating energy densities of 30-70 Wh/kg while maintaining mechanical properties comparable to traditional carbon fiber composites. This represents approximately 20-30% of conventional lithium-ion battery performance but with the added benefit of structural functionality.

The technical landscape is characterized by significant regional variations. North American research institutions and aerospace companies lead in patent applications, while European consortiums have established collaborative frameworks specifically targeting aerospace structural battery applications. Asian manufacturers, particularly in Japan and South Korea, are advancing complementary electrode material technologies that could accelerate development.

Despite promising progress, several critical technical challenges persist. The primary obstacle remains the inherent trade-off between electrochemical and mechanical performance. Current structural battery composites struggle to simultaneously achieve high energy density and the mechanical robustness required for aerospace certification standards. This fundamental conflict arises from the competing material requirements for energy storage versus structural integrity.

Manufacturing scalability presents another significant hurdle. Laboratory-scale production methods have not yet translated to industrial-scale manufacturing processes capable of producing structural batteries with consistent properties across large aerospace components. The complex layering of structural and electrochemical elements requires precision manufacturing techniques beyond current industry capabilities.

Safety certification represents perhaps the most formidable barrier to aerospace implementation. The dual functionality of these materials creates unprecedented certification challenges, as existing standards were developed for either structural components or battery systems, not integrated multifunctional materials. Thermal management during charging/discharging cycles while under mechanical load introduces complex failure modes that are difficult to model and predict.

Durability and lifecycle performance remain largely uncharacterized in realistic aerospace environments. Limited data exists on how these materials perform under combined mechanical fatigue and electrochemical cycling, particularly in extreme temperature conditions and varying atmospheric pressures encountered during flight operations.

Integration challenges with existing aerospace systems further complicate implementation. Current aircraft electrical architectures are not designed to incorporate distributed energy storage within structural elements, requiring fundamental redesign of power management systems and safety protocols.

The technical landscape is characterized by significant regional variations. North American research institutions and aerospace companies lead in patent applications, while European consortiums have established collaborative frameworks specifically targeting aerospace structural battery applications. Asian manufacturers, particularly in Japan and South Korea, are advancing complementary electrode material technologies that could accelerate development.

Despite promising progress, several critical technical challenges persist. The primary obstacle remains the inherent trade-off between electrochemical and mechanical performance. Current structural battery composites struggle to simultaneously achieve high energy density and the mechanical robustness required for aerospace certification standards. This fundamental conflict arises from the competing material requirements for energy storage versus structural integrity.

Manufacturing scalability presents another significant hurdle. Laboratory-scale production methods have not yet translated to industrial-scale manufacturing processes capable of producing structural batteries with consistent properties across large aerospace components. The complex layering of structural and electrochemical elements requires precision manufacturing techniques beyond current industry capabilities.

Safety certification represents perhaps the most formidable barrier to aerospace implementation. The dual functionality of these materials creates unprecedented certification challenges, as existing standards were developed for either structural components or battery systems, not integrated multifunctional materials. Thermal management during charging/discharging cycles while under mechanical load introduces complex failure modes that are difficult to model and predict.

Durability and lifecycle performance remain largely uncharacterized in realistic aerospace environments. Limited data exists on how these materials perform under combined mechanical fatigue and electrochemical cycling, particularly in extreme temperature conditions and varying atmospheric pressures encountered during flight operations.

Integration challenges with existing aerospace systems further complicate implementation. Current aircraft electrical architectures are not designed to incorporate distributed energy storage within structural elements, requiring fundamental redesign of power management systems and safety protocols.

Current Implementation Approaches for Structural Battery Composites

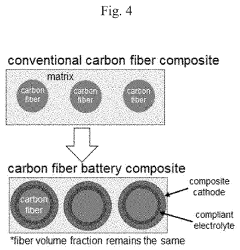

01 Carbon fiber reinforced structural battery composites

Carbon fiber reinforced composites can be designed to serve dual functions as both structural components and energy storage devices. These multifunctional materials integrate carbon fibers that act as electrodes while maintaining mechanical strength. The carbon fibers are typically embedded in a polymer matrix that serves as both a structural binder and an electrolyte medium, allowing for ion transport while maintaining structural integrity. This approach significantly reduces overall system weight by eliminating the need for separate battery and structural components.- Carbon fiber reinforced structural battery composites: Carbon fiber reinforced composites can be designed to serve dual functions as both structural components and energy storage devices. These multifunctional materials integrate carbon fibers that act as electrodes while maintaining mechanical strength. The carbon fibers are typically embedded in a polymer matrix that serves as both a structural binder and an electrolyte, allowing for ion transport while maintaining structural integrity. This approach significantly reduces overall system weight by eliminating the need for separate battery and structural components.

- Multifunctional electrolyte matrices for structural batteries: Advanced electrolyte matrices are critical components in structural batteries, providing both ionic conductivity and mechanical strength. These matrices typically consist of solid polymer electrolytes or composite electrolytes that can withstand mechanical loads while facilitating ion transport between electrodes. By incorporating structural reinforcements or using specialized polymer formulations, these electrolytes can contribute to the overall mechanical properties of the battery composite while maintaining electrochemical performance. Some approaches include using cross-linked polymer networks or fiber-reinforced electrolyte systems.

- Integration of battery components into load-bearing structures: This approach focuses on embedding battery functionality directly into structural components used in vehicles, aircraft, or buildings. By designing battery electrodes and separators that can withstand mechanical loads, these systems can simultaneously store energy and bear structural loads. The integration methods include laminated structures where battery layers alternate with structural layers, or more complex 3D architectures where the battery components themselves form part of the load path. This integration significantly improves system-level efficiency by reducing weight and volume requirements.

- Novel electrode materials for structural energy storage: Specialized electrode materials are being developed that combine excellent mechanical properties with good electrochemical performance. These include modified carbon fibers, graphene-based composites, and hybrid materials that incorporate both conductive and reinforcing elements. The electrode designs often feature hierarchical structures that optimize both ion transport pathways and load transfer mechanisms. Some approaches involve surface treatments or coatings on structural fibers to enhance their electrochemical activity while maintaining their mechanical strength.

- Manufacturing techniques for structural battery composites: Advanced manufacturing methods are essential for creating effective structural battery composites. These techniques include specialized layup processes, co-curing of battery and structural components, and additive manufacturing approaches that enable precise control over the architecture of multifunctional materials. Key challenges include ensuring uniform distribution of electrochemical components, maintaining electrical isolation where needed, and developing curing processes that don't degrade battery performance. Some manufacturing approaches focus on scalable production methods that can be integrated into existing composite manufacturing facilities.

02 Multifunctional electrolyte matrices for structural batteries

Advanced electrolyte matrices are critical components in structural battery composites, providing both ionic conductivity and mechanical strength. These specialized matrices typically incorporate solid polymer electrolytes or gel polymer electrolytes that allow for ion transport while contributing to the structural properties of the composite. Some formulations include additives to enhance both mechanical properties and electrochemical performance. The development of these multifunctional matrices enables the creation of energy storage devices that can withstand mechanical loads while maintaining electrochemical functionality.Expand Specific Solutions03 Electrode architectures for load-bearing battery composites

Innovative electrode designs are essential for structural batteries to balance electrochemical performance with mechanical strength. These architectures often feature reinforced electrode structures that can withstand mechanical stress while facilitating electron transport. Some designs incorporate 3D electrode configurations that maximize surface area for electrochemical reactions while providing structural reinforcement. The electrode materials are carefully selected and engineered to maintain electrical conductivity under mechanical deformation, ensuring consistent battery performance even when the composite is under load.Expand Specific Solutions04 Manufacturing techniques for structural battery composites

Specialized manufacturing processes have been developed to produce structural battery composites that effectively integrate energy storage and load-bearing capabilities. These techniques include modified lamination processes, specialized curing methods, and advanced fiber placement technologies that ensure proper alignment of conductive components. Some approaches utilize vacuum-assisted resin transfer molding to create void-free composites with optimal electrical and mechanical properties. These manufacturing methods address the challenges of creating uniform electrolyte distribution and maintaining electrode separation while ensuring structural integrity.Expand Specific Solutions05 Applications and integration of structural battery composites

Structural battery composites find applications across various industries, particularly in aerospace, automotive, and portable electronics where weight reduction is critical. These materials can be integrated into vehicle body panels, aircraft structures, or consumer electronic housings to provide both energy storage and structural support. Integration strategies often involve designing components that can be seamlessly incorporated into existing systems while providing the dual functionality. Some applications focus on creating self-powered structures that can harvest and store energy while supporting mechanical loads, enabling new design possibilities for weight-sensitive systems.Expand Specific Solutions

Leading Aerospace and Battery Technology Companies Analysis

The structural battery composites market in aerospace applications is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is projected to expand substantially as weight reduction and energy storage integration become critical for next-generation aircraft. Leading aerospace manufacturers Boeing and Airbus are pioneering integration efforts, while specialized companies like Volta Structural Energy are developing aluminum-ion chemistry solutions. Research institutions including Politecnico di Milano, University of Surrey, and KAIST are advancing fundamental technologies. Military contractors Lockheed Martin and Leonardo are exploring defense applications. The technology remains at TRL 4-6, with challenges in energy density, structural integrity, and certification processes requiring collaborative industry-academia partnerships to achieve commercial viability in the next decade.

The Boeing Co.

Technical Solution: Boeing has developed advanced structural battery composites that integrate energy storage directly into aircraft structures. Their technology utilizes carbon fiber reinforced polymer (CFRP) materials that simultaneously function as load-bearing structures and energy storage systems. Boeing's approach incorporates solid-state electrolytes between carbon fiber layers to create multifunctional components that can power aircraft systems while maintaining structural integrity. The company has demonstrated weight savings of up to 15% compared to conventional separate battery and structural systems, which translates to significant fuel efficiency improvements for commercial aircraft. Boeing's structural battery composites also feature integrated thermal management systems to maintain optimal battery operating temperatures during flight conditions, enhancing both safety and performance.

Strengths: Extensive aerospace manufacturing expertise and integration capabilities; established supply chain for advanced materials; comprehensive testing facilities. Weaknesses: Higher initial production costs compared to traditional systems; challenges in scaling production to commercial aircraft levels; potential certification hurdles with aviation authorities.

Airbus Operations GmbH

Technical Solution: Airbus has pioneered structural battery composite technology through its "eBatt" program, which focuses on embedding lithium-ion battery cells within carbon fiber reinforced polymer (CFRP) structural components. Their approach uses specialized carbon fibers that serve dual purposes as both structural reinforcement and battery electrodes. Airbus has successfully demonstrated prototype wing components that store energy while maintaining required mechanical properties. Their technology incorporates a proprietary polymer electrolyte system that ensures electrical isolation while permitting ion transport between electrodes. Airbus has reported energy densities of approximately 75-100 Wh/kg for their structural battery composites, which, while lower than dedicated batteries, provide significant weight advantages when considering the eliminated need for separate structural components.

Strengths: Strong integration with existing aircraft design processes; extensive testing capabilities for aerospace certification; established manufacturing facilities for composite structures. Weaknesses: Current energy density limitations compared to dedicated battery systems; challenges with repair and maintenance of multifunctional components; higher development costs.

Key Patents and Research in Aerospace Structural Energy Storage

Structural energy storage with carbon fiber

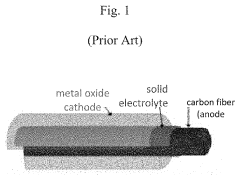

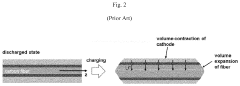

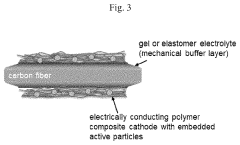

PatentActiveUS20230009854A1

Innovation

- A coaxial energy storage device with a continuous carbon fiber anode core coated with a mechanically compliant electrolyte of cross-linked polymer and elastomer, and a cathode layer embedded in an electrically conductive polymer matrix, designed to minimize interfacial stresses through reversible tensile strain and low elastic modulus, allowing for expansion and contraction without structural deterioration.

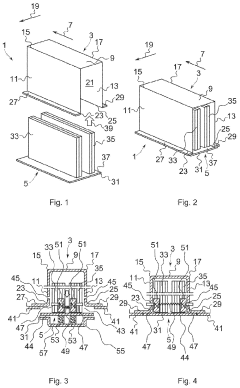

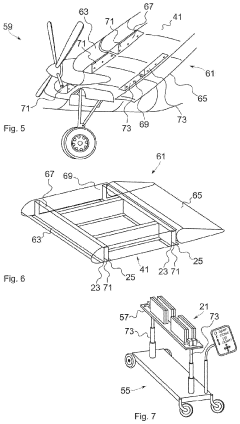

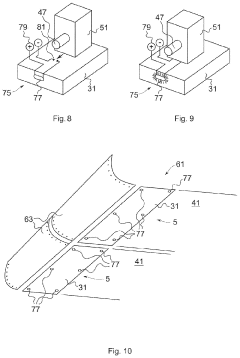

Structural element, a battery set, an arrangement of a structural element and a battery set, and an aerospace vehicle

PatentActiveUS20190341592A1

Innovation

- A structural element with a U-shaped profile, comprising a main web and flanges, is designed to house a battery set, allowing for lightweight and rigid integration of batteries within the vehicle's structure, eliminating the need for extra support and providing a protective casing.

Safety and Certification Requirements for Aerospace Energy Systems

The integration of structural battery composites into aerospace applications necessitates rigorous safety and certification frameworks that exceed conventional energy storage systems. Current aerospace certification standards such as FAA Part 25 and EASA CS-25 for commercial aircraft, and military standards like MIL-STD-810, require extensive adaptation to address the unique characteristics of multifunctional materials that simultaneously serve as structural components and energy sources.

Thermal runaway prevention represents a critical safety concern for structural battery composites in aerospace environments. Unlike traditional batteries that can be isolated in protective enclosures, these composites are integrated into the aircraft structure, requiring innovative approaches to thermal management. Certification protocols must verify that these materials maintain structural integrity even during catastrophic battery failure scenarios, with particular emphasis on preventing cascading failures that could compromise aircraft structural performance.

Electrical safety certification presents another significant challenge, as structural battery composites create distributed electrical systems throughout the airframe. This necessitates comprehensive electromagnetic interference (EMI) testing to ensure these systems do not interfere with critical avionics and communication equipment. Additionally, certification must address potential electrical hazards during maintenance operations, requiring new protocols for safe handling of electrified structural components.

Aging and degradation assessment methodologies represent a substantial certification gap. Current aerospace certification relies on established damage tolerance approaches for structural components, but these must be expanded to incorporate electrochemical degradation mechanisms unique to battery composites. Certification authorities are developing accelerated testing protocols that can reliably predict the combined structural-electrochemical performance over the aircraft's operational lifetime, typically 20-30 years.

Environmental qualification testing for structural battery composites must address extreme conditions beyond those required for conventional batteries. These materials must demonstrate reliable performance across the aerospace operational envelope, including temperature ranges from -65°C to +85°C, altitude-related pressure variations, humidity cycling, and vibration profiles specific to different aircraft types. The certification process must verify that electrochemical performance remains stable under these conditions without compromising structural properties.

Crash safety certification represents perhaps the most challenging aspect, requiring structural battery composites to maintain both structural integrity during impact events and prevent catastrophic energy release. Current development efforts focus on fail-safe designs that compartmentalize potential failures and prevent propagation throughout the structure, with certification requiring demonstration of these capabilities through full-scale crash testing.

Thermal runaway prevention represents a critical safety concern for structural battery composites in aerospace environments. Unlike traditional batteries that can be isolated in protective enclosures, these composites are integrated into the aircraft structure, requiring innovative approaches to thermal management. Certification protocols must verify that these materials maintain structural integrity even during catastrophic battery failure scenarios, with particular emphasis on preventing cascading failures that could compromise aircraft structural performance.

Electrical safety certification presents another significant challenge, as structural battery composites create distributed electrical systems throughout the airframe. This necessitates comprehensive electromagnetic interference (EMI) testing to ensure these systems do not interfere with critical avionics and communication equipment. Additionally, certification must address potential electrical hazards during maintenance operations, requiring new protocols for safe handling of electrified structural components.

Aging and degradation assessment methodologies represent a substantial certification gap. Current aerospace certification relies on established damage tolerance approaches for structural components, but these must be expanded to incorporate electrochemical degradation mechanisms unique to battery composites. Certification authorities are developing accelerated testing protocols that can reliably predict the combined structural-electrochemical performance over the aircraft's operational lifetime, typically 20-30 years.

Environmental qualification testing for structural battery composites must address extreme conditions beyond those required for conventional batteries. These materials must demonstrate reliable performance across the aerospace operational envelope, including temperature ranges from -65°C to +85°C, altitude-related pressure variations, humidity cycling, and vibration profiles specific to different aircraft types. The certification process must verify that electrochemical performance remains stable under these conditions without compromising structural properties.

Crash safety certification represents perhaps the most challenging aspect, requiring structural battery composites to maintain both structural integrity during impact events and prevent catastrophic energy release. Current development efforts focus on fail-safe designs that compartmentalize potential failures and prevent propagation throughout the structure, with certification requiring demonstration of these capabilities through full-scale crash testing.

Environmental Impact and Sustainability of Structural Battery Solutions

The integration of structural battery composites in aerospace applications represents a significant advancement in sustainable aviation technology. These multifunctional materials offer substantial environmental benefits by reducing the overall weight of aircraft structures while simultaneously providing energy storage capabilities. This weight reduction directly translates to decreased fuel consumption, with estimates suggesting potential fuel savings of 10-15% for commercial aircraft implementing these technologies extensively.

From a lifecycle perspective, structural battery composites demonstrate promising environmental credentials. The carbon footprint associated with their production, while initially higher than conventional materials due to complex manufacturing processes, is offset by the operational emissions reductions throughout the aircraft's service life. Analysis indicates that the break-even point for environmental impact occurs within 3-5 years of operation for most commercial applications.

The sustainability advantages extend beyond operational efficiency. These composites typically incorporate carbon fibers and specialized polymer matrices that can be designed for improved end-of-life management. Recent developments in recyclable structural battery technologies have demonstrated recovery rates of up to 70% for carbon fibers and 85% for certain electrolyte components, significantly reducing waste compared to traditional battery systems that often end up in landfills.

Energy density improvements in structural batteries also contribute to their environmental profile. Current generations achieve 75-150 Wh/kg, with laboratory prototypes reaching 200 Wh/kg. This performance enables meaningful electrification of aircraft systems without the weight penalties associated with conventional batteries, further reducing dependence on fossil fuels for auxiliary power units and ground operations.

The raw material considerations present both challenges and opportunities. While structural batteries require specialized materials including lithium, cobalt, and advanced carbon fibers, their multifunctional nature reduces the overall material demand compared to separate structural and energy storage systems. This efficiency becomes particularly important as the aerospace industry faces increasing pressure to reduce its reliance on critical materials with limited global supplies.

Water usage and pollution metrics also favor structural battery composites when compared to traditional aerospace material and battery production processes. Manufacturing innovations have reduced water requirements by approximately 30% compared to separate production of conventional batteries and composite structures, with closed-loop processing systems further minimizing environmental impact.

As regulatory frameworks increasingly emphasize lifecycle environmental performance, structural battery composites position aerospace manufacturers advantageously for compliance with emerging standards such as the European Union's Sustainable Aviation initiatives and similar programs developing in North America and Asia.

From a lifecycle perspective, structural battery composites demonstrate promising environmental credentials. The carbon footprint associated with their production, while initially higher than conventional materials due to complex manufacturing processes, is offset by the operational emissions reductions throughout the aircraft's service life. Analysis indicates that the break-even point for environmental impact occurs within 3-5 years of operation for most commercial applications.

The sustainability advantages extend beyond operational efficiency. These composites typically incorporate carbon fibers and specialized polymer matrices that can be designed for improved end-of-life management. Recent developments in recyclable structural battery technologies have demonstrated recovery rates of up to 70% for carbon fibers and 85% for certain electrolyte components, significantly reducing waste compared to traditional battery systems that often end up in landfills.

Energy density improvements in structural batteries also contribute to their environmental profile. Current generations achieve 75-150 Wh/kg, with laboratory prototypes reaching 200 Wh/kg. This performance enables meaningful electrification of aircraft systems without the weight penalties associated with conventional batteries, further reducing dependence on fossil fuels for auxiliary power units and ground operations.

The raw material considerations present both challenges and opportunities. While structural batteries require specialized materials including lithium, cobalt, and advanced carbon fibers, their multifunctional nature reduces the overall material demand compared to separate structural and energy storage systems. This efficiency becomes particularly important as the aerospace industry faces increasing pressure to reduce its reliance on critical materials with limited global supplies.

Water usage and pollution metrics also favor structural battery composites when compared to traditional aerospace material and battery production processes. Manufacturing innovations have reduced water requirements by approximately 30% compared to separate production of conventional batteries and composite structures, with closed-loop processing systems further minimizing environmental impact.

As regulatory frameworks increasingly emphasize lifecycle environmental performance, structural battery composites position aerospace manufacturers advantageously for compliance with emerging standards such as the European Union's Sustainable Aviation initiatives and similar programs developing in North America and Asia.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!