Interfacial Toughening Strategies In Structural Electrodes

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Interfacial Toughening Background and Objectives

Interfacial toughening in structural electrodes represents a critical frontier in the development of next-generation energy storage systems. The evolution of this technology can be traced back to early 2000s when researchers began recognizing the significance of interface stability in determining the overall performance and durability of electrochemical devices. Initially, research focused primarily on enhancing electronic conductivity at interfaces, but gradually shifted towards mechanical integrity as cycling-induced degradation mechanisms became better understood.

The technological trajectory has been shaped by the increasing demand for multifunctional materials that can simultaneously store energy and bear mechanical loads. This dual functionality requirement has pushed researchers to explore novel approaches for strengthening the inherently weak interfaces between active materials, conductive additives, and polymer binders within electrode structures.

Recent advancements in nanomaterial science, polymer chemistry, and surface modification techniques have accelerated progress in this field. The introduction of carbon nanotubes, graphene, and other two-dimensional materials as interfacial reinforcement agents marked a significant milestone around 2010-2015. Subsequently, the development of functional binders and surface coating technologies further expanded the toolkit for interface engineering.

The primary objective of interfacial toughening research is to develop electrodes that maintain structural integrity during electrochemical cycling while preserving or enhancing energy storage capabilities. This involves addressing several key challenges: preventing delamination between active materials and current collectors, minimizing particle isolation during volume changes, and maintaining conductive networks throughout the electrode lifetime.

Specifically, researchers aim to increase interfacial fracture toughness by at least an order of magnitude compared to conventional electrodes, while simultaneously ensuring that ionic and electronic transport pathways remain uncompromised. The target is to achieve structural electrodes capable of withstanding thousands of cycles under mechanical loading conditions.

Another critical objective is to establish standardized testing protocols and metrics for evaluating interfacial strength in electrochemical environments, as current mechanical characterization methods often fail to capture the complex electrochemically-induced degradation mechanisms. This includes developing in-situ and operando techniques to monitor interfacial changes during cycling.

The field is now moving toward predictive design principles that can guide the rational development of toughening strategies tailored to specific electrode chemistries and applications. This involves creating comprehensive models that integrate electrochemical, mechanical, and thermal behaviors across multiple length scales, from molecular interactions to macroscopic electrode properties.

The technological trajectory has been shaped by the increasing demand for multifunctional materials that can simultaneously store energy and bear mechanical loads. This dual functionality requirement has pushed researchers to explore novel approaches for strengthening the inherently weak interfaces between active materials, conductive additives, and polymer binders within electrode structures.

Recent advancements in nanomaterial science, polymer chemistry, and surface modification techniques have accelerated progress in this field. The introduction of carbon nanotubes, graphene, and other two-dimensional materials as interfacial reinforcement agents marked a significant milestone around 2010-2015. Subsequently, the development of functional binders and surface coating technologies further expanded the toolkit for interface engineering.

The primary objective of interfacial toughening research is to develop electrodes that maintain structural integrity during electrochemical cycling while preserving or enhancing energy storage capabilities. This involves addressing several key challenges: preventing delamination between active materials and current collectors, minimizing particle isolation during volume changes, and maintaining conductive networks throughout the electrode lifetime.

Specifically, researchers aim to increase interfacial fracture toughness by at least an order of magnitude compared to conventional electrodes, while simultaneously ensuring that ionic and electronic transport pathways remain uncompromised. The target is to achieve structural electrodes capable of withstanding thousands of cycles under mechanical loading conditions.

Another critical objective is to establish standardized testing protocols and metrics for evaluating interfacial strength in electrochemical environments, as current mechanical characterization methods often fail to capture the complex electrochemically-induced degradation mechanisms. This includes developing in-situ and operando techniques to monitor interfacial changes during cycling.

The field is now moving toward predictive design principles that can guide the rational development of toughening strategies tailored to specific electrode chemistries and applications. This involves creating comprehensive models that integrate electrochemical, mechanical, and thermal behaviors across multiple length scales, from molecular interactions to macroscopic electrode properties.

Market Analysis for Structural Battery Applications

The structural battery market is experiencing significant growth driven by the increasing demand for lightweight, multifunctional materials across various industries. Current market projections indicate that the global structural battery market could reach approximately $2.5 billion by 2030, with a compound annual growth rate of 15-20% from 2023 onwards. This growth is primarily fueled by the automotive and aerospace sectors, which together account for over 60% of the potential market share.

In the automotive industry, the push for electric vehicles has created a substantial demand for structural batteries that can reduce vehicle weight while maintaining or enhancing structural integrity. Major automotive manufacturers including Tesla, Volkswagen, and Volvo have announced significant investments in structural battery technology, with Volvo's recent commitment of $1 billion towards developing and implementing structural battery solutions in their electric vehicle lineup by 2025.

The aerospace sector represents another crucial market for structural batteries, with Boeing and Airbus exploring integration of these technologies to reduce aircraft weight and increase energy efficiency. Market analysis suggests that implementing structural batteries in commercial aircraft could reduce overall weight by 10-15%, translating to fuel savings of approximately 7-9% - a significant economic and environmental benefit.

Consumer electronics manufacturers are also showing increased interest in structural batteries, particularly for applications in smartphones, laptops, and wearable devices. This segment is expected to grow at 25% annually through 2028, driven by consumer demand for longer battery life without increased device weight or size.

Market barriers include high production costs, with current structural battery solutions costing 3-5 times more than conventional battery systems. Technical challenges related to interfacial toughening remain significant market entry barriers, as manufacturers require solutions that can withstand mechanical stresses while maintaining electrical performance over thousands of charge cycles.

Regulatory frameworks are evolving to accommodate these new technologies, with particular focus on safety standards and end-of-life recycling requirements. The European Union's Battery Directive revision, expected to be implemented by 2025, will likely include specific provisions for structural battery technologies.

Regional analysis shows North America and Europe leading in structural battery research and development, with combined investments exceeding $3 billion in 2022. However, Asia-Pacific markets, particularly China, Japan, and South Korea, are rapidly expanding their capabilities, with government-backed initiatives supporting domestic development of structural battery technologies.

In the automotive industry, the push for electric vehicles has created a substantial demand for structural batteries that can reduce vehicle weight while maintaining or enhancing structural integrity. Major automotive manufacturers including Tesla, Volkswagen, and Volvo have announced significant investments in structural battery technology, with Volvo's recent commitment of $1 billion towards developing and implementing structural battery solutions in their electric vehicle lineup by 2025.

The aerospace sector represents another crucial market for structural batteries, with Boeing and Airbus exploring integration of these technologies to reduce aircraft weight and increase energy efficiency. Market analysis suggests that implementing structural batteries in commercial aircraft could reduce overall weight by 10-15%, translating to fuel savings of approximately 7-9% - a significant economic and environmental benefit.

Consumer electronics manufacturers are also showing increased interest in structural batteries, particularly for applications in smartphones, laptops, and wearable devices. This segment is expected to grow at 25% annually through 2028, driven by consumer demand for longer battery life without increased device weight or size.

Market barriers include high production costs, with current structural battery solutions costing 3-5 times more than conventional battery systems. Technical challenges related to interfacial toughening remain significant market entry barriers, as manufacturers require solutions that can withstand mechanical stresses while maintaining electrical performance over thousands of charge cycles.

Regulatory frameworks are evolving to accommodate these new technologies, with particular focus on safety standards and end-of-life recycling requirements. The European Union's Battery Directive revision, expected to be implemented by 2025, will likely include specific provisions for structural battery technologies.

Regional analysis shows North America and Europe leading in structural battery research and development, with combined investments exceeding $3 billion in 2022. However, Asia-Pacific markets, particularly China, Japan, and South Korea, are rapidly expanding their capabilities, with government-backed initiatives supporting domestic development of structural battery technologies.

Current Challenges in Electrode-Electrolyte Interfaces

The electrode-electrolyte interface represents a critical frontier in the development of high-performance structural electrodes. Despite significant advancements in materials science, several persistent challenges continue to impede optimal performance and durability of these interfaces, particularly in applications requiring both mechanical integrity and electrochemical functionality.

Mechanical instability at the interface remains a primary concern, as electrodes typically undergo volumetric changes during charge-discharge cycles. These dimensional fluctuations create mechanical stresses that can lead to delamination, cracking, and eventual failure of the electrode structure. In silicon-based anodes, for example, volume expansions exceeding 300% during lithiation create extreme interfacial stresses that conventional binding mechanisms struggle to accommodate.

Chemical degradation presents another significant challenge. The formation of solid-electrolyte interphase (SEI) layers, while necessary for stable operation in many systems, often occurs in an uncontrolled manner. This results in continuously evolving interfaces with unpredictable mechanical properties. The chemical reactivity between electrode materials and electrolytes frequently leads to parasitic reactions that consume active materials and degrade performance over time.

Ion transport limitations across the interface significantly impact power density and rate capability. The presence of resistive interfacial layers, poor wetting characteristics, or inadequate contact between electrode and electrolyte components can create bottlenecks for ion movement. This is particularly problematic in solid-state systems where physical contact must be maintained despite mechanical stresses.

Manufacturing scalability of interfacially toughened electrodes presents substantial technical hurdles. Current laboratory-scale approaches for interface engineering often involve complex processing steps that are difficult to translate to industrial production. Techniques such as atomic layer deposition or specialized surface functionalization may yield excellent results but remain challenging to implement cost-effectively at scale.

Environmental stability poses additional challenges, as many interface modification strategies perform well under controlled laboratory conditions but degrade rapidly when exposed to moisture, oxygen, or temperature fluctuations. This limits practical deployment in real-world applications where environmental control is not always possible.

The multidisciplinary nature of interface engineering further complicates progress, requiring expertise spanning electrochemistry, mechanical engineering, materials science, and manufacturing technology. Developing comprehensive solutions demands integrated approaches that simultaneously address mechanical, chemical, and electrochemical aspects of interface behavior.

Mechanical instability at the interface remains a primary concern, as electrodes typically undergo volumetric changes during charge-discharge cycles. These dimensional fluctuations create mechanical stresses that can lead to delamination, cracking, and eventual failure of the electrode structure. In silicon-based anodes, for example, volume expansions exceeding 300% during lithiation create extreme interfacial stresses that conventional binding mechanisms struggle to accommodate.

Chemical degradation presents another significant challenge. The formation of solid-electrolyte interphase (SEI) layers, while necessary for stable operation in many systems, often occurs in an uncontrolled manner. This results in continuously evolving interfaces with unpredictable mechanical properties. The chemical reactivity between electrode materials and electrolytes frequently leads to parasitic reactions that consume active materials and degrade performance over time.

Ion transport limitations across the interface significantly impact power density and rate capability. The presence of resistive interfacial layers, poor wetting characteristics, or inadequate contact between electrode and electrolyte components can create bottlenecks for ion movement. This is particularly problematic in solid-state systems where physical contact must be maintained despite mechanical stresses.

Manufacturing scalability of interfacially toughened electrodes presents substantial technical hurdles. Current laboratory-scale approaches for interface engineering often involve complex processing steps that are difficult to translate to industrial production. Techniques such as atomic layer deposition or specialized surface functionalization may yield excellent results but remain challenging to implement cost-effectively at scale.

Environmental stability poses additional challenges, as many interface modification strategies perform well under controlled laboratory conditions but degrade rapidly when exposed to moisture, oxygen, or temperature fluctuations. This limits practical deployment in real-world applications where environmental control is not always possible.

The multidisciplinary nature of interface engineering further complicates progress, requiring expertise spanning electrochemistry, mechanical engineering, materials science, and manufacturing technology. Developing comprehensive solutions demands integrated approaches that simultaneously address mechanical, chemical, and electrochemical aspects of interface behavior.

State-of-the-Art Interfacial Toughening Solutions

01 Interfacial toughening mechanisms for structural electrodes

Various mechanisms can be employed to enhance the interfacial toughness between electrodes and other components in energy storage devices. These include the use of specialized coatings, adhesion promoters, and surface treatments that create stronger bonds at the interface. By improving the mechanical integrity at these interfaces, the overall durability and performance of structural electrodes can be significantly enhanced, reducing delamination and failure under mechanical stress.- Interfacial toughening mechanisms for structural electrodes: Various mechanisms can be employed to enhance the interfacial toughening of structural electrodes, including the use of specialized coatings, adhesion promoters, and surface treatments. These approaches improve the mechanical integrity of the electrode-substrate interface, reducing delamination and increasing overall structural stability. The interfacial toughening techniques help distribute stress more evenly across the electrode structure, preventing crack propagation and enhancing durability under mechanical and thermal cycling conditions.

- Composite materials for structural electrode applications: Composite materials combining conductive elements with structural reinforcements can be used to create electrodes with both electrical functionality and mechanical strength. These composites often incorporate carbon-based materials like carbon nanotubes, graphene, or carbon fibers embedded in polymer or ceramic matrices. The resulting electrodes exhibit improved fracture toughness, impact resistance, and flexural strength while maintaining necessary electrical properties. The composite approach allows for customization of mechanical and electrical properties to meet specific application requirements.

- Surface modification techniques for enhanced electrode bonding: Surface modification techniques can significantly improve the bonding between electrodes and adjacent materials. These techniques include plasma treatment, chemical etching, laser texturing, and the application of coupling agents. By creating controlled surface roughness or chemical functionalization, these methods increase the effective contact area and promote chemical bonding at the interface. Enhanced bonding leads to improved mechanical properties, better electrical contact, and increased resistance to environmental degradation.

- Gradient structures for stress distribution in electrodes: Gradient structures can be designed within electrodes to better distribute mechanical stress and prevent interfacial failure. These structures feature gradual transitions in material composition, porosity, or mechanical properties across the electrode thickness or at interfaces. By avoiding abrupt changes in material properties, gradient structures minimize stress concentrations that typically lead to crack initiation. This approach is particularly effective for electrodes subjected to thermal cycling or mechanical loading during operation.

- Self-healing mechanisms for electrode interfaces: Self-healing mechanisms can be incorporated into electrode interfaces to automatically repair damage and extend operational lifetime. These mechanisms include microencapsulated healing agents, reversible chemical bonds, or shape memory materials that activate in response to damage. When cracks or delamination occur at the interface, the self-healing components are triggered to restore mechanical integrity and electrical conductivity. This approach is particularly valuable for applications where maintenance access is limited or where long-term reliability is critical.

02 Composite materials for structural battery electrodes

Composite materials combining conductive elements with structural reinforcements can be used to create electrodes that serve both electrical and load-bearing functions. These composites often incorporate carbon fibers, nanotubes, or other high-strength conductive materials embedded in polymer matrices. The resulting electrodes exhibit improved mechanical properties including fracture toughness and interfacial strength while maintaining necessary electrical conductivity for energy storage applications.Expand Specific Solutions03 Surface modification techniques for electrode interfaces

Various surface modification techniques can be applied to electrode materials to enhance their interfacial properties. These include plasma treatment, chemical functionalization, and the application of coupling agents that create stronger chemical bonds between dissimilar materials. Such modifications can significantly improve the adhesion between electrodes and electrolytes or current collectors, leading to enhanced mechanical stability and reduced interfacial resistance.Expand Specific Solutions04 Nanostructured interfaces for enhanced toughening

Nanostructured interfaces can be engineered to improve the toughness of structural electrodes. By creating hierarchical structures at the nanoscale, such as interlocking features, gradient interfaces, or nanoporous regions, stress concentration can be reduced and crack propagation inhibited. These nanostructured interfaces provide multiple energy dissipation mechanisms, enhancing the overall toughness and durability of the electrode-substrate interface under mechanical loading conditions.Expand Specific Solutions05 Self-healing mechanisms for electrode interfaces

Self-healing mechanisms can be incorporated into structural electrodes to automatically repair damage at interfaces. These approaches include microencapsulated healing agents, reversible chemical bonds, or shape memory materials that can restore mechanical integrity after damage occurs. By implementing such self-healing capabilities, the long-term durability of structural electrodes can be significantly improved, particularly in applications subject to cyclic loading or environmental stresses.Expand Specific Solutions

Leading Companies and Research Institutions

The interfacial toughening strategies in structural electrodes market is currently in a growth phase, with increasing demand driven by energy storage applications. The global market size is expanding rapidly, projected to reach significant value as battery technologies evolve. Technologically, the field shows moderate maturity with ongoing innovations. Key players include established electronics manufacturers like Samsung Electronics, Panasonic Holdings, and Murata Manufacturing, who leverage their materials expertise. Battery specialists such as Saft Groupe and LG Energy Solution are advancing electrode-electrolyte interface solutions. Research institutions like Harbin Institute of Technology and semiconductor companies including GLOBALFOUNDRIES and ASM International are contributing novel approaches to interface engineering, indicating a competitive landscape with diverse technological approaches.

Saft Groupe SA

Technical Solution: Saft Groupe has developed an innovative interfacial toughening strategy for structural electrodes called "Gradient Interface Architecture" (GIA). This approach creates functionally graded interfaces between electrode components with progressively changing mechanical properties to minimize stress concentration and prevent delamination. Their technology incorporates specialized polymer binders with engineered adhesion promoters that form strong chemical bonds with both active materials and current collectors. Saft's research has focused on silicon-carbon composite anodes where interfacial failure is particularly challenging due to large volumetric changes during cycling. Their solution includes a hierarchical interface design with primary and secondary binding networks - the primary network provides structural integrity while the secondary network offers elasticity to accommodate volume changes. Additionally, Saft has pioneered surface modification techniques using plasma treatment and chemical functionalization to enhance wettability and adhesion at critical interfaces, resulting in electrodes that maintain structural integrity even under extreme mechanical and thermal conditions.

Strengths: Exceptional cycling stability with demonstrated 90% capacity retention after 1000 cycles in high-silicon content anodes; superior mechanical adhesion under thermal and mechanical stress; compatibility with existing manufacturing processes. Weaknesses: Higher material costs compared to conventional electrode formulations; increased process complexity requiring precise control of interface formation; potential for reduced energy density due to additional interface components.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a comprehensive interfacial toughening approach for structural electrodes through their "Multi-Scale Interface Engineering" technology. This strategy involves the application of nanoscale ceramic-polymer composite coatings at electrode-electrolyte interfaces to enhance mechanical stability while maintaining ionic conductivity. Their proprietary process incorporates functionalized carbon nanotubes (CNTs) and graphene derivatives that form strong covalent bonds with both active materials and current collectors, creating mechanically robust interfaces that can withstand volumetric changes during cycling. Samsung has also pioneered atomic layer deposition (ALD) techniques to create ultrathin conformal protective layers on electrode surfaces that significantly improve interfacial strength without compromising electrochemical performance. Their recent advancements include self-assembling polymer networks that dynamically respond to mechanical stress by redistributing force across the electrode structure, preventing localized failure points and extending cycle life.

Strengths: Exceptional mechanical durability with demonstrated resistance to microcracking under high strain conditions; superior cycling stability in high-energy density applications; compatibility with existing manufacturing infrastructure. Weaknesses: Increased production complexity and associated costs; potential for higher internal resistance at modified interfaces; challenges in quality control for nanoscale interface modifications at production scale.

Key Patents and Scientific Breakthroughs

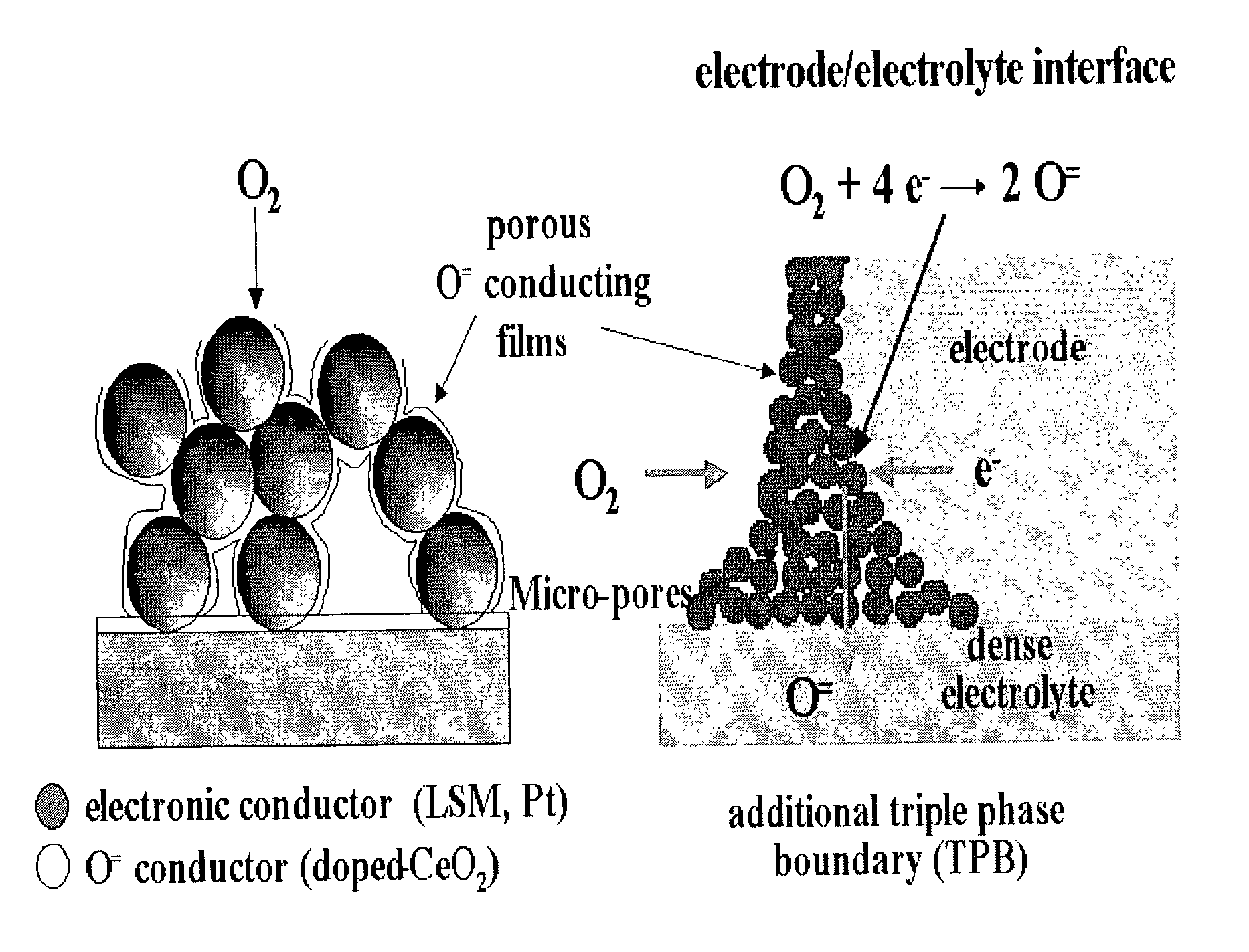

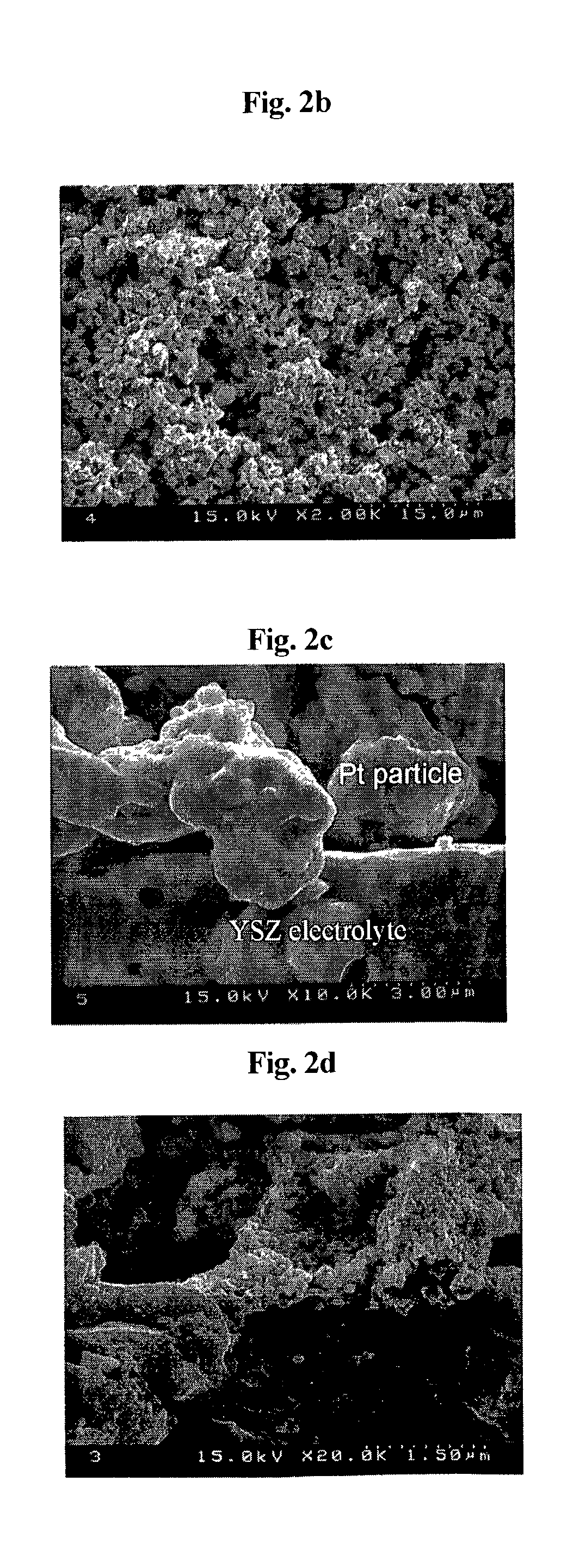

Electrode having microstructure of extended triple phase boundary by porous ion conductive ceria film coating and method to manufacture the said electrode

PatentInactiveUS7141329B2

Innovation

- A novel electrode coated with a porous oxygen ion conductive ceramic ceria film using a sol-gel method, maintaining independent electron and ion conductive paths and extending the triple phase boundary, allowing for lower temperature manufacturing and preventing undesired interfacial reaction products.

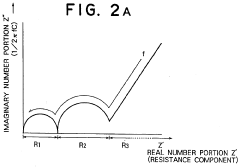

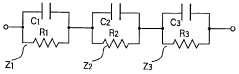

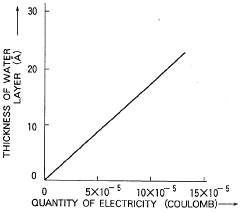

Interfacial component detection apparatus

PatentInactiveCA2053054A1

Innovation

- An interfacial component detection apparatus utilizing a solid electrolytic layer and multiple electrodes to apply electrical signals and detect impedance frequency dependency or electrolyze the interfacial layer, allowing for accurate detection of water and other components through impedance and electrolysis characteristics.

Materials Sustainability and Environmental Impact

The sustainability aspects of interfacial toughening strategies in structural electrodes represent a critical dimension that must be addressed for their widespread adoption. Current manufacturing processes for advanced electrode materials often involve energy-intensive procedures and environmentally harmful chemicals, raising significant concerns about their ecological footprint. The synthesis of nanomaterials and specialized polymers used in interfacial engineering frequently requires toxic solvents and generates hazardous waste, necessitating careful consideration of end-of-life management.

Life cycle assessment (LCA) studies indicate that while interfacial toughening can extend battery lifespans by up to 40%, potentially reducing overall material consumption, the environmental benefits may be offset by increased manufacturing complexity. The carbon footprint of producing specialized coating materials and implementing precise interfacial control measures must be weighed against the sustainability gains from improved electrode durability and performance.

Recycling challenges present another significant concern. The multi-material nature of toughened interfaces complicates end-of-life recovery processes. Current recycling technologies struggle to efficiently separate and recover the diverse materials present in advanced electrode structures, potentially leading to valuable resource loss and increased waste generation. Research indicates that only 5-10% of specialized interfacial materials are currently recoverable through conventional recycling methods.

Emerging green chemistry approaches offer promising alternatives for more sustainable interfacial engineering. Bio-derived polymers, water-based processing techniques, and solvent-free manufacturing methods are being developed to reduce environmental impact. These approaches have demonstrated up to 70% reduction in toxic solvent usage while maintaining comparable interfacial properties in laboratory settings.

Resource scarcity also influences sustainability considerations. Many high-performance interfacial materials rely on critical elements with limited global supplies. Developing toughening strategies that utilize abundant, non-toxic elements represents a key research direction. Recent advances in silicon-based and carbon-derived interfacial materials demonstrate the potential for creating robust interfaces without depending on scarce resources.

Regulatory frameworks worldwide are increasingly emphasizing materials sustainability, with the European Union's Battery Directive and similar initiatives in Asia and North America establishing stringent requirements for battery material composition and recyclability. These regulations will likely accelerate the transition toward more environmentally benign interfacial toughening approaches in the coming decade.

Life cycle assessment (LCA) studies indicate that while interfacial toughening can extend battery lifespans by up to 40%, potentially reducing overall material consumption, the environmental benefits may be offset by increased manufacturing complexity. The carbon footprint of producing specialized coating materials and implementing precise interfacial control measures must be weighed against the sustainability gains from improved electrode durability and performance.

Recycling challenges present another significant concern. The multi-material nature of toughened interfaces complicates end-of-life recovery processes. Current recycling technologies struggle to efficiently separate and recover the diverse materials present in advanced electrode structures, potentially leading to valuable resource loss and increased waste generation. Research indicates that only 5-10% of specialized interfacial materials are currently recoverable through conventional recycling methods.

Emerging green chemistry approaches offer promising alternatives for more sustainable interfacial engineering. Bio-derived polymers, water-based processing techniques, and solvent-free manufacturing methods are being developed to reduce environmental impact. These approaches have demonstrated up to 70% reduction in toxic solvent usage while maintaining comparable interfacial properties in laboratory settings.

Resource scarcity also influences sustainability considerations. Many high-performance interfacial materials rely on critical elements with limited global supplies. Developing toughening strategies that utilize abundant, non-toxic elements represents a key research direction. Recent advances in silicon-based and carbon-derived interfacial materials demonstrate the potential for creating robust interfaces without depending on scarce resources.

Regulatory frameworks worldwide are increasingly emphasizing materials sustainability, with the European Union's Battery Directive and similar initiatives in Asia and North America establishing stringent requirements for battery material composition and recyclability. These regulations will likely accelerate the transition toward more environmentally benign interfacial toughening approaches in the coming decade.

Scalability and Manufacturing Considerations

The scalability of interfacial toughening strategies represents a critical factor in determining their commercial viability for structural electrode applications. Current laboratory-scale demonstrations, while promising, face significant challenges when transitioning to industrial production volumes. Manufacturing processes must be adapted to accommodate the specialized interface treatments without compromising production efficiency or increasing costs prohibitively.

Mass production of toughened interfaces requires careful consideration of process compatibility with existing manufacturing infrastructure. Techniques such as chemical vapor deposition (CVD) for carbon coating or atomic layer deposition (ALD) for oxide layers demand specialized equipment that may not be readily integrated into conventional battery production lines. The capital investment required for such equipment upgrades presents a substantial barrier to widespread adoption, particularly for smaller manufacturers.

Time constraints in manufacturing environments pose another significant challenge. Many interfacial toughening treatments require extended processing times that conflict with the high-throughput demands of commercial production. For instance, solution-based surface modifications often involve multiple steps including pre-treatment, coating application, and post-processing, each adding production time and complexity. Streamlining these processes without sacrificing interface quality remains an ongoing research focus.

Material supply chains must also be considered when evaluating scalability. Some advanced interfacial treatments utilize specialized polymers, nanoparticles, or other materials that may have limited availability or inconsistent quality at industrial scales. Establishing robust supply chains for these materials is essential for sustainable manufacturing implementation.

Cost-effectiveness ultimately determines commercial adoption potential. While laboratory demonstrations may utilize expensive materials or energy-intensive processes, commercial viability requires optimization for cost efficiency. Preliminary cost analyses suggest that certain interfacial toughening approaches, particularly those utilizing low-cost carbon-based materials or simplified polymer coatings, offer the most promising path to commercial implementation.

Recent advances in roll-to-roll processing techniques show particular promise for scaling interfacial treatments. These continuous manufacturing methods allow for high-throughput surface modification compatible with existing battery production infrastructure. Several companies have demonstrated pilot-scale implementation of roll-to-roll interfacial modification processes, achieving production rates approaching those required for commercial viability while maintaining consistent interface quality.

Mass production of toughened interfaces requires careful consideration of process compatibility with existing manufacturing infrastructure. Techniques such as chemical vapor deposition (CVD) for carbon coating or atomic layer deposition (ALD) for oxide layers demand specialized equipment that may not be readily integrated into conventional battery production lines. The capital investment required for such equipment upgrades presents a substantial barrier to widespread adoption, particularly for smaller manufacturers.

Time constraints in manufacturing environments pose another significant challenge. Many interfacial toughening treatments require extended processing times that conflict with the high-throughput demands of commercial production. For instance, solution-based surface modifications often involve multiple steps including pre-treatment, coating application, and post-processing, each adding production time and complexity. Streamlining these processes without sacrificing interface quality remains an ongoing research focus.

Material supply chains must also be considered when evaluating scalability. Some advanced interfacial treatments utilize specialized polymers, nanoparticles, or other materials that may have limited availability or inconsistent quality at industrial scales. Establishing robust supply chains for these materials is essential for sustainable manufacturing implementation.

Cost-effectiveness ultimately determines commercial adoption potential. While laboratory demonstrations may utilize expensive materials or energy-intensive processes, commercial viability requires optimization for cost efficiency. Preliminary cost analyses suggest that certain interfacial toughening approaches, particularly those utilizing low-cost carbon-based materials or simplified polymer coatings, offer the most promising path to commercial implementation.

Recent advances in roll-to-roll processing techniques show particular promise for scaling interfacial treatments. These continuous manufacturing methods allow for high-throughput surface modification compatible with existing battery production infrastructure. Several companies have demonstrated pilot-scale implementation of roll-to-roll interfacial modification processes, achieving production rates approaching those required for commercial viability while maintaining consistent interface quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!