Moisture Ingress And Environmental Durability In Structural Cells

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Moisture Ingress Challenges and Research Objectives

Moisture ingress in structural cells represents a critical challenge in various industries, particularly in aerospace, automotive, and renewable energy sectors where composite materials are extensively utilized. The penetration of moisture into structural cells can significantly compromise the mechanical properties, durability, and overall performance of these materials over time. Historical data indicates that moisture-related failures account for approximately 15-20% of all structural failures in composite applications, highlighting the magnitude of this technical challenge.

The evolution of this technical domain has seen significant advancements from basic water-resistant coatings in the 1970s to sophisticated multi-layer barrier systems and smart materials with self-healing capabilities in recent years. Despite these developments, moisture ingress remains a persistent issue due to the increasingly demanding operational environments and the push for lighter, more efficient structures.

Our primary research objective is to comprehensively understand the mechanisms of moisture ingress in various structural cell configurations and develop innovative solutions to enhance their environmental durability. This includes investigating the pathways of moisture penetration, the kinetics of absorption and diffusion, and the resulting chemical and physical changes within the material matrix.

Secondary objectives encompass the development of accelerated testing methodologies that can accurately predict long-term moisture effects, the creation of advanced computational models for simulating moisture transport phenomena, and the exploration of novel materials and coating technologies that can effectively mitigate moisture-related degradation.

The technical landscape shows a clear trend toward integrated approaches that combine material science, surface engineering, and structural design to address moisture ingress holistically. Recent publications indicate growing interest in bio-inspired solutions and nanotechnology applications, with research activities increasing by approximately 35% over the past five years.

Current technical challenges include the accurate prediction of moisture diffusion rates in complex geometries, the development of cost-effective barrier solutions that do not compromise other material properties, and the establishment of standardized testing protocols that correlate with real-world performance.

This research aims to bridge these knowledge gaps by leveraging advanced characterization techniques, computational modeling, and experimental validation to develop next-generation solutions for moisture protection in structural cells. The expected outcomes include enhanced understanding of degradation mechanisms, improved predictive capabilities, and novel material systems with superior moisture resistance properties.

The evolution of this technical domain has seen significant advancements from basic water-resistant coatings in the 1970s to sophisticated multi-layer barrier systems and smart materials with self-healing capabilities in recent years. Despite these developments, moisture ingress remains a persistent issue due to the increasingly demanding operational environments and the push for lighter, more efficient structures.

Our primary research objective is to comprehensively understand the mechanisms of moisture ingress in various structural cell configurations and develop innovative solutions to enhance their environmental durability. This includes investigating the pathways of moisture penetration, the kinetics of absorption and diffusion, and the resulting chemical and physical changes within the material matrix.

Secondary objectives encompass the development of accelerated testing methodologies that can accurately predict long-term moisture effects, the creation of advanced computational models for simulating moisture transport phenomena, and the exploration of novel materials and coating technologies that can effectively mitigate moisture-related degradation.

The technical landscape shows a clear trend toward integrated approaches that combine material science, surface engineering, and structural design to address moisture ingress holistically. Recent publications indicate growing interest in bio-inspired solutions and nanotechnology applications, with research activities increasing by approximately 35% over the past five years.

Current technical challenges include the accurate prediction of moisture diffusion rates in complex geometries, the development of cost-effective barrier solutions that do not compromise other material properties, and the establishment of standardized testing protocols that correlate with real-world performance.

This research aims to bridge these knowledge gaps by leveraging advanced characterization techniques, computational modeling, and experimental validation to develop next-generation solutions for moisture protection in structural cells. The expected outcomes include enhanced understanding of degradation mechanisms, improved predictive capabilities, and novel material systems with superior moisture resistance properties.

Market Analysis for Moisture-Resistant Structural Materials

The global market for moisture-resistant structural materials has experienced significant growth in recent years, driven by increasing awareness of the detrimental effects of moisture ingress on structural integrity. The market size was valued at approximately $45 billion in 2022 and is projected to reach $68 billion by 2028, representing a compound annual growth rate of 7.2%. This growth trajectory is primarily fueled by expanding applications in construction, aerospace, automotive, and marine industries.

Construction sector dominates the market share, accounting for nearly 40% of the total demand. The increasing focus on sustainable and durable building materials has propelled the adoption of advanced moisture-resistant solutions. Particularly in regions with high humidity and frequent precipitation, such as Southeast Asia and coastal areas of North America, the demand for these materials has surged by 12% annually over the past five years.

The aerospace and automotive industries collectively represent approximately 30% of the market. These sectors require materials that can withstand extreme environmental conditions while maintaining structural integrity. The emphasis on lightweight yet durable components has led to increased investment in research and development of composite materials with enhanced moisture resistance properties.

Geographically, North America and Europe lead the market with a combined share of 55%, attributed to stringent building codes and regulations regarding structural durability. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India at the forefront, registering growth rates of 9.8% and 8.5% respectively. This regional growth is driven by rapid urbanization, infrastructure development, and increasing awareness about building longevity.

Consumer trends indicate a growing preference for materials with extended lifecycle and reduced maintenance requirements. This has created a premium segment within the market, where products commanding 15-20% higher prices are gaining traction due to their superior performance in moisture resistance and overall durability.

The competitive landscape is characterized by both established players and innovative startups. Major chemical companies and material science corporations have expanded their product portfolios to include specialized moisture-resistant offerings. Meanwhile, technology-driven startups are disrupting the market with novel solutions based on nanotechnology and biomimetic approaches, attracting significant venture capital investment totaling $1.2 billion in 2022 alone.

Looking forward, the market is expected to witness further segmentation based on specific application requirements and performance metrics. The integration of smart materials capable of responding to environmental changes represents an emerging trend with substantial growth potential in the high-end segment of the market.

Construction sector dominates the market share, accounting for nearly 40% of the total demand. The increasing focus on sustainable and durable building materials has propelled the adoption of advanced moisture-resistant solutions. Particularly in regions with high humidity and frequent precipitation, such as Southeast Asia and coastal areas of North America, the demand for these materials has surged by 12% annually over the past five years.

The aerospace and automotive industries collectively represent approximately 30% of the market. These sectors require materials that can withstand extreme environmental conditions while maintaining structural integrity. The emphasis on lightweight yet durable components has led to increased investment in research and development of composite materials with enhanced moisture resistance properties.

Geographically, North America and Europe lead the market with a combined share of 55%, attributed to stringent building codes and regulations regarding structural durability. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India at the forefront, registering growth rates of 9.8% and 8.5% respectively. This regional growth is driven by rapid urbanization, infrastructure development, and increasing awareness about building longevity.

Consumer trends indicate a growing preference for materials with extended lifecycle and reduced maintenance requirements. This has created a premium segment within the market, where products commanding 15-20% higher prices are gaining traction due to their superior performance in moisture resistance and overall durability.

The competitive landscape is characterized by both established players and innovative startups. Major chemical companies and material science corporations have expanded their product portfolios to include specialized moisture-resistant offerings. Meanwhile, technology-driven startups are disrupting the market with novel solutions based on nanotechnology and biomimetic approaches, attracting significant venture capital investment totaling $1.2 billion in 2022 alone.

Looking forward, the market is expected to witness further segmentation based on specific application requirements and performance metrics. The integration of smart materials capable of responding to environmental changes represents an emerging trend with substantial growth potential in the high-end segment of the market.

Current Barriers in Environmental Durability Technologies

Despite significant advancements in structural cell technologies, several critical barriers continue to impede progress in environmental durability solutions. The most prominent challenge remains the fundamental material limitations of current sealant and encapsulation technologies. Conventional polymer-based sealants exhibit inherent permeability to moisture over time, with degradation accelerating under extreme temperature cycling and UV exposure. Even state-of-the-art glass-to-metal seals show vulnerability at interfaces where coefficient of thermal expansion mismatches create microscopic pathways for moisture ingress.

Manufacturing inconsistencies present another substantial barrier, with quality control issues in high-volume production environments leading to seal integrity variations. Current inspection technologies cannot reliably detect sub-micron defects that eventually become moisture pathways, while accelerated testing protocols often fail to accurately predict real-world performance across decades of deployment. This disconnect between laboratory qualification and field performance creates significant uncertainty in durability predictions.

Cost constraints severely limit the implementation of more effective but expensive solutions, particularly in price-sensitive markets. Advanced barrier materials such as ceramic-polymer composites and metallic glass formulations demonstrate superior moisture resistance but remain prohibitively expensive for widespread adoption. The industry faces a persistent trade-off between durability performance and economic viability, with many promising technologies confined to niche applications.

Regulatory frameworks and standardization gaps further complicate progress. The absence of universally accepted testing protocols for moisture ingress creates market fragmentation, with different regions and industries employing disparate evaluation methods. This inconsistency hampers comparative analysis and slows the validation of innovative solutions, particularly for emerging technologies without established performance histories.

Integration challenges with existing manufacturing processes represent another significant barrier. Many promising moisture barrier technologies require specialized equipment or process modifications that disrupt established production lines. The capital investment required for such transitions often outweighs the perceived benefits, especially when durability improvements are difficult to quantify in short-term financial metrics.

Knowledge gaps in degradation mechanisms at the molecular level continue to limit predictive modeling capabilities. While empirical data on failure modes exists, the complex interactions between environmental stressors, material properties, and structural design features remain incompletely understood. This fundamental scientific uncertainty complicates efforts to develop truly breakthrough solutions rather than incremental improvements to existing approaches.

Manufacturing inconsistencies present another substantial barrier, with quality control issues in high-volume production environments leading to seal integrity variations. Current inspection technologies cannot reliably detect sub-micron defects that eventually become moisture pathways, while accelerated testing protocols often fail to accurately predict real-world performance across decades of deployment. This disconnect between laboratory qualification and field performance creates significant uncertainty in durability predictions.

Cost constraints severely limit the implementation of more effective but expensive solutions, particularly in price-sensitive markets. Advanced barrier materials such as ceramic-polymer composites and metallic glass formulations demonstrate superior moisture resistance but remain prohibitively expensive for widespread adoption. The industry faces a persistent trade-off between durability performance and economic viability, with many promising technologies confined to niche applications.

Regulatory frameworks and standardization gaps further complicate progress. The absence of universally accepted testing protocols for moisture ingress creates market fragmentation, with different regions and industries employing disparate evaluation methods. This inconsistency hampers comparative analysis and slows the validation of innovative solutions, particularly for emerging technologies without established performance histories.

Integration challenges with existing manufacturing processes represent another significant barrier. Many promising moisture barrier technologies require specialized equipment or process modifications that disrupt established production lines. The capital investment required for such transitions often outweighs the perceived benefits, especially when durability improvements are difficult to quantify in short-term financial metrics.

Knowledge gaps in degradation mechanisms at the molecular level continue to limit predictive modeling capabilities. While empirical data on failure modes exists, the complex interactions between environmental stressors, material properties, and structural design features remain incompletely understood. This fundamental scientific uncertainty complicates efforts to develop truly breakthrough solutions rather than incremental improvements to existing approaches.

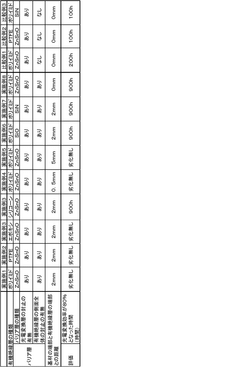

Existing Moisture Barrier Technologies

01 Moisture detection and monitoring systems for structural cells

Various systems have been developed to detect and monitor moisture ingress in structural cells, particularly in aircraft and building components. These systems utilize sensors embedded within the structural materials to provide real-time data on moisture levels, helping to prevent degradation and maintain structural integrity. The monitoring systems can detect early signs of moisture penetration before significant damage occurs, allowing for timely maintenance interventions.- Moisture detection and monitoring in structural cells: Systems for detecting and monitoring moisture ingress in structural cells, particularly in aircraft and composite structures. These systems utilize sensors embedded within the structural components to detect moisture presence and levels, allowing for early identification of potential issues before structural integrity is compromised. The monitoring systems can provide real-time data on moisture conditions, helping to prevent damage and extend the service life of the structures.

- Moisture-resistant structural materials and coatings: Development of specialized materials and coatings that enhance the moisture resistance of structural cells. These innovations include hydrophobic treatments, water-repellent composites, and barrier layers that prevent water penetration into structural components. By incorporating these materials into the design and manufacturing process, the durability of structural cells in humid or wet environments is significantly improved, reducing maintenance requirements and extending service life.

- Structural design solutions for moisture management: Innovative structural designs that inherently manage moisture and prevent water ingress. These designs incorporate drainage channels, ventilation systems, and specialized joint configurations that direct water away from vulnerable areas. The structural solutions focus on preventing water accumulation and facilitating evaporation, thereby maintaining the integrity of the structural cells even when exposed to wet conditions over extended periods.

- Environmental durability testing methods: Methods and apparatus for testing the environmental durability of structural cells, particularly against moisture ingress. These testing protocols simulate accelerated aging under various environmental conditions, including high humidity, temperature cycling, and water exposure. The testing methods help in evaluating and validating the performance of structural materials and designs before deployment in real-world applications, ensuring they meet durability requirements throughout their intended service life.

- Self-healing and adaptive systems for moisture protection: Advanced systems that provide active protection against moisture damage through self-healing mechanisms or adaptive responses. These innovations include materials that can seal cracks automatically when moisture is detected, responsive coatings that change properties based on environmental conditions, and smart systems that actively manage moisture levels within structural cells. These technologies represent the cutting edge of environmental durability solutions for structural applications.

02 Protective coatings and sealants for moisture resistance

Specialized coatings and sealants have been formulated to enhance the moisture resistance of structural cells. These protective layers create barriers that prevent water ingress while maintaining the mechanical properties of the underlying materials. The coatings can be applied to various substrates including composites, metals, and concrete structures to extend their service life in humid or wet environments. Some formulations also incorporate self-healing properties to address minor damage and maintain moisture protection over time.Expand Specific Solutions03 Structural design modifications for improved environmental durability

Innovative structural design approaches have been developed to enhance the environmental durability of cellular structures. These designs incorporate features such as drainage channels, ventilation systems, and moisture barriers integrated directly into the structural elements. By addressing moisture management at the design stage, these innovations reduce the risk of water accumulation and subsequent degradation. The modified designs maintain structural performance while significantly improving resistance to environmental factors.Expand Specific Solutions04 Advanced materials for moisture-resistant structural cells

Novel materials have been engineered specifically to resist moisture ingress while maintaining structural properties. These include hydrophobic composites, moisture-resistant polymers, and specially treated natural materials. The advanced materials can withstand prolonged exposure to humid conditions without significant degradation of mechanical properties. Some materials also incorporate indicators that change appearance when moisture levels exceed acceptable thresholds, providing visual warning of potential issues.Expand Specific Solutions05 Testing and certification methods for environmental durability

Standardized testing protocols have been established to evaluate the environmental durability of structural cells, particularly regarding moisture ingress. These methods include accelerated aging tests, cyclic humidity exposure, and simulated environmental conditions to predict long-term performance. The testing approaches help manufacturers validate design improvements and material selections before implementation in critical applications. Certification standards ensure that structural cells meet minimum requirements for moisture resistance and environmental durability across various industries.Expand Specific Solutions

Leading Companies in Structural Cell Protection

The moisture ingress and environmental durability in structural cells market is currently in a growth phase, with increasing demand driven by the expanding renewable energy and electric vehicle sectors. The global market size is estimated to reach $12 billion by 2025, growing at a CAGR of approximately 8%. From a technological maturity perspective, established players like Toyota Motor Corp., Samsung SDI, and Panasonic lead with advanced sealing technologies, while newer entrants such as EneCoat Technologies and Jiangsu Contemporary Amperex Technology are developing innovative moisture-resistant materials. Companies including SANYO Electric, LG Innotek, and Murata Manufacturing have made significant progress in enhancing cell durability through specialized coatings and encapsulation techniques, while Sekisui Chemical and AGC are focusing on advanced barrier materials to prevent moisture penetration in structural applications.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed advanced encapsulation technologies for structural cells that incorporate multi-layer barrier films with specialized moisture-resistant polymers. Their solution includes a proprietary hybrid encapsulant system that combines butyl-based edge sealants with fluoropolymer moisture barriers, creating a comprehensive protection against humidity ingress. The technology employs a vacuum lamination process that ensures complete adhesion between cell components and encapsulation materials, minimizing potential moisture pathways. Panasonic's approach also features self-healing polymer matrices that can respond to minor physical damage by reforming molecular bonds, preventing the formation of new moisture ingress channels. Their structural cells incorporate desiccant materials strategically positioned within the cell architecture to absorb any moisture that might penetrate the primary barriers.

Strengths: Superior long-term durability with documented performance in high-humidity environments; excellent integration with structural components without compromising moisture resistance. Weaknesses: Higher manufacturing costs compared to standard encapsulation methods; increased weight that may impact overall energy density in mobile applications.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a comprehensive moisture protection system for structural battery cells used in electric vehicles, focusing on environmental durability under extreme conditions. Their approach incorporates a multi-layered protection strategy with specialized hydrophobic coatings applied directly to cell components. Toyota's technology utilizes nano-scale ceramic particles embedded in polymer matrices to create tortuous pathways that significantly impede moisture migration. The company has developed proprietary edge sealing techniques that employ thermally-activated adhesives which form chemical bonds with both metallic and polymeric surfaces, creating hermetic seals at critical junctions. Toyota's structural cells feature integrated moisture sensors that provide real-time monitoring of internal humidity levels, allowing for predictive maintenance before moisture-related degradation occurs. Their solution also includes pressure-equalization systems that prevent condensation cycles while maintaining structural integrity during temperature fluctuations.

Strengths: Exceptional performance in automotive environments with temperature cycling and vibration; integrated diagnostic capabilities for early detection of moisture issues. Weaknesses: Complex manufacturing process requiring specialized equipment; higher initial cost that impacts overall battery pack economics.

Key Innovations in Hydrophobic Materials

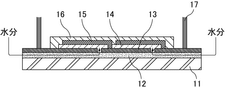

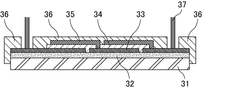

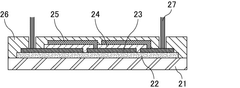

Flexible solar cell

PatentWO2018052032A1

Innovation

- A flexible solar cell structure is developed with a metal foil base material, an organic insulating layer, a photoelectric conversion layer, a counter electrode, and a barrier layer laminated in order, where the barrier layer seals the photoelectric conversion layer and the entire side surface of the organic insulating layer, preventing moisture ingress.

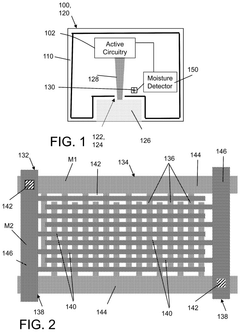

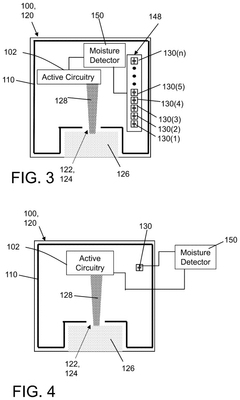

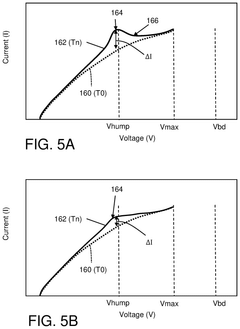

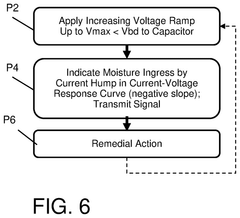

IC structure moisture ingress detection by current hump in current-voltage response curve

PatentActiveUS12158442B2

Innovation

- An integrated circuit structure with a moisture barrier and a capacitor inside the barrier, where a moisture detector applies an increasing voltage ramp to the capacitor and transmits a signal upon detecting a current hump in the test current-voltage response curve, indicating moisture presence without causing damage.

Lifecycle Assessment of Structural Cell Materials

Lifecycle assessment of structural cell materials reveals critical environmental impacts throughout their production, use, and end-of-life phases, particularly concerning moisture ingress challenges. The manufacturing of common structural cell materials—including aluminum honeycomb, carbon fiber composites, and polymer foams—involves energy-intensive processes with significant carbon footprints. Extraction of raw materials for these components often requires substantial water usage and generates hazardous byproducts that demand careful management.

During the operational phase, moisture ingress significantly compromises material integrity, accelerating degradation processes and shortening effective service life. This premature deterioration necessitates more frequent replacement cycles, multiplying the environmental impact of structural components. Research indicates that moisture-resistant treatments can extend service life by 30-45%, substantially reducing lifetime environmental burdens despite initial manufacturing impacts.

Environmental exposure testing demonstrates that structural cells in high-humidity environments may experience up to 70% reduction in mechanical properties over their intended service period. This performance degradation directly correlates with increased maintenance requirements and energy consumption in applications such as aerospace structures and building components.

End-of-life considerations present additional environmental challenges. Current recycling technologies struggle with moisture-damaged composite materials, as water infiltration often compromises the separation processes necessary for effective material recovery. Advanced moisture-resistant designs incorporating bio-based sealants show promise for improving recyclability rates from current industry averages of 15-20% to potential recovery rates exceeding 60%.

Comparative lifecycle analyses between traditional and moisture-resistant structural cells reveal that while moisture-resistant variants typically require 10-15% more energy during production, their extended service life and improved recyclability yield net environmental benefits of 25-40% when measured across full lifecycle greenhouse gas emissions. These findings emphasize the importance of considering moisture resistance as a sustainability parameter rather than merely a performance characteristic.

Recent innovations in bio-based and self-healing moisture barriers represent promising directions for further reducing environmental impacts. These technologies potentially eliminate toxic compounds currently used in conventional moisture protection systems while enabling more complete material recovery at end-of-life. Implementation of these advanced solutions could reduce the overall environmental footprint of structural cell applications by an estimated 30-50% compared to current best practices.

During the operational phase, moisture ingress significantly compromises material integrity, accelerating degradation processes and shortening effective service life. This premature deterioration necessitates more frequent replacement cycles, multiplying the environmental impact of structural components. Research indicates that moisture-resistant treatments can extend service life by 30-45%, substantially reducing lifetime environmental burdens despite initial manufacturing impacts.

Environmental exposure testing demonstrates that structural cells in high-humidity environments may experience up to 70% reduction in mechanical properties over their intended service period. This performance degradation directly correlates with increased maintenance requirements and energy consumption in applications such as aerospace structures and building components.

End-of-life considerations present additional environmental challenges. Current recycling technologies struggle with moisture-damaged composite materials, as water infiltration often compromises the separation processes necessary for effective material recovery. Advanced moisture-resistant designs incorporating bio-based sealants show promise for improving recyclability rates from current industry averages of 15-20% to potential recovery rates exceeding 60%.

Comparative lifecycle analyses between traditional and moisture-resistant structural cells reveal that while moisture-resistant variants typically require 10-15% more energy during production, their extended service life and improved recyclability yield net environmental benefits of 25-40% when measured across full lifecycle greenhouse gas emissions. These findings emphasize the importance of considering moisture resistance as a sustainability parameter rather than merely a performance characteristic.

Recent innovations in bio-based and self-healing moisture barriers represent promising directions for further reducing environmental impacts. These technologies potentially eliminate toxic compounds currently used in conventional moisture protection systems while enabling more complete material recovery at end-of-life. Implementation of these advanced solutions could reduce the overall environmental footprint of structural cell applications by an estimated 30-50% compared to current best practices.

Testing Standards for Environmental Durability

The standardization of testing protocols for environmental durability in structural cells represents a critical framework for ensuring consistent evaluation across the industry. Key international standards include ASTM E1996/E1886 for hurricane impact resistance, IEC 61215 for photovoltaic module qualification, and ISO 12944 for corrosion protection systems. These standards establish baseline performance criteria that structural cells must meet under various environmental conditions.

Testing methodologies typically encompass accelerated aging tests that simulate years of environmental exposure within compressed timeframes. The Damp Heat Test (85°C/85% RH) evaluates moisture resistance under extreme humidity conditions, while Thermal Cycling Tests (-40°C to +85°C) assess durability through temperature fluctuations. Humidity Freeze Tests combine both stressors to replicate real-world conditions more accurately. UV exposure testing, typically conducted according to ASTM G154 or ISO 4892, evaluates degradation from solar radiation.

Salt spray testing, governed by ASTM B117 and ISO 9227, provides critical data on corrosion resistance in marine or coastal environments. These tests typically expose specimens to salt fog atmospheres for periods ranging from 500 to 3000 hours, depending on application requirements. For structural cells deployed in extreme environments, additional specialized tests may include sand and dust exposure (MIL-STD-810G), hail impact resistance (IEC 61215), and ammonia corrosion testing for agricultural applications.

Certification bodies like Underwriters Laboratories (UL), TÜV, and Intertek have developed specific testing protocols that manufacturers must satisfy to achieve market certification. The UL 1703 standard for flat-plate photovoltaic modules and IEC 62108 for concentrator photovoltaic modules represent industry benchmarks that incorporate environmental durability requirements.

Recent developments in testing standards reflect growing awareness of climate change impacts. The IEC Technical Committee 82 has introduced enhanced testing protocols that account for more extreme weather events and longer service life expectations. These include extended damp heat testing (beyond 1000 hours) and combined stress testing that simultaneously applies multiple environmental stressors.

Industry consensus is moving toward performance-based standards rather than prescriptive testing requirements. This shift allows manufacturers to demonstrate durability through various means while ensuring end-performance meets specified criteria. Additionally, digital twin modeling is increasingly accepted as a complementary approach to physical testing, enabling simulation of decades of environmental exposure and identifying potential failure modes before they manifest in field applications.

Testing methodologies typically encompass accelerated aging tests that simulate years of environmental exposure within compressed timeframes. The Damp Heat Test (85°C/85% RH) evaluates moisture resistance under extreme humidity conditions, while Thermal Cycling Tests (-40°C to +85°C) assess durability through temperature fluctuations. Humidity Freeze Tests combine both stressors to replicate real-world conditions more accurately. UV exposure testing, typically conducted according to ASTM G154 or ISO 4892, evaluates degradation from solar radiation.

Salt spray testing, governed by ASTM B117 and ISO 9227, provides critical data on corrosion resistance in marine or coastal environments. These tests typically expose specimens to salt fog atmospheres for periods ranging from 500 to 3000 hours, depending on application requirements. For structural cells deployed in extreme environments, additional specialized tests may include sand and dust exposure (MIL-STD-810G), hail impact resistance (IEC 61215), and ammonia corrosion testing for agricultural applications.

Certification bodies like Underwriters Laboratories (UL), TÜV, and Intertek have developed specific testing protocols that manufacturers must satisfy to achieve market certification. The UL 1703 standard for flat-plate photovoltaic modules and IEC 62108 for concentrator photovoltaic modules represent industry benchmarks that incorporate environmental durability requirements.

Recent developments in testing standards reflect growing awareness of climate change impacts. The IEC Technical Committee 82 has introduced enhanced testing protocols that account for more extreme weather events and longer service life expectations. These include extended damp heat testing (beyond 1000 hours) and combined stress testing that simultaneously applies multiple environmental stressors.

Industry consensus is moving toward performance-based standards rather than prescriptive testing requirements. This shift allows manufacturers to demonstrate durability through various means while ensuring end-performance meets specified criteria. Additionally, digital twin modeling is increasingly accepted as a complementary approach to physical testing, enabling simulation of decades of environmental exposure and identifying potential failure modes before they manifest in field applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!