Manufacturing Routes For Structural Battery Panels And Beams

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Technology Background and Objectives

Structural batteries represent a revolutionary approach to energy storage by integrating battery functionality directly into load-bearing structures. This dual-purpose technology aims to simultaneously provide mechanical support and electrical energy storage, effectively eliminating the traditional distinction between structural components and power sources. The concept originated in the early 2000s but has gained significant momentum over the past decade due to increasing demands for lightweight, energy-efficient solutions in transportation and portable electronics.

The evolution of structural batteries has been driven by advancements in materials science, particularly in carbon fiber composites and solid-state electrolytes. Early iterations focused primarily on embedding conventional battery cells within structural components, while contemporary approaches seek to develop truly multifunctional materials where the structure itself functions as an electrochemical cell. This paradigm shift represents a fundamental reimagining of how energy storage can be integrated into engineered systems.

The primary technical objective of structural battery development is to achieve competitive performance in both mechanical and electrochemical domains without significant compromises to either function. Current targets include achieving specific energy densities of 75-150 Wh/kg while maintaining structural properties comparable to conventional carbon fiber composites. Secondary objectives include developing manufacturing processes that can be scaled to industrial production volumes and ensuring long-term durability under combined mechanical and electrochemical cycling.

From a sustainability perspective, structural batteries offer significant potential for weight reduction in transportation applications, potentially reducing energy consumption and associated emissions. In electric vehicles, for example, the integration of energy storage into structural components could reduce overall vehicle weight by 15-25%, extending range or allowing for smaller battery packs.

The development of manufacturing routes for structural battery panels and beams represents a critical challenge in translating laboratory concepts to practical applications. Current research focuses on several promising approaches, including laminated designs that alternate structural and electrochemical layers, fiber-based architectures where carbon fibers serve as both reinforcement and active electrode material, and 3D architectures that optimize ion transport pathways while maintaining mechanical integrity.

Significant technical hurdles remain, particularly in achieving reliable electrical connections, managing thermal effects during operation, and developing manufacturing processes compatible with existing industrial infrastructure. Despite these challenges, the potential benefits of structural batteries have attracted substantial research investment from aerospace, automotive, and defense sectors, accelerating the pace of innovation and technological maturity.

The evolution of structural batteries has been driven by advancements in materials science, particularly in carbon fiber composites and solid-state electrolytes. Early iterations focused primarily on embedding conventional battery cells within structural components, while contemporary approaches seek to develop truly multifunctional materials where the structure itself functions as an electrochemical cell. This paradigm shift represents a fundamental reimagining of how energy storage can be integrated into engineered systems.

The primary technical objective of structural battery development is to achieve competitive performance in both mechanical and electrochemical domains without significant compromises to either function. Current targets include achieving specific energy densities of 75-150 Wh/kg while maintaining structural properties comparable to conventional carbon fiber composites. Secondary objectives include developing manufacturing processes that can be scaled to industrial production volumes and ensuring long-term durability under combined mechanical and electrochemical cycling.

From a sustainability perspective, structural batteries offer significant potential for weight reduction in transportation applications, potentially reducing energy consumption and associated emissions. In electric vehicles, for example, the integration of energy storage into structural components could reduce overall vehicle weight by 15-25%, extending range or allowing for smaller battery packs.

The development of manufacturing routes for structural battery panels and beams represents a critical challenge in translating laboratory concepts to practical applications. Current research focuses on several promising approaches, including laminated designs that alternate structural and electrochemical layers, fiber-based architectures where carbon fibers serve as both reinforcement and active electrode material, and 3D architectures that optimize ion transport pathways while maintaining mechanical integrity.

Significant technical hurdles remain, particularly in achieving reliable electrical connections, managing thermal effects during operation, and developing manufacturing processes compatible with existing industrial infrastructure. Despite these challenges, the potential benefits of structural batteries have attracted substantial research investment from aerospace, automotive, and defense sectors, accelerating the pace of innovation and technological maturity.

Market Analysis for Structural Battery Components

The structural battery components market is experiencing significant growth driven by the increasing demand for lightweight, energy-efficient solutions across multiple industries. Currently valued at approximately $1.2 billion, this market is projected to reach $5.7 billion by 2030, representing a compound annual growth rate of 21.3% during the forecast period. This remarkable growth trajectory is primarily fueled by the automotive and aerospace sectors, which together account for over 65% of the total market share.

In the automotive industry, the push for electric vehicles has created an urgent need for structural battery components that can reduce vehicle weight while maintaining or enhancing structural integrity. Major automotive manufacturers including Tesla, Volkswagen, and Toyota have announced substantial investments in structural battery technology, with Tesla's $1.5 billion commitment being particularly noteworthy. The integration of structural batteries into vehicle frames could potentially reduce overall weight by 15-20%, translating to increased range and improved performance.

The aerospace sector presents another significant market opportunity, with companies like Airbus and Boeing exploring structural battery solutions to address the weight constraints in aircraft design. The commercial aircraft segment is expected to grow at 24.7% annually within this market, as manufacturers seek to reduce fuel consumption and operational costs while meeting increasingly stringent environmental regulations.

Consumer electronics represents a smaller but rapidly expanding segment, growing at 18.9% annually. Manufacturers are exploring structural battery components for smartphones, laptops, and wearable devices to maximize internal space utilization and extend battery life without increasing device dimensions.

Regional analysis indicates that North America currently leads the market with a 38% share, followed closely by Europe at 35% and Asia-Pacific at 22%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 25.6% annually, driven by expanding manufacturing capabilities in China, South Korea, and Japan, along with increasing adoption of electric vehicles in these markets.

Key challenges affecting market adoption include high manufacturing costs, which currently average 2.3-3.5 times those of conventional battery systems, and technical limitations related to energy density and cycle life. Despite these challenges, the potential weight savings of 25-40% compared to traditional battery-plus-structure designs continues to drive investment and innovation in this sector.

In the automotive industry, the push for electric vehicles has created an urgent need for structural battery components that can reduce vehicle weight while maintaining or enhancing structural integrity. Major automotive manufacturers including Tesla, Volkswagen, and Toyota have announced substantial investments in structural battery technology, with Tesla's $1.5 billion commitment being particularly noteworthy. The integration of structural batteries into vehicle frames could potentially reduce overall weight by 15-20%, translating to increased range and improved performance.

The aerospace sector presents another significant market opportunity, with companies like Airbus and Boeing exploring structural battery solutions to address the weight constraints in aircraft design. The commercial aircraft segment is expected to grow at 24.7% annually within this market, as manufacturers seek to reduce fuel consumption and operational costs while meeting increasingly stringent environmental regulations.

Consumer electronics represents a smaller but rapidly expanding segment, growing at 18.9% annually. Manufacturers are exploring structural battery components for smartphones, laptops, and wearable devices to maximize internal space utilization and extend battery life without increasing device dimensions.

Regional analysis indicates that North America currently leads the market with a 38% share, followed closely by Europe at 35% and Asia-Pacific at 22%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 25.6% annually, driven by expanding manufacturing capabilities in China, South Korea, and Japan, along with increasing adoption of electric vehicles in these markets.

Key challenges affecting market adoption include high manufacturing costs, which currently average 2.3-3.5 times those of conventional battery systems, and technical limitations related to energy density and cycle life. Despite these challenges, the potential weight savings of 25-40% compared to traditional battery-plus-structure designs continues to drive investment and innovation in this sector.

Current Manufacturing Challenges and Limitations

Despite significant advancements in structural battery technology, manufacturing routes for structural battery panels and beams face substantial challenges that impede widespread industrial adoption. The integration of energy storage functionality with load-bearing capabilities creates unique manufacturing complexities not encountered in traditional composite or battery production processes.

Material compatibility issues represent a primary limitation, as the carbon fiber reinforcements that provide structural integrity must interface effectively with battery components without compromising either functionality. The electrolyte, particularly, presents challenges as it must maintain ionic conductivity while being compatible with structural materials and manufacturing processes. Current electrolyte solutions often degrade during high-temperature curing processes necessary for structural composites.

Scale-up challenges persist across the manufacturing pipeline. Laboratory-scale production methods that successfully create functional prototypes frequently encounter barriers when transitioning to industrial-scale manufacturing. The precise layering of battery components while maintaining structural integrity becomes increasingly difficult with larger panel dimensions, resulting in performance inconsistencies and manufacturing defects.

Process integration represents another significant hurdle. The manufacturing routes must reconcile the clean-room conditions required for battery component assembly with the more robust environments typical of composite manufacturing. This dichotomy creates logistical complexities and increases production costs, as specialized facilities and equipment become necessary.

Quality control and testing methodologies remain underdeveloped for these multifunctional components. Traditional battery testing protocols cannot adequately assess structural performance, while mechanical testing standards fail to account for electrochemical functionality. This gap in standardized testing procedures complicates manufacturing validation and quality assurance.

Thermal management during manufacturing presents additional complications. The curing processes for structural composites typically require elevated temperatures that can degrade battery components, particularly electrolytes and separators. Conversely, lower-temperature processes may result in suboptimal mechanical properties for the structural elements.

Automation capabilities for structural battery manufacturing lag behind those established for either conventional batteries or structural composites. The precision required for component placement, combined with the need to maintain both structural integrity and electrochemical functionality, exceeds the capabilities of current automated manufacturing systems.

Cost-effectiveness remains perhaps the most significant limitation. Current manufacturing routes involve complex, multi-step processes with specialized materials and equipment, resulting in prohibitively high production costs compared to separate battery and structural systems. This economic barrier significantly impedes commercial viability despite the potential weight and space savings offered by structural batteries.

Material compatibility issues represent a primary limitation, as the carbon fiber reinforcements that provide structural integrity must interface effectively with battery components without compromising either functionality. The electrolyte, particularly, presents challenges as it must maintain ionic conductivity while being compatible with structural materials and manufacturing processes. Current electrolyte solutions often degrade during high-temperature curing processes necessary for structural composites.

Scale-up challenges persist across the manufacturing pipeline. Laboratory-scale production methods that successfully create functional prototypes frequently encounter barriers when transitioning to industrial-scale manufacturing. The precise layering of battery components while maintaining structural integrity becomes increasingly difficult with larger panel dimensions, resulting in performance inconsistencies and manufacturing defects.

Process integration represents another significant hurdle. The manufacturing routes must reconcile the clean-room conditions required for battery component assembly with the more robust environments typical of composite manufacturing. This dichotomy creates logistical complexities and increases production costs, as specialized facilities and equipment become necessary.

Quality control and testing methodologies remain underdeveloped for these multifunctional components. Traditional battery testing protocols cannot adequately assess structural performance, while mechanical testing standards fail to account for electrochemical functionality. This gap in standardized testing procedures complicates manufacturing validation and quality assurance.

Thermal management during manufacturing presents additional complications. The curing processes for structural composites typically require elevated temperatures that can degrade battery components, particularly electrolytes and separators. Conversely, lower-temperature processes may result in suboptimal mechanical properties for the structural elements.

Automation capabilities for structural battery manufacturing lag behind those established for either conventional batteries or structural composites. The precision required for component placement, combined with the need to maintain both structural integrity and electrochemical functionality, exceeds the capabilities of current automated manufacturing systems.

Cost-effectiveness remains perhaps the most significant limitation. Current manufacturing routes involve complex, multi-step processes with specialized materials and equipment, resulting in prohibitively high production costs compared to separate battery and structural systems. This economic barrier significantly impedes commercial viability despite the potential weight and space savings offered by structural batteries.

Current Manufacturing Processes for Structural Batteries

01 Integration of battery cells into structural panels

Structural battery panels can be designed by integrating battery cells directly into load-bearing panels. This approach combines energy storage functionality with structural support, reducing overall weight and space requirements in vehicles, aircraft, or buildings. The battery cells are embedded within the panel structure, often using composite materials that provide both mechanical strength and electrical connectivity. This integration allows for dual functionality where the panels serve as both power sources and structural elements.- Integration of battery cells into structural panels: Structural battery panels can be designed by integrating battery cells directly into load-bearing panels. This approach combines energy storage capabilities with structural functions, reducing overall weight and space requirements in vehicles, aircraft, or buildings. The battery cells are embedded within the panel structure, often using composite materials as a matrix, allowing the panel to simultaneously store energy and withstand mechanical loads.

- Beam structures with integrated energy storage: Beams can be designed to incorporate battery components while maintaining their structural integrity and load-bearing capabilities. These multifunctional beams serve dual purposes by providing structural support and energy storage in a single component. Various designs include hollow beams with battery cells inside, composite beams with battery materials in the core, or sandwich structures where the battery forms part of the beam's cross-section.

- Composite materials for structural batteries: Advanced composite materials are utilized to create structural battery components that offer both mechanical strength and electrochemical functionality. These composites typically combine carbon fibers or other reinforcing materials with polymer electrolytes and active battery materials. The reinforcing fibers provide mechanical strength while simultaneously serving as electrodes or current collectors, creating a truly multifunctional material system.

- Connection and assembly methods for structural battery systems: Specialized connection and assembly techniques are required to integrate battery functionality into structural elements. These methods address challenges such as electrical connections between cells, thermal management, and maintaining structural integrity. Techniques include embedded wiring systems, specialized fasteners that serve as electrical connectors, and modular designs that allow for replacement of battery components without compromising structural performance.

- Building construction applications of structural battery panels: Structural battery panels can be incorporated into building construction to create energy-storing walls, floors, and roofing elements. These multifunctional building components can store energy from renewable sources like solar panels and provide power for building systems. The integration reduces the need for separate battery storage spaces while enhancing the building's energy efficiency and self-sufficiency.

02 Beam structures with embedded energy storage capabilities

Structural beams can be designed with integrated battery components to serve dual purposes of load support and energy storage. These beams typically feature hollow or compartmentalized sections where battery cells are housed while maintaining structural integrity. Advanced composite materials are often used to ensure the beams meet both mechanical load requirements and electrical performance specifications. This approach is particularly valuable in applications where space and weight optimization are critical, such as aerospace or automotive industries.Expand Specific Solutions03 Multifunctional composite materials for structural batteries

Advanced composite materials can be engineered to serve as both structural components and energy storage media. These multifunctional composites typically incorporate carbon fibers or other conductive materials that act as electrodes, while maintaining mechanical properties suitable for load-bearing applications. The matrix material may contain or be infused with electrolyte components. This approach enables the creation of truly integrated structural batteries where the distinction between the battery and the structure is minimized, offering significant weight and volume savings.Expand Specific Solutions04 Connection and assembly methods for structural battery systems

Specialized connection and assembly techniques are required for structural battery panels and beams to ensure both electrical connectivity and mechanical integrity. These methods include innovative joining technologies that maintain electrical pathways while providing structural continuity. Modular design approaches allow for easier maintenance and replacement of components. The assembly processes must address challenges related to thermal management, electrical insulation, and structural load distribution to ensure safe and efficient operation of the integrated system.Expand Specific Solutions05 Safety and protection systems for structural batteries

Structural battery panels and beams require specialized safety and protection systems to address the unique risks associated with combining energy storage and load-bearing functions. These systems include thermal management solutions to prevent overheating, electrical isolation to prevent short circuits, and structural reinforcement to maintain integrity in case of battery failure. Protective coatings and compartmentalization strategies are employed to contain potential failures and prevent cascading damage. These safety measures are critical for the practical implementation of structural batteries in various applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The structural battery panel and beam manufacturing landscape is evolving rapidly, with major automotive players like Toyota, Honda, and Nissan driving innovation alongside specialized battery manufacturers such as LG Energy Solution, CATL, and SK On. Currently in the early commercialization phase, this technology represents a growing market segment within the $100+ billion global battery industry. Technical maturity varies significantly: established companies like Panasonic and Johnson Controls focus on integration with existing vehicle architectures, while newer entrants like 24M Technologies and Sasung Power are developing novel manufacturing approaches that combine structural and energy storage functions. Research institutions including KU Leuven and Shanghai University are advancing fundamental technologies, suggesting the field remains 3-5 years from widespread commercial deployment.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative approach to structural battery panels manufacturing that integrates battery cells directly into vehicle structural components. Their process involves a multi-layer composite structure where battery cells are sandwiched between carbon fiber reinforced polymer (CFRP) layers, creating panels that serve both as energy storage and load-bearing elements. Toyota's manufacturing route employs automated fiber placement (AFP) technology to precisely lay carbon fibers impregnated with thermosetting resins around battery cells, followed by vacuum-assisted resin transfer molding (VARTM) to create a unified structure. This approach allows for the creation of complex three-dimensional battery panels that can be integrated into various vehicle components, including floor panels, roof structures, and side impact beams. Toyota has also developed specialized cooling channels within these structural panels to manage thermal loads during battery operation and charging.

Strengths: Significant weight reduction (up to 40%) compared to conventional separate battery and structural components; improved vehicle range due to weight savings; enhanced crash safety through distributed energy absorption. Weaknesses: Higher manufacturing complexity requiring specialized equipment; potential challenges in battery replacement or servicing; higher initial production costs compared to conventional battery systems.

24M Technologies, Inc.

Technical Solution: 24M Technologies has pioneered a semi-solid manufacturing process specifically adapted for structural battery applications. Their SemiSolid technology creates clay-like electrodes that can be directly molded into structural forms, eliminating many traditional battery manufacturing steps. For structural battery panels and beams, 24M employs a unique co-extrusion process where the semi-solid electrode material is extruded alongside structural reinforcement elements (such as carbon fiber or fiberglass strands) to create integrated components. This approach allows for the creation of battery elements that follow complex geometrical paths within structural members. The manufacturing route involves precision dispensing of their proprietary semi-solid electrode material into molds containing pre-positioned structural elements, followed by a single-step curing process that activates both the electrochemical and structural properties simultaneously. This eliminates the need for separate battery cell manufacturing and structural integration steps, significantly reducing production complexity.

Strengths: Simplified manufacturing process with fewer steps than conventional lithium-ion production; ability to create complex geometries that conform to vehicle structural requirements; reduced manufacturing costs through elimination of multiple assembly steps. Weaknesses: Lower energy density compared to some conventional lithium-ion technologies; limited track record in high-volume automotive applications; potential challenges in achieving consistent quality at scale.

Key Patents and Technical Innovations

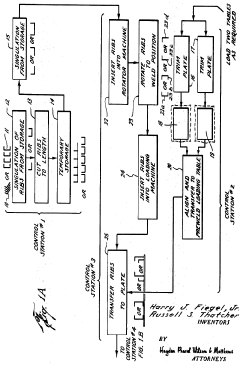

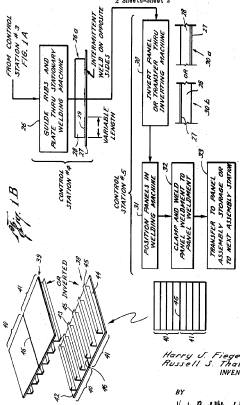

Method of manufacturing structural panels

PatentInactiveUS3574921A

Innovation

- A method involving the simultaneous welding of multiple rib members to a plate member using automated control stations, including preparation, positioning, and welding, to efficiently manufacture structural panels and assemblies.

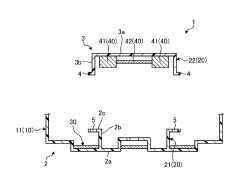

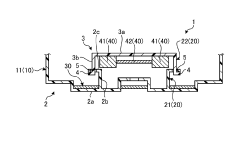

Manufacturing method of battery pack structure

PatentInactiveJP2023180905A

Innovation

- Integrated molding of battery pack casing, lower case of junction box, and metallic plate as a single component, reducing assembly steps and improving structural integrity.

- Utilization of snap-fitting mechanism for connecting the second component (energization component fixed to upper case) to the first component, enabling easier assembly without additional fasteners.

- Two-step manufacturing process that separates the structural components from the electrical components, allowing for more efficient production and quality control of each subsystem.

Material Science Advancements for Structural Batteries

Recent advancements in material science have significantly propelled the development of structural batteries, enabling the creation of multifunctional components that simultaneously bear mechanical loads and store electrical energy. Carbon fiber reinforced polymers (CFRPs) have emerged as the primary structural material for these applications due to their exceptional strength-to-weight ratio and electrical conductivity properties. The integration of solid-state electrolytes with these carbon-based structures represents a critical breakthrough, allowing for safer and more efficient energy storage within load-bearing elements.

Nanomaterial innovations have further enhanced structural battery performance, with graphene and carbon nanotubes providing improved electrical conductivity while maintaining or enhancing mechanical properties. These nanomaterials create more efficient pathways for electron movement while contributing to structural integrity. Additionally, silicon-carbon composite anodes have demonstrated capacity improvements of up to 300% compared to traditional graphite anodes, though challenges related to volume expansion during charging cycles remain.

Self-healing polymers represent another significant advancement, addressing the durability concerns in structural batteries. These materials can repair microcracks autonomously, extending the operational lifespan of structural battery components and maintaining both mechanical and electrochemical performance over time. Polymer electrolytes with enhanced ionic conductivity at ambient temperatures have also been developed, eliminating the need for liquid electrolytes that compromise structural integrity.

Ceramic-polymer hybrid electrolytes have emerged as promising materials that balance mechanical strength with ionic conductivity. These composites typically incorporate ceramic nanoparticles within a polymer matrix, creating pathways for ion transport while maintaining structural rigidity. Recent research has achieved ionic conductivities approaching 10^-3 S/cm at room temperature, a significant improvement over earlier generations.

Surface modification techniques for carbon fibers have enhanced the fiber-matrix interface, improving both mechanical load transfer and electrochemical performance. Treatments using silane coupling agents, plasma activation, and electrochemical functionalization have demonstrated up to 40% improvements in interfacial shear strength while simultaneously enhancing electrical connectivity between components.

Multifunctional coatings that serve as both electrical insulators and structural reinforcements represent another frontier in material science for structural batteries. These coatings prevent short circuits between battery components while contributing to the overall mechanical performance of the structure, addressing one of the key challenges in structural battery design.

Nanomaterial innovations have further enhanced structural battery performance, with graphene and carbon nanotubes providing improved electrical conductivity while maintaining or enhancing mechanical properties. These nanomaterials create more efficient pathways for electron movement while contributing to structural integrity. Additionally, silicon-carbon composite anodes have demonstrated capacity improvements of up to 300% compared to traditional graphite anodes, though challenges related to volume expansion during charging cycles remain.

Self-healing polymers represent another significant advancement, addressing the durability concerns in structural batteries. These materials can repair microcracks autonomously, extending the operational lifespan of structural battery components and maintaining both mechanical and electrochemical performance over time. Polymer electrolytes with enhanced ionic conductivity at ambient temperatures have also been developed, eliminating the need for liquid electrolytes that compromise structural integrity.

Ceramic-polymer hybrid electrolytes have emerged as promising materials that balance mechanical strength with ionic conductivity. These composites typically incorporate ceramic nanoparticles within a polymer matrix, creating pathways for ion transport while maintaining structural rigidity. Recent research has achieved ionic conductivities approaching 10^-3 S/cm at room temperature, a significant improvement over earlier generations.

Surface modification techniques for carbon fibers have enhanced the fiber-matrix interface, improving both mechanical load transfer and electrochemical performance. Treatments using silane coupling agents, plasma activation, and electrochemical functionalization have demonstrated up to 40% improvements in interfacial shear strength while simultaneously enhancing electrical connectivity between components.

Multifunctional coatings that serve as both electrical insulators and structural reinforcements represent another frontier in material science for structural batteries. These coatings prevent short circuits between battery components while contributing to the overall mechanical performance of the structure, addressing one of the key challenges in structural battery design.

Sustainability and Lifecycle Assessment

The sustainability aspects of structural battery panels and beams manufacturing represent a critical dimension in evaluating their viability for widespread adoption. Life Cycle Assessment (LCA) studies indicate that structural batteries offer significant potential for reducing overall environmental impact compared to conventional systems where batteries and structural components are separate entities. This integration eliminates redundant materials and potentially reduces vehicle weight, leading to improved energy efficiency during operation.

Carbon footprint analyses of current manufacturing routes reveal varying environmental impacts across different production methods. Electrolyte infusion processes typically demonstrate lower energy consumption compared to high-temperature curing methods. However, the specialized carbon fibers used as electrodes often require energy-intensive manufacturing processes, creating a sustainability challenge that requires optimization.

Material selection significantly influences the environmental profile of structural batteries. The use of bio-based or recycled carbon fibers could substantially reduce environmental impacts, though these alternatives currently face performance limitations. Similarly, developing electrolytes from renewable sources represents an important research direction for improving sustainability metrics.

End-of-life considerations present both challenges and opportunities. The intimate integration of battery components with structural elements complicates disassembly and recycling processes. Current research focuses on developing separation techniques that can effectively recover valuable materials like lithium and carbon fibers without excessive energy expenditure or chemical waste generation.

Energy payback calculations suggest that structural batteries in transportation applications may offset their manufacturing energy investment within 1-3 years of operation, depending on usage patterns and manufacturing efficiency. This relatively rapid payback period strengthens their environmental case, particularly for long-lifecycle applications.

Water usage and chemical waste generation during manufacturing remain significant concerns. Solvent-based processes for electrolyte incorporation typically require substantial water for purification steps and generate chemical waste streams requiring specialized treatment. Developing water-efficient manufacturing routes and benign chemistry approaches represents a key sustainability challenge.

Regulatory frameworks increasingly emphasize producer responsibility for battery lifecycle management, creating additional incentives for designing structural batteries with sustainability in mind. Manufacturers pursuing structural battery technology must consider these evolving requirements when developing production routes and material selection strategies.

Carbon footprint analyses of current manufacturing routes reveal varying environmental impacts across different production methods. Electrolyte infusion processes typically demonstrate lower energy consumption compared to high-temperature curing methods. However, the specialized carbon fibers used as electrodes often require energy-intensive manufacturing processes, creating a sustainability challenge that requires optimization.

Material selection significantly influences the environmental profile of structural batteries. The use of bio-based or recycled carbon fibers could substantially reduce environmental impacts, though these alternatives currently face performance limitations. Similarly, developing electrolytes from renewable sources represents an important research direction for improving sustainability metrics.

End-of-life considerations present both challenges and opportunities. The intimate integration of battery components with structural elements complicates disassembly and recycling processes. Current research focuses on developing separation techniques that can effectively recover valuable materials like lithium and carbon fibers without excessive energy expenditure or chemical waste generation.

Energy payback calculations suggest that structural batteries in transportation applications may offset their manufacturing energy investment within 1-3 years of operation, depending on usage patterns and manufacturing efficiency. This relatively rapid payback period strengthens their environmental case, particularly for long-lifecycle applications.

Water usage and chemical waste generation during manufacturing remain significant concerns. Solvent-based processes for electrolyte incorporation typically require substantial water for purification steps and generate chemical waste streams requiring specialized treatment. Developing water-efficient manufacturing routes and benign chemistry approaches represents a key sustainability challenge.

Regulatory frameworks increasingly emphasize producer responsibility for battery lifecycle management, creating additional incentives for designing structural batteries with sustainability in mind. Manufacturers pursuing structural battery technology must consider these evolving requirements when developing production routes and material selection strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!