Carbon Fiber As Anode In Structural Battery Composites

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon Fiber Anode Technology Background and Objectives

Carbon fiber has emerged as a revolutionary material in the field of energy storage, particularly as an anode component in structural battery composites. The evolution of this technology can be traced back to the early 2000s when researchers began exploring the dual functionality of carbon fiber as both a structural reinforcement and an electrochemically active material. This convergence represents a significant paradigm shift from traditional battery designs, where energy storage and structural components are separate entities.

The development trajectory of carbon fiber anodes has been accelerated by the growing demand for lightweight, high-performance energy storage solutions in aerospace, automotive, and portable electronics industries. Initially, carbon fiber was primarily valued for its exceptional mechanical properties, including high tensile strength and low weight. However, its electrical conductivity and potential for lithium-ion intercalation have opened new avenues for multifunctional applications.

Recent technological advancements have focused on enhancing the electrochemical performance of carbon fiber anodes through surface modifications, including coating with silicon or graphene, and optimizing fiber architecture to increase active surface area. These innovations have significantly improved energy density and cycle life, addressing key limitations of early prototypes.

The primary objective of carbon fiber anode technology in structural battery composites is to achieve true multifunctionality – where the material simultaneously excels in mechanical load-bearing and energy storage capabilities without compromising either function. This represents a departure from the traditional "mass penalty" paradigm, where adding battery components typically increases weight without contributing to structural integrity.

Secondary objectives include improving energy density to levels competitive with conventional lithium-ion batteries (>150 Wh/kg at the cell level), extending cycle life to thousands of charge-discharge cycles, and ensuring safety under mechanical stress and thermal variations. Additionally, researchers aim to develop scalable manufacturing processes that can transition this technology from laboratory demonstrations to commercial applications.

The long-term vision for carbon fiber anode technology encompasses the creation of "massless" energy storage, where the structural components of vehicles, aircraft, or buildings double as energy storage systems. This would revolutionize design approaches across multiple industries, enabling unprecedented weight reduction and energy efficiency improvements. The ultimate goal is to develop structural battery composites that can be tailored to specific applications, with customizable mechanical and electrochemical properties to meet diverse performance requirements.

The development trajectory of carbon fiber anodes has been accelerated by the growing demand for lightweight, high-performance energy storage solutions in aerospace, automotive, and portable electronics industries. Initially, carbon fiber was primarily valued for its exceptional mechanical properties, including high tensile strength and low weight. However, its electrical conductivity and potential for lithium-ion intercalation have opened new avenues for multifunctional applications.

Recent technological advancements have focused on enhancing the electrochemical performance of carbon fiber anodes through surface modifications, including coating with silicon or graphene, and optimizing fiber architecture to increase active surface area. These innovations have significantly improved energy density and cycle life, addressing key limitations of early prototypes.

The primary objective of carbon fiber anode technology in structural battery composites is to achieve true multifunctionality – where the material simultaneously excels in mechanical load-bearing and energy storage capabilities without compromising either function. This represents a departure from the traditional "mass penalty" paradigm, where adding battery components typically increases weight without contributing to structural integrity.

Secondary objectives include improving energy density to levels competitive with conventional lithium-ion batteries (>150 Wh/kg at the cell level), extending cycle life to thousands of charge-discharge cycles, and ensuring safety under mechanical stress and thermal variations. Additionally, researchers aim to develop scalable manufacturing processes that can transition this technology from laboratory demonstrations to commercial applications.

The long-term vision for carbon fiber anode technology encompasses the creation of "massless" energy storage, where the structural components of vehicles, aircraft, or buildings double as energy storage systems. This would revolutionize design approaches across multiple industries, enabling unprecedented weight reduction and energy efficiency improvements. The ultimate goal is to develop structural battery composites that can be tailored to specific applications, with customizable mechanical and electrochemical properties to meet diverse performance requirements.

Market Analysis for Structural Battery Composites

The structural battery composites market is experiencing significant growth driven by the increasing demand for lightweight, multifunctional materials across various industries. Current market valuation stands at approximately 150 million USD, with projections indicating a compound annual growth rate of 24% over the next five years. This accelerated growth is primarily fueled by the automotive and aerospace sectors, where weight reduction directly translates to improved energy efficiency and performance.

Carbon fiber as anode material in structural battery composites represents a particularly promising segment within this market. The dual functionality of carbon fiber—providing both mechanical strength and electrochemical performance—creates a compelling value proposition for manufacturers seeking to reduce component count and overall system weight.

The automotive industry currently constitutes the largest market share at 42%, with electric vehicle manufacturers showing particular interest in structural battery technology to address range anxiety concerns. Tesla, Volkswagen Group, and Chinese manufacturers like BYD are making substantial investments in this technology, recognizing its potential to increase energy density at the system level.

Aerospace applications represent the second-largest market segment at 31%, with both commercial aircraft manufacturers and defense contractors exploring structural batteries for unmanned aerial vehicles, satellites, and future electric aircraft designs. Boeing and Airbus have established dedicated research programs focusing on structural power solutions.

Consumer electronics represents an emerging application area at 15% market share, with potential implementations in laptops, smartphones, and wearable devices where space optimization is critical. The remaining 12% is distributed across marine, construction, and other industrial applications.

Geographically, North America leads the market with 38% share, followed by Europe at 35%, Asia-Pacific at 22%, and the rest of the world at 5%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years due to increasing manufacturing capabilities and government initiatives supporting electric mobility.

Key market drivers include stringent emissions regulations worldwide, increasing adoption of electric vehicles, growing focus on sustainable materials, and continuous pressure to improve energy efficiency across industries. The primary market restraints include high manufacturing costs, technical challenges in achieving optimal electrochemical-mechanical performance balance, and limited standardization across the industry.

Customer requirements are evolving toward higher energy density (targeting 250+ Wh/kg at the system level), improved cycle life (1000+ cycles), enhanced mechanical properties (comparable to conventional structural materials), and cost reduction to enable mass-market adoption.

Carbon fiber as anode material in structural battery composites represents a particularly promising segment within this market. The dual functionality of carbon fiber—providing both mechanical strength and electrochemical performance—creates a compelling value proposition for manufacturers seeking to reduce component count and overall system weight.

The automotive industry currently constitutes the largest market share at 42%, with electric vehicle manufacturers showing particular interest in structural battery technology to address range anxiety concerns. Tesla, Volkswagen Group, and Chinese manufacturers like BYD are making substantial investments in this technology, recognizing its potential to increase energy density at the system level.

Aerospace applications represent the second-largest market segment at 31%, with both commercial aircraft manufacturers and defense contractors exploring structural batteries for unmanned aerial vehicles, satellites, and future electric aircraft designs. Boeing and Airbus have established dedicated research programs focusing on structural power solutions.

Consumer electronics represents an emerging application area at 15% market share, with potential implementations in laptops, smartphones, and wearable devices where space optimization is critical. The remaining 12% is distributed across marine, construction, and other industrial applications.

Geographically, North America leads the market with 38% share, followed by Europe at 35%, Asia-Pacific at 22%, and the rest of the world at 5%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years due to increasing manufacturing capabilities and government initiatives supporting electric mobility.

Key market drivers include stringent emissions regulations worldwide, increasing adoption of electric vehicles, growing focus on sustainable materials, and continuous pressure to improve energy efficiency across industries. The primary market restraints include high manufacturing costs, technical challenges in achieving optimal electrochemical-mechanical performance balance, and limited standardization across the industry.

Customer requirements are evolving toward higher energy density (targeting 250+ Wh/kg at the system level), improved cycle life (1000+ cycles), enhanced mechanical properties (comparable to conventional structural materials), and cost reduction to enable mass-market adoption.

Current Status and Technical Challenges of Carbon Fiber Anodes

Carbon fiber has emerged as a promising anode material for structural battery composites, offering unique advantages in terms of mechanical properties and electrical conductivity. Currently, the state-of-the-art carbon fiber anodes utilize polyacrylonitrile (PAN)-based carbon fibers with surface modifications to enhance lithium-ion intercalation capabilities. These fibers typically demonstrate specific capacities ranging from 250-350 mAh/g, which is notably lower than the theoretical capacity of graphite (372 mAh/g) used in conventional lithium-ion batteries.

Recent advancements have focused on improving the electrochemical performance through various surface treatment methods, including thermal oxidation, chemical etching, and coating with conductive polymers or carbon nanomaterials. Research conducted at Chalmers University of Technology and KTH Royal Institute of Technology has demonstrated that controlled oxidation of carbon fiber surfaces can increase lithium-ion storage capacity by up to 30% compared to untreated fibers.

Despite these improvements, several significant technical challenges persist in the development of carbon fiber anodes for structural batteries. The primary challenge lies in balancing the mechanical and electrochemical properties of the fibers. Surface modifications that enhance electrochemical performance often compromise the mechanical strength and stiffness of the fibers, creating a fundamental trade-off that limits overall performance.

Another critical challenge is the relatively low first-cycle coulombic efficiency, typically ranging from 70-80%, which results in significant capacity loss during the initial charge-discharge cycle. This inefficiency stems from irreversible lithium consumption during solid electrolyte interphase (SEI) formation on the carbon fiber surface.

The rate capability of carbon fiber anodes also presents a significant limitation. Current carbon fiber anodes exhibit poor performance at high charge-discharge rates, restricting their application in high-power demand scenarios. This limitation is primarily attributed to the relatively low electrical conductivity along the radial direction of carbon fibers and the limited lithium diffusion pathways within the fiber structure.

Scalability and manufacturing consistency represent additional hurdles. The production of carbon fiber anodes with uniform electrochemical properties at industrial scale remains challenging, with significant batch-to-batch variations observed in both mechanical and electrochemical performance metrics.

Furthermore, the long-term cycling stability of carbon fiber anodes needs improvement. Current systems typically show capacity retention of 80-85% after 100 cycles, which falls short of the performance requirements for practical applications that demand thousands of cycles with minimal degradation.

Recent advancements have focused on improving the electrochemical performance through various surface treatment methods, including thermal oxidation, chemical etching, and coating with conductive polymers or carbon nanomaterials. Research conducted at Chalmers University of Technology and KTH Royal Institute of Technology has demonstrated that controlled oxidation of carbon fiber surfaces can increase lithium-ion storage capacity by up to 30% compared to untreated fibers.

Despite these improvements, several significant technical challenges persist in the development of carbon fiber anodes for structural batteries. The primary challenge lies in balancing the mechanical and electrochemical properties of the fibers. Surface modifications that enhance electrochemical performance often compromise the mechanical strength and stiffness of the fibers, creating a fundamental trade-off that limits overall performance.

Another critical challenge is the relatively low first-cycle coulombic efficiency, typically ranging from 70-80%, which results in significant capacity loss during the initial charge-discharge cycle. This inefficiency stems from irreversible lithium consumption during solid electrolyte interphase (SEI) formation on the carbon fiber surface.

The rate capability of carbon fiber anodes also presents a significant limitation. Current carbon fiber anodes exhibit poor performance at high charge-discharge rates, restricting their application in high-power demand scenarios. This limitation is primarily attributed to the relatively low electrical conductivity along the radial direction of carbon fibers and the limited lithium diffusion pathways within the fiber structure.

Scalability and manufacturing consistency represent additional hurdles. The production of carbon fiber anodes with uniform electrochemical properties at industrial scale remains challenging, with significant batch-to-batch variations observed in both mechanical and electrochemical performance metrics.

Furthermore, the long-term cycling stability of carbon fiber anodes needs improvement. Current systems typically show capacity retention of 80-85% after 100 cycles, which falls short of the performance requirements for practical applications that demand thousands of cycles with minimal degradation.

Current Carbon Fiber Anode Implementation Methods

01 Carbon fiber as structural anode material

Carbon fibers can serve as both structural reinforcement and anode material in structural battery composites. These multifunctional materials combine mechanical strength with electrochemical performance, allowing the battery to bear mechanical loads while storing energy. The carbon fibers provide electrical conductivity and lithium-ion intercalation sites, enabling them to function as anodes while maintaining their structural integrity.- Carbon fiber as structural anode material: Carbon fibers can serve as both structural reinforcement and anode material in battery composites. These multifunctional materials combine mechanical strength with electrochemical properties, allowing the battery to bear loads while storing energy. The carbon fibers provide electrical conductivity and lithium-ion intercalation capabilities, making them ideal for structural battery applications where weight and space efficiency are critical.

- Manufacturing methods for carbon fiber anodes: Various manufacturing techniques are employed to create carbon fiber anode structural battery composites. These include electrospinning, chemical vapor deposition, and specialized coating processes to enhance the electrochemical properties of carbon fibers. Surface treatments and functionalization methods improve the interface between carbon fibers and electrolyte materials, optimizing both mechanical and electrochemical performance of the composite structure.

- Electrolyte integration with carbon fiber structures: Effective integration of electrolytes with carbon fiber structures is crucial for structural battery performance. Specialized solid or semi-solid electrolytes are designed to permeate the carbon fiber matrix while maintaining structural integrity. These electrolytes facilitate ion transport between electrodes while contributing to the mechanical properties of the composite. Advanced polymer electrolytes and ionic liquids are particularly suitable for these applications due to their compatibility with carbon fibers.

- Cathode integration in structural battery composites: The integration of cathode materials with carbon fiber anodes creates complete structural battery systems. Various cathode materials, including lithium metal oxides and sulfur-based compounds, are incorporated into the composite structure. These cathode materials are often applied as coatings or integrated as separate layers within the carbon fiber matrix. The design must balance electrochemical performance with structural requirements to achieve optimal energy density and mechanical properties.

- Performance optimization and applications: Optimizing the performance of carbon fiber anode structural batteries involves balancing energy storage capacity, mechanical strength, and cycle life. These multifunctional composites find applications in aerospace, automotive, and portable electronics where weight reduction is critical. Research focuses on improving energy density while maintaining structural integrity through novel material combinations and architectural designs. Advanced testing methods evaluate both the mechanical and electrochemical properties simultaneously to ensure reliable performance in real-world applications.

02 Surface modification of carbon fiber anodes

Surface treatments and modifications of carbon fibers can enhance their electrochemical performance as anodes in structural batteries. These modifications include coating with active materials, functionalization with specific chemical groups, or creating hierarchical structures on the fiber surface. Such treatments improve lithium-ion storage capacity, cycling stability, and interface properties while maintaining the mechanical properties of the carbon fibers.Expand Specific Solutions03 Electrolyte systems for structural battery composites

Specialized electrolyte systems are crucial for structural battery composites with carbon fiber anodes. These electrolytes must provide ionic conductivity while maintaining mechanical properties of the composite. Solid or semi-solid electrolytes, polymer electrolytes, and structural electrolytes that can transfer mechanical loads are developed to enable effective ion transport between carbon fiber anodes and cathodes while contributing to the structural integrity of the battery composite.Expand Specific Solutions04 Manufacturing processes for structural battery composites

Specialized manufacturing techniques are developed for integrating carbon fiber anodes into structural battery composites. These processes include modified composite layup methods, resin infusion techniques adapted for battery components, and novel curing processes that preserve electrochemical functionality. The manufacturing approaches focus on ensuring uniform distribution of electrochemical components while maintaining structural integrity and preventing short circuits between electrodes.Expand Specific Solutions05 Multifunctional design of structural battery systems

Multifunctional design approaches optimize the dual performance of carbon fiber anode structural batteries. These designs balance electrochemical energy storage capabilities with mechanical load-bearing requirements. Various architectures incorporate carbon fiber anodes in ways that maximize both energy density and structural efficiency, including sandwich structures, laminated designs, and 3D reinforcement patterns. The designs consider weight reduction, mechanical strength, and electrochemical performance for applications in aerospace, automotive, and portable electronics.Expand Specific Solutions

Leading Companies and Research Institutions in Structural Batteries

The carbon fiber anode market in structural battery composites is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is projected to expand rapidly as automotive and aerospace industries seek lightweight energy storage solutions, with companies like Sila Nanotechnologies, LeydenJar Technologies, and Nexeon leading innovation in silicon-carbon composite anodes. Established players including Sony, Toyota, and LG Energy Solution are leveraging their battery expertise to develop structural battery technologies. Research institutions like Fraunhofer-Gesellschaft and universities collaborate with industry partners to overcome technical challenges in energy density, cycle life, and manufacturing scalability, indicating the technology is advancing toward commercial viability but remains 3-5 years from widespread adoption.

Hydro-Québec

Technical Solution: Hydro-Québec has developed innovative structural battery composites utilizing carbon fiber as anode materials through their advanced energy storage research division. Their technology leverages specially modified carbon fibers that serve dual functions as structural reinforcement and active battery components. The company's approach involves treating carbon fibers with proprietary surface modifications to enhance lithium-ion intercalation while preserving mechanical properties. Hydro-Québec's structural batteries employ a solid-state electrolyte system that permeates the carbon fiber matrix, creating a mechanically robust yet electrochemically active composite. Their latest prototypes have demonstrated energy densities of approximately 45-55 Wh/kg while maintaining structural integrity comparable to conventional carbon fiber composites. The company has focused on applications in electric vehicles and grid storage, where weight reduction and structural integration provide significant advantages. Hydro-Québec has established partnerships with automotive manufacturers to test these composites in vehicle components, showing potential weight reductions of 10-15% compared to conventional designs.

Strengths: Extensive experience in battery technology development; strong research capabilities and intellectual property portfolio; established relationships with manufacturing partners. Weaknesses: Challenges in scaling production to commercial volumes; lower energy density compared to dedicated battery systems; potential durability concerns under combined mechanical and electrochemical cycling.

Airbus Operations GmbH

Technical Solution: Airbus has developed advanced structural battery composites utilizing carbon fiber as anode materials specifically for aerospace applications. Their proprietary technology integrates carbon fiber reinforced polymers (CFRPs) that serve dual functions as structural components and battery anodes. The carbon fibers undergo specialized surface treatments to enhance lithium-ion intercalation while preserving mechanical properties. Airbus employs a multi-layer design where carbon fiber layers are strategically positioned between electrolyte-infused separators and cathode materials. This architecture enables the composite to withstand mechanical loads while facilitating electrochemical reactions. Their latest prototypes have demonstrated energy densities approaching 75 Wh/kg with structural properties meeting aviation safety standards. Airbus has integrated these components into non-critical aircraft structures for real-world testing, showing promising results for future implementation in commercial aircraft.

Strengths: Extensive aerospace certification expertise; advanced manufacturing capabilities for large-scale composite structures; strong integration with existing aircraft design processes. Weaknesses: Higher initial costs compared to traditional structures; challenges in ensuring uniform electrochemical performance across large structural components; potential safety certification hurdles.

Key Patents and Research on Carbon Fiber Electrode Materials

Structural energy storage with carbon fiber

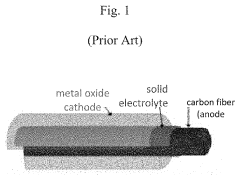

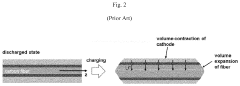

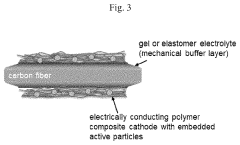

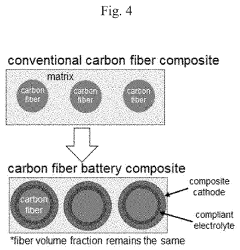

PatentActiveUS20230009854A1

Innovation

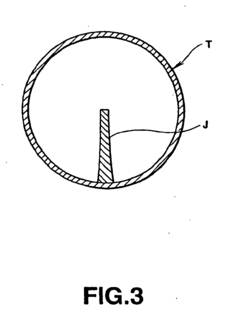

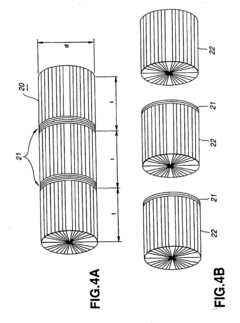

- A coaxial energy storage device with a continuous carbon fiber anode core coated with a mechanically compliant electrolyte of cross-linked polymer and elastomer, and a cathode layer embedded in an electrically conductive polymer matrix, designed to minimize interfacial stresses through reversible tensile strain and low elastic modulus, allowing for expansion and contraction without structural deterioration.

Carbon fiber structures for use as lithium-ion secondary cell anode material

PatentInactiveEP2267823B1

Innovation

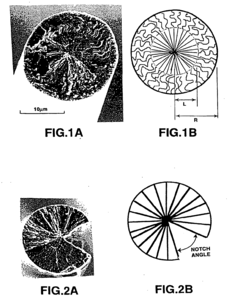

- The development of carbon fibers with a specific cross-sectional shape, including an area replenishment rate of 0.8 or more, circularity of 0.8 or more, fractal dimension between 1.1 and 1.8, and a notch structure, along with a radial type central portion and random radial type surface layer, to enhance electrode filling ability, crystallinity, and cycle reversibility.

Environmental Impact and Sustainability Assessment

The integration of carbon fiber as an anode material in structural battery composites represents a significant advancement in sustainable energy storage technology. Life cycle assessment (LCA) studies indicate that carbon fiber-based structural batteries offer substantial environmental benefits compared to conventional battery systems. The production of carbon fiber, while energy-intensive, demonstrates improved environmental performance when utilized in multifunctional applications that eliminate the need for separate structural and energy storage components.

Carbon fiber anodes in structural batteries contribute to significant weight reduction in applications such as electric vehicles and aerospace systems. This weight reduction translates directly into lower energy consumption during operation, with estimates suggesting potential energy savings of 15-25% in transportation applications. The extended lifecycle of carbon fiber composites, often exceeding 10-15 years, further enhances their sustainability profile by reducing the frequency of replacement and associated resource consumption.

The recyclability of carbon fiber components presents both challenges and opportunities. Current recycling processes for carbon fiber composites typically recover 60-80% of the original material properties, with ongoing research aimed at improving these rates. Advanced recycling technologies, including solvolysis and pyrolysis methods specifically adapted for structural battery composites, show promise for recovering both the carbon fiber and the embedded electrode materials with minimal environmental impact.

From a raw material perspective, carbon fiber production relies less on critical minerals compared to traditional lithium-ion battery technologies. This reduced dependence on geographically concentrated resources like cobalt and nickel enhances supply chain resilience and reduces environmental impacts associated with mining operations. The carbon footprint of structural battery composites is estimated to be 30-40% lower than conventional separate battery and structural systems when assessed on a full lifecycle basis.

Water usage and toxicity metrics also favor carbon fiber anode structural batteries. Manufacturing processes for these composites typically consume 40-60% less water than traditional battery production. Additionally, the stable carbon structure minimizes leaching of toxic materials during use and end-of-life phases, addressing key environmental concerns associated with conventional battery technologies.

Policy frameworks supporting circular economy principles increasingly recognize the potential of structural battery composites. Several jurisdictions have implemented incentives for technologies that demonstrate improved lifecycle environmental performance, creating favorable conditions for the commercial development of carbon fiber anode structural batteries. These regulatory trends, combined with growing consumer demand for sustainable energy solutions, suggest a positive outlook for the environmental competitiveness of this technology.

Carbon fiber anodes in structural batteries contribute to significant weight reduction in applications such as electric vehicles and aerospace systems. This weight reduction translates directly into lower energy consumption during operation, with estimates suggesting potential energy savings of 15-25% in transportation applications. The extended lifecycle of carbon fiber composites, often exceeding 10-15 years, further enhances their sustainability profile by reducing the frequency of replacement and associated resource consumption.

The recyclability of carbon fiber components presents both challenges and opportunities. Current recycling processes for carbon fiber composites typically recover 60-80% of the original material properties, with ongoing research aimed at improving these rates. Advanced recycling technologies, including solvolysis and pyrolysis methods specifically adapted for structural battery composites, show promise for recovering both the carbon fiber and the embedded electrode materials with minimal environmental impact.

From a raw material perspective, carbon fiber production relies less on critical minerals compared to traditional lithium-ion battery technologies. This reduced dependence on geographically concentrated resources like cobalt and nickel enhances supply chain resilience and reduces environmental impacts associated with mining operations. The carbon footprint of structural battery composites is estimated to be 30-40% lower than conventional separate battery and structural systems when assessed on a full lifecycle basis.

Water usage and toxicity metrics also favor carbon fiber anode structural batteries. Manufacturing processes for these composites typically consume 40-60% less water than traditional battery production. Additionally, the stable carbon structure minimizes leaching of toxic materials during use and end-of-life phases, addressing key environmental concerns associated with conventional battery technologies.

Policy frameworks supporting circular economy principles increasingly recognize the potential of structural battery composites. Several jurisdictions have implemented incentives for technologies that demonstrate improved lifecycle environmental performance, creating favorable conditions for the commercial development of carbon fiber anode structural batteries. These regulatory trends, combined with growing consumer demand for sustainable energy solutions, suggest a positive outlook for the environmental competitiveness of this technology.

Manufacturing Scalability and Cost Analysis

The current manufacturing processes for carbon fiber as anode in structural battery composites face significant scalability challenges that must be addressed for commercial viability. Traditional carbon fiber production methods involve energy-intensive processes with high temperature treatments exceeding 1500°C, contributing substantially to manufacturing costs. When adapting these fibers for dual structural-electrochemical functionality, additional surface treatments and modifications further increase production complexity and expenses.

Analysis of manufacturing costs reveals that carbon fiber production represents approximately 50-60% of the total structural battery composite cost, with specialized surface treatments adding another 15-20%. The remaining costs are distributed across electrolyte systems, cathode materials, and assembly processes. Current production methods yield limited output volumes, typically under 100 kg per batch for specialized battery-grade carbon fibers.

Economies of scale present a critical pathway toward cost reduction. Industry projections suggest that scaling production from laboratory to industrial levels could potentially reduce costs by 30-40% within five years. However, this requires significant capital investment in specialized equipment and process optimization. Companies like Toray Industries and Mitsubishi Chemical have begun exploring dedicated production lines for battery-grade carbon fibers, though these remain in early development stages.

Automation represents another key factor in manufacturing scalability. Current production methods for structural battery composites involve numerous manual steps, particularly in fiber alignment, electrolyte infusion, and final assembly. Automated systems for precise fiber placement and controlled electrolyte distribution could increase throughput by 3-5 times while improving consistency in electrochemical performance.

Material efficiency improvements offer additional cost reduction opportunities. Current processes typically generate 15-25% waste during carbon fiber production and composite fabrication. Advanced recycling methods and optimized cutting patterns could reduce waste to below 10%, significantly improving cost structures. Additionally, research into lower-temperature carbonization processes could reduce energy consumption by up to 40%, directly impacting production costs.

Supply chain considerations also affect manufacturing scalability. The precursor materials for specialized carbon fibers, particularly polyacrylonitrile (PAN) with modified properties, remain limited in availability and subject to price volatility. Developing robust supply chains with multiple qualified suppliers will be essential for large-scale production. Strategic partnerships between carbon fiber manufacturers, battery technology companies, and automotive or aerospace manufacturers could facilitate the necessary investments in production infrastructure.

Analysis of manufacturing costs reveals that carbon fiber production represents approximately 50-60% of the total structural battery composite cost, with specialized surface treatments adding another 15-20%. The remaining costs are distributed across electrolyte systems, cathode materials, and assembly processes. Current production methods yield limited output volumes, typically under 100 kg per batch for specialized battery-grade carbon fibers.

Economies of scale present a critical pathway toward cost reduction. Industry projections suggest that scaling production from laboratory to industrial levels could potentially reduce costs by 30-40% within five years. However, this requires significant capital investment in specialized equipment and process optimization. Companies like Toray Industries and Mitsubishi Chemical have begun exploring dedicated production lines for battery-grade carbon fibers, though these remain in early development stages.

Automation represents another key factor in manufacturing scalability. Current production methods for structural battery composites involve numerous manual steps, particularly in fiber alignment, electrolyte infusion, and final assembly. Automated systems for precise fiber placement and controlled electrolyte distribution could increase throughput by 3-5 times while improving consistency in electrochemical performance.

Material efficiency improvements offer additional cost reduction opportunities. Current processes typically generate 15-25% waste during carbon fiber production and composite fabrication. Advanced recycling methods and optimized cutting patterns could reduce waste to below 10%, significantly improving cost structures. Additionally, research into lower-temperature carbonization processes could reduce energy consumption by up to 40%, directly impacting production costs.

Supply chain considerations also affect manufacturing scalability. The precursor materials for specialized carbon fibers, particularly polyacrylonitrile (PAN) with modified properties, remain limited in availability and subject to price volatility. Developing robust supply chains with multiple qualified suppliers will be essential for large-scale production. Strategic partnerships between carbon fiber manufacturers, battery technology companies, and automotive or aerospace manufacturers could facilitate the necessary investments in production infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!