Joining And Repair Techniques For Structural Battery Assemblies

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Evolution and Objectives

Structural batteries represent a revolutionary approach to energy storage, combining load-bearing capabilities with energy storage functionality. The evolution of structural batteries began in the early 2000s with conceptual designs that integrated battery components into composite materials. These early designs faced significant challenges in balancing mechanical properties with electrochemical performance, resulting in compromised efficiency in both aspects.

The field gained momentum around 2010 when researchers at Imperial College London and KTH Royal Institute of Technology pioneered carbon fiber-based structural battery composites. These designs utilized carbon fibers as both structural reinforcement and battery electrodes, marking a significant advancement in the integration of dual functionalities. By 2015, several research groups had demonstrated proof-of-concept prototypes with energy densities approaching 35-50 Wh/kg, though still below conventional lithium-ion batteries.

A critical milestone occurred in 2018 when Chalmers University of Technology developed structural battery composites achieving both higher mechanical strength and improved energy density. Their approach incorporated carbon fiber negative electrodes with solid polymer electrolytes, addressing previous limitations in ion conductivity while maintaining structural integrity. This breakthrough catalyzed increased industrial interest and research funding.

The current technological landscape focuses on addressing joining and repair techniques, which represent critical challenges for practical implementation. Traditional battery assembly methods are incompatible with structural requirements, while conventional structural joining techniques can compromise battery functionality. The primary objective is to develop joining methodologies that maintain both structural integrity and electrochemical connectivity across component interfaces.

Secondary objectives include creating repair techniques that can address damage without complete component replacement, as structural batteries inherently face higher risk of mechanical damage than conventional batteries. Additionally, researchers aim to establish standardized testing protocols specifically designed for evaluating joint performance under combined mechanical and electrochemical stresses.

Looking forward, the field targets achieving energy densities exceeding 75 Wh/kg with competitive mechanical properties by 2025, and surpassing 100 Wh/kg by 2030. These ambitious goals require fundamental innovations in joining technologies that can seamlessly integrate structural battery components while maintaining optimal performance characteristics. The ultimate vision is to enable widespread adoption in aerospace, automotive, and portable electronics sectors, where weight reduction through multifunctional materials offers significant competitive advantages.

The field gained momentum around 2010 when researchers at Imperial College London and KTH Royal Institute of Technology pioneered carbon fiber-based structural battery composites. These designs utilized carbon fibers as both structural reinforcement and battery electrodes, marking a significant advancement in the integration of dual functionalities. By 2015, several research groups had demonstrated proof-of-concept prototypes with energy densities approaching 35-50 Wh/kg, though still below conventional lithium-ion batteries.

A critical milestone occurred in 2018 when Chalmers University of Technology developed structural battery composites achieving both higher mechanical strength and improved energy density. Their approach incorporated carbon fiber negative electrodes with solid polymer electrolytes, addressing previous limitations in ion conductivity while maintaining structural integrity. This breakthrough catalyzed increased industrial interest and research funding.

The current technological landscape focuses on addressing joining and repair techniques, which represent critical challenges for practical implementation. Traditional battery assembly methods are incompatible with structural requirements, while conventional structural joining techniques can compromise battery functionality. The primary objective is to develop joining methodologies that maintain both structural integrity and electrochemical connectivity across component interfaces.

Secondary objectives include creating repair techniques that can address damage without complete component replacement, as structural batteries inherently face higher risk of mechanical damage than conventional batteries. Additionally, researchers aim to establish standardized testing protocols specifically designed for evaluating joint performance under combined mechanical and electrochemical stresses.

Looking forward, the field targets achieving energy densities exceeding 75 Wh/kg with competitive mechanical properties by 2025, and surpassing 100 Wh/kg by 2030. These ambitious goals require fundamental innovations in joining technologies that can seamlessly integrate structural battery components while maintaining optimal performance characteristics. The ultimate vision is to enable widespread adoption in aerospace, automotive, and portable electronics sectors, where weight reduction through multifunctional materials offers significant competitive advantages.

Market Analysis for Structural Battery Applications

The structural battery market is experiencing significant growth as industries seek more efficient energy storage solutions that can simultaneously serve structural functions. Current market projections indicate that the global structural battery market could reach $2.5 billion by 2030, with a compound annual growth rate of approximately 25% from 2023 to 2030. This growth is primarily driven by the automotive and aerospace sectors, which together account for over 70% of the potential market demand.

In the automotive industry, structural batteries offer a revolutionary approach to electric vehicle design by integrating energy storage directly into vehicle components. This integration can potentially reduce vehicle weight by 15-20%, thereby extending driving range without increasing battery size. Major automotive manufacturers including Tesla, Volvo, and BMW have already initiated research programs focused on structural battery implementation, signaling strong industry interest.

The aerospace sector represents another significant market opportunity, with potential applications in drones, urban air mobility vehicles, and commercial aircraft. Weight reduction is particularly valuable in aerospace applications, where each kilogram saved can translate to substantial fuel savings or increased payload capacity. Companies like Airbus and Boeing have invested in structural battery research as part of their sustainability initiatives.

Consumer electronics constitutes a smaller but rapidly growing segment for structural battery applications. Manufacturers are exploring ways to integrate batteries into device casings, potentially increasing battery capacity by 30-40% without enlarging device dimensions. This application is particularly relevant for smartphones, laptops, and wearable technology.

Market barriers include high manufacturing costs, which currently make structural batteries 3-5 times more expensive than conventional lithium-ion batteries on a per-kWh basis. Additionally, concerns regarding repairability and end-of-life recycling present challenges that must be addressed before widespread adoption can occur.

Regional analysis shows that Europe leads in structural battery research and development, with significant investments from both public and private sectors. North America follows closely, while Asia-Pacific regions, particularly China, Japan, and South Korea, are rapidly increasing their market presence through strategic investments in manufacturing capabilities.

Customer requirements vary across industries but consistently emphasize safety, reliability, and cost-effectiveness. Survey data indicates that potential industrial adopters prioritize long-term durability and repairability over initial performance advantages, highlighting the importance of developing robust joining and repair techniques for structural battery assemblies.

In the automotive industry, structural batteries offer a revolutionary approach to electric vehicle design by integrating energy storage directly into vehicle components. This integration can potentially reduce vehicle weight by 15-20%, thereby extending driving range without increasing battery size. Major automotive manufacturers including Tesla, Volvo, and BMW have already initiated research programs focused on structural battery implementation, signaling strong industry interest.

The aerospace sector represents another significant market opportunity, with potential applications in drones, urban air mobility vehicles, and commercial aircraft. Weight reduction is particularly valuable in aerospace applications, where each kilogram saved can translate to substantial fuel savings or increased payload capacity. Companies like Airbus and Boeing have invested in structural battery research as part of their sustainability initiatives.

Consumer electronics constitutes a smaller but rapidly growing segment for structural battery applications. Manufacturers are exploring ways to integrate batteries into device casings, potentially increasing battery capacity by 30-40% without enlarging device dimensions. This application is particularly relevant for smartphones, laptops, and wearable technology.

Market barriers include high manufacturing costs, which currently make structural batteries 3-5 times more expensive than conventional lithium-ion batteries on a per-kWh basis. Additionally, concerns regarding repairability and end-of-life recycling present challenges that must be addressed before widespread adoption can occur.

Regional analysis shows that Europe leads in structural battery research and development, with significant investments from both public and private sectors. North America follows closely, while Asia-Pacific regions, particularly China, Japan, and South Korea, are rapidly increasing their market presence through strategic investments in manufacturing capabilities.

Customer requirements vary across industries but consistently emphasize safety, reliability, and cost-effectiveness. Survey data indicates that potential industrial adopters prioritize long-term durability and repairability over initial performance advantages, highlighting the importance of developing robust joining and repair techniques for structural battery assemblies.

Current Joining Challenges in Structural Battery Technology

The integration of structural batteries into various applications faces significant joining challenges that impede widespread adoption. Traditional joining methods like mechanical fastening, adhesive bonding, and welding each present unique complications when applied to structural battery assemblies. Mechanical fastening requires drilling holes through battery components, potentially damaging electrodes and separators while creating stress concentration points that compromise both structural integrity and electrochemical performance. These penetrations also risk internal short circuits and thermal runaway events.

Adhesive bonding, while avoiding penetration issues, introduces concerns regarding electrical connectivity and thermal management. Most structural adhesives are electrically insulating, creating challenges for establishing reliable electrical connections between battery cells and external circuits. Additionally, adhesives often exhibit poor thermal conductivity, potentially leading to heat accumulation within the battery structure during charging and discharging cycles, which accelerates degradation and reduces service life.

Welding techniques present perhaps the most severe limitations due to the heat-sensitive nature of battery components. Traditional fusion welding methods generate excessive heat that can damage electrolytes, separators, and active materials. Even advanced welding techniques like ultrasonic or laser welding require precise parameter control to avoid thermal damage to battery internals while still achieving sufficient joint strength.

The multifunctional nature of structural batteries further complicates joining processes. Unlike conventional batteries, structural batteries must simultaneously maintain electrical performance and load-bearing capabilities at the joints. This dual functionality requirement creates competing design constraints, as optimizing for electrical conductivity may compromise mechanical strength and vice versa.

Interface compatibility between dissimilar materials presents another significant challenge. Structural batteries typically incorporate carbon fiber composites, metals, and polymeric components, each with different thermal expansion coefficients and surface properties. These material differences create difficulties in establishing durable, high-strength bonds that can withstand both mechanical loads and electrochemical cycling.

Current joining methods also struggle with scalability and automation requirements for mass production. Many existing techniques require manual intervention or complex tooling setups that limit production throughput and increase manufacturing costs. The lack of standardized joining protocols specifically designed for structural batteries further impedes industrial adoption and quality control.

Repair and maintenance considerations add another layer of complexity. Joined structural battery assemblies must allow for potential disassembly and repair without compromising the integrity of the remaining components. Current joining methods often result in permanent connections that make component replacement difficult or impossible without damaging the entire assembly.

Adhesive bonding, while avoiding penetration issues, introduces concerns regarding electrical connectivity and thermal management. Most structural adhesives are electrically insulating, creating challenges for establishing reliable electrical connections between battery cells and external circuits. Additionally, adhesives often exhibit poor thermal conductivity, potentially leading to heat accumulation within the battery structure during charging and discharging cycles, which accelerates degradation and reduces service life.

Welding techniques present perhaps the most severe limitations due to the heat-sensitive nature of battery components. Traditional fusion welding methods generate excessive heat that can damage electrolytes, separators, and active materials. Even advanced welding techniques like ultrasonic or laser welding require precise parameter control to avoid thermal damage to battery internals while still achieving sufficient joint strength.

The multifunctional nature of structural batteries further complicates joining processes. Unlike conventional batteries, structural batteries must simultaneously maintain electrical performance and load-bearing capabilities at the joints. This dual functionality requirement creates competing design constraints, as optimizing for electrical conductivity may compromise mechanical strength and vice versa.

Interface compatibility between dissimilar materials presents another significant challenge. Structural batteries typically incorporate carbon fiber composites, metals, and polymeric components, each with different thermal expansion coefficients and surface properties. These material differences create difficulties in establishing durable, high-strength bonds that can withstand both mechanical loads and electrochemical cycling.

Current joining methods also struggle with scalability and automation requirements for mass production. Many existing techniques require manual intervention or complex tooling setups that limit production throughput and increase manufacturing costs. The lack of standardized joining protocols specifically designed for structural batteries further impedes industrial adoption and quality control.

Repair and maintenance considerations add another layer of complexity. Joined structural battery assemblies must allow for potential disassembly and repair without compromising the integrity of the remaining components. Current joining methods often result in permanent connections that make component replacement difficult or impossible without damaging the entire assembly.

State-of-the-Art Joining and Repair Solutions

01 Joining methods for structural battery assemblies

Various joining methods are employed for structural battery assemblies, including welding, adhesive bonding, and mechanical fastening. These techniques ensure proper electrical and mechanical connections between battery components while maintaining structural integrity. Advanced joining processes can accommodate different materials used in battery structures, providing both strength and necessary electrical conductivity for battery function.- Joining methods for structural battery assemblies: Various joining methods are employed for structural battery assemblies, including welding, adhesive bonding, and mechanical fastening. These techniques ensure proper electrical and mechanical connections between battery components while maintaining structural integrity. Advanced joining processes can accommodate different materials used in battery structures, providing both strength and necessary electrical conductivity for power transmission.

- Repair techniques for damaged battery structures: Repair techniques for structural battery assemblies involve identification of damage, removal of compromised sections, and restoration of both structural and electrical functionality. Methods include patch repairs, component replacement, and specialized adhesive applications. These repair processes must maintain the original performance characteristics of the battery while ensuring safety and reliability after the repair is completed.

- Integration of batteries into load-bearing structures: Structural batteries are designed to be integrated into load-bearing components of vehicles, aircraft, or buildings. This integration requires specialized assembly techniques that preserve both the energy storage capabilities and the mechanical properties of the structure. The assembly methods include embedding battery cells within composite materials, creating multifunctional structures that simultaneously provide energy storage and structural support.

- Connection systems for modular battery assemblies: Modular connection systems allow for the assembly and disassembly of structural battery components, facilitating maintenance, replacement, and upgrades. These systems include specialized connectors, bus bars, and interface designs that maintain electrical continuity while providing mechanical strength. The modular approach enables more efficient manufacturing, installation, and servicing of structural battery systems.

- Quality control and testing for structural battery joints: Quality control methods for structural battery assemblies include non-destructive testing techniques to verify joint integrity, electrical connectivity, and structural performance. These methods encompass ultrasonic inspection, electrical resistance measurements, and mechanical load testing. Automated systems can be employed to ensure consistent quality during manufacturing and to validate repairs, ensuring that joined battery components meet both electrical and structural requirements.

02 Repair techniques for structural battery components

Repair techniques for structural battery components involve methods to restore damaged battery elements without compromising the overall system integrity. These include patch repairs, component replacement, and specialized adhesive applications. Repair protocols must address both the structural aspects and the electrochemical functionality of the battery system, ensuring safe operation after maintenance.Expand Specific Solutions03 Integration of battery systems into structural components

Structural battery assemblies can be integrated directly into load-bearing components of vehicles, aircraft, or buildings. This integration involves specialized design approaches that allow the battery to simultaneously function as an energy storage device and a structural element. The integration methods include embedding battery cells within composite materials, creating multifunctional structures that reduce overall weight while maintaining mechanical performance.Expand Specific Solutions04 Thermal management in structural battery assemblies

Thermal management systems are crucial for structural battery assemblies to maintain optimal operating temperatures and prevent thermal runaway. These systems include heat dissipation methods, insulation techniques, and active cooling mechanisms integrated into the structural design. Proper thermal management ensures battery longevity, safety, and consistent performance under various environmental conditions and load scenarios.Expand Specific Solutions05 Diagnostic and monitoring systems for structural batteries

Diagnostic and monitoring systems for structural batteries enable real-time assessment of both electrical performance and structural integrity. These systems incorporate sensors that detect mechanical strain, temperature variations, and electrochemical parameters. Advanced monitoring techniques allow for early detection of potential failures, facilitating preventive maintenance and ensuring the safety and reliability of the structural battery assembly throughout its operational life.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The structural battery assembly market is currently in an early growth phase, characterized by significant R&D investments but limited commercial deployment. The global market size is estimated to reach $2-3 billion by 2030, driven by automotive electrification and sustainable energy demands. Leading automotive manufacturers like Toyota, Mercedes-Benz, and Nissan are collaborating with battery specialists including LG Energy Solution, CATL, and SK On to develop innovative joining and repair techniques. Technical maturity varies significantly, with companies like Bosch and Hitachi focusing on advanced connection systems, while newer entrants like American Battery Solutions and BattSwap develop modular approaches. The competition is intensifying as battery manufacturers and automotive OEMs race to establish intellectual property positions in this emerging field that promises to revolutionize EV design and performance.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive structural battery assembly system focusing on safety and repairability. Their approach uses a multi-layer architecture where battery cells are embedded within composite structural elements using specialized thermally conductive adhesives. These adhesives serve dual purposes: maintaining structural integrity while facilitating heat dissipation. For electrical connections, LG employs a combination of laser welding and mechanical fastening with redundant pathways to ensure reliability. Their repair technology includes diagnostic systems that can pinpoint damaged cells or connections within the structural assembly. LG's modular design philosophy allows for sectional replacement of damaged components without compromising the entire structure. They've also pioneered remote diagnostic capabilities that can identify potential failure points before physical damage occurs, enabling preventative maintenance of structural battery assemblies.

Strengths: Superior thermal management integration within structural elements enhances safety and longevity. Advanced diagnostic systems enable predictive maintenance and targeted repairs. Weaknesses: Complex multi-layer design increases manufacturing steps and potential failure points. Repair procedures require specialized equipment and training, limiting field serviceability.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced structural battery assembly techniques that integrate battery cells directly into vehicle structures. Their approach uses carbon fiber reinforced polymer (CFRP) frames with embedded battery modules, creating multi-functional components that serve both as structural elements and energy storage. Toyota's joining techniques include specialized adhesive bonding systems that maintain electrical isolation while ensuring structural integrity. For repair, they've implemented modular designs allowing targeted component replacement without compromising the entire battery structure. Their system includes ultrasonic welding for cell-to-busbar connections and laser welding for structural components, with thermal management systems integrated directly into the structural elements. Toyota has also pioneered self-healing polymer composites that can repair minor damage automatically, extending battery assembly lifespan.

Strengths: Superior integration of batteries into load-bearing structures, reducing overall vehicle weight while maintaining structural integrity. Advanced repair protocols enable targeted component replacement. Weaknesses: Higher manufacturing complexity and cost compared to conventional battery systems. Repair procedures require specialized training and equipment, limiting serviceability outside authorized facilities.

Key Patents in Structural Battery Assembly Techniques

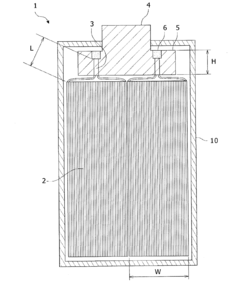

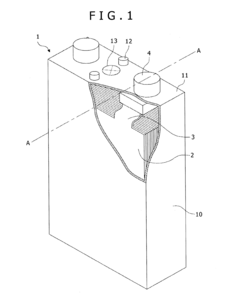

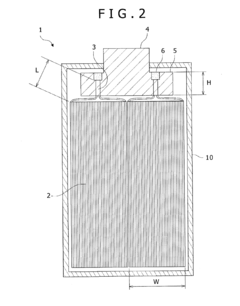

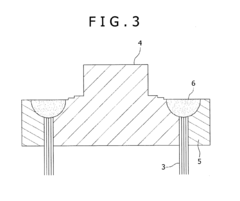

Joint structure, joining method, secondary battery, and method of manufacturing secondary battery

PatentInactiveUS20150188116A1

Innovation

- A joint structure and method using friction stir welding to integrate current collecting tabs with an external terminal and a cover block, ensuring tight contact and reducing electric resistance by forming a wider, deeper joint area, thereby improving routing performance and reducing heat generation.

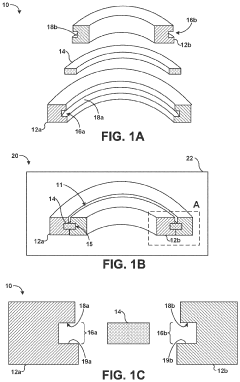

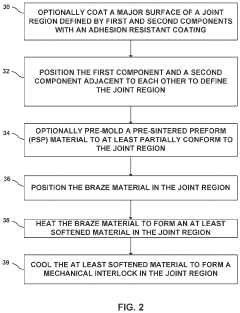

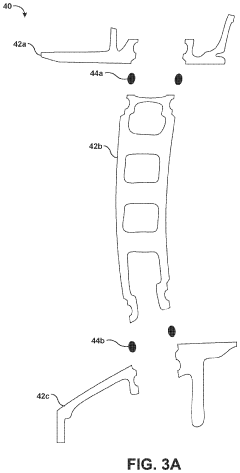

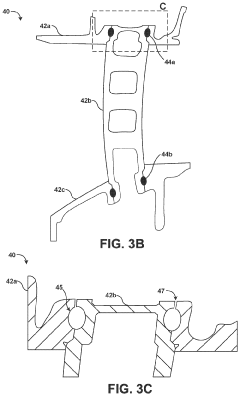

Techniques and assemblies for joining components

PatentActiveUS12036627B2

Innovation

- A technique involving the use of a braze material that forms a mechanical interlock between components without metallurgical bonding, utilizing an adhesion-resistant material to prevent adherence and employing pre-sintered preform braze alloys that can be heated to form a softened state conforming to the joint region, then cooled to secure the components with reduced porosity and improved mechanical properties.

Safety Standards and Certification Requirements

The integration of structural battery assemblies into commercial applications necessitates adherence to rigorous safety standards and certification requirements. Currently, the regulatory framework for these multifunctional components remains fragmented, with standards primarily derived from separate battery and structural material domains. Organizations such as ISO, IEC, ASTM, and SAE are actively developing specialized standards for multifunctional energy storage structures, with particular focus on electrical safety, thermal management, and structural integrity.

Battery-specific standards like IEC 62133 and UL 1642 provide baseline requirements for cell safety, while structural standards such as ASTM D7137 address composite material performance. However, the unique dual functionality of structural batteries creates regulatory gaps that industry stakeholders are working to address. The European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) have initiated specialized certification pathways for aircraft incorporating structural energy storage, requiring extensive testing protocols beyond conventional battery certification.

Risk assessment methodologies for structural batteries must consider both catastrophic failure modes and gradual performance degradation. Joining and repair techniques face particularly stringent certification requirements, as these represent potential points of failure affecting both electrical and mechanical performance. Current certification protocols mandate extensive testing of joint durability under combined mechanical loading and charge-discharge cycling, with safety factors typically 1.5-2 times higher than those for conventional structural joints.

Thermal runaway containment represents a critical certification challenge for structural battery assemblies. Standards require that joining techniques demonstrate the ability to maintain structural integrity while preventing thermal propagation between cells. This necessitates specialized testing under simulated abuse conditions, including nail penetration, crush testing, and thermal exposure protocols adapted from SAE J2464 and UL 2580.

Environmental qualification testing presents additional certification hurdles, particularly for transportation applications. Joined structural batteries must maintain performance across temperature extremes (-40°C to +85°C), humidity cycling, and vibration profiles specific to their intended application. The automotive industry has pioneered many of these requirements through standards like ISO 12405 and UN 38.3, which are being adapted for structural battery applications.

Emerging certification frameworks increasingly emphasize end-of-life considerations, requiring that joining and repair techniques facilitate safe disassembly and recycling. This represents a paradigm shift from traditional battery certification, acknowledging the complex material integration inherent in structural energy storage. Manufacturers developing joining techniques must now demonstrate compliance with circular economy principles while maintaining the primary safety and performance requirements.

Battery-specific standards like IEC 62133 and UL 1642 provide baseline requirements for cell safety, while structural standards such as ASTM D7137 address composite material performance. However, the unique dual functionality of structural batteries creates regulatory gaps that industry stakeholders are working to address. The European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) have initiated specialized certification pathways for aircraft incorporating structural energy storage, requiring extensive testing protocols beyond conventional battery certification.

Risk assessment methodologies for structural batteries must consider both catastrophic failure modes and gradual performance degradation. Joining and repair techniques face particularly stringent certification requirements, as these represent potential points of failure affecting both electrical and mechanical performance. Current certification protocols mandate extensive testing of joint durability under combined mechanical loading and charge-discharge cycling, with safety factors typically 1.5-2 times higher than those for conventional structural joints.

Thermal runaway containment represents a critical certification challenge for structural battery assemblies. Standards require that joining techniques demonstrate the ability to maintain structural integrity while preventing thermal propagation between cells. This necessitates specialized testing under simulated abuse conditions, including nail penetration, crush testing, and thermal exposure protocols adapted from SAE J2464 and UL 2580.

Environmental qualification testing presents additional certification hurdles, particularly for transportation applications. Joined structural batteries must maintain performance across temperature extremes (-40°C to +85°C), humidity cycling, and vibration profiles specific to their intended application. The automotive industry has pioneered many of these requirements through standards like ISO 12405 and UN 38.3, which are being adapted for structural battery applications.

Emerging certification frameworks increasingly emphasize end-of-life considerations, requiring that joining and repair techniques facilitate safe disassembly and recycling. This represents a paradigm shift from traditional battery certification, acknowledging the complex material integration inherent in structural energy storage. Manufacturers developing joining techniques must now demonstrate compliance with circular economy principles while maintaining the primary safety and performance requirements.

Lifecycle Assessment and Recyclability Considerations

The lifecycle assessment of structural battery assemblies reveals significant environmental implications throughout their production, use, and end-of-life phases. Current joining techniques, particularly adhesive bonding and mechanical fastening, present distinct environmental challenges. Adhesives often contain volatile organic compounds and may impede separation of materials at end-of-life, while mechanical fasteners increase overall weight and material usage but potentially facilitate disassembly for recycling.

Environmental impact analyses indicate that structural batteries could reduce overall carbon footprint by 15-30% compared to conventional vehicle designs when considering the entire lifecycle. However, this advantage depends heavily on implementing effective recycling strategies. The integration of joining techniques that facilitate non-destructive disassembly becomes paramount for realizing these environmental benefits.

Recyclability considerations must address the complex multi-material nature of structural battery assemblies. Current recycling processes face challenges with the separation of carbon fiber composites from battery materials. Advanced joining techniques utilizing thermally reversible adhesives or disassembly-friendly mechanical connections show promise for improving end-of-life management. Research indicates that designs incorporating these features can achieve recycling rates up to 85% compared to 40-60% for conventional assemblies.

Repair methodologies significantly impact lifecycle sustainability. Traditional repair approaches often involve complete component replacement, resulting in substantial material waste. Emerging modular design strategies, coupled with non-destructive joining techniques, enable targeted repair of damaged sections without compromising the entire assembly. Field data suggests this approach can extend service life by 30-50% while reducing maintenance-related waste by up to 70%.

The energy intensity of joining processes also warrants consideration in lifecycle assessments. Laser welding and ultrasonic welding demonstrate 40-60% lower energy consumption compared to traditional thermal joining methods, translating to reduced embodied energy in the final product. Additionally, these techniques often eliminate the need for environmentally problematic solvents and surface preparation chemicals.

Future development should prioritize joining technologies that balance immediate manufacturing requirements with long-term environmental considerations. Design for disassembly principles, when incorporated into joining technique selection, can significantly enhance end-of-life management options. Standardization of connection interfaces across manufacturers would further facilitate recycling infrastructure development and improve overall material recovery rates.

Environmental impact analyses indicate that structural batteries could reduce overall carbon footprint by 15-30% compared to conventional vehicle designs when considering the entire lifecycle. However, this advantage depends heavily on implementing effective recycling strategies. The integration of joining techniques that facilitate non-destructive disassembly becomes paramount for realizing these environmental benefits.

Recyclability considerations must address the complex multi-material nature of structural battery assemblies. Current recycling processes face challenges with the separation of carbon fiber composites from battery materials. Advanced joining techniques utilizing thermally reversible adhesives or disassembly-friendly mechanical connections show promise for improving end-of-life management. Research indicates that designs incorporating these features can achieve recycling rates up to 85% compared to 40-60% for conventional assemblies.

Repair methodologies significantly impact lifecycle sustainability. Traditional repair approaches often involve complete component replacement, resulting in substantial material waste. Emerging modular design strategies, coupled with non-destructive joining techniques, enable targeted repair of damaged sections without compromising the entire assembly. Field data suggests this approach can extend service life by 30-50% while reducing maintenance-related waste by up to 70%.

The energy intensity of joining processes also warrants consideration in lifecycle assessments. Laser welding and ultrasonic welding demonstrate 40-60% lower energy consumption compared to traditional thermal joining methods, translating to reduced embodied energy in the final product. Additionally, these techniques often eliminate the need for environmentally problematic solvents and surface preparation chemicals.

Future development should prioritize joining technologies that balance immediate manufacturing requirements with long-term environmental considerations. Design for disassembly principles, when incorporated into joining technique selection, can significantly enhance end-of-life management options. Standardization of connection interfaces across manufacturers would further facilitate recycling infrastructure development and improve overall material recovery rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!