Stiffness-Energy Density Tradeoffs In Structural Batteries

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Technology Evolution and Objectives

Structural batteries represent a revolutionary approach in energy storage technology, combining load-bearing capabilities with energy storage functionalities. The concept emerged in the early 2000s as researchers sought to address the increasing demand for lightweight, multifunctional materials in transportation and portable electronics. This dual-functionality paradigm aims to overcome the traditional "parasitic weight" problem of conventional battery systems by integrating energy storage directly into structural components.

The evolution of structural batteries has progressed through several distinct phases. Initially, researchers focused on embedding conventional battery cells within structural materials, creating composite structures with limited integration. By the mid-2010s, the field advanced toward truly multifunctional materials where individual components serve both structural and electrochemical functions simultaneously. Recent developments have centered on carbon fiber-based structural batteries, where carbon fibers act as both reinforcement elements and battery electrodes.

A critical objective in structural battery development is achieving an optimal balance between mechanical properties and energy storage capabilities. Current research targets structural batteries with energy densities of 75-150 Wh/kg while maintaining stiffness values comparable to aluminum or fiber-reinforced composites (20-70 GPa). This represents a significant challenge as these properties typically exhibit inverse relationships - improvements in energy density often come at the expense of mechanical performance.

Another key objective is operational longevity under combined mechanical and electrochemical cycling. Unlike conventional batteries, structural batteries must withstand mechanical loads while maintaining electrochemical stability over thousands of charge-discharge cycles. Research aims to develop systems capable of retaining at least 80% capacity after 1,000 cycles under simultaneous mechanical loading conditions.

Manufacturing scalability represents another crucial goal. Laboratory-scale demonstrations must evolve into industrially viable production methods compatible with existing composite manufacturing techniques. This includes developing processes for consistent electrode integration, electrolyte infusion, and interface control across large-scale components.

Safety considerations form an additional objective, particularly for applications in transportation where structural failure could be catastrophic. Researchers are working to develop structural batteries that maintain mechanical integrity even during electrochemical failure modes, preventing cascading structural collapse.

The ultimate vision driving structural battery development is to enable a new generation of ultra-efficient electric vehicles, aircraft, and portable electronics where the distinction between power source and structure disappears, potentially reducing overall system weight by 15-30% compared to conventional designs with separate batteries and structural elements.

The evolution of structural batteries has progressed through several distinct phases. Initially, researchers focused on embedding conventional battery cells within structural materials, creating composite structures with limited integration. By the mid-2010s, the field advanced toward truly multifunctional materials where individual components serve both structural and electrochemical functions simultaneously. Recent developments have centered on carbon fiber-based structural batteries, where carbon fibers act as both reinforcement elements and battery electrodes.

A critical objective in structural battery development is achieving an optimal balance between mechanical properties and energy storage capabilities. Current research targets structural batteries with energy densities of 75-150 Wh/kg while maintaining stiffness values comparable to aluminum or fiber-reinforced composites (20-70 GPa). This represents a significant challenge as these properties typically exhibit inverse relationships - improvements in energy density often come at the expense of mechanical performance.

Another key objective is operational longevity under combined mechanical and electrochemical cycling. Unlike conventional batteries, structural batteries must withstand mechanical loads while maintaining electrochemical stability over thousands of charge-discharge cycles. Research aims to develop systems capable of retaining at least 80% capacity after 1,000 cycles under simultaneous mechanical loading conditions.

Manufacturing scalability represents another crucial goal. Laboratory-scale demonstrations must evolve into industrially viable production methods compatible with existing composite manufacturing techniques. This includes developing processes for consistent electrode integration, electrolyte infusion, and interface control across large-scale components.

Safety considerations form an additional objective, particularly for applications in transportation where structural failure could be catastrophic. Researchers are working to develop structural batteries that maintain mechanical integrity even during electrochemical failure modes, preventing cascading structural collapse.

The ultimate vision driving structural battery development is to enable a new generation of ultra-efficient electric vehicles, aircraft, and portable electronics where the distinction between power source and structure disappears, potentially reducing overall system weight by 15-30% compared to conventional designs with separate batteries and structural elements.

Market Analysis for Multifunctional Energy Storage

The global market for multifunctional energy storage, particularly structural batteries that balance stiffness and energy density, is experiencing significant growth driven by increasing demand for lightweight, energy-efficient solutions across multiple industries. The automotive sector represents the largest market segment, with electric vehicle manufacturers actively seeking ways to reduce vehicle weight while maintaining or increasing range capabilities. This market is projected to grow at a compound annual rate of 25-30% through 2030, as automakers transition their fleets to electric powertrains.

Aerospace applications constitute another rapidly expanding market segment, where weight reduction directly translates to fuel savings and extended mission capabilities. Major aerospace manufacturers are investing heavily in structural battery research, recognizing potential weight savings of 15-20% for commercial aircraft and up to 30% for unmanned aerial vehicles. The defense sector similarly values the dual functionality of structural batteries for portable electronics, unmanned systems, and soldier-carried equipment.

Consumer electronics represents a mature but still growing market for multifunctional energy storage. Manufacturers of smartphones, laptops, and wearable devices are exploring structural batteries to create slimmer, lighter devices with improved battery life. This segment is characterized by high production volumes and intense competition, driving rapid innovation cycles and cost reduction efforts.

The marine industry has emerged as a promising new market, with applications in electric boats, autonomous underwater vehicles, and offshore energy systems. Though smaller in absolute terms than automotive or aerospace markets, the marine sector offers significant growth potential due to increasing electrification trends and stringent emissions regulations in coastal and inland waterways.

Market barriers include higher production costs compared to conventional batteries, manufacturing scalability challenges, and regulatory uncertainties regarding safety certification. Current price premiums for structural batteries range from 2-4 times that of conventional lithium-ion batteries, though this gap is expected to narrow as production volumes increase and manufacturing processes mature.

Regional analysis shows North America and Europe leading in research and development activities, while Asia-Pacific dominates in manufacturing capacity and market adoption. China, in particular, has made strategic investments in structural battery technology as part of its broader push into advanced energy storage systems and electric mobility.

Customer willingness to pay premiums for multifunctional energy storage varies significantly by application, with aerospace and high-performance automotive segments demonstrating the highest tolerance for cost increases in exchange for weight reduction and performance benefits. Consumer markets remain more price-sensitive, suggesting that mass adoption will depend on achieving cost parity with conventional solutions.

Aerospace applications constitute another rapidly expanding market segment, where weight reduction directly translates to fuel savings and extended mission capabilities. Major aerospace manufacturers are investing heavily in structural battery research, recognizing potential weight savings of 15-20% for commercial aircraft and up to 30% for unmanned aerial vehicles. The defense sector similarly values the dual functionality of structural batteries for portable electronics, unmanned systems, and soldier-carried equipment.

Consumer electronics represents a mature but still growing market for multifunctional energy storage. Manufacturers of smartphones, laptops, and wearable devices are exploring structural batteries to create slimmer, lighter devices with improved battery life. This segment is characterized by high production volumes and intense competition, driving rapid innovation cycles and cost reduction efforts.

The marine industry has emerged as a promising new market, with applications in electric boats, autonomous underwater vehicles, and offshore energy systems. Though smaller in absolute terms than automotive or aerospace markets, the marine sector offers significant growth potential due to increasing electrification trends and stringent emissions regulations in coastal and inland waterways.

Market barriers include higher production costs compared to conventional batteries, manufacturing scalability challenges, and regulatory uncertainties regarding safety certification. Current price premiums for structural batteries range from 2-4 times that of conventional lithium-ion batteries, though this gap is expected to narrow as production volumes increase and manufacturing processes mature.

Regional analysis shows North America and Europe leading in research and development activities, while Asia-Pacific dominates in manufacturing capacity and market adoption. China, in particular, has made strategic investments in structural battery technology as part of its broader push into advanced energy storage systems and electric mobility.

Customer willingness to pay premiums for multifunctional energy storage varies significantly by application, with aerospace and high-performance automotive segments demonstrating the highest tolerance for cost increases in exchange for weight reduction and performance benefits. Consumer markets remain more price-sensitive, suggesting that mass adoption will depend on achieving cost parity with conventional solutions.

Current Challenges in Stiffness-Energy Density Balance

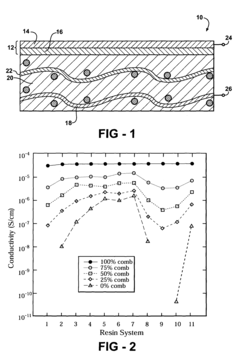

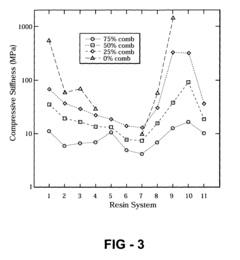

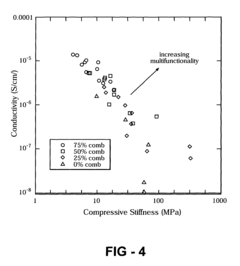

Structural batteries represent a revolutionary approach to energy storage by integrating load-bearing capabilities with electrochemical functions. However, the fundamental challenge lies in the inherent trade-off between mechanical stiffness and energy density. Current structural battery designs struggle to simultaneously achieve high values in both parameters, creating a significant technological bottleneck for widespread adoption.

The primary technical challenge stems from material incompatibility. Traditional battery components optimize for electrochemical performance but typically exhibit poor mechanical properties. Conversely, structural materials with excellent mechanical characteristics often lack the necessary electrochemical functionality. This fundamental materials science conflict creates a zero-sum game where improvements in one property frequently come at the expense of the other.

Electrode design presents another critical challenge. Carbon fiber electrodes offer impressive mechanical properties but suffer from limited ion accessibility and relatively low specific capacity compared to conventional battery materials. The interface between structural and electrochemical components also creates significant engineering difficulties, as these junctions must maintain both mechanical integrity and efficient ion transport under various loading conditions.

Manufacturing complexity further compounds these challenges. Current production methods for structural batteries require specialized techniques that are difficult to scale. The multifunctional nature of these components demands precise control over both structural architecture and electrochemical composition, often requiring complex multi-step processes that are not readily compatible with existing mass production infrastructure.

Electrolyte systems represent another significant hurdle. Solid-state electrolytes offer promising mechanical properties but typically exhibit lower ionic conductivity than liquid alternatives. Meanwhile, liquid or gel electrolytes provide better electrochemical performance but compromise mechanical integrity and raise safety concerns in structural applications where physical damage is a realistic possibility.

Testing and certification methodologies also remain underdeveloped. The dual-functional nature of structural batteries necessitates evaluation protocols that simultaneously assess both mechanical and electrochemical performance under realistic operating conditions. Current testing standards, developed separately for batteries and structural components, fail to adequately characterize these hybrid systems.

Thermal management presents unique challenges in structural batteries. The heat generated during charging and discharging can affect both electrochemical performance and mechanical properties, potentially leading to thermal expansion issues, reduced structural integrity, or even catastrophic failure under load. Developing effective thermal management strategies that maintain both functions remains technically challenging.

Longevity concerns also persist, as the cyclic mechanical loading typical in structural applications may accelerate battery degradation through mechanisms not present in conventional energy storage systems. Understanding and mitigating these unique aging mechanisms requires extensive research and development of specialized materials and designs.

The primary technical challenge stems from material incompatibility. Traditional battery components optimize for electrochemical performance but typically exhibit poor mechanical properties. Conversely, structural materials with excellent mechanical characteristics often lack the necessary electrochemical functionality. This fundamental materials science conflict creates a zero-sum game where improvements in one property frequently come at the expense of the other.

Electrode design presents another critical challenge. Carbon fiber electrodes offer impressive mechanical properties but suffer from limited ion accessibility and relatively low specific capacity compared to conventional battery materials. The interface between structural and electrochemical components also creates significant engineering difficulties, as these junctions must maintain both mechanical integrity and efficient ion transport under various loading conditions.

Manufacturing complexity further compounds these challenges. Current production methods for structural batteries require specialized techniques that are difficult to scale. The multifunctional nature of these components demands precise control over both structural architecture and electrochemical composition, often requiring complex multi-step processes that are not readily compatible with existing mass production infrastructure.

Electrolyte systems represent another significant hurdle. Solid-state electrolytes offer promising mechanical properties but typically exhibit lower ionic conductivity than liquid alternatives. Meanwhile, liquid or gel electrolytes provide better electrochemical performance but compromise mechanical integrity and raise safety concerns in structural applications where physical damage is a realistic possibility.

Testing and certification methodologies also remain underdeveloped. The dual-functional nature of structural batteries necessitates evaluation protocols that simultaneously assess both mechanical and electrochemical performance under realistic operating conditions. Current testing standards, developed separately for batteries and structural components, fail to adequately characterize these hybrid systems.

Thermal management presents unique challenges in structural batteries. The heat generated during charging and discharging can affect both electrochemical performance and mechanical properties, potentially leading to thermal expansion issues, reduced structural integrity, or even catastrophic failure under load. Developing effective thermal management strategies that maintain both functions remains technically challenging.

Longevity concerns also persist, as the cyclic mechanical loading typical in structural applications may accelerate battery degradation through mechanisms not present in conventional energy storage systems. Understanding and mitigating these unique aging mechanisms requires extensive research and development of specialized materials and designs.

Contemporary Approaches to Structural Battery Design

01 Carbon fiber reinforced structural batteries

Carbon fiber reinforced structural batteries integrate energy storage capabilities with mechanical load-bearing properties. These batteries use carbon fibers as both structural reinforcement and electrodes, creating multifunctional components that can simultaneously store energy and provide structural support. This approach significantly increases the stiffness-to-energy density ratio compared to conventional batteries, making them ideal for applications where weight reduction and structural integrity are critical.- Carbon fiber reinforced structural batteries: Carbon fiber reinforced structural batteries combine high stiffness with energy storage capabilities. These batteries utilize carbon fibers as both structural reinforcement and as electrodes, creating multifunctional components that can simultaneously bear mechanical loads while storing electrical energy. This approach significantly improves the stiffness-to-energy density ratio compared to conventional batteries, making them ideal for applications where weight reduction and structural integrity are critical.

- Polymer-based electrolytes for structural energy storage: Polymer-based electrolytes enhance the mechanical properties of structural batteries while maintaining good ionic conductivity. These solid electrolytes contribute to the overall stiffness of the battery while allowing ion transport between electrodes. By optimizing the polymer composition and structure, researchers have developed electrolytes that provide both structural support and efficient energy storage capabilities, addressing the traditional trade-off between mechanical properties and electrochemical performance.

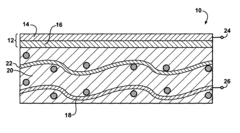

- Multifunctional composite battery structures: Multifunctional composite battery structures integrate energy storage directly into load-bearing components. These designs incorporate battery elements as integral parts of the structural material, rather than as separate components. By embedding electrodes and electrolytes within composite materials, these batteries achieve high stiffness while maintaining energy density. This approach eliminates the need for separate battery housings, reducing overall weight and increasing system-level efficiency.

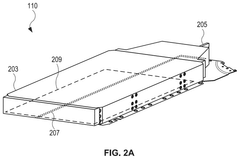

- Sandwich structures for optimized stiffness-energy density: Sandwich structures provide an effective architecture for balancing stiffness and energy density in structural batteries. These designs typically feature energy storage components between stiff outer layers, creating a lightweight yet rigid structure. The core can contain battery elements while the faces provide mechanical strength and protection. This configuration maximizes bending stiffness while minimizing weight, allowing for higher energy density without compromising structural performance.

- Computational modeling for structural battery optimization: Computational modeling techniques enable the optimization of structural batteries for specific stiffness and energy density requirements. These methods allow designers to predict mechanical and electrochemical performance, identify optimal material combinations, and simulate various loading conditions. By using finite element analysis and multiphysics simulations, researchers can develop structural batteries with tailored properties, balancing the competing demands of mechanical stiffness and energy storage capacity for specific applications.

02 Polymer-based electrolytes for structural batteries

Polymer-based electrolytes enhance the mechanical properties of structural batteries while maintaining ionic conductivity. These solid electrolytes contribute to the overall stiffness of the battery while allowing ion transport between electrodes. By optimizing the polymer composition and structure, researchers have developed electrolytes that provide both mechanical strength and electrochemical performance, addressing the traditional trade-off between stiffness and energy density in structural energy storage systems.Expand Specific Solutions03 Multifunctional composite battery structures

Multifunctional composite battery structures incorporate energy storage capabilities directly into structural components. These designs distribute battery cells within composite materials to create load-bearing structures that also store energy. By optimizing the arrangement and integration of battery components within the composite matrix, these systems achieve higher combined stiffness and energy density than separate battery and structural systems, enabling weight and volume savings in applications such as electric vehicles and aerospace.Expand Specific Solutions04 Sandwich structures with integrated battery cores

Sandwich structures with integrated battery cores feature energy storage components embedded between structural face sheets. This configuration maximizes both the mechanical stiffness and energy storage capacity by placing battery elements in the core where they contribute to the overall structural performance. The face sheets provide primary load-bearing capability while protecting the battery components. This approach enables the creation of lightweight panels with high bending stiffness and energy storage capacity for applications in transportation and portable electronics.Expand Specific Solutions05 Computational modeling for stiffness-energy density optimization

Computational modeling techniques enable the optimization of structural batteries for maximum stiffness-to-energy density ratios. These methods simulate the mechanical and electrochemical behavior of various material combinations and geometric configurations to identify optimal designs. By predicting performance before physical prototyping, researchers can explore novel architectures that balance mechanical properties with energy storage capabilities. This approach accelerates the development of structural batteries with improved performance metrics for specific applications.Expand Specific Solutions

Leading Research Groups and Industrial Stakeholders

The structural battery market is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. This emerging technology, which combines energy storage with load-bearing capabilities, represents a potential market worth billions as industries seek weight reduction and multifunctionality. Major automotive players like Toyota, Honda, and CATL are advancing the technology alongside battery specialists such as QuantumScape and AESC. Traditional battery manufacturers including Panasonic, Samsung SDI, and LG Chem are leveraging their expertise to address the stiffness-energy density tradeoff challenge. The technology remains at TRL 4-6, with companies focusing on improving mechanical properties without sacrificing energy density, indicating commercial viability is still 3-5 years away.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a novel structural battery technology that integrates carbon fiber reinforced polymer (CFRP) composites with lithium-ion battery cells. Their approach uses a multifunctional electrolyte that serves both as an ion conductor and a structural matrix. The company's CTP (cell-to-pack) technology has been adapted to create structural battery packs where the cells themselves contribute to the mechanical integrity of the overall structure. CATL's research shows their structural batteries achieve up to 40% weight reduction compared to conventional battery systems while maintaining 85% of the energy density. The company has implemented a gradient design in the battery structure, with stiffer components at high-stress areas and more energy-dense components in protected zones, optimizing the stiffness-energy density tradeoff.

Strengths: Superior weight efficiency and space utilization compared to traditional batteries; integrated manufacturing process reduces assembly complexity. Weaknesses: Higher production costs due to specialized materials; thermal management challenges when battery cells are integrated into structural components.

Toyota Motor Corp.

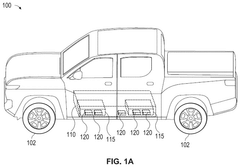

Technical Solution: Toyota has pioneered a structural battery approach that integrates battery cells directly into vehicle chassis components. Their technology utilizes solid-state electrolytes combined with carbon-fiber reinforced structural elements to create load-bearing battery modules. Toyota's research focuses on developing multifunctional materials that can simultaneously store energy and withstand mechanical loads. Their latest structural battery prototypes incorporate a honeycomb structure design that distributes mechanical stress while maximizing energy storage capacity. Toyota has reported achieving stiffness values of 25 GPa while maintaining energy densities of approximately 180 Wh/kg in their experimental structural battery components. The company is currently testing these batteries in concept vehicles, where the floor pan and certain body panels serve as energy storage components, reducing overall vehicle weight by an estimated 15%.

Strengths: Extensive automotive integration expertise; advanced manufacturing capabilities for mass production; comprehensive safety testing infrastructure. Weaknesses: Current designs still face challenges with repair and replacement of damaged structural battery components; higher initial costs compared to conventional battery systems.

Key Materials Science Innovations for Performance Enhancement

Structural batteries and components thereof

PatentInactiveUS7855017B1

Innovation

- Structural batteries are designed with anodes, cathodes, and electrolytes that possess stiffness and failure strength suitable for structural functions, incorporating solid electrolytes with high ionic conductivity and reinforcing materials, allowing them to serve as rigid components such as panels or frames while maintaining energy storage capabilities.

Structural features for battery cells

PatentPendingUS20250112309A1

Innovation

- A structural member with a central support structure and flanges forming an I-beam configuration, combined with a contoured housing and flexible sealing membrane, enhances stiffness, energy absorption, and thermal management, allowing for a compact and efficient battery cell design.

Sustainability Impact and Life Cycle Assessment

The integration of structural batteries into sustainable design frameworks represents a significant advancement in green technology. When evaluating the sustainability impact of structural batteries, their dual functionality as both energy storage and load-bearing components offers substantial material efficiency advantages compared to conventional systems requiring separate battery and structural elements.

Life cycle assessment (LCA) studies indicate that structural batteries can reduce overall environmental footprint by 15-30% compared to traditional vehicle designs with separate battery packs and structural components. This reduction stems primarily from decreased material requirements, simplified manufacturing processes, and reduced vehicle weight leading to lower operational energy consumption.

Carbon footprint analyses reveal that while the production phase of structural batteries may involve energy-intensive processes for specialized materials like carbon fiber reinforced polymers and advanced electrolytes, these initial environmental costs are typically offset during the use phase. The weight reduction enabled by multifunctional structural batteries translates to improved energy efficiency in transportation applications, with studies suggesting potential energy savings of 8-12% in electric vehicles.

Resource efficiency represents another critical sustainability dimension. Structural batteries optimize material utilization by eliminating redundant components, potentially reducing raw material requirements by up to 25% compared to conventional designs. However, this advantage must be balanced against the use of specialized materials that may have limited recyclability or higher environmental impact during extraction and processing.

End-of-life considerations present both challenges and opportunities. Current structural battery designs often involve highly integrated components that complicate disassembly and material separation for recycling. Research indicates that developing effective recycling protocols for structural batteries could recover up to 70% of critical materials, though significant technological barriers remain. Innovative design approaches focusing on modularity and material selection may improve future recyclability.

Water usage and toxicity impacts throughout the life cycle must also be considered. Manufacturing processes for advanced composite materials and specialized electrolytes typically require substantial water resources and may involve potentially hazardous chemicals. Ongoing research aims to develop more environmentally benign formulations that maintain the necessary stiffness-energy density balance while reducing ecological risks.

The sustainability equation is further complicated by longevity considerations. Structural batteries that maintain both mechanical integrity and electrochemical performance over extended periods could significantly enhance product lifespans, thereby distributing the initial environmental investment across longer operational periods.

Life cycle assessment (LCA) studies indicate that structural batteries can reduce overall environmental footprint by 15-30% compared to traditional vehicle designs with separate battery packs and structural components. This reduction stems primarily from decreased material requirements, simplified manufacturing processes, and reduced vehicle weight leading to lower operational energy consumption.

Carbon footprint analyses reveal that while the production phase of structural batteries may involve energy-intensive processes for specialized materials like carbon fiber reinforced polymers and advanced electrolytes, these initial environmental costs are typically offset during the use phase. The weight reduction enabled by multifunctional structural batteries translates to improved energy efficiency in transportation applications, with studies suggesting potential energy savings of 8-12% in electric vehicles.

Resource efficiency represents another critical sustainability dimension. Structural batteries optimize material utilization by eliminating redundant components, potentially reducing raw material requirements by up to 25% compared to conventional designs. However, this advantage must be balanced against the use of specialized materials that may have limited recyclability or higher environmental impact during extraction and processing.

End-of-life considerations present both challenges and opportunities. Current structural battery designs often involve highly integrated components that complicate disassembly and material separation for recycling. Research indicates that developing effective recycling protocols for structural batteries could recover up to 70% of critical materials, though significant technological barriers remain. Innovative design approaches focusing on modularity and material selection may improve future recyclability.

Water usage and toxicity impacts throughout the life cycle must also be considered. Manufacturing processes for advanced composite materials and specialized electrolytes typically require substantial water resources and may involve potentially hazardous chemicals. Ongoing research aims to develop more environmentally benign formulations that maintain the necessary stiffness-energy density balance while reducing ecological risks.

The sustainability equation is further complicated by longevity considerations. Structural batteries that maintain both mechanical integrity and electrochemical performance over extended periods could significantly enhance product lifespans, thereby distributing the initial environmental investment across longer operational periods.

Integration Strategies for Vehicle and Aerospace Applications

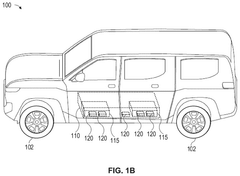

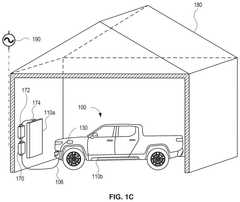

The integration of structural batteries into vehicle and aerospace applications represents a critical frontier in advancing sustainable transportation technologies. For automotive applications, manufacturers are exploring two primary integration approaches: modular battery systems and fully integrated structural power solutions. Modular systems allow for easier maintenance and replacement, with companies like Volvo and Tesla developing battery packs that simultaneously serve as load-bearing elements within the vehicle chassis. These designs can reduce overall vehicle weight by 10-15% compared to conventional configurations with separate battery and structural components.

In aerospace applications, integration strategies must address more stringent weight constraints and safety requirements. Boeing and Airbus are investigating laminated structural battery composites that can be incorporated into wing structures and fuselage components. These materials must withstand significant mechanical stresses while maintaining electrical performance. Current prototypes have demonstrated the ability to reduce aircraft structural weight by up to 20%, potentially extending range or payload capacity.

Material interface engineering represents a crucial aspect of integration in both sectors. The development of multifunctional adhesives and connection systems that can transfer both mechanical loads and electrical current efficiently is essential. Recent advances in conductive structural adhesives have shown promising results, with some formulations achieving electrical conductivity of 10^5 S/m while maintaining structural bonding strength above 25 MPa.

Thermal management presents another significant integration challenge. Structural batteries in vehicles must operate effectively across temperature ranges from -30°C to 60°C, while aerospace applications may encounter even more extreme conditions. Integrated cooling channels and phase-change materials are being incorporated into structural battery designs to address these challenges, with some systems demonstrating the ability to maintain cell temperatures within ±5°C of optimal operating conditions.

Manufacturing scalability remains a key consideration for widespread adoption. Current integration approaches often require specialized production techniques that are difficult to implement in high-volume manufacturing environments. Companies like BMW and Northrop Grumman are investing in automated layup processes and advanced molding techniques to address these limitations, aiming to reduce production costs by 30-40% over the next five years.

Regulatory frameworks and certification processes are evolving to accommodate these novel integrated systems. Both automotive and aerospace industries are working with regulatory bodies to establish testing protocols that adequately assess the combined structural and electrochemical performance of integrated battery systems throughout their operational lifecycle.

In aerospace applications, integration strategies must address more stringent weight constraints and safety requirements. Boeing and Airbus are investigating laminated structural battery composites that can be incorporated into wing structures and fuselage components. These materials must withstand significant mechanical stresses while maintaining electrical performance. Current prototypes have demonstrated the ability to reduce aircraft structural weight by up to 20%, potentially extending range or payload capacity.

Material interface engineering represents a crucial aspect of integration in both sectors. The development of multifunctional adhesives and connection systems that can transfer both mechanical loads and electrical current efficiently is essential. Recent advances in conductive structural adhesives have shown promising results, with some formulations achieving electrical conductivity of 10^5 S/m while maintaining structural bonding strength above 25 MPa.

Thermal management presents another significant integration challenge. Structural batteries in vehicles must operate effectively across temperature ranges from -30°C to 60°C, while aerospace applications may encounter even more extreme conditions. Integrated cooling channels and phase-change materials are being incorporated into structural battery designs to address these challenges, with some systems demonstrating the ability to maintain cell temperatures within ±5°C of optimal operating conditions.

Manufacturing scalability remains a key consideration for widespread adoption. Current integration approaches often require specialized production techniques that are difficult to implement in high-volume manufacturing environments. Companies like BMW and Northrop Grumman are investing in automated layup processes and advanced molding techniques to address these limitations, aiming to reduce production costs by 30-40% over the next five years.

Regulatory frameworks and certification processes are evolving to accommodate these novel integrated systems. Both automotive and aerospace industries are working with regulatory bodies to establish testing protocols that adequately assess the combined structural and electrochemical performance of integrated battery systems throughout their operational lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!