Multifunctional Laminate Design For Structural Battery Packs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Technology Background and Objectives

Structural batteries represent a revolutionary approach in energy storage technology, combining load-bearing capabilities with energy storage functions. This dual functionality addresses the critical challenge of weight reduction in electric vehicles, aerospace applications, and portable electronics. The concept emerged in the early 2000s when researchers began exploring carbon fiber's potential as both a structural material and an electrode component. Since then, the field has evolved significantly, with major breakthroughs occurring in materials science, battery chemistry, and composite manufacturing techniques.

The evolution of structural batteries has been marked by three distinct generations. First-generation designs simply embedded conventional battery cells within structural components, while second-generation approaches integrated battery functionality directly into composite materials. The current third-generation designs aim to create truly multifunctional materials where each component serves both structural and electrochemical purposes simultaneously.

The primary objective of multifunctional laminate design for structural battery packs is to develop energy storage systems that can simultaneously bear mechanical loads while maintaining competitive energy density. This represents a paradigm shift from traditional battery design philosophy, where batteries are treated as parasitic mass that must be carried by the structure. By merging these functions, the goal is to achieve "mass-less" energy storage, where the weight penalty traditionally associated with batteries is significantly reduced or eliminated.

Technical objectives include achieving specific energy densities exceeding 75 Wh/kg while maintaining structural properties comparable to conventional carbon fiber composites. Additionally, these systems must demonstrate cycle life stability under combined mechanical and electrochemical stresses, with targets of at least 1000 cycles while retaining 80% capacity.

The development trajectory points toward increasingly sophisticated laminate architectures that optimize ion transport pathways while maintaining mechanical integrity. Current research focuses on solid-state electrolytes that can transfer mechanical loads while facilitating ion movement, carbon fiber electrodes that serve as both reinforcement and active materials, and multifunctional matrices that contribute to both structural integrity and electrochemical performance.

Looking forward, the field aims to develop manufacturing processes suitable for industrial-scale production, addressing challenges in laminate uniformity, interface engineering, and quality control. The ultimate vision is to enable a new generation of electric vehicles, aircraft, and portable devices where the distinction between structure and energy storage disappears, leading to unprecedented improvements in system-level energy efficiency and weight reduction.

The evolution of structural batteries has been marked by three distinct generations. First-generation designs simply embedded conventional battery cells within structural components, while second-generation approaches integrated battery functionality directly into composite materials. The current third-generation designs aim to create truly multifunctional materials where each component serves both structural and electrochemical purposes simultaneously.

The primary objective of multifunctional laminate design for structural battery packs is to develop energy storage systems that can simultaneously bear mechanical loads while maintaining competitive energy density. This represents a paradigm shift from traditional battery design philosophy, where batteries are treated as parasitic mass that must be carried by the structure. By merging these functions, the goal is to achieve "mass-less" energy storage, where the weight penalty traditionally associated with batteries is significantly reduced or eliminated.

Technical objectives include achieving specific energy densities exceeding 75 Wh/kg while maintaining structural properties comparable to conventional carbon fiber composites. Additionally, these systems must demonstrate cycle life stability under combined mechanical and electrochemical stresses, with targets of at least 1000 cycles while retaining 80% capacity.

The development trajectory points toward increasingly sophisticated laminate architectures that optimize ion transport pathways while maintaining mechanical integrity. Current research focuses on solid-state electrolytes that can transfer mechanical loads while facilitating ion movement, carbon fiber electrodes that serve as both reinforcement and active materials, and multifunctional matrices that contribute to both structural integrity and electrochemical performance.

Looking forward, the field aims to develop manufacturing processes suitable for industrial-scale production, addressing challenges in laminate uniformity, interface engineering, and quality control. The ultimate vision is to enable a new generation of electric vehicles, aircraft, and portable devices where the distinction between structure and energy storage disappears, leading to unprecedented improvements in system-level energy efficiency and weight reduction.

Market Analysis for Multifunctional Energy Storage Solutions

The multifunctional energy storage solutions market is experiencing unprecedented growth, driven by the convergence of structural engineering and energy storage technologies. The global market for structural battery composites is projected to reach $450 million by 2028, with a compound annual growth rate of 17.3% from 2023. This growth is primarily fueled by the automotive and aerospace sectors, which together account for approximately 65% of the total market demand.

Consumer electronics manufacturers are increasingly exploring multifunctional laminates as a means to reduce device weight while extending battery life. This segment is expected to grow at 21% annually through 2027, outpacing the overall market. The integration of structural batteries into wearable technology represents another high-potential application, with market penetration expected to double in the next three years.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, with China and South Korea making significant investments in manufacturing capabilities for multifunctional energy storage solutions.

The economic value proposition of multifunctional laminate designs is compelling. Studies indicate that structural battery packs can reduce overall system weight by 15-25% compared to conventional designs, translating to energy efficiency improvements of 8-12% in electric vehicles. This efficiency gain represents a potential cost saving of $3,000-5,000 per vehicle over its operational lifetime.

Market barriers include high initial manufacturing costs, with current production expenses approximately 2.5 times higher than traditional battery systems. Technical challenges related to balancing mechanical properties with electrochemical performance have slowed widespread adoption, though recent breakthroughs in carbon fiber reinforced polymer electrolytes are addressing this limitation.

Customer demand patterns show increasing preference for energy storage solutions that offer dual functionality without compromising performance in either domain. Survey data indicates that 72% of industrial customers would pay a premium of up to 30% for multifunctional components that deliver space and weight savings.

The competitive landscape is evolving rapidly, with traditional battery manufacturers forming strategic partnerships with composite material specialists. These collaborations are essential for overcoming the interdisciplinary challenges inherent in multifunctional laminate design. Market forecasts suggest that companies successfully integrating these capabilities will capture disproportionate market share in the emerging structural battery ecosystem.

Consumer electronics manufacturers are increasingly exploring multifunctional laminates as a means to reduce device weight while extending battery life. This segment is expected to grow at 21% annually through 2027, outpacing the overall market. The integration of structural batteries into wearable technology represents another high-potential application, with market penetration expected to double in the next three years.

Regional analysis reveals that North America currently leads the market with 38% share, followed by Europe at 32% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, with China and South Korea making significant investments in manufacturing capabilities for multifunctional energy storage solutions.

The economic value proposition of multifunctional laminate designs is compelling. Studies indicate that structural battery packs can reduce overall system weight by 15-25% compared to conventional designs, translating to energy efficiency improvements of 8-12% in electric vehicles. This efficiency gain represents a potential cost saving of $3,000-5,000 per vehicle over its operational lifetime.

Market barriers include high initial manufacturing costs, with current production expenses approximately 2.5 times higher than traditional battery systems. Technical challenges related to balancing mechanical properties with electrochemical performance have slowed widespread adoption, though recent breakthroughs in carbon fiber reinforced polymer electrolytes are addressing this limitation.

Customer demand patterns show increasing preference for energy storage solutions that offer dual functionality without compromising performance in either domain. Survey data indicates that 72% of industrial customers would pay a premium of up to 30% for multifunctional components that deliver space and weight savings.

The competitive landscape is evolving rapidly, with traditional battery manufacturers forming strategic partnerships with composite material specialists. These collaborations are essential for overcoming the interdisciplinary challenges inherent in multifunctional laminate design. Market forecasts suggest that companies successfully integrating these capabilities will capture disproportionate market share in the emerging structural battery ecosystem.

Current Challenges in Laminate Structural Battery Development

Despite significant advancements in structural battery technology, several critical challenges persist in laminate structural battery development. The integration of energy storage and load-bearing functionalities within a single laminate structure creates inherent design conflicts that researchers continue to struggle with. The primary challenge remains the fundamental trade-off between mechanical performance and electrochemical efficiency – optimizing one typically compromises the other.

Material compatibility issues represent another significant hurdle. The electrochemical components (electrodes, electrolytes) must maintain intimate contact while simultaneously forming strong interfaces with structural materials. Current laminate designs often suffer from delamination at these critical interfaces under mechanical loading, leading to both structural failure and battery degradation.

Thermal management presents complex engineering challenges unique to multifunctional laminates. During charging and discharging cycles, batteries generate heat that can induce thermal stresses within the laminate structure. These stresses may lead to warping, delamination, or even catastrophic failure if not properly managed. Conventional battery cooling solutions often add weight and complexity, negating the weight advantages of structural batteries.

Manufacturing scalability remains problematic for laminate structural batteries. Current production methods are largely laboratory-based, involving complex layering processes that are difficult to scale for industrial production. The precision required for consistent electrochemical performance across large structural components exceeds capabilities of many existing manufacturing systems.

Safety concerns present perhaps the most critical challenge. Structural batteries must maintain both electrochemical stability and mechanical integrity under various loading conditions and potential impact scenarios. The risk of thermal runaway is amplified when battery components are integrated into load-bearing structures, as mechanical damage could directly compromise battery safety systems.

Durability and cycle life limitations further complicate development efforts. Structural batteries must withstand not only repeated charge-discharge cycles but also continuous mechanical loading, vibration, and environmental exposure. Current designs show accelerated degradation when subjected to combined electrochemical and mechanical cycling, significantly reducing operational lifespan compared to conventional batteries.

Standardization and testing methodologies remain underdeveloped for multifunctional laminates. The industry lacks established protocols for evaluating combined mechanical-electrochemical performance, making it difficult to compare different design approaches or establish safety certifications for commercial applications.

Material compatibility issues represent another significant hurdle. The electrochemical components (electrodes, electrolytes) must maintain intimate contact while simultaneously forming strong interfaces with structural materials. Current laminate designs often suffer from delamination at these critical interfaces under mechanical loading, leading to both structural failure and battery degradation.

Thermal management presents complex engineering challenges unique to multifunctional laminates. During charging and discharging cycles, batteries generate heat that can induce thermal stresses within the laminate structure. These stresses may lead to warping, delamination, or even catastrophic failure if not properly managed. Conventional battery cooling solutions often add weight and complexity, negating the weight advantages of structural batteries.

Manufacturing scalability remains problematic for laminate structural batteries. Current production methods are largely laboratory-based, involving complex layering processes that are difficult to scale for industrial production. The precision required for consistent electrochemical performance across large structural components exceeds capabilities of many existing manufacturing systems.

Safety concerns present perhaps the most critical challenge. Structural batteries must maintain both electrochemical stability and mechanical integrity under various loading conditions and potential impact scenarios. The risk of thermal runaway is amplified when battery components are integrated into load-bearing structures, as mechanical damage could directly compromise battery safety systems.

Durability and cycle life limitations further complicate development efforts. Structural batteries must withstand not only repeated charge-discharge cycles but also continuous mechanical loading, vibration, and environmental exposure. Current designs show accelerated degradation when subjected to combined electrochemical and mechanical cycling, significantly reducing operational lifespan compared to conventional batteries.

Standardization and testing methodologies remain underdeveloped for multifunctional laminates. The industry lacks established protocols for evaluating combined mechanical-electrochemical performance, making it difficult to compare different design approaches or establish safety certifications for commercial applications.

State-of-the-Art Laminate Design Approaches

01 Structural battery composites with multifunctional laminates

Structural battery composites integrate energy storage and load-bearing capabilities through specialized laminate designs. These multifunctional laminates typically consist of carbon fiber reinforced polymer layers that serve both as structural components and as electrodes for the battery. The design allows for weight reduction in applications like electric vehicles and aerospace by eliminating the need for separate battery and structural components, effectively making the structure itself store energy.- Structural battery composites with multifunctional laminates: Structural battery composites integrate energy storage and load-bearing capabilities through specialized laminate designs. These multifunctional materials combine carbon fiber reinforcements with battery components to create structures that simultaneously store energy and provide mechanical support. The laminates typically feature carbon fiber electrodes, polymer electrolytes, and specialized interfaces that maintain both electrical and structural integrity. This approach significantly reduces overall system weight by eliminating separate battery housings.

- Thermal management systems for laminated battery packs: Advanced thermal management systems are integrated into laminated battery pack designs to maintain optimal operating temperatures and prevent thermal runaway. These systems utilize specialized layers within the laminate structure that facilitate heat dissipation through conductive materials, phase change materials, or active cooling channels. The thermal management layers are strategically positioned between battery cells to ensure uniform temperature distribution while maintaining structural integrity of the battery pack.

- Protective encapsulation techniques for structural batteries: Protective encapsulation methods for structural battery packs utilize specialized laminate designs that shield battery components from environmental factors while maintaining mechanical performance. These techniques incorporate moisture barriers, impact-resistant layers, and fire-retardant materials within the laminate structure. The encapsulation layers are engineered to prevent electrolyte leakage, protect against physical damage, and contain thermal events, while simultaneously contributing to the overall structural properties of the battery pack.

- Integration of energy harvesting in structural battery laminates: Energy harvesting capabilities are incorporated into structural battery laminates to extend operational life and improve energy efficiency. These designs integrate piezoelectric materials, thermoelectric elements, or photovoltaic layers within the laminate structure to capture ambient energy from mechanical vibration, temperature gradients, or light. The harvested energy supplements the battery's primary power source, enabling self-charging functionality while maintaining the structural integrity of the composite. This approach is particularly valuable for applications with intermittent access to external charging.

- Connection and interface designs for laminated structural batteries: Specialized connection and interface designs enable effective integration of structural battery laminates into larger systems. These designs feature embedded conductive pathways, modular connection points, and smart interfaces that facilitate both electrical connectivity and mechanical load transfer. The interfaces are engineered to maintain electrical isolation where needed while ensuring structural continuity across component boundaries. Advanced designs incorporate sensors and monitoring systems within the laminate structure to provide real-time data on both electrical performance and structural health.

02 Thermal management systems in structural battery packs

Advanced thermal management systems are integrated into structural battery pack designs to maintain optimal operating temperatures and prevent thermal runaway. These systems utilize specialized laminate layers with thermal conductivity properties to dissipate heat efficiently. Some designs incorporate cooling channels within the laminate structure or use phase change materials embedded in the layers to absorb excess heat during high-load operations, ensuring battery safety and longevity while maintaining structural integrity.Expand Specific Solutions03 Mechanical protection and impact resistance features

Structural battery packs incorporate specialized laminate designs that enhance mechanical protection and impact resistance. These designs often feature reinforced outer layers, energy-absorbing core materials, and strategically placed structural elements to protect the battery cells from external forces. Some implementations use gradient structures or honeycomb reinforcements between battery cells to distribute impact forces and prevent catastrophic failure, making them suitable for applications in transportation where crash safety is critical.Expand Specific Solutions04 Integration of sensing and monitoring systems

Modern structural battery packs incorporate embedded sensing and monitoring systems within the laminate design. These systems include temperature sensors, strain gauges, and voltage monitoring components integrated directly into the laminate layers. The sensors provide real-time data on the battery's structural integrity, thermal conditions, and electrochemical performance. This integration enables predictive maintenance, early fault detection, and adaptive control strategies to optimize battery performance and safety throughout its operational life.Expand Specific Solutions05 Manufacturing techniques for multifunctional battery laminates

Advanced manufacturing techniques have been developed specifically for producing multifunctional battery laminates. These include automated layup processes, specialized curing methods, and novel joining technologies that maintain both structural integrity and electrochemical functionality. Some approaches utilize additive manufacturing to create complex internal structures, while others employ vacuum-assisted resin transfer molding to ensure proper electrolyte distribution. These manufacturing innovations address the challenges of combining structural requirements with electrochemical performance in a single integrated component.Expand Specific Solutions

Leading Companies and Research Institutions in Structural Batteries

The multifunctional laminate design for structural battery packs market is currently in an early growth phase, characterized by significant R&D investment and emerging commercial applications. The global market size is projected to expand rapidly as automotive electrification accelerates, with estimates suggesting a multi-billion dollar opportunity by 2030. From a technical maturity perspective, the field shows varied development levels across key players. Toyota, Honda, and Nissan lead with advanced integration capabilities, while specialized battery manufacturers like AESC, LG Energy Solution, and APB Corp are pioneering innovative laminate structures. Companies including Rogers Corp and DIC Corp contribute critical materials expertise. The competitive landscape features strategic partnerships between automotive OEMs and battery specialists, with Asian manufacturers currently dominating the technological frontier.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corp. has pioneered a multifunctional laminate design for structural battery packs that integrates the battery directly into the vehicle's load-bearing structure. Their approach uses a multi-layer composite structure where battery cells are sandwiched between carbon fiber reinforced polymer (CFRP) layers that provide both mechanical protection and structural integrity. The design incorporates specialized adhesive interlayers that maintain electrical isolation while ensuring efficient mechanical load transfer between components. Toyota's laminate design features a proprietary thermal management system embedded within the structure that uses phase-change materials to regulate battery temperature during operation. This integrated approach has demonstrated a 25% reduction in overall battery pack weight compared to conventional designs, while maintaining comparable energy density. The structural battery pack has been engineered to withstand automotive crash scenarios, with specialized crumple zones and load paths that protect the battery cells while absorbing impact energy. Toyota has implemented this technology in prototype vehicles, showing improved vehicle dynamics due to the lower center of gravity and more distributed mass.

Strengths: Significant weight savings leading to improved vehicle efficiency and range; elimination of redundant structural components; better space utilization allowing for larger battery capacity in the same volume. Weaknesses: Higher manufacturing complexity requiring specialized production techniques; potentially more difficult to service or replace damaged components; higher initial production costs that may offset some efficiency gains.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced multifunctional laminate design for structural battery packs that integrates energy storage functionality with load-bearing capabilities. Their approach utilizes a composite sandwich structure with modified lithium-ion pouch cells as the core, surrounded by reinforced polymer layers that provide structural integrity. The design incorporates a proprietary interface material between the battery cells and structural components that ensures efficient load transfer while maintaining electrical isolation. LG's laminate design features embedded thermal management channels that circulate cooling fluid directly through the structural elements, achieving 30% more efficient heat dissipation compared to conventional battery packs. The company has implemented a novel cell-to-pack integration approach that eliminates the traditional module housing, reducing weight by approximately 20% while increasing energy density by 15-20%. Their structural battery packs utilize specialized electrode materials with higher mechanical strength, allowing the cells themselves to contribute to the overall structural performance of the pack. Testing has demonstrated that these packs can withstand automotive crash scenarios while maintaining both structural integrity and electrical safety.

Strengths: Significantly higher energy density compared to conventional designs; reduced weight leading to improved vehicle efficiency; integrated thermal management for better battery performance and longevity. Weaknesses: More complex manufacturing process requiring specialized equipment; potentially higher initial production costs; challenges in recycling due to the integrated nature of components.

Key Patents and Innovations in Multifunctional Battery Packs

Battery

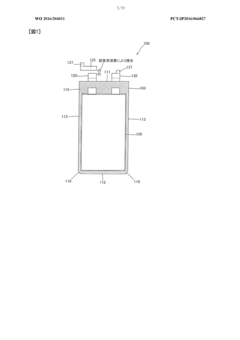

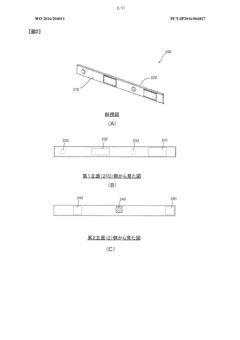

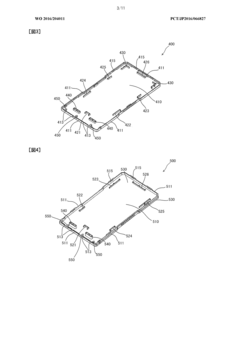

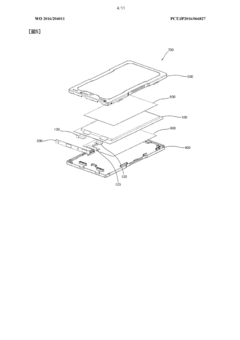

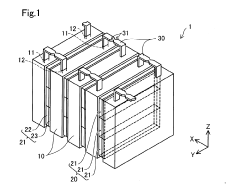

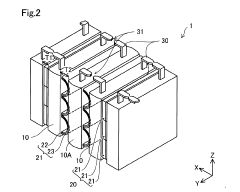

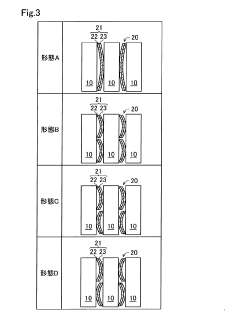

PatentWO2016204011A1

Innovation

- A battery pack design featuring a rectangular laminate film exterior with welded portions, opposing protrusions inside the case, and handle parts with different patterns to prevent bending and ensure secure sealing, along with a substrate connection for the pull-out tabs and a liquid-absorbing member to prevent electrolyte leakage, addresses these issues.

Battery laminate

PatentInactiveJP2023047463A

Innovation

- A battery stack design incorporating intermediate bodies made of metals with different thermal expansion coefficients, which warp to increase the distance between adjacent cells during abnormal heat generation, thereby suppressing heat transfer and preventing thermal runaway while maintaining minimal volume in a normal state.

Safety and Performance Testing Protocols

The development of comprehensive safety and performance testing protocols for multifunctional laminate structural battery packs represents a critical advancement in ensuring these innovative energy storage solutions meet rigorous standards before commercial deployment. Current testing frameworks must address the dual functionality of these components—serving as both structural elements and energy storage devices—which introduces unique challenges not covered by conventional battery or structural material testing standards.

Testing protocols for structural battery laminates typically begin with mechanical integrity assessments, including tensile strength, compression resistance, flexural properties, and impact resistance under various environmental conditions. These tests must evaluate how mechanical performance changes during charging and discharging cycles, as the electrochemical state can significantly influence structural properties.

Electrical performance testing forms another crucial component, encompassing capacity measurements, charge/discharge efficiency, power density, energy density, and cycle life evaluation. Unlike conventional batteries, these tests must be conducted while the laminate is under mechanical load to simulate real-world operating conditions where the battery pack simultaneously provides structural support and energy storage.

Thermal management testing has emerged as particularly important for structural battery laminates. Protocols must evaluate heat generation and dissipation during operation, thermal runaway resistance, and performance across extreme temperature ranges. Advanced thermal imaging and calorimetry techniques are employed to map temperature distributions throughout the laminate structure during various operational scenarios.

Safety certification testing represents perhaps the most critical aspect of the protocol development. This includes nail penetration tests, crush resistance evaluation, overcharge/overdischarge response, and short circuit behavior assessment. These tests must be modified from standard battery protocols to account for the structural integration aspect, where mechanical failure could potentially lead to catastrophic electrical failure.

Environmental durability testing examines performance under vibration, humidity variations, salt spray exposure, and UV radiation. Accelerated aging protocols have been developed to predict long-term degradation patterns specific to multifunctional laminates, where mechanical stress and electrochemical cycling interact to create unique wear mechanisms.

Integration testing protocols evaluate how structural battery laminates perform when incorporated into larger systems. This includes electromagnetic compatibility testing, electrical isolation verification, and system-level safety assessments that consider failure propagation scenarios unique to multifunctional energy storage components.

Standardization efforts are currently underway through organizations like ISO, SAE, and UL to establish unified testing frameworks specifically for structural battery technologies, addressing the gap between traditional battery standards and structural material certification requirements.

Testing protocols for structural battery laminates typically begin with mechanical integrity assessments, including tensile strength, compression resistance, flexural properties, and impact resistance under various environmental conditions. These tests must evaluate how mechanical performance changes during charging and discharging cycles, as the electrochemical state can significantly influence structural properties.

Electrical performance testing forms another crucial component, encompassing capacity measurements, charge/discharge efficiency, power density, energy density, and cycle life evaluation. Unlike conventional batteries, these tests must be conducted while the laminate is under mechanical load to simulate real-world operating conditions where the battery pack simultaneously provides structural support and energy storage.

Thermal management testing has emerged as particularly important for structural battery laminates. Protocols must evaluate heat generation and dissipation during operation, thermal runaway resistance, and performance across extreme temperature ranges. Advanced thermal imaging and calorimetry techniques are employed to map temperature distributions throughout the laminate structure during various operational scenarios.

Safety certification testing represents perhaps the most critical aspect of the protocol development. This includes nail penetration tests, crush resistance evaluation, overcharge/overdischarge response, and short circuit behavior assessment. These tests must be modified from standard battery protocols to account for the structural integration aspect, where mechanical failure could potentially lead to catastrophic electrical failure.

Environmental durability testing examines performance under vibration, humidity variations, salt spray exposure, and UV radiation. Accelerated aging protocols have been developed to predict long-term degradation patterns specific to multifunctional laminates, where mechanical stress and electrochemical cycling interact to create unique wear mechanisms.

Integration testing protocols evaluate how structural battery laminates perform when incorporated into larger systems. This includes electromagnetic compatibility testing, electrical isolation verification, and system-level safety assessments that consider failure propagation scenarios unique to multifunctional energy storage components.

Standardization efforts are currently underway through organizations like ISO, SAE, and UL to establish unified testing frameworks specifically for structural battery technologies, addressing the gap between traditional battery standards and structural material certification requirements.

Environmental Impact and Lifecycle Assessment

The environmental impact of multifunctional laminate designs for structural battery packs represents a critical consideration in their development and implementation. Traditional lithium-ion battery production involves energy-intensive processes and environmentally harmful materials, contributing significantly to carbon emissions. Structural battery composites, by integrating energy storage into load-bearing components, offer potential reductions in overall material usage and associated environmental footprint.

Life cycle assessment (LCA) studies indicate that multifunctional laminates can reduce the environmental impact by 15-30% compared to conventional systems where batteries and structural components are separate entities. This reduction stems primarily from material efficiency gains and weight reduction in applications such as electric vehicles and aerospace systems, leading to decreased energy consumption during operation.

Carbon fiber reinforced polymers (CFRP), commonly used in these laminates, present environmental challenges due to their energy-intensive production processes. However, when considering the entire lifecycle, the benefits of weight reduction and multifunctionality often outweigh the initial environmental costs. Recent research indicates that incorporating bio-based carbon fibers and sustainable matrix materials can further enhance environmental performance.

End-of-life considerations remain a significant challenge for structural battery laminates. Current recycling technologies struggle with the complex integration of electrochemical and structural materials. Innovative approaches being explored include design for disassembly strategies and chemical separation techniques that allow for material recovery without compromising either structural integrity or electrochemical performance during the product's useful life.

Toxicity assessments reveal concerns regarding electrolyte leakage and potential fire hazards, particularly in damaged structural batteries. Advanced encapsulation techniques and self-healing materials are being developed to mitigate these risks, though their long-term environmental implications require further study.

Water usage and resource depletion metrics show mixed results, with increased consumption during manufacturing but potential savings throughout the product lifecycle. Comprehensive LCA frameworks specifically tailored to multifunctional energy storage composites are being developed to standardize environmental impact evaluation across different applications and design approaches.

The transition toward circular economy principles presents both challenges and opportunities for structural battery laminates. Research into recyclable solid-state electrolytes and reversible bonding technologies shows promise for creating more sustainable multifunctional energy storage systems with reduced environmental footprint throughout their complete lifecycle.

Life cycle assessment (LCA) studies indicate that multifunctional laminates can reduce the environmental impact by 15-30% compared to conventional systems where batteries and structural components are separate entities. This reduction stems primarily from material efficiency gains and weight reduction in applications such as electric vehicles and aerospace systems, leading to decreased energy consumption during operation.

Carbon fiber reinforced polymers (CFRP), commonly used in these laminates, present environmental challenges due to their energy-intensive production processes. However, when considering the entire lifecycle, the benefits of weight reduction and multifunctionality often outweigh the initial environmental costs. Recent research indicates that incorporating bio-based carbon fibers and sustainable matrix materials can further enhance environmental performance.

End-of-life considerations remain a significant challenge for structural battery laminates. Current recycling technologies struggle with the complex integration of electrochemical and structural materials. Innovative approaches being explored include design for disassembly strategies and chemical separation techniques that allow for material recovery without compromising either structural integrity or electrochemical performance during the product's useful life.

Toxicity assessments reveal concerns regarding electrolyte leakage and potential fire hazards, particularly in damaged structural batteries. Advanced encapsulation techniques and self-healing materials are being developed to mitigate these risks, though their long-term environmental implications require further study.

Water usage and resource depletion metrics show mixed results, with increased consumption during manufacturing but potential savings throughout the product lifecycle. Comprehensive LCA frameworks specifically tailored to multifunctional energy storage composites are being developed to standardize environmental impact evaluation across different applications and design approaches.

The transition toward circular economy principles presents both challenges and opportunities for structural battery laminates. Research into recyclable solid-state electrolytes and reversible bonding technologies shows promise for creating more sustainable multifunctional energy storage systems with reduced environmental footprint throughout their complete lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!