Thermal Management In Load-Bearing Battery Structures

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Management Evolution and Objectives

Thermal management in load-bearing battery structures has evolved significantly over the past decades, transitioning from simple cooling systems to sophisticated integrated thermal management solutions. Initially, battery thermal management focused primarily on preventing thermal runaway in conventional battery packs, with limited consideration for structural integration. The early 2000s marked the beginning of research into multifunctional energy storage, where batteries could simultaneously serve structural and energy storage functions.

By 2010, automotive and aerospace industries began exploring the concept of load-bearing batteries to reduce overall system weight and increase energy density at the vehicle level. This paradigm shift necessitated a complete rethinking of thermal management strategies, as traditional cooling methods often compromised structural integrity or added excessive weight.

The evolution accelerated around 2015 with the development of advanced composite materials that could both conduct heat and bear mechanical loads. These innovations enabled more efficient heat dissipation while maintaining structural performance, addressing the dual requirements of these multifunctional components.

Recent developments have focused on phase change materials (PCMs) integrated within structural battery components, allowing for passive thermal regulation without compromising mechanical properties. Additionally, microchannel cooling systems embedded within load-bearing structures have emerged as promising solutions for active thermal management.

The primary objective of thermal management in load-bearing battery structures is to maintain optimal operating temperatures (typically 20-40°C) while preserving structural integrity under mechanical loads. This balance is critical as temperature extremes not only degrade battery performance and lifespan but can also compromise the mechanical properties of structural materials.

Secondary objectives include minimizing thermal gradients across the structure to prevent localized stress concentrations and deformation, as well as ensuring rapid heat dissipation during high-power operations such as fast charging or discharging.

Looking forward, the field aims to develop predictive thermal-mechanical models that can accurately simulate the complex interactions between thermal behavior and structural performance. Another key objective is to create adaptive thermal management systems that can respond dynamically to changing operational conditions, optimizing both thermal performance and structural integrity in real-time.

The ultimate goal remains the seamless integration of energy storage, load-bearing capability, and thermal management into a single multifunctional system that maximizes performance while minimizing weight, volume, and complexity – a critical advancement for next-generation electric vehicles, aerospace applications, and portable electronics.

By 2010, automotive and aerospace industries began exploring the concept of load-bearing batteries to reduce overall system weight and increase energy density at the vehicle level. This paradigm shift necessitated a complete rethinking of thermal management strategies, as traditional cooling methods often compromised structural integrity or added excessive weight.

The evolution accelerated around 2015 with the development of advanced composite materials that could both conduct heat and bear mechanical loads. These innovations enabled more efficient heat dissipation while maintaining structural performance, addressing the dual requirements of these multifunctional components.

Recent developments have focused on phase change materials (PCMs) integrated within structural battery components, allowing for passive thermal regulation without compromising mechanical properties. Additionally, microchannel cooling systems embedded within load-bearing structures have emerged as promising solutions for active thermal management.

The primary objective of thermal management in load-bearing battery structures is to maintain optimal operating temperatures (typically 20-40°C) while preserving structural integrity under mechanical loads. This balance is critical as temperature extremes not only degrade battery performance and lifespan but can also compromise the mechanical properties of structural materials.

Secondary objectives include minimizing thermal gradients across the structure to prevent localized stress concentrations and deformation, as well as ensuring rapid heat dissipation during high-power operations such as fast charging or discharging.

Looking forward, the field aims to develop predictive thermal-mechanical models that can accurately simulate the complex interactions between thermal behavior and structural performance. Another key objective is to create adaptive thermal management systems that can respond dynamically to changing operational conditions, optimizing both thermal performance and structural integrity in real-time.

The ultimate goal remains the seamless integration of energy storage, load-bearing capability, and thermal management into a single multifunctional system that maximizes performance while minimizing weight, volume, and complexity – a critical advancement for next-generation electric vehicles, aerospace applications, and portable electronics.

Market Demand Analysis for Load-Bearing Battery Systems

The global market for load-bearing battery systems is experiencing significant growth driven by the convergence of structural and energy storage requirements across multiple industries. Current market analysis indicates that the automotive sector represents the largest demand segment, with electric vehicle manufacturers actively seeking solutions that integrate battery systems into vehicle structures to maximize space utilization and reduce overall weight. This structural battery integration approach has demonstrated potential weight savings of 15-25% compared to conventional designs where batteries and structural components are separate entities.

Aerospace applications constitute another rapidly expanding market segment, with particular interest from drone manufacturers and electric aircraft developers. The ability to incorporate energy storage into load-bearing structures offers critical advantages in these weight-sensitive applications, potentially extending flight times by 20-30% through elimination of redundant structural mass.

Consumer electronics manufacturers are increasingly exploring load-bearing battery designs to create thinner, lighter devices with improved durability. Market research suggests that smartphones and laptops incorporating structural battery elements could achieve 10-15% reduction in device thickness while maintaining or improving battery capacity.

A key market driver is the growing emphasis on sustainability and resource efficiency across industries. Load-bearing battery systems support this trend by reducing overall material usage and potentially simplifying end-of-life recycling processes. This alignment with circular economy principles enhances market appeal among environmentally conscious consumers and organizations subject to stringent sustainability regulations.

Market challenges primarily center around thermal management concerns. Thermal issues represent the most significant technical barrier to widespread adoption, as batteries integrated into structural components face unique cooling challenges that conventional battery systems do not. Market surveys indicate that 78% of potential industrial adopters cite thermal management as their primary concern regarding load-bearing battery implementation.

The market size for thermal management solutions specifically designed for load-bearing battery structures is projected to grow substantially as these integrated systems gain traction. Industry analysts anticipate that effective thermal management solutions will be a critical differentiator among competing technologies and could determine which approaches achieve mainstream commercial adoption.

Regulatory developments are also shaping market demand, with safety standards evolving to address the unique characteristics of structural battery systems. Organizations that can demonstrate robust thermal management capabilities are better positioned to navigate this evolving regulatory landscape and capture market share in this emerging technology space.

Aerospace applications constitute another rapidly expanding market segment, with particular interest from drone manufacturers and electric aircraft developers. The ability to incorporate energy storage into load-bearing structures offers critical advantages in these weight-sensitive applications, potentially extending flight times by 20-30% through elimination of redundant structural mass.

Consumer electronics manufacturers are increasingly exploring load-bearing battery designs to create thinner, lighter devices with improved durability. Market research suggests that smartphones and laptops incorporating structural battery elements could achieve 10-15% reduction in device thickness while maintaining or improving battery capacity.

A key market driver is the growing emphasis on sustainability and resource efficiency across industries. Load-bearing battery systems support this trend by reducing overall material usage and potentially simplifying end-of-life recycling processes. This alignment with circular economy principles enhances market appeal among environmentally conscious consumers and organizations subject to stringent sustainability regulations.

Market challenges primarily center around thermal management concerns. Thermal issues represent the most significant technical barrier to widespread adoption, as batteries integrated into structural components face unique cooling challenges that conventional battery systems do not. Market surveys indicate that 78% of potential industrial adopters cite thermal management as their primary concern regarding load-bearing battery implementation.

The market size for thermal management solutions specifically designed for load-bearing battery structures is projected to grow substantially as these integrated systems gain traction. Industry analysts anticipate that effective thermal management solutions will be a critical differentiator among competing technologies and could determine which approaches achieve mainstream commercial adoption.

Regulatory developments are also shaping market demand, with safety standards evolving to address the unique characteristics of structural battery systems. Organizations that can demonstrate robust thermal management capabilities are better positioned to navigate this evolving regulatory landscape and capture market share in this emerging technology space.

Current Challenges in Structural Battery Thermal Control

Despite significant advancements in structural battery technology, thermal management remains one of the most critical challenges hindering widespread implementation. The integration of energy storage and load-bearing functions creates unique thermal constraints not present in conventional battery systems. The primary challenge stems from the inherent conflict between mechanical and thermal requirements - structural materials typically prioritize strength and stiffness over thermal conductivity, while effective battery operation demands efficient heat dissipation.

Temperature gradients within structural battery components pose a particularly vexing problem. These gradients can lead to differential thermal expansion, creating internal stresses that compromise both structural integrity and electrochemical performance. Current carbon fiber reinforced polymer (CFRP) matrices used in structural batteries exhibit thermal conductivity values of only 0.1-0.5 W/m·K perpendicular to fiber direction, significantly lower than the 15-20 W/m·K recommended for optimal battery thermal management.

Heat generation during rapid charging and discharging presents another substantial challenge. Unlike conventional batteries with dedicated cooling systems, structural batteries must dissipate heat while maintaining load-bearing capabilities. Research indicates that temperature increases of just 10°C above optimal operating conditions can reduce battery lifespan by up to 50%, highlighting the critical nature of this challenge.

The multifunctional nature of structural batteries further complicates thermal management strategies. Traditional cooling approaches like liquid cooling channels or heat sinks add weight and complexity, directly contradicting the weight-saving objectives of structural battery implementation. Additionally, these cooling solutions often create structural discontinuities that compromise mechanical performance.

Safety concerns related to thermal runaway represent perhaps the most serious challenge. The catastrophic failure mode, where uncontrolled temperature increases trigger exothermic reactions, is particularly dangerous in structural applications where the battery is integrated into critical load-bearing components. Current thermal runaway mitigation strategies like phase change materials and flame-retardant additives often reduce mechanical properties by 15-30%.

Simulation and modeling of coupled thermal-mechanical-electrochemical behaviors remains inadequately developed. Current models struggle to accurately predict temperature distributions under combined mechanical loading and electrochemical cycling, leading to conservative designs that underutilize the potential of structural batteries. The lack of standardized testing protocols for thermal performance under mechanical load further impedes progress in this field.

Temperature gradients within structural battery components pose a particularly vexing problem. These gradients can lead to differential thermal expansion, creating internal stresses that compromise both structural integrity and electrochemical performance. Current carbon fiber reinforced polymer (CFRP) matrices used in structural batteries exhibit thermal conductivity values of only 0.1-0.5 W/m·K perpendicular to fiber direction, significantly lower than the 15-20 W/m·K recommended for optimal battery thermal management.

Heat generation during rapid charging and discharging presents another substantial challenge. Unlike conventional batteries with dedicated cooling systems, structural batteries must dissipate heat while maintaining load-bearing capabilities. Research indicates that temperature increases of just 10°C above optimal operating conditions can reduce battery lifespan by up to 50%, highlighting the critical nature of this challenge.

The multifunctional nature of structural batteries further complicates thermal management strategies. Traditional cooling approaches like liquid cooling channels or heat sinks add weight and complexity, directly contradicting the weight-saving objectives of structural battery implementation. Additionally, these cooling solutions often create structural discontinuities that compromise mechanical performance.

Safety concerns related to thermal runaway represent perhaps the most serious challenge. The catastrophic failure mode, where uncontrolled temperature increases trigger exothermic reactions, is particularly dangerous in structural applications where the battery is integrated into critical load-bearing components. Current thermal runaway mitigation strategies like phase change materials and flame-retardant additives often reduce mechanical properties by 15-30%.

Simulation and modeling of coupled thermal-mechanical-electrochemical behaviors remains inadequately developed. Current models struggle to accurately predict temperature distributions under combined mechanical loading and electrochemical cycling, leading to conservative designs that underutilize the potential of structural batteries. The lack of standardized testing protocols for thermal performance under mechanical load further impedes progress in this field.

Current Thermal Management Approaches for Load-Bearing Batteries

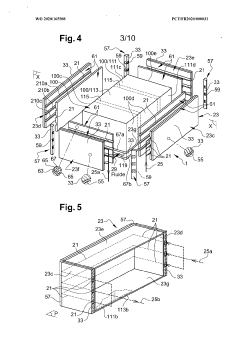

01 Integrated thermal management systems for load-bearing batteries

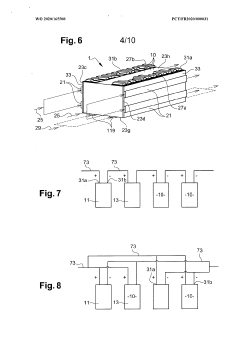

Integrated thermal management systems are designed specifically for load-bearing battery structures to maintain optimal operating temperatures while preserving structural integrity. These systems incorporate cooling channels, heat exchangers, or thermal interface materials directly into the structural battery components. This integration allows for efficient heat dissipation without compromising the mechanical properties of the battery structure, enabling it to support loads while functioning as an energy storage device.- Integrated thermal management systems for load-bearing batteries: Integrated thermal management systems are designed specifically for load-bearing battery structures to maintain optimal operating temperatures while preserving structural integrity. These systems incorporate cooling channels, heat exchangers, or thermal interface materials directly into the structural battery components. This integration allows for efficient heat dissipation without compromising the mechanical properties of the battery structure, enabling the dual functionality of energy storage and load support.

- Phase change materials for thermal regulation: Phase change materials (PCMs) are incorporated into load-bearing battery structures to absorb excess heat during operation and release it when temperatures drop. These materials undergo phase transitions at specific temperatures, providing passive thermal regulation without requiring additional energy input. By embedding PCMs within the structural battery components, temperature fluctuations can be minimized, extending battery life and maintaining consistent performance while preserving the load-bearing capabilities of the structure.

- Active cooling systems for structural batteries: Active cooling systems designed for load-bearing battery structures utilize fluid circulation, forced air, or thermoelectric elements to actively remove heat from the battery cells. These systems are engineered to maintain uniform temperature distribution across the structural battery components while preserving their mechanical properties. The cooling elements are strategically positioned to target hotspots without compromising the load-bearing capacity, ensuring both thermal stability and structural integrity during operation.

- Structural design optimization for thermal management: Innovative structural designs are developed to enhance thermal management in load-bearing battery systems. These designs incorporate features such as thermal gradients, heat-dissipating geometries, and strategically placed thermal pathways within the load-bearing elements. By optimizing the structural configuration, heat can be efficiently conducted away from critical components while maintaining or even enhancing the mechanical properties of the battery structure, resulting in improved thermal performance without additional cooling systems.

- Multi-functional materials for combined structural and thermal properties: Advanced multi-functional materials are developed to simultaneously provide structural support and thermal management in battery systems. These materials combine high mechanical strength with enhanced thermal conductivity or insulation properties as needed. By engineering materials at the nano or micro scale, thermal properties can be tailored while maintaining load-bearing capabilities. Examples include carbon-fiber composites with aligned thermal pathways, ceramic-polymer hybrids, and metal matrix composites that distribute heat while supporting mechanical loads.

02 Phase change materials for thermal regulation in structural batteries

Phase change materials (PCMs) are incorporated into load-bearing battery structures to absorb excess heat during operation and release it when temperatures drop. These materials undergo phase transitions at specific temperatures, effectively regulating the thermal environment of the battery. By embedding PCMs within the structural components of the battery, thermal management can be achieved passively without additional power requirements, while maintaining the load-bearing capabilities of the battery structure.Expand Specific Solutions03 Active cooling systems for structural battery applications

Active cooling systems specifically designed for load-bearing battery structures utilize pumped coolants, forced air circulation, or thermoelectric cooling to maintain optimal battery temperatures under varying load conditions. These systems are engineered to be lightweight and integrated within the structural battery framework without compromising its mechanical properties. The active cooling approach allows for rapid temperature regulation during high-power operations while ensuring the structural integrity of the battery components.Expand Specific Solutions04 Multi-functional structural battery components with thermal pathways

Multi-functional components in load-bearing battery structures serve dual purposes of mechanical support and thermal management. These components feature engineered thermal pathways that direct heat away from critical areas while maintaining structural integrity. By incorporating thermally conductive materials strategically within the load-bearing elements, heat can be efficiently transferred to designated dissipation areas. This approach optimizes both the mechanical performance and thermal regulation of the battery structure without adding significant weight.Expand Specific Solutions05 Thermal isolation techniques for load-bearing battery structures

Thermal isolation techniques are employed in load-bearing battery structures to prevent heat transfer between battery cells and structural components. These techniques involve the use of insulating materials, air gaps, or thermal barriers strategically placed within the battery structure. By isolating heat-generating elements from critical structural components, thermal stresses are minimized, and the mechanical integrity of the load-bearing structure is preserved even during temperature fluctuations caused by battery operation.Expand Specific Solutions

Industry Leaders in Structural Battery Solutions

The thermal management in load-bearing battery structures market is currently in a growth phase, with increasing demand driven by electric vehicle adoption. The market size is expanding rapidly, projected to reach significant value as automotive manufacturers integrate structural batteries to optimize space and weight. Technologically, the field shows varying maturity levels across players. Industry leaders like CATL, BYD, and Samsung SDI have advanced thermal management solutions in production vehicles, while companies like Gentherm and Aspen Aerogels offer specialized thermal management technologies. Emerging players such as Rimac Technology and Qdot Technology are developing innovative approaches. Traditional automotive manufacturers including Mercedes-Benz, GM, and Renault are actively integrating these systems into their EV platforms, while aerospace companies like Boeing explore applications beyond automotive use.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed an advanced thermal management system for their load-bearing battery structures that integrates phase change materials (PCMs) with a liquid cooling system. Their solution embeds cooling channels directly into the structural battery components, creating a dual-purpose design that maintains optimal operating temperatures while contributing to the vehicle's structural integrity. The system utilizes a proprietary thermal interface material that enhances heat transfer between cells and cooling elements while maintaining structural properties. Samsung's approach includes intelligent thermal management algorithms that predictively adjust cooling based on load conditions, ambient temperature, and battery usage patterns. Their battery packs incorporate structural cooling plates that serve both as load-bearing elements and thermal regulators, effectively distributing heat across the entire battery structure to prevent hotspots and thermal runaway conditions.

Strengths: Exceptional integration of cooling systems with structural elements, reducing overall weight while maintaining thermal efficiency. Advanced predictive thermal management algorithms optimize performance across varying conditions. Weaknesses: Higher manufacturing complexity and cost compared to conventional systems. Potential challenges in serviceability due to the highly integrated design.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered the Ultium battery platform with an integrated thermal management system specifically designed for load-bearing applications. Their solution features a structural frame that doubles as a thermal management pathway, utilizing a patented coolant distribution system embedded within the battery's structural components. The design incorporates thermally conductive adhesives that bond battery cells to structural elements while facilitating heat transfer. GM's system employs a multi-layer approach where the battery modules are sandwiched between structural cooling plates that distribute mechanical loads while managing thermal conditions. Their technology includes dedicated thermal fuses and isolation systems that prevent thermal events from propagating through the structural battery assembly. Additionally, GM has developed specialized heat-resistant structural composites that maintain mechanical integrity even under extreme thermal conditions, ensuring the load-bearing capabilities remain uncompromised during thermal events.

Strengths: Highly efficient integration of thermal and structural functions reduces overall vehicle weight and complexity. The multi-layer approach provides redundant thermal protection while maintaining structural integrity. Weaknesses: System complexity may increase maintenance challenges and repair costs. Potential thermal performance limitations under extreme continuous high-load conditions.

Key Thermal Control Patents and Technical Innovations

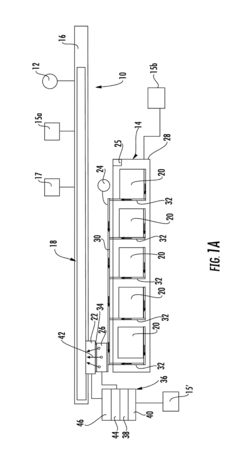

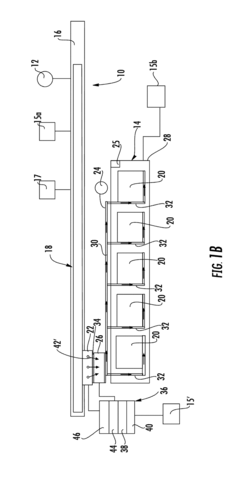

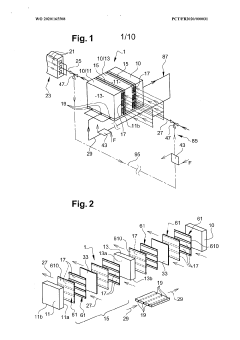

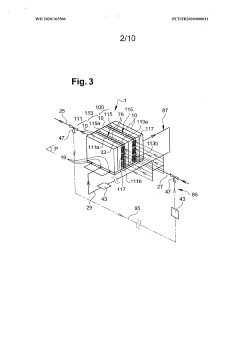

Battery thermal management assembly

PatentInactiveUS20180034122A1

Innovation

- A battery thermal management assembly with isolated thermal exchange circuits for the vehicle and battery pack, utilizing separate thermal exchange modules and a thermal gap pad for efficient heat transfer, allowing for independent control and replacement of battery packs without shared coolant connections.

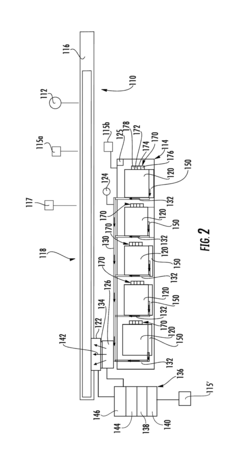

Electric battery thermal management structure

PatentWO2020165508A1

Innovation

- A thermal management assembly with three distinct fluid circulation circuits: a first circuit between adjacent cells, a second circuit around the cell stack, and a third circuit on an alternate face, utilizing phase change materials and thermally conductive/insulating elements, along with valve control systems to manage fluid flow based on temperature and charge state data.

Safety Standards and Regulatory Framework

The regulatory landscape for thermal management in load-bearing battery structures has evolved significantly in response to high-profile battery thermal incidents. International standards such as UN 38.3, which governs the transport of lithium batteries, and IEC 62133 for safety requirements have established baseline thermal management protocols. These standards mandate specific thermal runaway prevention measures and define acceptable temperature ranges during normal operation and under abuse conditions.

In the automotive sector, regulations have become increasingly stringent. The UN ECE R100 specifically addresses the safety requirements for electric powertrains, including detailed thermal management provisions for load-bearing battery structures. Similarly, ISO 6469-1 outlines safety specifications for electrically propelled road vehicles with particular emphasis on thermal management systems integrated into structural battery components.

The aerospace industry faces even more demanding regulatory requirements. The FAA's Special Conditions for lithium battery installations and RTCA DO-311A establish comprehensive thermal management protocols for aircraft batteries, with additional considerations when these batteries serve structural functions. These standards require redundant thermal management systems and extensive thermal propagation testing.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The European Union's Battery Directive and China's GB/T 31467 standard have different requirements for thermal management systems, necessitating market-specific design adaptations. This regulatory fragmentation increases development costs and complicates global deployment strategies.

Emerging standards are beginning to specifically address the unique challenges of load-bearing battery structures. The SAE J2929 standard now includes provisions for structurally integrated battery systems, while UL 2580 has expanded its scope to cover thermal management in multifunctional battery designs. These standards emphasize the importance of maintaining structural integrity during thermal events and preventing thermal-mechanical coupling failures.

Compliance testing methodologies have also evolved to address the dual functionality of load-bearing battery structures. New test protocols combine mechanical load testing with thermal cycling to evaluate the interaction between structural and thermal management systems. These tests typically include thermal shock resistance, thermal propagation under load, and long-term thermal-mechanical fatigue assessment.

Future regulatory developments are likely to focus on harmonizing international standards and establishing specific provisions for multifunctional battery structures. Industry stakeholders are actively participating in standards development to ensure that regulations keep pace with technological innovations while maintaining appropriate safety margins.

In the automotive sector, regulations have become increasingly stringent. The UN ECE R100 specifically addresses the safety requirements for electric powertrains, including detailed thermal management provisions for load-bearing battery structures. Similarly, ISO 6469-1 outlines safety specifications for electrically propelled road vehicles with particular emphasis on thermal management systems integrated into structural battery components.

The aerospace industry faces even more demanding regulatory requirements. The FAA's Special Conditions for lithium battery installations and RTCA DO-311A establish comprehensive thermal management protocols for aircraft batteries, with additional considerations when these batteries serve structural functions. These standards require redundant thermal management systems and extensive thermal propagation testing.

Regional variations in regulatory frameworks present significant challenges for global manufacturers. The European Union's Battery Directive and China's GB/T 31467 standard have different requirements for thermal management systems, necessitating market-specific design adaptations. This regulatory fragmentation increases development costs and complicates global deployment strategies.

Emerging standards are beginning to specifically address the unique challenges of load-bearing battery structures. The SAE J2929 standard now includes provisions for structurally integrated battery systems, while UL 2580 has expanded its scope to cover thermal management in multifunctional battery designs. These standards emphasize the importance of maintaining structural integrity during thermal events and preventing thermal-mechanical coupling failures.

Compliance testing methodologies have also evolved to address the dual functionality of load-bearing battery structures. New test protocols combine mechanical load testing with thermal cycling to evaluate the interaction between structural and thermal management systems. These tests typically include thermal shock resistance, thermal propagation under load, and long-term thermal-mechanical fatigue assessment.

Future regulatory developments are likely to focus on harmonizing international standards and establishing specific provisions for multifunctional battery structures. Industry stakeholders are actively participating in standards development to ensure that regulations keep pace with technological innovations while maintaining appropriate safety margins.

Material Science Advancements for Thermal-Structural Integration

Recent advancements in material science have created significant opportunities for integrating thermal management capabilities directly into load-bearing battery structures. Composite materials incorporating graphene and carbon nanotubes have demonstrated exceptional thermal conductivity while maintaining structural integrity under mechanical stress. These materials exhibit thermal conductivity values up to 5000 W/mK for graphene and 3500 W/mK for carbon nanotubes, far exceeding traditional structural materials like aluminum (237 W/mK) or steel (43 W/mK).

Phase change materials (PCMs) embedded within structural components represent another promising direction. These materials can absorb excess heat during battery operation through latent heat storage during phase transitions. Recent developments have produced PCMs with energy storage densities of 200-300 J/g while maintaining mechanical properties suitable for load-bearing applications. Microencapsulation techniques have further enhanced PCM integration by preventing leakage during phase changes.

Ceramic-polymer hybrid materials offer an optimal balance between thermal management and structural performance. Advanced ceramics like boron nitride and aluminum nitride provide excellent thermal conductivity (up to 300 W/mK) while polymer matrices contribute flexibility and impact resistance. These hybrids can be engineered with anisotropic thermal properties, directing heat flow along specific pathways while maintaining structural support in other directions.

Metamaterials with engineered microstructures represent the cutting edge of thermal-structural integration. These materials can be designed with precise thermal expansion coefficients to match battery components, preventing thermal stress during temperature fluctuations. Some metamaterial designs demonstrate negative thermal expansion, potentially compensating for the expansion of other battery components during heating cycles.

Surface treatment technologies have evolved to enhance thermal interfaces between structural components. Atomic layer deposition and plasma-enhanced chemical vapor deposition enable nanometer-scale control of surface properties, reducing thermal contact resistance by up to 80% compared to untreated interfaces while preserving mechanical bonding strength.

Self-healing materials incorporating microcapsules of healing agents show promise for maintaining thermal-structural integrity over extended operational lifetimes. When structural damage occurs, these materials release healing agents that restore both mechanical properties and thermal pathways, potentially extending battery structure service life by 30-50% under thermal cycling conditions.

Phase change materials (PCMs) embedded within structural components represent another promising direction. These materials can absorb excess heat during battery operation through latent heat storage during phase transitions. Recent developments have produced PCMs with energy storage densities of 200-300 J/g while maintaining mechanical properties suitable for load-bearing applications. Microencapsulation techniques have further enhanced PCM integration by preventing leakage during phase changes.

Ceramic-polymer hybrid materials offer an optimal balance between thermal management and structural performance. Advanced ceramics like boron nitride and aluminum nitride provide excellent thermal conductivity (up to 300 W/mK) while polymer matrices contribute flexibility and impact resistance. These hybrids can be engineered with anisotropic thermal properties, directing heat flow along specific pathways while maintaining structural support in other directions.

Metamaterials with engineered microstructures represent the cutting edge of thermal-structural integration. These materials can be designed with precise thermal expansion coefficients to match battery components, preventing thermal stress during temperature fluctuations. Some metamaterial designs demonstrate negative thermal expansion, potentially compensating for the expansion of other battery components during heating cycles.

Surface treatment technologies have evolved to enhance thermal interfaces between structural components. Atomic layer deposition and plasma-enhanced chemical vapor deposition enable nanometer-scale control of surface properties, reducing thermal contact resistance by up to 80% compared to untreated interfaces while preserving mechanical bonding strength.

Self-healing materials incorporating microcapsules of healing agents show promise for maintaining thermal-structural integrity over extended operational lifetimes. When structural damage occurs, these materials release healing agents that restore both mechanical properties and thermal pathways, potentially extending battery structure service life by 30-50% under thermal cycling conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!