Design Of Structural Battery Wing Skins And Fuselage Panels

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Technology Background and Objectives

Structural battery technology represents a revolutionary approach to energy storage by integrating battery functionality directly into load-bearing structural components. This concept emerged in the early 2000s as researchers sought to address the fundamental weight limitations of conventional aircraft designs. Traditional aircraft architecture treats batteries and structural elements as separate systems, resulting in what engineers term "parasitic weight" - components that contribute to overall mass without serving multiple functions.

The evolution of structural batteries has been driven by advances in materials science, particularly in the development of carbon fiber composites and solid-state electrolytes. Early research focused primarily on theoretical models, with significant breakthroughs occurring around 2010 when researchers at Imperial College London and KTH Royal Institute of Technology demonstrated the first functional prototypes of carbon fiber-based structural battery composites.

The primary objective of structural battery technology is to achieve multifunctionality - components that simultaneously store electrical energy and bear mechanical loads. For aircraft applications specifically, this translates to wing skins and fuselage panels that can power onboard systems while maintaining structural integrity. This dual functionality promises weight reductions of 15-30% compared to conventional designs, potentially transforming aircraft performance metrics.

Current technical objectives focus on achieving energy density targets of 75-150 Wh/kg while maintaining mechanical properties comparable to traditional aerospace composites. This represents a significant challenge, as conventional lithium-ion batteries typically sacrifice structural integrity for energy storage capability, while aerospace composites prioritize mechanical performance over electrical functionality.

The development trajectory aims to progress from laboratory demonstrations to full-scale implementation in unmanned aerial vehicles (UAVs) before eventual adoption in commercial aircraft. This phased approach allows for iterative improvement of both energy density and mechanical reliability, addressing the stringent safety requirements of aerospace applications.

Research initiatives worldwide are exploring various architectural approaches, including fiber-based designs where individual carbon fibers serve as electrodes, and laminate-based designs where battery layers are integrated between structural plies. Each approach presents unique advantages and challenges regarding manufacturability, repairability, and performance optimization.

The ultimate goal extends beyond mere weight reduction to enabling entirely new aircraft configurations and operational capabilities. By distributing energy storage throughout the airframe, structural batteries could facilitate novel electric propulsion systems, extended flight ranges, and reduced environmental impact through decreased fuel consumption and emissions.

The evolution of structural batteries has been driven by advances in materials science, particularly in the development of carbon fiber composites and solid-state electrolytes. Early research focused primarily on theoretical models, with significant breakthroughs occurring around 2010 when researchers at Imperial College London and KTH Royal Institute of Technology demonstrated the first functional prototypes of carbon fiber-based structural battery composites.

The primary objective of structural battery technology is to achieve multifunctionality - components that simultaneously store electrical energy and bear mechanical loads. For aircraft applications specifically, this translates to wing skins and fuselage panels that can power onboard systems while maintaining structural integrity. This dual functionality promises weight reductions of 15-30% compared to conventional designs, potentially transforming aircraft performance metrics.

Current technical objectives focus on achieving energy density targets of 75-150 Wh/kg while maintaining mechanical properties comparable to traditional aerospace composites. This represents a significant challenge, as conventional lithium-ion batteries typically sacrifice structural integrity for energy storage capability, while aerospace composites prioritize mechanical performance over electrical functionality.

The development trajectory aims to progress from laboratory demonstrations to full-scale implementation in unmanned aerial vehicles (UAVs) before eventual adoption in commercial aircraft. This phased approach allows for iterative improvement of both energy density and mechanical reliability, addressing the stringent safety requirements of aerospace applications.

Research initiatives worldwide are exploring various architectural approaches, including fiber-based designs where individual carbon fibers serve as electrodes, and laminate-based designs where battery layers are integrated between structural plies. Each approach presents unique advantages and challenges regarding manufacturability, repairability, and performance optimization.

The ultimate goal extends beyond mere weight reduction to enabling entirely new aircraft configurations and operational capabilities. By distributing energy storage throughout the airframe, structural batteries could facilitate novel electric propulsion systems, extended flight ranges, and reduced environmental impact through decreased fuel consumption and emissions.

Market Analysis for Multifunctional Aerospace Materials

The global market for multifunctional aerospace materials, particularly structural battery composites for wing skins and fuselage panels, is experiencing significant growth driven by the aviation industry's push toward more electric aircraft (MEA) and sustainable aviation. Current market estimates value the advanced aerospace materials sector at approximately $32 billion, with multifunctional materials representing an emerging segment projected to grow at a compound annual rate of 6.8% through 2030.

Structural battery composites address a critical market need in aerospace: reducing weight while maintaining or improving structural integrity and adding energy storage functionality. This dual-purpose capability could potentially reduce aircraft weight by 15-20%, translating to substantial fuel savings and emissions reductions. Airlines and aircraft manufacturers face increasing pressure to meet stringent environmental regulations, with the International Air Transport Association (IATA) committing to net-zero carbon emissions by 2050.

Market segmentation reveals varying adoption potential across different aircraft types. Commercial passenger aircraft represent the largest potential market segment, with Boeing and Airbus collectively planning to deliver over 40,000 new aircraft in the next two decades. Military aerospace applications form another significant segment, with defense contractors seeking advanced materials for next-generation aircraft with enhanced range and stealth capabilities.

Regional market analysis indicates North America currently leads in aerospace materials innovation, holding approximately 42% of the market share, followed by Europe at 31%. However, Asia-Pacific represents the fastest-growing region with increasing investments in aerospace manufacturing capabilities, particularly in China, Japan, and India.

Customer demand analysis reveals aircraft manufacturers prioritize materials that offer weight reduction, improved fuel efficiency, and enhanced safety. The potential cost savings from structural battery integration are substantial – industry analyses suggest that a 1% reduction in aircraft weight can result in 0.75-1.5% fuel savings throughout the aircraft's operational life.

Market barriers include certification challenges, high initial development costs, and manufacturing scalability. The aerospace industry's stringent safety requirements mean new materials face extensive testing and certification processes, typically taking 5-8 years from concept to commercial implementation. Despite these challenges, venture capital investment in multifunctional aerospace materials has increased by 45% since 2018, indicating strong market confidence.

Competitive analysis shows established aerospace material suppliers like Hexcel, Toray, and Solvay are investing in multifunctional composites research, while startups focused specifically on structural battery technology are emerging with innovative approaches to address this growing market opportunity.

Structural battery composites address a critical market need in aerospace: reducing weight while maintaining or improving structural integrity and adding energy storage functionality. This dual-purpose capability could potentially reduce aircraft weight by 15-20%, translating to substantial fuel savings and emissions reductions. Airlines and aircraft manufacturers face increasing pressure to meet stringent environmental regulations, with the International Air Transport Association (IATA) committing to net-zero carbon emissions by 2050.

Market segmentation reveals varying adoption potential across different aircraft types. Commercial passenger aircraft represent the largest potential market segment, with Boeing and Airbus collectively planning to deliver over 40,000 new aircraft in the next two decades. Military aerospace applications form another significant segment, with defense contractors seeking advanced materials for next-generation aircraft with enhanced range and stealth capabilities.

Regional market analysis indicates North America currently leads in aerospace materials innovation, holding approximately 42% of the market share, followed by Europe at 31%. However, Asia-Pacific represents the fastest-growing region with increasing investments in aerospace manufacturing capabilities, particularly in China, Japan, and India.

Customer demand analysis reveals aircraft manufacturers prioritize materials that offer weight reduction, improved fuel efficiency, and enhanced safety. The potential cost savings from structural battery integration are substantial – industry analyses suggest that a 1% reduction in aircraft weight can result in 0.75-1.5% fuel savings throughout the aircraft's operational life.

Market barriers include certification challenges, high initial development costs, and manufacturing scalability. The aerospace industry's stringent safety requirements mean new materials face extensive testing and certification processes, typically taking 5-8 years from concept to commercial implementation. Despite these challenges, venture capital investment in multifunctional aerospace materials has increased by 45% since 2018, indicating strong market confidence.

Competitive analysis shows established aerospace material suppliers like Hexcel, Toray, and Solvay are investing in multifunctional composites research, while startups focused specifically on structural battery technology are emerging with innovative approaches to address this growing market opportunity.

Current Challenges in Structural Battery Integration

Despite the promising potential of structural battery composites (SBCs) for aerospace applications, several significant challenges impede their widespread integration into wing skins and fuselage panels. The multifunctional nature of these components creates inherent design conflicts between mechanical performance and electrochemical efficiency that remain unresolved in current implementations.

Material interface optimization presents a primary challenge, as the electrochemical requirements of battery functionality often contradict the mechanical needs of structural components. The carbon fiber reinforcements that serve as electrodes must maintain electrical connectivity while simultaneously providing structural integrity, creating competing design parameters that current manufacturing processes struggle to reconcile.

Thermal management represents another critical obstacle. Structural batteries generate heat during charging and discharging cycles, which can compromise both the electrochemical performance and the mechanical properties of the composite structure. This is particularly problematic for aerospace applications where temperature fluctuations are extreme and thermal expansion differences between battery components and surrounding structures can lead to delamination and structural failure.

Safety certification pathways remain largely undefined for these novel multifunctional materials. Current aerospace certification standards were not developed with consideration for components that serve dual structural and energy storage functions. The potential for thermal runaway, electrolyte leakage, or mechanical failure due to electrical cycling creates complex failure modes that are difficult to predict and mitigate within existing regulatory frameworks.

Manufacturing scalability continues to limit practical implementation. Current production methods for structural batteries are laboratory-focused, with limited capacity for scaling to the dimensions required for aircraft components. The precision required to maintain consistent electrochemical properties across large surface areas while ensuring structural homogeneity exceeds current manufacturing capabilities.

Durability under cyclic loading presents unique challenges for structural batteries in aerospace applications. The repeated mechanical stresses experienced by wing skins and fuselage panels can accelerate degradation of battery components, while electrochemical cycling can similarly compromise structural integrity. This bidirectional degradation mechanism is poorly understood and difficult to model accurately.

Weight optimization remains suboptimal compared to dedicated systems. Current structural batteries achieve approximately 30-50% of the energy density of conventional lithium-ion batteries while providing only 30-60% of the specific strength of traditional carbon fiber composites, creating an efficiency gap that limits practical application in weight-sensitive aerospace designs.

Material interface optimization presents a primary challenge, as the electrochemical requirements of battery functionality often contradict the mechanical needs of structural components. The carbon fiber reinforcements that serve as electrodes must maintain electrical connectivity while simultaneously providing structural integrity, creating competing design parameters that current manufacturing processes struggle to reconcile.

Thermal management represents another critical obstacle. Structural batteries generate heat during charging and discharging cycles, which can compromise both the electrochemical performance and the mechanical properties of the composite structure. This is particularly problematic for aerospace applications where temperature fluctuations are extreme and thermal expansion differences between battery components and surrounding structures can lead to delamination and structural failure.

Safety certification pathways remain largely undefined for these novel multifunctional materials. Current aerospace certification standards were not developed with consideration for components that serve dual structural and energy storage functions. The potential for thermal runaway, electrolyte leakage, or mechanical failure due to electrical cycling creates complex failure modes that are difficult to predict and mitigate within existing regulatory frameworks.

Manufacturing scalability continues to limit practical implementation. Current production methods for structural batteries are laboratory-focused, with limited capacity for scaling to the dimensions required for aircraft components. The precision required to maintain consistent electrochemical properties across large surface areas while ensuring structural homogeneity exceeds current manufacturing capabilities.

Durability under cyclic loading presents unique challenges for structural batteries in aerospace applications. The repeated mechanical stresses experienced by wing skins and fuselage panels can accelerate degradation of battery components, while electrochemical cycling can similarly compromise structural integrity. This bidirectional degradation mechanism is poorly understood and difficult to model accurately.

Weight optimization remains suboptimal compared to dedicated systems. Current structural batteries achieve approximately 30-50% of the energy density of conventional lithium-ion batteries while providing only 30-60% of the specific strength of traditional carbon fiber composites, creating an efficiency gap that limits practical application in weight-sensitive aerospace designs.

Current Structural Battery Integration Solutions

01 Integration of structural batteries in aircraft wings and fuselage

Structural batteries can be integrated into aircraft wings and fuselage panels to serve dual purposes of providing structural support and electrical power. This integration reduces the overall weight of the aircraft by eliminating the need for separate battery systems. The structural battery components are designed to withstand the mechanical loads experienced during flight while simultaneously storing and delivering electrical energy to aircraft systems.- Integration of structural batteries in aircraft wing skins: Structural batteries can be integrated into aircraft wing skins to serve dual purposes of providing structural support and electrical power. These multifunctional components reduce overall aircraft weight by eliminating the need for separate battery systems. The batteries are designed to withstand aerodynamic loads while storing and delivering electrical energy, improving the aircraft's energy efficiency and range.

- Composite materials for structural battery panels in fuselage: Advanced composite materials are used to create structural battery panels for aircraft fuselage. These materials combine carbon fiber reinforcement with battery chemistry to create lightweight, high-strength components that can store electrical energy. The composite structure provides mechanical integrity while embedded electrochemical components enable energy storage, resulting in multifunctional panels that contribute to the aircraft's structural integrity and power system.

- Energy harvesting and distribution systems in structural panels: Structural panels in aircraft wings and fuselage can incorporate energy harvesting and distribution systems. These systems capture energy from various sources such as vibration, thermal gradients, or solar radiation and convert it into electrical power. The harvested energy is then stored in the structural batteries integrated within the panels and distributed to aircraft systems as needed, enhancing energy efficiency and reducing dependence on traditional power sources.

- Manufacturing techniques for structural battery components: Specialized manufacturing techniques are employed to produce structural battery components for aircraft. These include automated layup processes, co-curing methods, and advanced bonding technologies that integrate battery elements with structural materials. The manufacturing processes ensure proper electrical isolation, structural integrity, and battery functionality while maintaining the aerodynamic profile of wing skins and fuselage panels.

- Structural design considerations for battery-integrated aircraft components: The integration of batteries into structural components of aircraft requires specific design considerations. These include load path management, thermal management systems to regulate battery temperature, protection against impact damage, and provisions for maintenance access. The designs must balance structural requirements with electrochemical performance while ensuring safety and reliability under various flight conditions and potential failure scenarios.

02 Composite materials for structural battery panels

Advanced composite materials are used to create structural battery panels for aircraft wings and fuselage. These materials combine carbon fiber reinforcement with battery chemistry to create multifunctional structures. The composites are engineered to provide high strength-to-weight ratios while incorporating electrochemical components that enable energy storage. This approach allows for the development of lightweight yet strong panels that contribute to the aircraft's structural integrity while providing power.Expand Specific Solutions03 Design configurations for structural battery wing skins

Various design configurations have been developed for structural battery wing skins to optimize both energy storage capacity and structural performance. These designs include sandwich structures with battery cores, laminated configurations with battery layers integrated between structural plies, and hybrid approaches that combine traditional structural elements with battery components. The configurations are tailored to specific aircraft requirements, considering factors such as aerodynamic loads, energy demands, and manufacturing constraints.Expand Specific Solutions04 Manufacturing methods for structural battery panels

Specialized manufacturing methods have been developed for producing structural battery panels for aircraft applications. These methods include co-curing processes that simultaneously form the structural and electrochemical components, automated layup techniques for precise placement of battery elements within composite structures, and innovative joining methods to connect battery panels to the aircraft frame. These manufacturing approaches ensure consistent quality, reliability, and performance of the multifunctional structures.Expand Specific Solutions05 Testing and certification of structural battery components

Rigorous testing and certification procedures are essential for structural battery components used in aircraft construction. These procedures include mechanical load testing to verify structural integrity, electrical performance testing to ensure battery functionality, environmental testing to confirm operation under various conditions, and safety testing to address potential failure modes. The certification process ensures that structural battery wing skins and fuselage panels meet both aerospace structural requirements and electrical safety standards.Expand Specific Solutions

Leading Aerospace and Battery Technology Companies

The structural battery wing skins and fuselage panels market is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. Major aerospace manufacturers including Airbus Operations, Boeing, and COMAC are leading development efforts, with emerging competition from specialized entities like Spirit AeroSystems and academic institutions such as Politecnico di Milano and Northwestern Polytechnical University. The technology remains at TRL 4-6, with Airbus and Boeing demonstrating the most advanced prototypes. Market size is projected to reach $2-3 billion by 2030, driven by commercial aviation's push for electrification and weight reduction. Technical challenges in power density, structural integrity, and safety certification are currently limiting widespread adoption despite the promising weight and energy efficiency benefits.

Airbus Operations GmbH

Technical Solution: Airbus has developed a multifunctional structural battery composite (SBC) system for aircraft wing skins and fuselage panels that integrates energy storage directly into load-bearing structures. Their approach uses carbon fiber reinforced polymer (CFRP) as both structural material and battery electrode substrate. The system employs a sandwich design with carbon fiber layers serving as current collectors and electrodes, separated by a solid-state electrolyte that maintains structural integrity. Airbus has demonstrated up to 35% weight reduction compared to conventional separate battery and structure systems. Their technology incorporates self-healing capabilities to address microcracks and utilizes advanced manufacturing techniques including automated fiber placement (AFP) for precise layup of battery-integrated composites. The system includes thermal management solutions to maintain optimal battery operating temperatures during flight conditions.

Strengths: Industry-leading integration of energy storage into primary aircraft structures; extensive testing infrastructure; proven weight savings. Weaknesses: Challenges with certification of multifunctional materials; potential thermal management complexity in extreme flight conditions; lower energy density compared to dedicated battery systems.

The Boeing Co.

Technical Solution: Boeing has pioneered a structural battery composite technology for wing skins and fuselage panels that utilizes a proprietary matrix-embedded energy storage system. Their approach incorporates lithium-ion battery chemistry directly into carbon fiber reinforced polymer structures through a specialized manufacturing process that maintains structural integrity while enabling energy storage. Boeing's system features a distributed cell architecture that minimizes catastrophic failure risks and optimizes weight distribution across the airframe. The technology employs nano-engineered interfaces between structural and electrochemical components to ensure mechanical load transfer while maintaining electrical functionality. Boeing has demonstrated structural batteries with energy densities approaching 75 Wh/kg while maintaining 85% of the mechanical properties of traditional composites. Their manufacturing process includes specialized curing cycles that simultaneously optimize both structural and electrochemical performance of the composite.

Strengths: Advanced failure containment systems; proven integration with existing aircraft electrical systems; mature manufacturing processes adaptable to current production lines. Weaknesses: Higher initial production costs compared to conventional structures; challenges with battery replacement/maintenance in structural components; performance degradation concerns over aircraft lifetime.

Key Patents in Structural Energy Storage

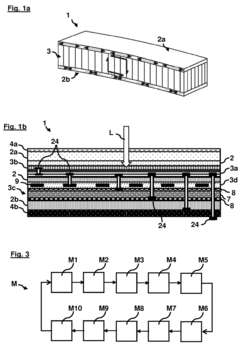

Skin panel with an energy-storing layer for an aircraft or spacecraft and method for manufacturing an energy-storing layer for a skin panel

PatentActiveEP3222514A1

Innovation

- A skin panel with a composite laminate structure that includes structural layers for stability and an embedded electro-chemical battery layer, which is manufactured using spread tow tapes and ion-enriched matrix-material filaments to form anode and cathode layers, enabling the skin to provide electrical power for internal and external devices.

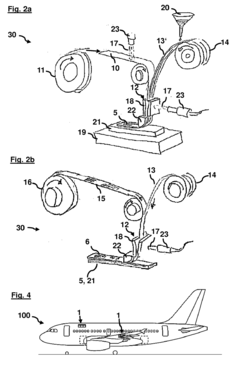

Aircraft with electric batteries, in particular a hybrid aircraft

PatentActiveEP3538435A1

Innovation

- The use of structural batteries made from composite multi-functional materials integrated into the aircraft's fuselage and wing surfaces, which support mechanical loads and store electrical energy, maximizing energy storage while minimizing weight and operational costs.

Weight-Performance Trade-offs in Aircraft Structures

The integration of structural battery composites into aircraft wing skins and fuselage panels presents significant weight-performance trade-offs that must be carefully evaluated. Traditional aircraft design has always balanced structural integrity against weight considerations, but the introduction of multifunctional materials fundamentally alters this equation.

Structural battery composites offer dual functionality by simultaneously providing mechanical load-bearing capacity and energy storage capabilities. This integration potentially eliminates the need for separate battery systems, reducing the overall aircraft weight by 15-20% compared to conventional designs with separate structural and energy storage systems.

However, these weight savings come with performance compromises. Current structural battery materials exhibit lower specific strength (approximately 30-40% less) than advanced carbon fiber composites used in modern aircraft. This necessitates thicker structural elements to maintain equivalent load-bearing capacity, partially offsetting weight advantages.

Thermal management presents another critical trade-off. Structural batteries generate heat during charge-discharge cycles, requiring thermal management systems that add weight and complexity. Studies indicate that these systems can add back 3-5% of the weight initially saved, depending on the specific battery chemistry and operational parameters.

Durability considerations further complicate the equation. Aircraft structures typically have design lives of 20+ years with tens of thousands of flight cycles, while current structural battery technology demonstrates significant capacity degradation after 500-1000 charge cycles. This mismatch creates maintenance and replacement challenges that impact long-term performance and operational costs.

Safety certification represents perhaps the most significant performance trade-off. Structural batteries must simultaneously satisfy both structural airworthiness requirements and battery safety standards. This dual certification pathway often necessitates design compromises that reduce either structural efficiency or energy density compared to single-function optimized systems.

Manufacturability also influences the weight-performance relationship. Current production methods for structural batteries are complex and precision-dependent, often resulting in thicker, heavier components than theoretically possible to ensure consistent quality and performance across large structural elements.

The ultimate weight-performance optimization depends heavily on specific aircraft mission profiles. Short-range electric aircraft may benefit most from structural batteries despite performance compromises, while long-range aircraft might find the trade-offs less advantageous due to the need for maximum structural efficiency over extended flight envelopes.

Structural battery composites offer dual functionality by simultaneously providing mechanical load-bearing capacity and energy storage capabilities. This integration potentially eliminates the need for separate battery systems, reducing the overall aircraft weight by 15-20% compared to conventional designs with separate structural and energy storage systems.

However, these weight savings come with performance compromises. Current structural battery materials exhibit lower specific strength (approximately 30-40% less) than advanced carbon fiber composites used in modern aircraft. This necessitates thicker structural elements to maintain equivalent load-bearing capacity, partially offsetting weight advantages.

Thermal management presents another critical trade-off. Structural batteries generate heat during charge-discharge cycles, requiring thermal management systems that add weight and complexity. Studies indicate that these systems can add back 3-5% of the weight initially saved, depending on the specific battery chemistry and operational parameters.

Durability considerations further complicate the equation. Aircraft structures typically have design lives of 20+ years with tens of thousands of flight cycles, while current structural battery technology demonstrates significant capacity degradation after 500-1000 charge cycles. This mismatch creates maintenance and replacement challenges that impact long-term performance and operational costs.

Safety certification represents perhaps the most significant performance trade-off. Structural batteries must simultaneously satisfy both structural airworthiness requirements and battery safety standards. This dual certification pathway often necessitates design compromises that reduce either structural efficiency or energy density compared to single-function optimized systems.

Manufacturability also influences the weight-performance relationship. Current production methods for structural batteries are complex and precision-dependent, often resulting in thicker, heavier components than theoretically possible to ensure consistent quality and performance across large structural elements.

The ultimate weight-performance optimization depends heavily on specific aircraft mission profiles. Short-range electric aircraft may benefit most from structural batteries despite performance compromises, while long-range aircraft might find the trade-offs less advantageous due to the need for maximum structural efficiency over extended flight envelopes.

Safety and Certification Requirements for Battery-Integrated Aircraft

The integration of structural batteries into aircraft wing skins and fuselage panels introduces unprecedented safety challenges that must be addressed through rigorous certification frameworks. Current aviation safety regulations were not designed with battery-integrated structures in mind, creating a regulatory gap that manufacturers and certification authorities must navigate collaboratively.

Primary safety concerns include thermal runaway management, which presents unique challenges when batteries are embedded within load-bearing structures. Unlike conventional battery installations, structural battery components cannot be easily isolated or ejected in failure scenarios, necessitating novel containment strategies and thermal management systems that maintain structural integrity during thermal events.

Electrical safety requirements must address potential short circuits, electromagnetic interference, and lightning strike protection. The distributed nature of structural batteries throughout the airframe creates complex electrical pathways that must be thoroughly analyzed for failure modes and effects. Certification will require demonstration of electrical isolation capabilities and robust protection against environmental factors that could compromise battery performance.

Structural integrity testing protocols need significant adaptation to account for the dual functionality of these components. Current certification standards for composite structures (such as FAR 25.573) must be expanded to address how battery state-of-charge, charging cycles, and aging affect mechanical properties over the aircraft's service life. Accelerated life testing methodologies will need development to validate the long-term performance of these integrated systems.

Maintenance and inspection requirements present another certification challenge. Non-destructive testing techniques must be developed to assess both structural health and battery condition without compromising either function. The certification framework will need to establish clear guidelines for inspection intervals, replacement criteria, and end-of-life procedures for structural battery components.

Emergency response procedures also require reconsideration. First responders must be equipped with specialized training and equipment to address incidents involving aircraft with structural batteries, as conventional firefighting approaches may be ineffective or potentially hazardous when applied to battery-integrated structures.

Regulatory bodies including the FAA, EASA, and CAAC are currently developing special conditions and guidance materials for these novel structures, with industry-government working groups collaborating to establish performance-based certification standards rather than prescriptive requirements. This approach allows for technological innovation while maintaining the aviation industry's exemplary safety record.

Primary safety concerns include thermal runaway management, which presents unique challenges when batteries are embedded within load-bearing structures. Unlike conventional battery installations, structural battery components cannot be easily isolated or ejected in failure scenarios, necessitating novel containment strategies and thermal management systems that maintain structural integrity during thermal events.

Electrical safety requirements must address potential short circuits, electromagnetic interference, and lightning strike protection. The distributed nature of structural batteries throughout the airframe creates complex electrical pathways that must be thoroughly analyzed for failure modes and effects. Certification will require demonstration of electrical isolation capabilities and robust protection against environmental factors that could compromise battery performance.

Structural integrity testing protocols need significant adaptation to account for the dual functionality of these components. Current certification standards for composite structures (such as FAR 25.573) must be expanded to address how battery state-of-charge, charging cycles, and aging affect mechanical properties over the aircraft's service life. Accelerated life testing methodologies will need development to validate the long-term performance of these integrated systems.

Maintenance and inspection requirements present another certification challenge. Non-destructive testing techniques must be developed to assess both structural health and battery condition without compromising either function. The certification framework will need to establish clear guidelines for inspection intervals, replacement criteria, and end-of-life procedures for structural battery components.

Emergency response procedures also require reconsideration. First responders must be equipped with specialized training and equipment to address incidents involving aircraft with structural batteries, as conventional firefighting approaches may be ineffective or potentially hazardous when applied to battery-integrated structures.

Regulatory bodies including the FAA, EASA, and CAAC are currently developing special conditions and guidance materials for these novel structures, with industry-government working groups collaborating to establish performance-based certification standards rather than prescriptive requirements. This approach allows for technological innovation while maintaining the aviation industry's exemplary safety record.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!