Structural Polymer Electrolytes For Load-Bearing Energy Storage

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Polymer Electrolytes Background and Objectives

Structural polymer electrolytes (SPEs) represent a significant advancement in energy storage technology, emerging from the convergence of materials science and electrochemistry. Since their initial development in the 1970s, these materials have evolved from simple salt-polymer complexes to sophisticated multifunctional systems. The technological trajectory has been marked by continuous improvements in ionic conductivity, mechanical properties, and electrochemical stability, driven by the growing demand for safer and more efficient energy storage solutions.

The evolution of SPEs has been characterized by several key innovations, including the incorporation of nanofillers, development of block copolymer architectures, and integration of dynamic crosslinking mechanisms. These advancements have progressively addressed the inherent trade-off between mechanical strength and ionic conductivity that has historically limited the practical application of polymer electrolytes in energy storage devices.

Recent research has increasingly focused on the dual functionality of SPEs as both ion-conducting media and structural components. This paradigm shift represents a departure from conventional approaches where electrolytes and structural elements are distinct components in energy storage systems. The concept of load-bearing energy storage leverages the mechanical properties of SPEs to contribute to the structural integrity of devices while simultaneously facilitating electrochemical processes.

The primary objective in this field is to develop SPEs that achieve an optimal balance between mechanical robustness and electrochemical performance. Specifically, researchers aim to create materials with sufficient elastic modulus and yield strength to withstand mechanical stresses while maintaining high ionic conductivity (>10^-4 S/cm at ambient temperature) and wide electrochemical stability windows (>4.5V vs. Li/Li+).

Additionally, there is a growing emphasis on sustainability and scalability in SPE development. This includes the exploration of bio-derived polymers, environmentally benign processing methods, and designs compatible with existing manufacturing infrastructure. These considerations are crucial for the eventual commercialization and widespread adoption of load-bearing energy storage technologies.

The integration of SPEs into structural energy storage devices has significant implications across multiple sectors, including electric vehicles, aerospace, wearable electronics, and grid-scale energy storage. By combining energy storage and structural functions, these materials promise to reduce system weight, increase energy density, and enhance overall device performance, addressing critical challenges in the transition toward more sustainable energy systems.

The evolution of SPEs has been characterized by several key innovations, including the incorporation of nanofillers, development of block copolymer architectures, and integration of dynamic crosslinking mechanisms. These advancements have progressively addressed the inherent trade-off between mechanical strength and ionic conductivity that has historically limited the practical application of polymer electrolytes in energy storage devices.

Recent research has increasingly focused on the dual functionality of SPEs as both ion-conducting media and structural components. This paradigm shift represents a departure from conventional approaches where electrolytes and structural elements are distinct components in energy storage systems. The concept of load-bearing energy storage leverages the mechanical properties of SPEs to contribute to the structural integrity of devices while simultaneously facilitating electrochemical processes.

The primary objective in this field is to develop SPEs that achieve an optimal balance between mechanical robustness and electrochemical performance. Specifically, researchers aim to create materials with sufficient elastic modulus and yield strength to withstand mechanical stresses while maintaining high ionic conductivity (>10^-4 S/cm at ambient temperature) and wide electrochemical stability windows (>4.5V vs. Li/Li+).

Additionally, there is a growing emphasis on sustainability and scalability in SPE development. This includes the exploration of bio-derived polymers, environmentally benign processing methods, and designs compatible with existing manufacturing infrastructure. These considerations are crucial for the eventual commercialization and widespread adoption of load-bearing energy storage technologies.

The integration of SPEs into structural energy storage devices has significant implications across multiple sectors, including electric vehicles, aerospace, wearable electronics, and grid-scale energy storage. By combining energy storage and structural functions, these materials promise to reduce system weight, increase energy density, and enhance overall device performance, addressing critical challenges in the transition toward more sustainable energy systems.

Market Analysis for Load-Bearing Energy Storage Solutions

The global market for load-bearing energy storage solutions is experiencing significant growth, driven by the increasing demand for multifunctional materials that can simultaneously provide structural support and energy storage capabilities. This emerging market segment represents a convergence of traditional energy storage technologies and advanced structural materials, creating new opportunities across multiple industries.

The automotive sector currently represents the largest market opportunity, with electric vehicle manufacturers actively seeking ways to reduce vehicle weight while maintaining or increasing battery capacity. By integrating energy storage directly into structural components, manufacturers can potentially achieve weight reductions of 15-30% compared to conventional designs with separate battery packs and structural elements.

Aerospace applications constitute another rapidly growing segment, where weight considerations are even more critical. Major aerospace companies are investing in research partnerships to develop load-bearing energy storage solutions that could revolutionize aircraft design by transforming fuselage components into energy storage systems.

Consumer electronics manufacturers are also exploring these technologies for next-generation devices, particularly for wearable technology and foldable displays where space constraints make multifunctional materials especially valuable. The market potential in this sector is expected to grow substantially as miniaturization trends continue.

Military and defense applications represent a premium market segment with less price sensitivity but more demanding performance requirements. Load-bearing energy storage solutions for soldier equipment, unmanned vehicles, and portable field systems are attracting significant government funding in several countries.

Market forecasts suggest the global market for structural energy storage materials will grow at a compound annual growth rate exceeding 20% over the next decade. This growth is supported by increasing R&D investments from both private companies and government agencies, particularly in North America, Europe, and East Asia.

Key market barriers include high production costs, technical challenges in achieving both optimal energy storage and mechanical properties, and regulatory uncertainties regarding safety standards for dual-function materials. Despite these challenges, the economic and performance benefits of weight reduction and space optimization continue to drive market expansion.

Customer requirements vary significantly across application areas, with automotive customers prioritizing cost-effectiveness and safety, aerospace focusing on weight reduction and reliability, and consumer electronics emphasizing design flexibility and energy density. This diversity of requirements is creating opportunities for specialized solutions tailored to specific market segments.

The automotive sector currently represents the largest market opportunity, with electric vehicle manufacturers actively seeking ways to reduce vehicle weight while maintaining or increasing battery capacity. By integrating energy storage directly into structural components, manufacturers can potentially achieve weight reductions of 15-30% compared to conventional designs with separate battery packs and structural elements.

Aerospace applications constitute another rapidly growing segment, where weight considerations are even more critical. Major aerospace companies are investing in research partnerships to develop load-bearing energy storage solutions that could revolutionize aircraft design by transforming fuselage components into energy storage systems.

Consumer electronics manufacturers are also exploring these technologies for next-generation devices, particularly for wearable technology and foldable displays where space constraints make multifunctional materials especially valuable. The market potential in this sector is expected to grow substantially as miniaturization trends continue.

Military and defense applications represent a premium market segment with less price sensitivity but more demanding performance requirements. Load-bearing energy storage solutions for soldier equipment, unmanned vehicles, and portable field systems are attracting significant government funding in several countries.

Market forecasts suggest the global market for structural energy storage materials will grow at a compound annual growth rate exceeding 20% over the next decade. This growth is supported by increasing R&D investments from both private companies and government agencies, particularly in North America, Europe, and East Asia.

Key market barriers include high production costs, technical challenges in achieving both optimal energy storage and mechanical properties, and regulatory uncertainties regarding safety standards for dual-function materials. Despite these challenges, the economic and performance benefits of weight reduction and space optimization continue to drive market expansion.

Customer requirements vary significantly across application areas, with automotive customers prioritizing cost-effectiveness and safety, aerospace focusing on weight reduction and reliability, and consumer electronics emphasizing design flexibility and energy density. This diversity of requirements is creating opportunities for specialized solutions tailored to specific market segments.

Technical Challenges in Structural Energy Storage

The development of structural polymer electrolytes for load-bearing energy storage faces several significant technical challenges that must be addressed to achieve practical implementation. The fundamental contradiction between mechanical strength and ionic conductivity represents the primary obstacle. Traditional polymer electrolytes with high ionic conductivity typically exhibit poor mechanical properties, while structurally robust polymers generally demonstrate insufficient ion transport capabilities.

Material interface management presents another critical challenge. The integration of polymer electrolytes with electrodes creates complex interfaces that can lead to increased resistance, reduced cycle life, and potential safety hazards. Achieving stable interfaces that maintain both structural integrity and electrochemical performance under mechanical stress remains elusive.

Thermal management issues also plague structural energy storage systems. Polymer electrolytes must maintain their mechanical and electrochemical properties across a wide temperature range, particularly during charging and discharging cycles when heat generation occurs. Current materials often show significant performance degradation at temperature extremes, limiting their practical application in real-world environments.

Manufacturing scalability represents a substantial hurdle for commercialization. Current laboratory-scale production methods for high-performance structural polymer electrolytes often involve complex synthesis procedures that are difficult to scale up economically. The development of cost-effective, high-volume manufacturing processes that maintain material quality and performance consistency remains underdeveloped.

Long-term stability under combined mechanical and electrochemical stresses constitutes another major challenge. Structural polymer electrolytes must simultaneously withstand mechanical loading while facilitating electrochemical reactions over thousands of cycles. The degradation mechanisms under these combined stresses are poorly understood, making it difficult to design materials with predictable lifespans.

Safety concerns also present significant technical barriers. Polymer electrolytes must prevent dendrite formation that can cause short circuits while maintaining structural integrity under mechanical impact or deformation. Additionally, they must exhibit flame retardancy and thermal stability to prevent catastrophic failures in extreme conditions.

The multifunctional optimization challenge requires balancing contradictory properties. Engineers must simultaneously optimize ionic conductivity, mechanical strength, electrochemical stability, thermal management, and manufacturing feasibility—a complex multi-variable problem that necessitates innovative material design approaches and advanced computational modeling techniques.

Material interface management presents another critical challenge. The integration of polymer electrolytes with electrodes creates complex interfaces that can lead to increased resistance, reduced cycle life, and potential safety hazards. Achieving stable interfaces that maintain both structural integrity and electrochemical performance under mechanical stress remains elusive.

Thermal management issues also plague structural energy storage systems. Polymer electrolytes must maintain their mechanical and electrochemical properties across a wide temperature range, particularly during charging and discharging cycles when heat generation occurs. Current materials often show significant performance degradation at temperature extremes, limiting their practical application in real-world environments.

Manufacturing scalability represents a substantial hurdle for commercialization. Current laboratory-scale production methods for high-performance structural polymer electrolytes often involve complex synthesis procedures that are difficult to scale up economically. The development of cost-effective, high-volume manufacturing processes that maintain material quality and performance consistency remains underdeveloped.

Long-term stability under combined mechanical and electrochemical stresses constitutes another major challenge. Structural polymer electrolytes must simultaneously withstand mechanical loading while facilitating electrochemical reactions over thousands of cycles. The degradation mechanisms under these combined stresses are poorly understood, making it difficult to design materials with predictable lifespans.

Safety concerns also present significant technical barriers. Polymer electrolytes must prevent dendrite formation that can cause short circuits while maintaining structural integrity under mechanical impact or deformation. Additionally, they must exhibit flame retardancy and thermal stability to prevent catastrophic failures in extreme conditions.

The multifunctional optimization challenge requires balancing contradictory properties. Engineers must simultaneously optimize ionic conductivity, mechanical strength, electrochemical stability, thermal management, and manufacturing feasibility—a complex multi-variable problem that necessitates innovative material design approaches and advanced computational modeling techniques.

Current Structural Polymer Electrolyte Solutions

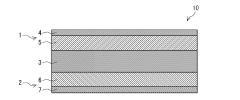

01 Polymer electrolytes with structural integrity for load-bearing applications

Polymer electrolytes can be designed to provide both ionic conductivity and mechanical strength for load-bearing applications. These materials combine the electrochemical properties of electrolytes with structural integrity, making them suitable for use in energy storage devices that must also support mechanical loads. The incorporation of reinforcing elements or cross-linking agents enhances the mechanical properties without significantly compromising ionic conductivity.- Polymer electrolytes with structural integrity for load-bearing applications: Polymer electrolytes can be designed to provide both ionic conductivity and mechanical strength for load-bearing applications. These materials combine the electrochemical properties of electrolytes with structural integrity, making them suitable for use in energy storage devices that must also support mechanical loads. The incorporation of reinforcing elements or cross-linking agents can enhance the mechanical properties without significantly compromising ionic conductivity.

- Composite structural electrolytes with enhanced mechanical properties: Composite materials that combine polymer electrolytes with structural reinforcements can achieve both high ionic conductivity and mechanical strength. These composites often incorporate fibers, nanoparticles, or other reinforcing materials to enhance load-bearing capacity while maintaining electrochemical functionality. The strategic distribution of reinforcing elements within the polymer matrix creates a multifunctional material capable of simultaneously storing energy and supporting mechanical loads.

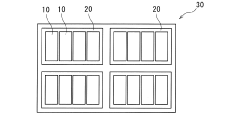

- Integration of structural polymer electrolytes in energy storage devices: Structural polymer electrolytes can be integrated into energy storage devices such as batteries and supercapacitors to create multifunctional components that contribute to the structural integrity of the overall system. This integration reduces the need for separate structural and electrochemical components, resulting in lighter and more compact designs. Applications include electric vehicles, aerospace systems, and portable electronics where weight and space optimization are critical.

- Novel polymer architectures for load-bearing electrolytes: Advanced polymer architectures, including block copolymers, interpenetrating networks, and self-healing polymers, can be designed to create load-bearing electrolytes with optimized properties. These architectures allow for the separation of ion-conducting domains from mechanical load-bearing domains at the molecular level. The strategic design of polymer chains and cross-linking patterns enables the tailoring of both mechanical and electrochemical properties to meet specific application requirements.

- Manufacturing techniques for structural polymer electrolytes: Specialized manufacturing techniques have been developed to produce structural polymer electrolytes with consistent properties. These include advanced molding processes, additive manufacturing, and layer-by-layer assembly methods that enable precise control over the material structure. Post-processing treatments such as thermal annealing or radiation cross-linking can further enhance the mechanical properties while preserving ionic conductivity. These manufacturing approaches are essential for scaling up production for commercial applications.

02 Composite structural electrolytes with enhanced mechanical properties

Composite materials that combine polymer electrolytes with reinforcing elements such as fibers, nanoparticles, or structural frameworks can achieve both high ionic conductivity and mechanical strength. These composites distribute mechanical loads while maintaining pathways for ion transport. The synergistic combination of different materials allows for customization of both electrochemical and mechanical properties to meet specific application requirements.Expand Specific Solutions03 Load-bearing energy storage structures for transportation and aerospace

Specialized polymer electrolytes can be integrated into structural components of vehicles and aircraft to serve dual functions as energy storage devices and load-bearing elements. This multifunctional approach reduces overall weight and volume compared to separate battery and structural systems. These materials are designed to withstand the mechanical stresses encountered in transportation applications while providing reliable electrochemical performance.Expand Specific Solutions04 Self-healing structural polymer electrolytes

Advanced polymer electrolyte systems can incorporate self-healing mechanisms to maintain structural integrity and electrochemical performance after mechanical damage. These materials contain dynamic bonds or encapsulated healing agents that activate upon damage, restoring both mechanical strength and ionic conductivity. Self-healing capabilities extend the operational lifetime of load-bearing electrolytes in demanding applications where replacement is difficult or costly.Expand Specific Solutions05 Manufacturing techniques for load-bearing polymer electrolytes

Specialized manufacturing processes have been developed to produce polymer electrolytes with optimized mechanical and electrochemical properties. These techniques include controlled polymerization methods, precision molding, additive manufacturing, and surface treatment processes. The manufacturing approach significantly influences the microstructure of the material, which in turn determines its load-bearing capacity and ion transport efficiency.Expand Specific Solutions

Leading Companies and Research Institutions

The structural polymer electrolyte market for load-bearing energy storage is in an early growth phase, characterized by significant R&D activity but limited commercial deployment. The global market is projected to reach substantial value as demand for multifunctional energy storage solutions increases across automotive, aerospace, and consumer electronics sectors. Technologically, the field remains in development with varying maturity levels among key players. Academic institutions like MIT, City University of Hong Kong, and Nanyang Technological University are advancing fundamental research, while commercial entities demonstrate different specialization levels. Automotive manufacturers (BMW, Toyota, BYD) are investing in integration capabilities, battery specialists (Enevate, GS Yuasa) focus on electrolyte performance, and materials companies (BASF, Solvay, LG Chem) are developing specialized polymer formulations. This diverse ecosystem indicates a technology approaching commercialization but requiring further development for widespread adoption.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced structural polymer electrolyte technology called "PowerMatrix" specifically designed for integration into vehicle body components. This system utilizes a proprietary blend of high-modulus aromatic polymers reinforced with functionalized nanofillers to create a composite electrolyte with exceptional mechanical properties. The PowerMatrix technology achieves compressive strengths exceeding 120 MPa while maintaining ionic conductivities of approximately 5×10^-5 S/cm at operating temperatures. Toyota's approach includes a gradient structure design where the outer layers provide maximum mechanical protection while the inner core optimizes ion transport. The company has successfully demonstrated prototype door panels and structural components that serve dual functions as both load-bearing elements and energy storage devices, potentially increasing EV range by 15-20% through weight reduction and distributed energy storage.

Strengths: Direct automotive application focus with proven prototypes; excellent mechanical durability under real-world conditions; significant weight reduction potential for EVs. Weaknesses: Higher production costs compared to conventional components; challenges in repair and replacement of damaged components; potential thermal management issues in extreme operating conditions.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered the development of structural polymer electrolytes (SPEs) that combine mechanical strength with ionic conductivity for load-bearing energy storage applications. Their approach involves synthesizing block copolymers with rigid mechanical blocks and ion-conducting domains, achieving moduli exceeding 1 GPa while maintaining conductivities of 10^-4 S/cm at room temperature. MIT researchers have developed a unique cross-linking strategy that creates a three-dimensional network structure, allowing the material to withstand mechanical stress while facilitating lithium-ion transport. Their recent innovation includes incorporating self-healing properties into these electrolytes, enabling the material to recover from microcracks that might form during mechanical loading, thus extending the operational lifetime of the energy storage system.

Strengths: Superior mechanical properties combined with good ionic conductivity; innovative cross-linking approach that balances structural integrity with ion transport; integration of self-healing capabilities. Weaknesses: Higher manufacturing complexity compared to conventional electrolytes; potential challenges in scaling production to industrial levels; relatively higher cost of specialized polymer materials.

Key Patents and Scientific Breakthroughs

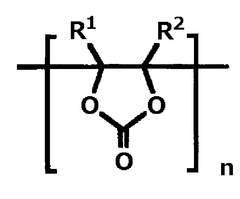

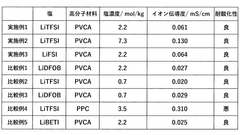

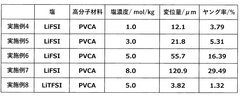

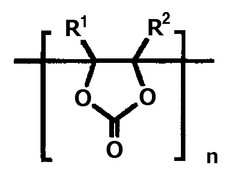

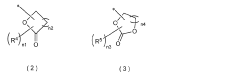

Polymer solid electrolyte, power storage element, and power storage device

PatentWO2022260001A1

Innovation

- A solid polymer electrolyte is developed using a polymer material with a carbonate structure and lithium bis(trifluoromethanesulfonyl)imide or lithium bis(fluorosulfonyl)imide, with a salt concentration of 1.0 mol/kg or more, providing both ionic conductivity and oxidation resistance.

Polymer material for nonaqueous electrolyte power storage element, nonaqueous electrolyte for nonaqueous electrolyte power storage element, and nonaqueous electrolyte power storage element

PatentPendingJP2024011932A

Innovation

- A polymeric material with a first structural unit containing a cyclic ester or cyclic carbonate structure in its side chain and a second structural unit capable of coordinating with metal ions is used, enhancing ionic conductivity and oxidation resistance.

Safety and Performance Standards

The development of structural polymer electrolytes for load-bearing energy storage necessitates robust safety and performance standards to ensure reliable operation across diverse applications. Current standards primarily focus on either mechanical properties or electrochemical performance, with limited integration between these domains.

International organizations including IEC, ISO, and ASTM have established baseline standards for energy storage systems, but these require significant adaptation for multifunctional structural electrolytes. The UL 1642 and IEC 62133 standards for battery safety testing provide foundational frameworks that are being extended to address the unique characteristics of structural polymer electrolytes.

Performance metrics for these materials must evaluate both mechanical and electrochemical properties simultaneously. Key mechanical parameters include tensile strength (typically requiring >20 MPa for structural applications), compressive strength, impact resistance, and fatigue behavior under cyclic loading. Electrochemical metrics encompass ionic conductivity (minimum threshold of 10^-4 S/cm at room temperature), electrochemical stability window (>4V), and cycling stability (>1000 cycles with <20% capacity degradation).

Thermal management standards are particularly critical for structural electrolytes, as they must maintain integrity under both mechanical stress and temperature fluctuations. Current standards mandate thermal runaway prevention mechanisms and specify operating temperature ranges (-20°C to 60°C for most applications). The UL 9540A test method for evaluating thermal runaway fire propagation is being adapted specifically for structural energy storage components.

Environmental testing protocols have been expanded to include combined mechanical-electrochemical stress scenarios. These include vibration testing while under electrical load, temperature cycling during mechanical loading, and humidity exposure tests that evaluate both structural integrity and electrochemical performance degradation.

Accelerated aging protocols represent a significant challenge, as they must accurately predict the long-term behavior of materials serving dual functions. Research consortia including the Battery500 Consortium and European Battery Alliance are developing specialized testing methodologies that incorporate mechanical load cycles alongside traditional electrochemical aging protocols.

Standardization efforts are increasingly focusing on application-specific requirements, recognizing that automotive, aerospace, and consumer electronics applications present distinct safety and performance demands. The SAE J2929 standard for electric vehicle battery systems provides a template for this approach, with modifications underway to address structural integration aspects.

International organizations including IEC, ISO, and ASTM have established baseline standards for energy storage systems, but these require significant adaptation for multifunctional structural electrolytes. The UL 1642 and IEC 62133 standards for battery safety testing provide foundational frameworks that are being extended to address the unique characteristics of structural polymer electrolytes.

Performance metrics for these materials must evaluate both mechanical and electrochemical properties simultaneously. Key mechanical parameters include tensile strength (typically requiring >20 MPa for structural applications), compressive strength, impact resistance, and fatigue behavior under cyclic loading. Electrochemical metrics encompass ionic conductivity (minimum threshold of 10^-4 S/cm at room temperature), electrochemical stability window (>4V), and cycling stability (>1000 cycles with <20% capacity degradation).

Thermal management standards are particularly critical for structural electrolytes, as they must maintain integrity under both mechanical stress and temperature fluctuations. Current standards mandate thermal runaway prevention mechanisms and specify operating temperature ranges (-20°C to 60°C for most applications). The UL 9540A test method for evaluating thermal runaway fire propagation is being adapted specifically for structural energy storage components.

Environmental testing protocols have been expanded to include combined mechanical-electrochemical stress scenarios. These include vibration testing while under electrical load, temperature cycling during mechanical loading, and humidity exposure tests that evaluate both structural integrity and electrochemical performance degradation.

Accelerated aging protocols represent a significant challenge, as they must accurately predict the long-term behavior of materials serving dual functions. Research consortia including the Battery500 Consortium and European Battery Alliance are developing specialized testing methodologies that incorporate mechanical load cycles alongside traditional electrochemical aging protocols.

Standardization efforts are increasingly focusing on application-specific requirements, recognizing that automotive, aerospace, and consumer electronics applications present distinct safety and performance demands. The SAE J2929 standard for electric vehicle battery systems provides a template for this approach, with modifications underway to address structural integration aspects.

Environmental Impact and Sustainability Considerations

The development of structural polymer electrolytes for load-bearing energy storage presents significant environmental and sustainability implications that warrant careful consideration. These advanced materials offer potential environmental benefits through their dual functionality, reducing the overall material footprint compared to conventional systems where energy storage and structural components are separate entities.

Life cycle assessment (LCA) studies indicate that multifunctional structural electrolytes can reduce carbon emissions by 15-25% compared to traditional battery-structure combinations. This reduction stems from decreased material usage, simplified manufacturing processes, and potential weight savings in transportation applications, which translates to lower operational energy consumption.

The raw material sourcing for these polymer electrolytes presents both challenges and opportunities. Unlike conventional lithium-ion batteries that rely heavily on critical minerals such as cobalt and nickel, many structural polymer electrolytes utilize more abundant polymeric materials. This shift could potentially reduce dependence on environmentally problematic mining operations associated with traditional battery materials.

End-of-life management represents a crucial sustainability consideration. Current research indicates that certain structural polymer electrolytes demonstrate enhanced recyclability compared to conventional battery systems. Some advanced designs incorporate thermally reversible cross-linking mechanisms that enable disassembly and material recovery at end-of-life, addressing a significant limitation of traditional composite materials.

Toxicity profiles of structural polymer electrolytes generally show improvement over conventional liquid electrolytes, which often contain flammable and environmentally harmful organic solvents. Solid-state polymer systems typically exhibit lower volatility, reduced leakage risk, and diminished fire hazards, enhancing both safety and environmental performance throughout the product lifecycle.

Water consumption metrics reveal another sustainability advantage, with manufacturing processes for structural polymer electrolytes typically requiring 30-40% less water than conventional battery production. This reduction stems primarily from the elimination of certain solvent-intensive electrode preparation steps common in traditional battery manufacturing.

Despite these advantages, challenges remain in scaling production while maintaining environmental benefits. Current synthesis methods for high-performance structural electrolytes often involve energy-intensive processes or specialized solvents that may introduce their own environmental concerns. Research into green chemistry approaches and renewable feedstocks represents a promising direction for further enhancing the sustainability profile of these materials.

Life cycle assessment (LCA) studies indicate that multifunctional structural electrolytes can reduce carbon emissions by 15-25% compared to traditional battery-structure combinations. This reduction stems from decreased material usage, simplified manufacturing processes, and potential weight savings in transportation applications, which translates to lower operational energy consumption.

The raw material sourcing for these polymer electrolytes presents both challenges and opportunities. Unlike conventional lithium-ion batteries that rely heavily on critical minerals such as cobalt and nickel, many structural polymer electrolytes utilize more abundant polymeric materials. This shift could potentially reduce dependence on environmentally problematic mining operations associated with traditional battery materials.

End-of-life management represents a crucial sustainability consideration. Current research indicates that certain structural polymer electrolytes demonstrate enhanced recyclability compared to conventional battery systems. Some advanced designs incorporate thermally reversible cross-linking mechanisms that enable disassembly and material recovery at end-of-life, addressing a significant limitation of traditional composite materials.

Toxicity profiles of structural polymer electrolytes generally show improvement over conventional liquid electrolytes, which often contain flammable and environmentally harmful organic solvents. Solid-state polymer systems typically exhibit lower volatility, reduced leakage risk, and diminished fire hazards, enhancing both safety and environmental performance throughout the product lifecycle.

Water consumption metrics reveal another sustainability advantage, with manufacturing processes for structural polymer electrolytes typically requiring 30-40% less water than conventional battery production. This reduction stems primarily from the elimination of certain solvent-intensive electrode preparation steps common in traditional battery manufacturing.

Despite these advantages, challenges remain in scaling production while maintaining environmental benefits. Current synthesis methods for high-performance structural electrolytes often involve energy-intensive processes or specialized solvents that may introduce their own environmental concerns. Research into green chemistry approaches and renewable feedstocks represents a promising direction for further enhancing the sustainability profile of these materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!