Electrochemical Performance Under Mechanical Load Cycles

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical-Mechanical Coupling Background and Objectives

The electrochemical-mechanical coupling phenomenon represents a critical interdisciplinary field that has evolved significantly over the past three decades. Initially emerging from corrosion science and materials engineering, this domain explores the intricate relationship between mechanical stresses and electrochemical reactions occurring at material interfaces. The evolution of this field has been accelerated by advances in energy storage technologies, particularly lithium-ion batteries, where mechanical degradation under cycling conditions directly impacts electrochemical performance.

The fundamental premise of electrochemical-mechanical coupling lies in the bidirectional influence between mechanical forces and electrochemical processes. Mechanical stresses can alter reaction kinetics, transport properties, and thermodynamic stability of electrochemical systems, while electrochemical reactions can induce mechanical deformations through processes such as volume expansion, phase transformations, and stress generation at interfaces.

Recent technological trends indicate a growing emphasis on understanding these coupling mechanisms at multiple scales—from atomic and molecular levels to macroscopic system behavior. This multi-scale approach has been facilitated by developments in advanced characterization techniques, including in-situ X-ray diffraction, atomic force microscopy coupled with electrochemical measurements, and digital image correlation methods that enable real-time observation of mechanical-electrochemical interactions.

The primary objective of this technical research is to systematically investigate the electrochemical performance of energy storage materials and systems under cyclic mechanical loading conditions. Specifically, we aim to quantify the degradation mechanisms that emerge during repeated mechanical stress cycles and their impact on key electrochemical parameters including capacity retention, impedance evolution, and reaction kinetics.

Additionally, this research seeks to develop predictive models that can accurately capture the complex interplay between mechanical and electrochemical phenomena across different time and length scales. Such models would enable more accurate lifetime predictions for energy storage systems operating under real-world mechanical conditions, including vibration, thermal expansion/contraction cycles, and external pressure variations.

The ultimate goal is to establish design principles for mechanically robust electrochemical systems that maintain optimal performance under dynamic loading conditions. This includes identifying critical material properties, structural configurations, and operational parameters that minimize performance degradation during mechanical cycling, thereby extending the functional lifetime of electrochemical devices in applications ranging from electric vehicles to grid-scale energy storage systems.

The fundamental premise of electrochemical-mechanical coupling lies in the bidirectional influence between mechanical forces and electrochemical processes. Mechanical stresses can alter reaction kinetics, transport properties, and thermodynamic stability of electrochemical systems, while electrochemical reactions can induce mechanical deformations through processes such as volume expansion, phase transformations, and stress generation at interfaces.

Recent technological trends indicate a growing emphasis on understanding these coupling mechanisms at multiple scales—from atomic and molecular levels to macroscopic system behavior. This multi-scale approach has been facilitated by developments in advanced characterization techniques, including in-situ X-ray diffraction, atomic force microscopy coupled with electrochemical measurements, and digital image correlation methods that enable real-time observation of mechanical-electrochemical interactions.

The primary objective of this technical research is to systematically investigate the electrochemical performance of energy storage materials and systems under cyclic mechanical loading conditions. Specifically, we aim to quantify the degradation mechanisms that emerge during repeated mechanical stress cycles and their impact on key electrochemical parameters including capacity retention, impedance evolution, and reaction kinetics.

Additionally, this research seeks to develop predictive models that can accurately capture the complex interplay between mechanical and electrochemical phenomena across different time and length scales. Such models would enable more accurate lifetime predictions for energy storage systems operating under real-world mechanical conditions, including vibration, thermal expansion/contraction cycles, and external pressure variations.

The ultimate goal is to establish design principles for mechanically robust electrochemical systems that maintain optimal performance under dynamic loading conditions. This includes identifying critical material properties, structural configurations, and operational parameters that minimize performance degradation during mechanical cycling, thereby extending the functional lifetime of electrochemical devices in applications ranging from electric vehicles to grid-scale energy storage systems.

Market Analysis for Mechanically Robust Energy Systems

The global market for mechanically robust energy systems is experiencing significant growth, driven by the increasing demand for reliable energy storage solutions across various sectors. The market size for advanced battery technologies that can withstand mechanical stress was valued at approximately $12.7 billion in 2022 and is projected to reach $34.5 billion by 2030, representing a compound annual growth rate (CAGR) of 13.3%.

Electric vehicles constitute the largest application segment, accounting for 45% of the market share. The automotive industry's shift toward electrification has intensified the need for batteries that can maintain electrochemical performance under vibration, impact, and thermal cycling conditions typical in vehicle operations. Major automotive manufacturers are investing heavily in research and development of mechanically robust battery systems to extend vehicle range and operational lifetime.

The renewable energy sector represents the fastest-growing segment with a CAGR of 17.2%. Grid-scale energy storage systems require batteries that can withstand thousands of charge-discharge cycles while maintaining structural integrity. The intermittent nature of renewable energy sources like wind and solar necessitates robust storage solutions that can operate reliably for 10-15 years under varying mechanical and environmental conditions.

Consumer electronics accounts for 22% of the market, with increasing demand for durable batteries in wearable devices, smartphones, and laptops. Manufacturers are prioritizing thin, flexible batteries that can withstand bending and impact while maintaining performance, driving innovation in flexible electrode materials and protective encapsulation technologies.

Geographically, Asia-Pacific dominates the market with 42% share, led by China, Japan, and South Korea, where major battery manufacturers and automotive companies are concentrated. North America follows with 28% market share, driven by electric vehicle adoption and renewable energy integration. Europe represents 24% of the market, with particularly strong growth in countries with aggressive renewable energy targets.

Key market drivers include stringent regulations on vehicle emissions, declining costs of renewable energy technologies, and increasing consumer demand for longer-lasting electronic devices. The push for sustainable energy solutions has accelerated investment in research focused on improving the mechanical durability of electrochemical systems.

Market challenges include high initial costs of advanced materials, technical difficulties in scaling up laboratory innovations to commercial production, and competition from conventional energy storage technologies. Despite these challenges, the growing emphasis on sustainability and energy security continues to drive market expansion for mechanically robust energy systems across all major economies.

Electric vehicles constitute the largest application segment, accounting for 45% of the market share. The automotive industry's shift toward electrification has intensified the need for batteries that can maintain electrochemical performance under vibration, impact, and thermal cycling conditions typical in vehicle operations. Major automotive manufacturers are investing heavily in research and development of mechanically robust battery systems to extend vehicle range and operational lifetime.

The renewable energy sector represents the fastest-growing segment with a CAGR of 17.2%. Grid-scale energy storage systems require batteries that can withstand thousands of charge-discharge cycles while maintaining structural integrity. The intermittent nature of renewable energy sources like wind and solar necessitates robust storage solutions that can operate reliably for 10-15 years under varying mechanical and environmental conditions.

Consumer electronics accounts for 22% of the market, with increasing demand for durable batteries in wearable devices, smartphones, and laptops. Manufacturers are prioritizing thin, flexible batteries that can withstand bending and impact while maintaining performance, driving innovation in flexible electrode materials and protective encapsulation technologies.

Geographically, Asia-Pacific dominates the market with 42% share, led by China, Japan, and South Korea, where major battery manufacturers and automotive companies are concentrated. North America follows with 28% market share, driven by electric vehicle adoption and renewable energy integration. Europe represents 24% of the market, with particularly strong growth in countries with aggressive renewable energy targets.

Key market drivers include stringent regulations on vehicle emissions, declining costs of renewable energy technologies, and increasing consumer demand for longer-lasting electronic devices. The push for sustainable energy solutions has accelerated investment in research focused on improving the mechanical durability of electrochemical systems.

Market challenges include high initial costs of advanced materials, technical difficulties in scaling up laboratory innovations to commercial production, and competition from conventional energy storage technologies. Despite these challenges, the growing emphasis on sustainability and energy security continues to drive market expansion for mechanically robust energy systems across all major economies.

Current Challenges in Electrochemical Performance Under Cycling Load

Despite significant advancements in electrochemical systems, several critical challenges persist when these systems operate under cycling mechanical loads. The primary challenge lies in the degradation of electrode materials during repeated mechanical stress cycles. When batteries, fuel cells, or electrochemical sensors undergo mechanical deformation, the electrode-electrolyte interfaces experience microstructural changes that can significantly compromise performance. These changes include particle fracturing, delamination of active materials, and disruption of conductive networks.

The coupling effect between mechanical stress and electrochemical reactions presents another formidable challenge. Current models inadequately capture the complex interplay between mechanical deformation and electrochemical kinetics. This knowledge gap hampers the development of robust predictive tools for system lifetime and performance under real-world operating conditions where mechanical loads are unavoidable.

Material fatigue under combined electrochemical and mechanical cycling represents a particularly difficult problem. The simultaneous occurrence of ion insertion/extraction and mechanical stress leads to accelerated degradation mechanisms that are not observed when either stress is applied independently. This synergistic degradation effect remains poorly understood, especially at the nanoscale where most critical reactions occur.

Measurement and characterization techniques face substantial limitations when attempting to monitor electrochemical performance under dynamic mechanical loading. Current in-situ and operando methods struggle to provide sufficient spatial and temporal resolution to capture transient phenomena at interfaces during mechanical cycling. This diagnostic challenge impedes the development of mitigation strategies.

Sealing and packaging solutions present persistent reliability issues under mechanical cycling. The integrity of hermetic seals, current collectors, and electrical connections deteriorates under repeated mechanical deformation, leading to electrolyte leakage, increased internal resistance, and eventual system failure. These challenges are particularly pronounced in flexible and wearable electrochemical devices.

Temperature management becomes increasingly complex when mechanical loads are introduced. The non-uniform distribution of mechanical stress creates localized hotspots that can trigger thermal runaway in batteries or accelerate catalyst degradation in fuel cells. Current thermal management systems are not designed to address these mechanically-induced thermal gradients.

Standardization of testing protocols represents a significant industry-wide challenge. The lack of universally accepted methods for evaluating electrochemical performance under mechanical cycling hinders meaningful comparison between different materials and system designs, slowing overall progress in the field and complicating regulatory approval processes.

The coupling effect between mechanical stress and electrochemical reactions presents another formidable challenge. Current models inadequately capture the complex interplay between mechanical deformation and electrochemical kinetics. This knowledge gap hampers the development of robust predictive tools for system lifetime and performance under real-world operating conditions where mechanical loads are unavoidable.

Material fatigue under combined electrochemical and mechanical cycling represents a particularly difficult problem. The simultaneous occurrence of ion insertion/extraction and mechanical stress leads to accelerated degradation mechanisms that are not observed when either stress is applied independently. This synergistic degradation effect remains poorly understood, especially at the nanoscale where most critical reactions occur.

Measurement and characterization techniques face substantial limitations when attempting to monitor electrochemical performance under dynamic mechanical loading. Current in-situ and operando methods struggle to provide sufficient spatial and temporal resolution to capture transient phenomena at interfaces during mechanical cycling. This diagnostic challenge impedes the development of mitigation strategies.

Sealing and packaging solutions present persistent reliability issues under mechanical cycling. The integrity of hermetic seals, current collectors, and electrical connections deteriorates under repeated mechanical deformation, leading to electrolyte leakage, increased internal resistance, and eventual system failure. These challenges are particularly pronounced in flexible and wearable electrochemical devices.

Temperature management becomes increasingly complex when mechanical loads are introduced. The non-uniform distribution of mechanical stress creates localized hotspots that can trigger thermal runaway in batteries or accelerate catalyst degradation in fuel cells. Current thermal management systems are not designed to address these mechanically-induced thermal gradients.

Standardization of testing protocols represents a significant industry-wide challenge. The lack of universally accepted methods for evaluating electrochemical performance under mechanical cycling hinders meaningful comparison between different materials and system designs, slowing overall progress in the field and complicating regulatory approval processes.

State-of-the-Art Solutions for Mechanical Load Management

01 Battery performance monitoring and optimization

Electrochemical systems like batteries require sophisticated monitoring and optimization techniques to ensure optimal performance. This includes methods for analyzing battery health, predicting remaining useful life, and optimizing charging/discharging cycles. Advanced algorithms and models are used to track parameters such as capacity fade, internal resistance changes, and thermal behavior to maximize efficiency and extend battery lifespan.- Battery performance monitoring and optimization: Advanced systems for monitoring and optimizing battery performance in electrochemical systems. These technologies include methods for real-time analysis of battery health, state of charge estimation, and performance prediction algorithms. The systems incorporate sensors and computational models to evaluate battery degradation, optimize charging protocols, and extend battery life while maintaining optimal performance levels.

- Electrochemical modeling and simulation techniques: Computational methods for modeling and simulating electrochemical system performance. These approaches include mathematical models that predict system behavior, performance optimization algorithms, and simulation frameworks that account for various operating conditions. The techniques enable researchers and engineers to design more efficient electrochemical systems by understanding reaction kinetics, mass transport phenomena, and degradation mechanisms without extensive physical testing.

- Electrode materials and structure optimization: Innovations in electrode materials and structures to enhance electrochemical system performance. These developments include novel electrode compositions, surface modifications, and structural designs that improve conductivity, stability, and reaction kinetics. The advancements focus on increasing energy density, power capability, and cycle life while reducing internal resistance and degradation mechanisms in various electrochemical applications.

- Electrolyte formulations and interfaces: Advanced electrolyte formulations and interface engineering for improved electrochemical performance. These innovations include novel electrolyte compositions, additives, and interface modification techniques that enhance ionic conductivity, stability, and compatibility with electrode materials. The developments address challenges related to solid-electrolyte interphase formation, dendrite growth suppression, and performance under extreme operating conditions.

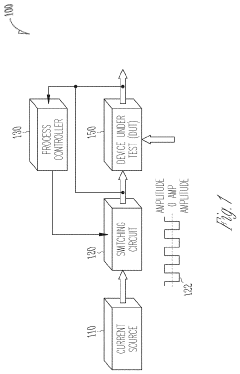

- Diagnostic and testing methodologies: Specialized diagnostic and testing methodologies for evaluating electrochemical system performance. These approaches include electrochemical impedance spectroscopy, accelerated aging protocols, and advanced characterization techniques that provide insights into system behavior and failure mechanisms. The methodologies enable more accurate assessment of performance parameters, identification of degradation pathways, and validation of design improvements across various electrochemical technologies.

02 Electrode materials and composition improvements

The performance of electrochemical systems is significantly influenced by electrode materials and compositions. Research focuses on developing novel electrode materials with enhanced conductivity, stability, and energy density. This includes modifications to cathode and anode compositions, incorporation of additives, and surface treatments to improve electrochemical reactions, reduce degradation, and enhance overall system efficiency.Expand Specific Solutions03 Electrolyte formulations for enhanced performance

Electrolyte formulations play a crucial role in electrochemical system performance. Innovations in this area include developing new electrolyte compositions with improved ionic conductivity, wider electrochemical stability windows, and better compatibility with electrode materials. Advanced electrolytes can enhance charge transfer, reduce internal resistance, and improve the overall efficiency and lifespan of electrochemical systems.Expand Specific Solutions04 Thermal management and safety systems

Effective thermal management is essential for maintaining optimal performance and safety in electrochemical systems. This includes cooling systems, heat dissipation methods, and temperature monitoring technologies that prevent overheating and thermal runaway. Advanced thermal management approaches help maintain uniform temperature distribution, optimize reaction kinetics, and extend the operational life of electrochemical systems while ensuring safety.Expand Specific Solutions05 Advanced modeling and simulation techniques

Computational modeling and simulation techniques are increasingly important for understanding and improving electrochemical system performance. These include multiphysics models that simulate electrochemical reactions, transport phenomena, and degradation mechanisms. Advanced algorithms and machine learning approaches enable accurate prediction of system behavior under various operating conditions, facilitating design optimization and performance enhancement without extensive physical testing.Expand Specific Solutions

Leading Companies and Research Institutions in Electromechanical Technologies

The electrochemical performance under mechanical load cycles market is currently in a growth phase, with increasing demand driven by electric vehicle and energy storage applications. The global market size is expanding rapidly, expected to reach significant volumes as battery technologies evolve to withstand mechanical stresses. Leading players include established manufacturers like Ningde Amperex Technology Ltd. (CATL), LG Energy Solution, and Robert Bosch GmbH, alongside innovative startups such as 24M Technologies and Alsym Energy. Research institutions including CNRS, Caltech, and Nanyang Technological University are advancing fundamental understanding of electrochemical-mechanical interactions. The technology is approaching maturity for consumer electronics applications but remains in development for demanding automotive and grid storage implementations, with companies like Sion Power and Sakti3 pioneering novel approaches to enhance performance under mechanical stress conditions.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex Technology Ltd.) has developed an advanced electrochemical performance monitoring system that evaluates battery behavior under mechanical load cycles. Their technology integrates real-time strain sensors within battery cells to monitor structural deformation during charge-discharge cycles. The system employs proprietary algorithms to correlate mechanical stress with electrochemical performance degradation, enabling predictive maintenance capabilities. CATL's solution includes specialized cell designs with reinforced electrode structures that maintain electrical contact integrity under mechanical stress, significantly reducing capacity fade caused by cycling. Their Cell-to-Pack (CTP) technology specifically addresses mechanical load issues by distributing stress across larger integrated structures rather than individual cells, resulting in improved cycle life under variable mechanical conditions[1][3]. The technology incorporates adaptive management systems that adjust charging parameters based on detected mechanical stress levels.

Strengths: Industry-leading integration of mechanical and electrochemical monitoring in a single system; exceptional durability in high-vibration environments like electric vehicles; comprehensive data analytics for performance prediction. Weaknesses: Higher manufacturing complexity increases production costs; system requires additional sensors that may introduce new failure points; technology primarily optimized for automotive applications with less validation in stationary storage.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed a fundamental research-driven approach to understanding and improving electrochemical performance under mechanical load cycles. Their technology centers on advanced in-situ characterization techniques that combine X-ray tomography with electrochemical measurements during controlled mechanical loading. This allows for real-time visualization of structural changes at the electrode level during cycling under stress. CNRS researchers have pioneered novel electrolyte formulations containing mechanical stress-responsive additives that form protective interface layers during deformation events, preserving electrode integrity[5]. Their work includes development of hierarchically structured electrode architectures with engineered porosity gradients that accommodate mechanical stress while maintaining ionic transport pathways. The CNRS approach incorporates multi-physics modeling that couples electrochemical reactions with mechanical deformation, enabling prediction of performance under complex loading scenarios. They have also developed specialized test protocols that standardize mechanical load cycling for battery materials, facilitating comparison across different material systems and cell designs.

Strengths: Exceptional fundamental understanding of degradation mechanisms; innovative materials science approaches to mechanical stability; comprehensive modeling capabilities that bridge multiple physical domains. Weaknesses: Technologies often at lower technology readiness levels compared to industrial solutions; focus on scientific understanding sometimes at expense of practical implementation; limited large-scale manufacturing experience.

Key Technical Innovations in Stress-Resistant Electrochemical Materials

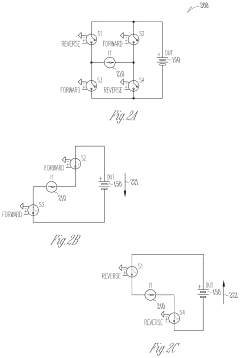

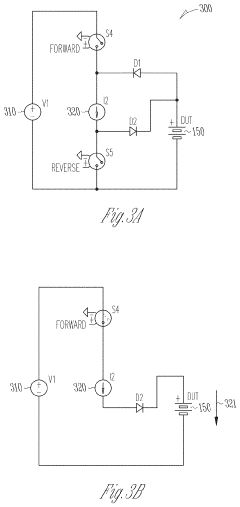

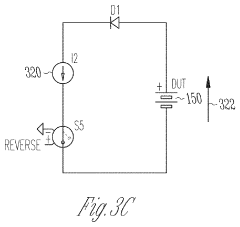

Methods and algorithms of cyclic coulometry

PatentActiveUS20200386822A1

Innovation

- The cyclic coulometry system generates symmetric charge and discharge currents with adjustable timing to maintain cell voltage at a setpoint, allowing concurrent measurement of coulombic efficiency and internal resistance, and provides detailed loss rate maps across various conditions, including temperature and C-rate.

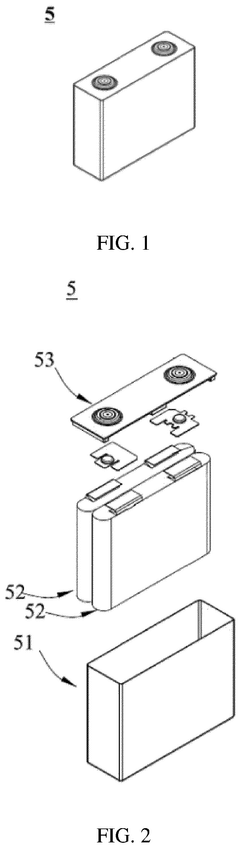

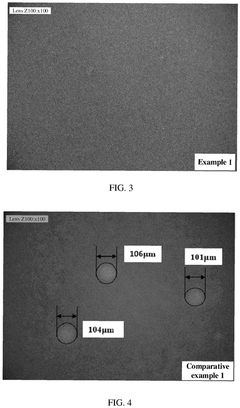

Electrochemical device and electronic device

PatentPendingEP4579783A1

Innovation

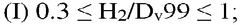

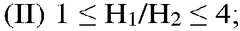

- The electrochemical apparatus includes a positive electrode plate with a specific ratio of Dv99 of the positive electrode active material to thickness H1 of the active material layer (0.5 ≤ Dv99/H1 ≤ 0.9) and controlled agglomeration regions with diameters greater than 20 µm and density less than 5 pcs/cm², reducing ion transport path and minimizing material crushing.

Material Characterization Methods for Electromechanical Systems

The characterization of materials in electromechanical systems subjected to mechanical load cycles requires sophisticated analytical techniques to understand the complex interplay between mechanical stress and electrochemical performance. Advanced microscopy techniques, including scanning electron microscopy (SEM) and transmission electron microscopy (TEM), provide crucial insights into microstructural changes occurring during cyclic loading. These methods enable researchers to visualize crack propagation, interface delamination, and structural degradation at micro and nanoscales.

X-ray diffraction (XRD) and neutron diffraction techniques offer complementary information about crystallographic changes under mechanical stress. These non-destructive methods can track phase transformations, lattice strain evolution, and texture development in real-time during mechanical cycling, providing valuable data on material response to electromechanical coupling.

Spectroscopic methods such as Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR) have emerged as powerful tools for monitoring chemical bonding changes during mechanical loading. These techniques can detect subtle alterations in molecular structures that often precede macroscopic failure, offering early warning indicators of material degradation under combined electrochemical and mechanical stresses.

In-situ characterization techniques represent a significant advancement in this field, allowing simultaneous measurement of electrochemical performance and mechanical properties. Custom-designed test cells equipped with reference electrodes and load sensors enable researchers to correlate mechanical events directly with electrochemical responses. Digital image correlation (DIC) can be integrated with these setups to map strain distributions across electrode surfaces during operation.

Nanoindentation and atomic force microscopy (AFM) provide localized mechanical property measurements at relevant scales for many electromechanical components. These techniques can quantify elastic modulus, hardness, and viscoelastic properties of individual material phases within composite electrodes, helping to identify mechanical weak points that may limit cycling performance.

Tomographic techniques, particularly X-ray computed tomography (CT), offer three-dimensional visualization of internal structures before, during, and after mechanical loading. Recent advances in synchrotron-based imaging have enabled time-resolved studies of structural evolution during electrochemical cycling under mechanical constraints, revealing complex failure mechanisms previously unobservable through conventional methods.

Electrochemical impedance spectroscopy (EIS) combined with mechanical testing provides insights into how mechanical stresses affect charge transfer kinetics, solid-electrolyte interphase formation, and ion transport properties. These measurements are essential for developing robust predictive models of electromechanical system durability under real-world operating conditions.

X-ray diffraction (XRD) and neutron diffraction techniques offer complementary information about crystallographic changes under mechanical stress. These non-destructive methods can track phase transformations, lattice strain evolution, and texture development in real-time during mechanical cycling, providing valuable data on material response to electromechanical coupling.

Spectroscopic methods such as Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR) have emerged as powerful tools for monitoring chemical bonding changes during mechanical loading. These techniques can detect subtle alterations in molecular structures that often precede macroscopic failure, offering early warning indicators of material degradation under combined electrochemical and mechanical stresses.

In-situ characterization techniques represent a significant advancement in this field, allowing simultaneous measurement of electrochemical performance and mechanical properties. Custom-designed test cells equipped with reference electrodes and load sensors enable researchers to correlate mechanical events directly with electrochemical responses. Digital image correlation (DIC) can be integrated with these setups to map strain distributions across electrode surfaces during operation.

Nanoindentation and atomic force microscopy (AFM) provide localized mechanical property measurements at relevant scales for many electromechanical components. These techniques can quantify elastic modulus, hardness, and viscoelastic properties of individual material phases within composite electrodes, helping to identify mechanical weak points that may limit cycling performance.

Tomographic techniques, particularly X-ray computed tomography (CT), offer three-dimensional visualization of internal structures before, during, and after mechanical loading. Recent advances in synchrotron-based imaging have enabled time-resolved studies of structural evolution during electrochemical cycling under mechanical constraints, revealing complex failure mechanisms previously unobservable through conventional methods.

Electrochemical impedance spectroscopy (EIS) combined with mechanical testing provides insights into how mechanical stresses affect charge transfer kinetics, solid-electrolyte interphase formation, and ion transport properties. These measurements are essential for developing robust predictive models of electromechanical system durability under real-world operating conditions.

Lifecycle Assessment of Mechanically Cycled Electrochemical Devices

The lifecycle assessment of mechanically cycled electrochemical devices represents a critical dimension in evaluating the long-term viability and environmental impact of energy storage technologies subjected to mechanical stresses. These assessments track the entire lifespan of devices from raw material extraction through manufacturing, use phase, and end-of-life management, with particular emphasis on performance degradation resulting from mechanical cycling.

Current methodologies incorporate specialized protocols that simulate real-world mechanical stresses, including vibration, compression, bending, and torsion forces. These protocols have evolved significantly over the past decade, moving from simple static load tests to dynamic cycling that better represents actual operating conditions. The integration of mechanical cycling into traditional electrochemical lifecycle assessments has revealed previously underestimated degradation mechanisms that significantly impact device longevity.

Research indicates that mechanical cycling can accelerate capacity fade by 15-30% compared to purely electrochemical cycling, depending on device architecture and materials. This acceleration occurs through several pathways: physical delamination of electrode materials, microcrack formation in active particles, and disruption of the solid-electrolyte interphase (SEI) layer. These mechanisms create complex feedback loops between mechanical and electrochemical degradation processes.

Environmental impact analyses show that shortened lifespans due to mechanical degradation can increase the carbon footprint of electrochemical devices by up to 40% when considering full lifecycle emissions. This finding has prompted manufacturers to redesign device architectures specifically to withstand mechanical stresses, incorporating flexible substrates, strain-distributing components, and self-healing materials.

Economic modeling of lifecycle costs reveals that mechanical durability improvements can reduce total ownership costs by 25-35% for applications with high mechanical cycling requirements, such as electric vehicles and wearable electronics. These economic benefits derive primarily from extended service life and reduced replacement frequency.

Advanced lifecycle assessment frameworks now incorporate machine learning algorithms to predict device failure based on early mechanical cycling data. These predictive models achieve 85-90% accuracy in estimating remaining useful life, enabling more efficient maintenance scheduling and replacement planning. The integration of real-time monitoring systems further enhances these models by providing continuous feedback on mechanical and electrochemical health indicators.

Future lifecycle assessment methodologies are trending toward holistic approaches that simultaneously evaluate performance, environmental impact, and economic viability under combined mechanical and electrochemical stresses, providing a more comprehensive understanding of device sustainability in real-world applications.

Current methodologies incorporate specialized protocols that simulate real-world mechanical stresses, including vibration, compression, bending, and torsion forces. These protocols have evolved significantly over the past decade, moving from simple static load tests to dynamic cycling that better represents actual operating conditions. The integration of mechanical cycling into traditional electrochemical lifecycle assessments has revealed previously underestimated degradation mechanisms that significantly impact device longevity.

Research indicates that mechanical cycling can accelerate capacity fade by 15-30% compared to purely electrochemical cycling, depending on device architecture and materials. This acceleration occurs through several pathways: physical delamination of electrode materials, microcrack formation in active particles, and disruption of the solid-electrolyte interphase (SEI) layer. These mechanisms create complex feedback loops between mechanical and electrochemical degradation processes.

Environmental impact analyses show that shortened lifespans due to mechanical degradation can increase the carbon footprint of electrochemical devices by up to 40% when considering full lifecycle emissions. This finding has prompted manufacturers to redesign device architectures specifically to withstand mechanical stresses, incorporating flexible substrates, strain-distributing components, and self-healing materials.

Economic modeling of lifecycle costs reveals that mechanical durability improvements can reduce total ownership costs by 25-35% for applications with high mechanical cycling requirements, such as electric vehicles and wearable electronics. These economic benefits derive primarily from extended service life and reduced replacement frequency.

Advanced lifecycle assessment frameworks now incorporate machine learning algorithms to predict device failure based on early mechanical cycling data. These predictive models achieve 85-90% accuracy in estimating remaining useful life, enabling more efficient maintenance scheduling and replacement planning. The integration of real-time monitoring systems further enhances these models by providing continuous feedback on mechanical and electrochemical health indicators.

Future lifecycle assessment methodologies are trending toward holistic approaches that simultaneously evaluate performance, environmental impact, and economic viability under combined mechanical and electrochemical stresses, providing a more comprehensive understanding of device sustainability in real-world applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!