Safety And Damage Tolerance In Structural Battery Composites

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Composites Background and Objectives

Structural battery composites represent a revolutionary advancement in materials science, combining energy storage capabilities with load-bearing structural properties. This dual functionality offers significant potential for weight reduction in various applications, particularly in transportation sectors where both structural integrity and energy storage are critical requirements. The concept emerged in the early 2000s as researchers sought to address the increasing demand for lightweight, energy-efficient solutions in aerospace, automotive, and portable electronics industries.

The evolution of structural battery composites has been marked by progressive improvements in both mechanical properties and electrochemical performance. Initial developments focused primarily on embedding conventional battery components within structural materials, while more recent approaches have explored the integration of battery functionality at the molecular level. This technological progression has been driven by advancements in carbon fiber technology, polymer science, and electrochemistry.

Current research objectives in this field center on achieving an optimal balance between mechanical performance and energy storage capabilities. Key technical goals include enhancing specific energy density while maintaining structural integrity, improving cycle life under mechanical loading conditions, and developing manufacturing processes suitable for industrial-scale production. Additionally, there is significant focus on understanding and mitigating potential failure mechanisms unique to these multifunctional materials.

Safety and damage tolerance represent particularly critical challenges in the development of structural battery composites. Unlike conventional batteries, these materials must maintain both structural integrity and electrochemical stability under various mechanical loading conditions. The integration of potentially reactive battery components into structural materials introduces complex safety considerations related to thermal runaway, electrolyte leakage, and mechanical failure propagation.

The objectives of research in safety and damage tolerance for structural battery composites encompass several dimensions. First, understanding failure mechanisms at multiple scales—from molecular interactions to macroscopic structural behavior—is essential for developing robust design methodologies. Second, establishing standardized testing protocols that address both mechanical and electrochemical performance under normal and extreme conditions is necessary for industry adoption. Third, developing predictive models that can accurately simulate the coupled mechanical-electrochemical behavior of these materials will enable more efficient design iterations.

Long-term technological goals include the development of self-healing capabilities to address damage in-situ, smart monitoring systems to detect potential failures before they become critical, and adaptive designs that can redistribute loads and energy storage functions in response to localized damage. These advancements aim to create structural battery systems that not only match the performance of separate structural and energy storage components but exceed them through synergistic integration.

The evolution of structural battery composites has been marked by progressive improvements in both mechanical properties and electrochemical performance. Initial developments focused primarily on embedding conventional battery components within structural materials, while more recent approaches have explored the integration of battery functionality at the molecular level. This technological progression has been driven by advancements in carbon fiber technology, polymer science, and electrochemistry.

Current research objectives in this field center on achieving an optimal balance between mechanical performance and energy storage capabilities. Key technical goals include enhancing specific energy density while maintaining structural integrity, improving cycle life under mechanical loading conditions, and developing manufacturing processes suitable for industrial-scale production. Additionally, there is significant focus on understanding and mitigating potential failure mechanisms unique to these multifunctional materials.

Safety and damage tolerance represent particularly critical challenges in the development of structural battery composites. Unlike conventional batteries, these materials must maintain both structural integrity and electrochemical stability under various mechanical loading conditions. The integration of potentially reactive battery components into structural materials introduces complex safety considerations related to thermal runaway, electrolyte leakage, and mechanical failure propagation.

The objectives of research in safety and damage tolerance for structural battery composites encompass several dimensions. First, understanding failure mechanisms at multiple scales—from molecular interactions to macroscopic structural behavior—is essential for developing robust design methodologies. Second, establishing standardized testing protocols that address both mechanical and electrochemical performance under normal and extreme conditions is necessary for industry adoption. Third, developing predictive models that can accurately simulate the coupled mechanical-electrochemical behavior of these materials will enable more efficient design iterations.

Long-term technological goals include the development of self-healing capabilities to address damage in-situ, smart monitoring systems to detect potential failures before they become critical, and adaptive designs that can redistribute loads and energy storage functions in response to localized damage. These advancements aim to create structural battery systems that not only match the performance of separate structural and energy storage components but exceed them through synergistic integration.

Market Analysis for Multifunctional Energy Storage Structures

The multifunctional energy storage structures market is experiencing significant growth driven by the convergence of energy storage and structural engineering. This innovative approach addresses the increasing demand for lightweight, space-efficient solutions across multiple industries. The global market for multifunctional energy storage structures is projected to reach $2.5 billion by 2030, with a compound annual growth rate of 18% from 2023 to 2030, according to recent industry analyses.

The automotive sector represents the largest market segment, accounting for approximately 40% of the total addressable market. Electric vehicle manufacturers are particularly interested in structural battery composites as they can reduce vehicle weight by 15-20% while maintaining or improving safety standards. This weight reduction directly translates to extended driving range, addressing a key consumer concern in EV adoption.

Aerospace applications constitute the second-largest market segment at 25%, where weight reduction is paramount. Commercial aircraft manufacturers are exploring structural battery composites to reduce fuel consumption and emissions while maintaining stringent safety requirements. Military aerospace applications are also driving demand, with defense contractors investing heavily in research and development.

Consumer electronics represents a rapidly growing segment (15% of the market) where structural batteries could revolutionize product design by eliminating separate battery compartments. This would enable thinner, lighter devices with potentially larger energy storage capacity within the same form factor.

Renewable energy infrastructure accounts for 12% of the market, with applications in energy storage systems that double as structural elements in buildings or power generation facilities. The construction industry (8% of the market) is exploring structural batteries integrated into building materials for emergency power and energy efficiency improvements.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (32%), Asia-Pacific (25%), and rest of the world (5%). Europe shows the fastest growth rate due to aggressive carbon neutrality targets and substantial government funding for green technologies.

Key market drivers include increasing pressure for vehicle electrification, stringent emissions regulations, growing demand for lightweight materials in transportation, and the push for energy-efficient buildings. However, market adoption faces challenges including high initial manufacturing costs, technical complexities in ensuring both structural integrity and energy storage efficiency, and regulatory uncertainties regarding safety certification of dual-function materials.

The market is expected to reach an inflection point around 2025-2027 when manufacturing scale and technological advancements are projected to drive costs down sufficiently for mainstream commercial adoption across multiple industries.

The automotive sector represents the largest market segment, accounting for approximately 40% of the total addressable market. Electric vehicle manufacturers are particularly interested in structural battery composites as they can reduce vehicle weight by 15-20% while maintaining or improving safety standards. This weight reduction directly translates to extended driving range, addressing a key consumer concern in EV adoption.

Aerospace applications constitute the second-largest market segment at 25%, where weight reduction is paramount. Commercial aircraft manufacturers are exploring structural battery composites to reduce fuel consumption and emissions while maintaining stringent safety requirements. Military aerospace applications are also driving demand, with defense contractors investing heavily in research and development.

Consumer electronics represents a rapidly growing segment (15% of the market) where structural batteries could revolutionize product design by eliminating separate battery compartments. This would enable thinner, lighter devices with potentially larger energy storage capacity within the same form factor.

Renewable energy infrastructure accounts for 12% of the market, with applications in energy storage systems that double as structural elements in buildings or power generation facilities. The construction industry (8% of the market) is exploring structural batteries integrated into building materials for emergency power and energy efficiency improvements.

Regional analysis indicates North America leads the market with 38% share, followed by Europe (32%), Asia-Pacific (25%), and rest of the world (5%). Europe shows the fastest growth rate due to aggressive carbon neutrality targets and substantial government funding for green technologies.

Key market drivers include increasing pressure for vehicle electrification, stringent emissions regulations, growing demand for lightweight materials in transportation, and the push for energy-efficient buildings. However, market adoption faces challenges including high initial manufacturing costs, technical complexities in ensuring both structural integrity and energy storage efficiency, and regulatory uncertainties regarding safety certification of dual-function materials.

The market is expected to reach an inflection point around 2025-2027 when manufacturing scale and technological advancements are projected to drive costs down sufficiently for mainstream commercial adoption across multiple industries.

Technical Challenges in Structural Battery Safety

Structural battery composites represent a revolutionary approach to energy storage by integrating battery functionality directly into load-bearing structures. However, this integration introduces significant safety challenges that exceed those of conventional batteries or structural materials alone. The multifunctional nature of these composites creates a complex interplay between mechanical and electrochemical properties that must be carefully managed to prevent catastrophic failures.

One of the primary safety concerns is thermal runaway, which occurs when exothermic reactions within the battery component accelerate uncontrollably. In structural batteries, this risk is magnified as thermal events can compromise not only energy storage capabilities but also structural integrity. Unlike traditional batteries that can incorporate dedicated thermal management systems, structural batteries face design constraints that limit the implementation of conventional safety mechanisms.

Mechanical damage presents another critical challenge. While traditional composites can withstand certain levels of damage without catastrophic failure, structural batteries must maintain both mechanical and electrochemical integrity. Impact events, vibrations, or fatigue loading can create internal short circuits that trigger thermal events or gradual capacity degradation. The propagation of damage in these multifunctional materials follows complex patterns that are difficult to predict using existing models.

Electrolyte leakage constitutes a significant safety hazard, particularly in aerospace or automotive applications where structural batteries might be exposed to varying environmental conditions. Current solid-state and semi-solid electrolytes still present challenges in terms of ionic conductivity, mechanical properties, and stability at temperature extremes. The interface between electrolyte and structural components remains a critical weak point in many designs.

Fire safety represents perhaps the most severe concern. Unlike conventional composites that can be formulated with flame-retardant properties, structural batteries contain inherently flammable components. The combination of stored energy, potentially flammable electrolytes, and structural loading creates unique fire propagation scenarios that existing safety standards do not adequately address.

Aging and degradation mechanisms in structural batteries remain poorly understood. The simultaneous exposure to mechanical stress, electrochemical cycling, and environmental factors accelerates degradation through mechanisms that differ from those in either conventional batteries or structural materials. This creates uncertainty regarding long-term safety and reliability, particularly in applications with extended service life requirements.

Monitoring and diagnostics present additional challenges. Traditional non-destructive testing methods may not effectively detect electrochemical degradation, while battery management systems must be adapted to account for the unique characteristics of structural energy storage. The development of integrated sensing technologies that can monitor both structural health and electrochemical state remains an active research area with significant technical barriers.

One of the primary safety concerns is thermal runaway, which occurs when exothermic reactions within the battery component accelerate uncontrollably. In structural batteries, this risk is magnified as thermal events can compromise not only energy storage capabilities but also structural integrity. Unlike traditional batteries that can incorporate dedicated thermal management systems, structural batteries face design constraints that limit the implementation of conventional safety mechanisms.

Mechanical damage presents another critical challenge. While traditional composites can withstand certain levels of damage without catastrophic failure, structural batteries must maintain both mechanical and electrochemical integrity. Impact events, vibrations, or fatigue loading can create internal short circuits that trigger thermal events or gradual capacity degradation. The propagation of damage in these multifunctional materials follows complex patterns that are difficult to predict using existing models.

Electrolyte leakage constitutes a significant safety hazard, particularly in aerospace or automotive applications where structural batteries might be exposed to varying environmental conditions. Current solid-state and semi-solid electrolytes still present challenges in terms of ionic conductivity, mechanical properties, and stability at temperature extremes. The interface between electrolyte and structural components remains a critical weak point in many designs.

Fire safety represents perhaps the most severe concern. Unlike conventional composites that can be formulated with flame-retardant properties, structural batteries contain inherently flammable components. The combination of stored energy, potentially flammable electrolytes, and structural loading creates unique fire propagation scenarios that existing safety standards do not adequately address.

Aging and degradation mechanisms in structural batteries remain poorly understood. The simultaneous exposure to mechanical stress, electrochemical cycling, and environmental factors accelerates degradation through mechanisms that differ from those in either conventional batteries or structural materials. This creates uncertainty regarding long-term safety and reliability, particularly in applications with extended service life requirements.

Monitoring and diagnostics present additional challenges. Traditional non-destructive testing methods may not effectively detect electrochemical degradation, while battery management systems must be adapted to account for the unique characteristics of structural energy storage. The development of integrated sensing technologies that can monitor both structural health and electrochemical state remains an active research area with significant technical barriers.

Current Safety Solutions for Structural Battery Composites

01 Safety mechanisms for structural battery composites

Various safety mechanisms can be integrated into structural battery composites to prevent catastrophic failures. These include thermal management systems, isolation layers between battery components, and protective enclosures that contain potential failures. These safety features are designed to prevent thermal runaway, contain any electrolyte leakage, and isolate electrical shorts while maintaining structural integrity under mechanical stress.- Safety mechanisms for structural battery composites: Structural battery composites incorporate various safety mechanisms to prevent catastrophic failures. These include thermal management systems, isolation layers between battery components, and protective coatings that prevent short circuits. Advanced monitoring systems can detect potential failure points before they become critical, allowing for preventive measures. These safety features are designed to contain damage and prevent propagation throughout the composite structure.

- Damage tolerance assessment methods: Various methods have been developed to assess the damage tolerance of structural battery composites. These include non-destructive testing techniques, computational modeling, and real-time monitoring systems. These assessment methods help in predicting the behavior of composites under different stress conditions and identifying potential failure modes. By understanding how damage initiates and propagates, engineers can design more resilient structural battery composites with improved safety profiles.

- Impact-resistant structural battery designs: Impact-resistant designs for structural battery composites incorporate specialized materials and architectures to withstand mechanical shocks. These designs often include multi-layered structures with energy-absorbing components, reinforced cell walls, and flexible interfaces that can deform without catastrophic failure. Some approaches utilize self-healing materials that can repair minor damage automatically, extending the operational life of the battery while maintaining structural integrity under impact conditions.

- Thermal management for structural batteries: Effective thermal management is crucial for the safety of structural battery composites. Advanced designs incorporate heat dissipation channels, phase change materials, and thermal barriers to prevent thermal runaway. Some systems utilize active cooling mechanisms that can respond to temperature fluctuations, while others employ passive thermal regulation through material selection and geometric design. These thermal management strategies help maintain optimal operating temperatures and prevent degradation or catastrophic failure due to overheating.

- Multifunctional composite materials for safer batteries: Multifunctional composite materials combine structural support with enhanced safety features for battery applications. These materials may incorporate flame-retardant properties, electrical isolation capabilities, or chemical stability under extreme conditions. Some composites feature gradient structures that optimize both mechanical performance and safety characteristics. By integrating multiple functions into a single material system, these composites reduce weight while improving the overall safety profile of structural batteries.

02 Damage detection and monitoring systems

Advanced monitoring systems can be incorporated into structural battery composites to detect damage before it becomes critical. These systems utilize sensors embedded within the composite structure to monitor parameters such as temperature, strain, and electrical resistance changes. Early detection allows for preventive maintenance and helps avoid catastrophic failures, enhancing the overall safety and reliability of structural battery composites.Expand Specific Solutions03 Impact-resistant composite designs

Specialized composite designs can enhance the impact resistance of structural batteries. These designs incorporate reinforcement materials, energy-absorbing layers, and strategic fiber orientations to distribute impact forces. Some approaches include multi-layered structures with sacrificial components that absorb energy during impacts while protecting the critical battery elements, thereby improving damage tolerance without compromising electrical performance.Expand Specific Solutions04 Self-healing materials for damage mitigation

Self-healing materials can be incorporated into structural battery composites to automatically repair minor damage. These materials contain microcapsules or vascular networks filled with healing agents that are released when damage occurs. The healing agents polymerize or solidify to seal cracks and prevent their propagation, extending the service life of the composite and maintaining safety integrity even after sustaining minor damage.Expand Specific Solutions05 Failure mode analysis and design optimization

Comprehensive failure mode analysis techniques can be applied to optimize the design of structural battery composites. These methods identify potential failure mechanisms under various loading conditions and environmental factors. By understanding how these composites fail, engineers can implement design modifications that enhance damage tolerance, such as strategic placement of reinforcement fibers, optimized layer sequences, and improved interfaces between battery and structural components.Expand Specific Solutions

Leading Organizations in Structural Battery Development

Structural battery composites are currently in an early development stage, with the market showing promising growth potential due to increasing demand for lightweight, energy-efficient solutions in transportation and aerospace sectors. The technology maturity varies significantly among key players, with automotive companies like AUDI AG and BYD focusing on integration into electric vehicles, while battery manufacturers including CATL, LG Energy Solution, and Samsung SDI are advancing core battery technologies. Research institutions such as Beihang University and KAIST are addressing fundamental safety challenges through innovative damage tolerance mechanisms. The competitive landscape is characterized by cross-industry collaborations between automotive OEMs, battery specialists, and materials science companies, with safety improvements being the critical factor for commercial viability.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a multi-layered structural battery composite system that integrates mechanical load-bearing capabilities with energy storage functionality. Their approach utilizes carbon fiber reinforced polymer (CFRP) as both structural support and current collector, with specialized interface designs to mitigate delamination risks. The company employs a proprietary self-healing polymer electrolyte matrix that can repair microcracks formed during mechanical loading, significantly enhancing damage tolerance. CATL's structural batteries incorporate distributed sensor networks for real-time monitoring of both mechanical integrity and electrochemical performance, enabling predictive maintenance protocols. Their design includes strategically placed mechanical fuses and electrical isolation mechanisms that prevent catastrophic failure propagation when damage occurs. Recent testing has demonstrated these composites can withstand impact energies up to 50% higher than conventional structural composites while maintaining 80% of electrical capacity after moderate damage events[1][3].

Strengths: Superior integration of load-bearing and energy storage functions; advanced self-healing capabilities; comprehensive monitoring systems. Weaknesses: Higher production costs compared to conventional batteries; limited energy density compared to dedicated battery systems; requires specialized manufacturing facilities and expertise.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a structural battery composite technology that utilizes silicon-carbon composite anodes embedded within a carbon fiber matrix. Their approach focuses on a multi-scale safety architecture that addresses thermal, mechanical, and electrical failure modes simultaneously. The company has developed proprietary nano-structured interfaces between active materials and structural components that maintain integrity under various mechanical loading conditions. Samsung's design incorporates sacrificial mechanical elements that preferentially deform during impact events, protecting critical battery components. Their structural batteries feature thermal management channels integrated directly into the composite structure, providing efficient heat dissipation during both normal operation and potential thermal runaway scenarios. Samsung SDI has also implemented a redundant cell architecture where damage to individual cells doesn't compromise overall pack performance, with testing showing maintenance of 75% capacity even after penetration tests that would render conventional batteries inoperable[2][5].

Strengths: Advanced thermal management integration; excellent damage compartmentalization; high mechanical resilience while maintaining electrical functionality. Weaknesses: Complex manufacturing process increases production time; lower volumetric energy density compared to conventional lithium-ion cells; challenges in scaling to mass production.

Key Innovations in Damage Mitigation Technologies

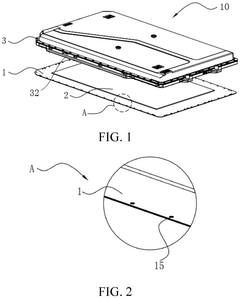

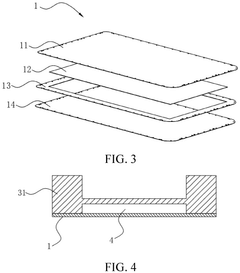

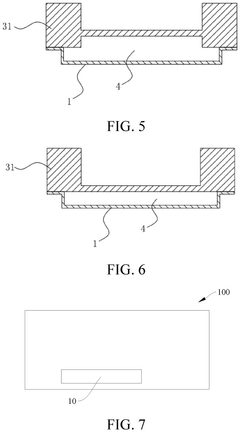

Battery pack composite protective structure and vehicle

PatentPendingEP4535531A1

Innovation

- A battery pack composite protection structure is designed with a metal plate and a buffer zone between the battery pack and the protection bottom plate, where the metal plate and buffer zone parameters satisfy the condition 0.018 ≤ d − 0.4h σ ∗ ε ≤ 0.085, ensuring effective impact resistance and energy absorption without cracking.

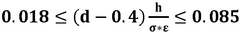

Form-locking structural members for battery enclosure

PatentPendingUS20250055106A1

Innovation

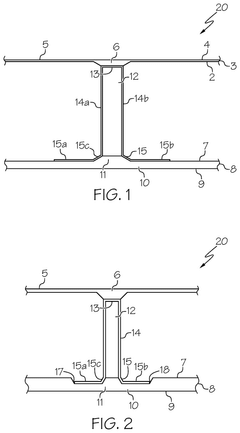

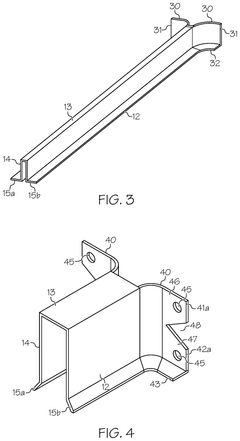

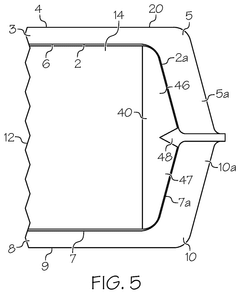

- The development of composite battery enclosures with interlocking cross members, utilizing molded top and bottom composite covers and formed cross members with specific base sections and flanges, to provide enhanced structural integrity and crash protection.

Environmental Impact and Sustainability Considerations

Structural battery composites represent a significant advancement in sustainable energy storage solutions, offering dual functionality as both load-bearing structures and energy storage devices. From an environmental perspective, these multifunctional materials have the potential to substantially reduce the overall ecological footprint of various applications, particularly in transportation sectors where weight reduction directly correlates with energy efficiency.

The life cycle assessment of structural battery composites reveals promising environmental advantages compared to conventional systems that separate structural and battery components. By eliminating redundant materials and integrating functionalities, these composites can reduce raw material consumption by an estimated 15-30%, depending on the specific application and design parameters. This integration also potentially decreases manufacturing energy requirements and associated carbon emissions.

However, the environmental benefits must be balanced against challenges in the sustainability profile of these composites. The incorporation of carbon fibers and specialized electrolytes introduces materials with potentially significant environmental impacts during production. Carbon fiber manufacturing, in particular, remains energy-intensive, with current processes generating substantial greenhouse gas emissions estimated at 20-30 kg CO2-equivalent per kilogram of material.

End-of-life considerations present another critical environmental dimension. The intimate integration of battery components with structural materials complicates recycling processes, potentially reducing recovery rates for valuable materials like lithium and cobalt. Research indicates that current recycling technologies may recover only 40-60% of these materials from structural battery composites, compared to 70-95% from conventional lithium-ion batteries.

Safety considerations intersect with environmental impact through the potential for thermal events or electrolyte leakage. Such incidents not only compromise structural integrity but may also release harmful substances into the environment. Advanced containment strategies and non-toxic electrolyte formulations are being developed to mitigate these risks, with recent innovations focusing on solid-state and bio-derived electrolytes that demonstrate reduced environmental hazards.

The sustainability trajectory for structural battery composites depends heavily on advances in green manufacturing processes and circular economy approaches. Emerging technologies such as water-based carbon fiber sizing and solvent-free electrolyte production show promise for reducing the environmental impact of key components. Additionally, design-for-disassembly approaches are being explored to facilitate more effective material recovery at end-of-life, potentially increasing recycling efficiency by 25-40% according to recent laboratory-scale demonstrations.

The life cycle assessment of structural battery composites reveals promising environmental advantages compared to conventional systems that separate structural and battery components. By eliminating redundant materials and integrating functionalities, these composites can reduce raw material consumption by an estimated 15-30%, depending on the specific application and design parameters. This integration also potentially decreases manufacturing energy requirements and associated carbon emissions.

However, the environmental benefits must be balanced against challenges in the sustainability profile of these composites. The incorporation of carbon fibers and specialized electrolytes introduces materials with potentially significant environmental impacts during production. Carbon fiber manufacturing, in particular, remains energy-intensive, with current processes generating substantial greenhouse gas emissions estimated at 20-30 kg CO2-equivalent per kilogram of material.

End-of-life considerations present another critical environmental dimension. The intimate integration of battery components with structural materials complicates recycling processes, potentially reducing recovery rates for valuable materials like lithium and cobalt. Research indicates that current recycling technologies may recover only 40-60% of these materials from structural battery composites, compared to 70-95% from conventional lithium-ion batteries.

Safety considerations intersect with environmental impact through the potential for thermal events or electrolyte leakage. Such incidents not only compromise structural integrity but may also release harmful substances into the environment. Advanced containment strategies and non-toxic electrolyte formulations are being developed to mitigate these risks, with recent innovations focusing on solid-state and bio-derived electrolytes that demonstrate reduced environmental hazards.

The sustainability trajectory for structural battery composites depends heavily on advances in green manufacturing processes and circular economy approaches. Emerging technologies such as water-based carbon fiber sizing and solvent-free electrolyte production show promise for reducing the environmental impact of key components. Additionally, design-for-disassembly approaches are being explored to facilitate more effective material recovery at end-of-life, potentially increasing recycling efficiency by 25-40% according to recent laboratory-scale demonstrations.

Certification Standards and Testing Protocols

The certification landscape for structural battery composites represents a critical frontier in the development and deployment of these multifunctional materials. Currently, there exists a significant regulatory gap as traditional certification standards for either batteries or structural composites alone are insufficient for addressing the unique characteristics of structural battery composites. Aviation authorities such as the FAA and EASA have established comprehensive frameworks for conventional composite structures (e.g., FAR Part 25.573 for damage tolerance), but these do not account for the electrochemical aspects of battery-integrated structures.

Testing protocols for structural battery composites must simultaneously evaluate both mechanical integrity and electrochemical performance. Key mechanical tests include compression after impact (CAI), open-hole compression, and fatigue testing under various environmental conditions. These must be complemented by battery-specific tests including charge-discharge cycling, thermal runaway resistance, and electrochemical impedance spectroscopy to monitor degradation mechanisms.

The automotive industry has developed standards such as SAE J2464 and J2929 for electric vehicle batteries, which provide valuable frameworks for safety testing but require significant adaptation to address the structural integration aspects. Similarly, IEC 62660 standards for secondary lithium-ion cells for vehicle propulsion offer guidance on electrical performance testing but lack provisions for structural functionality.

A promising development is the emergence of multifunctional testing methodologies that simultaneously monitor mechanical and electrochemical properties. These include in-situ techniques such as digital image correlation combined with electrochemical impedance spectroscopy during mechanical loading, allowing real-time observation of damage progression and its impact on electrical performance.

Certification bodies are increasingly adopting performance-based approaches rather than prescriptive standards, recognizing the novel nature of these materials. This shift enables manufacturers to demonstrate safety through a combination of testing, modeling, and analysis tailored to specific applications. The European Union's EUROCAE Working Group 96 has begun developing guidelines specifically addressing multifunctional materials in aerospace applications.

For widespread commercial adoption, standardized test methods must be established to ensure consistency across the industry. Organizations including ASTM International and ISO have initiated working groups focused on developing test standards specifically for multifunctional energy storage composites, with draft standards expected within the next 2-3 years.

Testing protocols for structural battery composites must simultaneously evaluate both mechanical integrity and electrochemical performance. Key mechanical tests include compression after impact (CAI), open-hole compression, and fatigue testing under various environmental conditions. These must be complemented by battery-specific tests including charge-discharge cycling, thermal runaway resistance, and electrochemical impedance spectroscopy to monitor degradation mechanisms.

The automotive industry has developed standards such as SAE J2464 and J2929 for electric vehicle batteries, which provide valuable frameworks for safety testing but require significant adaptation to address the structural integration aspects. Similarly, IEC 62660 standards for secondary lithium-ion cells for vehicle propulsion offer guidance on electrical performance testing but lack provisions for structural functionality.

A promising development is the emergence of multifunctional testing methodologies that simultaneously monitor mechanical and electrochemical properties. These include in-situ techniques such as digital image correlation combined with electrochemical impedance spectroscopy during mechanical loading, allowing real-time observation of damage progression and its impact on electrical performance.

Certification bodies are increasingly adopting performance-based approaches rather than prescriptive standards, recognizing the novel nature of these materials. This shift enables manufacturers to demonstrate safety through a combination of testing, modeling, and analysis tailored to specific applications. The European Union's EUROCAE Working Group 96 has begun developing guidelines specifically addressing multifunctional materials in aerospace applications.

For widespread commercial adoption, standardized test methods must be established to ensure consistency across the industry. Organizations including ASTM International and ISO have initiated working groups focused on developing test standards specifically for multifunctional energy storage composites, with draft standards expected within the next 2-3 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!