Crashworthiness And Certification For Structural Battery Components

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Technology Background and Objectives

Structural batteries represent a revolutionary approach to energy storage, combining load-bearing capabilities with energy storage functionality. This dual-purpose technology emerged from the need to address weight and space constraints in various applications, particularly in aerospace, automotive, and portable electronics sectors. The concept was first theoretically proposed in the early 2000s, but significant research momentum has only built up over the past decade with advancements in materials science and battery chemistry.

The evolution of structural batteries has been driven by the limitations of conventional battery systems, which add considerable weight to vehicles and devices without contributing to structural integrity. By integrating energy storage into the structural components themselves, engineers aim to achieve substantial weight reductions while maintaining or even enhancing mechanical performance. This paradigm shift aligns with broader industry trends toward multifunctional materials and systems integration.

Recent technological breakthroughs in carbon fiber composites, solid-state electrolytes, and advanced manufacturing techniques have accelerated development in this field. Carbon fiber, in particular, has emerged as a promising material due to its excellent mechanical properties and potential to serve as an electrode material. Similarly, advances in polymer electrolytes have enabled better integration of battery functionality into structural components without compromising safety or performance.

The primary technical objective for structural battery development is to achieve an optimal balance between mechanical properties and electrochemical performance. Current research targets include improving energy density while maintaining structural integrity, enhancing cycle life under mechanical stress conditions, and developing manufacturing processes suitable for mass production. Additionally, researchers aim to address safety concerns unique to structural batteries, particularly regarding crash scenarios and failure modes.

Another critical objective is the development of comprehensive testing and certification protocols specifically designed for structural battery components. Unlike conventional batteries, structural batteries must undergo rigorous mechanical testing alongside standard electrochemical evaluations. This includes crash testing, fatigue analysis, and structural integrity assessments under various environmental conditions.

Looking forward, the technology roadmap for structural batteries includes achieving energy densities comparable to conventional lithium-ion batteries (>200 Wh/kg) while providing structural properties similar to carbon fiber composites. Long-term goals include the development of self-healing capabilities, adaptive performance characteristics, and integration with energy harvesting technologies to create truly autonomous energy systems.

The evolution of structural batteries has been driven by the limitations of conventional battery systems, which add considerable weight to vehicles and devices without contributing to structural integrity. By integrating energy storage into the structural components themselves, engineers aim to achieve substantial weight reductions while maintaining or even enhancing mechanical performance. This paradigm shift aligns with broader industry trends toward multifunctional materials and systems integration.

Recent technological breakthroughs in carbon fiber composites, solid-state electrolytes, and advanced manufacturing techniques have accelerated development in this field. Carbon fiber, in particular, has emerged as a promising material due to its excellent mechanical properties and potential to serve as an electrode material. Similarly, advances in polymer electrolytes have enabled better integration of battery functionality into structural components without compromising safety or performance.

The primary technical objective for structural battery development is to achieve an optimal balance between mechanical properties and electrochemical performance. Current research targets include improving energy density while maintaining structural integrity, enhancing cycle life under mechanical stress conditions, and developing manufacturing processes suitable for mass production. Additionally, researchers aim to address safety concerns unique to structural batteries, particularly regarding crash scenarios and failure modes.

Another critical objective is the development of comprehensive testing and certification protocols specifically designed for structural battery components. Unlike conventional batteries, structural batteries must undergo rigorous mechanical testing alongside standard electrochemical evaluations. This includes crash testing, fatigue analysis, and structural integrity assessments under various environmental conditions.

Looking forward, the technology roadmap for structural batteries includes achieving energy densities comparable to conventional lithium-ion batteries (>200 Wh/kg) while providing structural properties similar to carbon fiber composites. Long-term goals include the development of self-healing capabilities, adaptive performance characteristics, and integration with energy harvesting technologies to create truly autonomous energy systems.

Market Analysis for Structural Battery Applications

The structural battery market is experiencing significant growth driven by the convergence of energy storage and structural functionality. Current market projections indicate that the global structural battery market could reach $2.5 billion by 2030, with a compound annual growth rate of approximately 25% from 2023 to 2030. This growth is primarily fueled by the automotive and aerospace sectors, which together account for over 70% of the potential applications.

In the automotive industry, structural batteries offer a revolutionary approach to electric vehicle design by integrating energy storage directly into load-bearing components. This integration can potentially reduce vehicle weight by 15-20%, thereby extending driving range without increasing battery size. Major automotive manufacturers including Tesla, Volkswagen, and Volvo have initiated research programs focused on structural battery implementation, with Volvo's partnership with Northvolt representing one of the most advanced commercial efforts.

The aerospace sector presents another significant market opportunity, with structural batteries potentially reducing aircraft weight by up to 30% compared to conventional designs using separate battery and structural systems. Boeing and Airbus have both established dedicated research divisions exploring structural battery applications for next-generation aircraft, with particular interest in unmanned aerial vehicles (UAVs) and urban air mobility platforms.

Consumer electronics represents a smaller but rapidly growing segment, with potential applications in laptops, smartphones, and wearable devices. The market demand in this sector is driven by the need for thinner, lighter devices with longer battery life. Apple and Samsung have filed multiple patents related to structural battery technologies for mobile devices.

Market barriers include certification challenges, manufacturing scalability, and cost concerns. The lack of standardized testing protocols for crashworthiness specifically designed for structural batteries represents a significant market entry barrier. Current certification processes add approximately 30-40% to development costs compared to conventional battery systems.

Customer requirements analysis reveals that safety certification ranks as the top concern among potential adopters, followed by energy density and cost. Survey data indicates that 85% of potential industrial customers consider crashworthiness certification as "extremely important" or "very important" in their purchasing decisions.

Regional analysis shows North America leading in research investment (42% of global funding), while Asia-Pacific demonstrates the fastest growth rate in patent applications related to structural battery crashworthiness. Europe maintains a strong position in regulatory framework development, with the European Union actively developing specific standards for structural battery certification.

In the automotive industry, structural batteries offer a revolutionary approach to electric vehicle design by integrating energy storage directly into load-bearing components. This integration can potentially reduce vehicle weight by 15-20%, thereby extending driving range without increasing battery size. Major automotive manufacturers including Tesla, Volkswagen, and Volvo have initiated research programs focused on structural battery implementation, with Volvo's partnership with Northvolt representing one of the most advanced commercial efforts.

The aerospace sector presents another significant market opportunity, with structural batteries potentially reducing aircraft weight by up to 30% compared to conventional designs using separate battery and structural systems. Boeing and Airbus have both established dedicated research divisions exploring structural battery applications for next-generation aircraft, with particular interest in unmanned aerial vehicles (UAVs) and urban air mobility platforms.

Consumer electronics represents a smaller but rapidly growing segment, with potential applications in laptops, smartphones, and wearable devices. The market demand in this sector is driven by the need for thinner, lighter devices with longer battery life. Apple and Samsung have filed multiple patents related to structural battery technologies for mobile devices.

Market barriers include certification challenges, manufacturing scalability, and cost concerns. The lack of standardized testing protocols for crashworthiness specifically designed for structural batteries represents a significant market entry barrier. Current certification processes add approximately 30-40% to development costs compared to conventional battery systems.

Customer requirements analysis reveals that safety certification ranks as the top concern among potential adopters, followed by energy density and cost. Survey data indicates that 85% of potential industrial customers consider crashworthiness certification as "extremely important" or "very important" in their purchasing decisions.

Regional analysis shows North America leading in research investment (42% of global funding), while Asia-Pacific demonstrates the fastest growth rate in patent applications related to structural battery crashworthiness. Europe maintains a strong position in regulatory framework development, with the European Union actively developing specific standards for structural battery certification.

Current Crashworthiness Standards and Technical Challenges

The current landscape of crashworthiness standards for conventional vehicles is primarily governed by regulations such as FMVSS (Federal Motor Vehicle Safety Standards) in the United States, UN-ECE regulations in Europe, and similar frameworks in other regions. These standards specify requirements for occupant protection during various crash scenarios including frontal impact, side impact, rollover, and rear impact. However, these established standards were developed for vehicles with traditional combustion engines and do not adequately address the unique challenges posed by structural battery components.

Structural battery composites (SBCs) represent a paradigm shift in vehicle design, as they serve dual functions of energy storage and load-bearing structure. This multifunctionality introduces unprecedented technical challenges for crashworthiness certification. Unlike conventional batteries that are protected within dedicated enclosures, structural batteries are integrated into the vehicle's architecture, making them directly susceptible to crash forces.

A significant technical challenge is the complex failure modes of SBCs during impact events. While traditional composite materials exhibit predictable failure patterns, structural batteries combine electrochemical and mechanical failure mechanisms that can interact in unpredictable ways. The potential for thermal runaway coupled with structural collapse creates scenarios not contemplated in existing standards.

Current test methodologies are inadequate for evaluating structural battery performance during crashes. Standard crash tests focus on occupant protection metrics but lack protocols for assessing the integrity of energy storage components that simultaneously serve structural functions. This gap necessitates the development of new test procedures that can evaluate both mechanical performance and electrochemical stability under dynamic loading conditions.

The certification process faces additional complications due to the limited historical data on structural battery behavior in real-world crash scenarios. Without extensive crash data, regulatory bodies struggle to establish appropriate safety thresholds and performance criteria. This creates uncertainty for manufacturers seeking to implement this technology and for insurance companies attempting to assess risk.

Material characterization presents another significant hurdle. Structural battery materials exhibit time-dependent and state-of-charge-dependent mechanical properties that can significantly affect crashworthiness. Current testing standards do not account for these variables, creating a disconnect between laboratory certification and real-world performance.

Computational modeling capabilities also lag behind the needs for structural battery certification. While finite element analysis is widely used for crash simulation, existing models cannot accurately capture the coupled mechanical-electrochemical behavior of structural batteries during impact events. This limitation hampers the industry's ability to perform virtual testing and validation, which is increasingly important in modern vehicle development processes.

Structural battery composites (SBCs) represent a paradigm shift in vehicle design, as they serve dual functions of energy storage and load-bearing structure. This multifunctionality introduces unprecedented technical challenges for crashworthiness certification. Unlike conventional batteries that are protected within dedicated enclosures, structural batteries are integrated into the vehicle's architecture, making them directly susceptible to crash forces.

A significant technical challenge is the complex failure modes of SBCs during impact events. While traditional composite materials exhibit predictable failure patterns, structural batteries combine electrochemical and mechanical failure mechanisms that can interact in unpredictable ways. The potential for thermal runaway coupled with structural collapse creates scenarios not contemplated in existing standards.

Current test methodologies are inadequate for evaluating structural battery performance during crashes. Standard crash tests focus on occupant protection metrics but lack protocols for assessing the integrity of energy storage components that simultaneously serve structural functions. This gap necessitates the development of new test procedures that can evaluate both mechanical performance and electrochemical stability under dynamic loading conditions.

The certification process faces additional complications due to the limited historical data on structural battery behavior in real-world crash scenarios. Without extensive crash data, regulatory bodies struggle to establish appropriate safety thresholds and performance criteria. This creates uncertainty for manufacturers seeking to implement this technology and for insurance companies attempting to assess risk.

Material characterization presents another significant hurdle. Structural battery materials exhibit time-dependent and state-of-charge-dependent mechanical properties that can significantly affect crashworthiness. Current testing standards do not account for these variables, creating a disconnect between laboratory certification and real-world performance.

Computational modeling capabilities also lag behind the needs for structural battery certification. While finite element analysis is widely used for crash simulation, existing models cannot accurately capture the coupled mechanical-electrochemical behavior of structural batteries during impact events. This limitation hampers the industry's ability to perform virtual testing and validation, which is increasingly important in modern vehicle development processes.

Existing Crashworthiness Testing Methodologies

01 Crash-resistant battery enclosures and housings

Battery enclosures and housings designed to withstand impact forces during vehicle collisions. These structures incorporate reinforced materials, strategic crumple zones, and impact-absorbing features to protect battery cells from damage. The designs focus on preventing battery rupture, thermal runaway, and electrolyte leakage while maintaining structural integrity of the vehicle during crash events.- Crash-resistant battery enclosures and housings: Specialized enclosures and housings designed to protect battery components during impact events. These structures incorporate reinforced materials, strategic crumple zones, and impact-absorbing features to maintain battery integrity during collisions. The designs focus on preventing battery damage while also managing energy dissipation to protect vehicle occupants and prevent thermal events.

- Energy-absorbing materials for battery protection: Implementation of specialized materials that can absorb and dissipate impact energy to protect battery components. These materials include composite structures, foam-based solutions, and engineered polymers that deform in controlled ways during crashes. The materials are strategically positioned around battery cells to prevent mechanical damage and subsequent thermal runaway.

- Structural battery integration with vehicle safety systems: Methods for integrating battery components into the overall vehicle safety architecture. These approaches treat batteries as structural elements that contribute to the vehicle's crash performance while being protected themselves. The integration includes strategic placement within the vehicle frame, connection to crumple zones, and coordination with other safety systems to ensure optimal crashworthiness.

- Battery cell arrangement for improved crash resistance: Specific configurations and arrangements of battery cells designed to enhance crash resistance. These designs include cell spacing, orientation, and mounting systems that minimize damage propagation during impacts. The arrangements consider both the protection of individual cells and the prevention of cascading failures across the battery pack.

- Simulation and testing methods for battery crashworthiness: Advanced computational and physical testing methodologies to evaluate and improve battery component crashworthiness. These include finite element analysis, crash simulations, and physical impact testing protocols specifically developed for battery systems. The methods help identify vulnerabilities and optimize designs before implementation in production vehicles.

02 Energy-absorbing materials and structures for battery protection

Implementation of specialized energy-absorbing materials and structures within battery systems to enhance crashworthiness. These include foam-based materials, honeycomb structures, composite materials, and engineered crush zones that can deform in a controlled manner to dissipate impact energy. These materials help protect battery components while minimizing weight penalties and maintaining overall vehicle structural performance.Expand Specific Solutions03 Structural battery integration with vehicle safety systems

Integration approaches that combine battery components with the vehicle's structural safety systems. These designs incorporate batteries as load-bearing elements while ensuring they contribute positively to crash energy management. The integration includes strategic placement within the vehicle architecture, connection to primary crash structures, and coordination with other safety systems to maintain occupant protection while safeguarding battery integrity.Expand Specific Solutions04 Battery cell arrangement and mounting for crash protection

Specific arrangements and mounting systems for battery cells that enhance crashworthiness. These include cell orientation strategies, modular designs that isolate damage, flexible mounting systems that absorb energy, and reinforced cell-to-cell connections. The arrangements are designed to prevent propagation of failure between cells during impact events while maintaining electrical connectivity and thermal management capabilities.Expand Specific Solutions05 Simulation and testing methods for battery crashworthiness

Advanced simulation techniques and physical testing methodologies developed specifically for evaluating battery component crashworthiness. These include finite element analysis models that predict battery behavior during impacts, specialized crash test procedures for battery systems, and combined physical-virtual testing approaches. These methods help optimize battery designs for crash scenarios while reducing development time and costs.Expand Specific Solutions

Leading Companies and Research Institutions in Structural Batteries

The crashworthiness and certification landscape for structural battery components is evolving rapidly, currently in an early growth phase with increasing market potential as electric vehicle adoption accelerates. The market is characterized by significant R&D investments from major automotive manufacturers (Volkswagen, Volvo, Renault, Nissan) partnering with leading battery producers (CATL, LG Energy Solution, Samsung SDI). Technical maturity varies considerably, with companies like Boeing and Ford developing advanced certification protocols, while battery specialists such as EVE Energy and CATL focus on integrating structural properties with safety requirements. University collaborations (South Carolina, Dortmund) are addressing fundamental challenges in impact resistance and standardization, indicating the technology remains pre-commercial but advancing toward implementation.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a comprehensive structural battery safety certification framework that integrates mechanical integrity with electrochemical stability. Their CTP (Cell-to-Pack) technology eliminates traditional module components, allowing battery cells to be directly integrated into the vehicle structure. This approach includes multi-level safety mechanisms: a honeycomb structure that enhances crash energy absorption by up to 50%, specialized flame-retardant materials that maintain structural integrity during thermal events, and an intelligent Battery Management System (BMS) that continuously monitors structural health. CATL's certification process involves rigorous testing including crush tests, penetration tests, and simulated crash scenarios that exceed standard regulatory requirements. Their structural batteries are designed to maintain integrity even when deformed up to 30% of their original dimensions, significantly higher than the industry average of 15-20%.

Strengths: Superior energy density (up to 255 Wh/kg) while maintaining structural integrity; comprehensive safety testing protocols that exceed regulatory standards; advanced thermal management systems integrated with structural components. Weaknesses: Higher manufacturing complexity increases production costs; potential challenges in battery replacement and serviceability; limited long-term crash performance data in real-world conditions.

Volvo Lastvagnar AB

Technical Solution: Volvo Trucks has pioneered an innovative structural battery certification approach specifically designed for heavy-duty commercial vehicles. Their system integrates battery modules directly into the chassis frame, creating a "battery-as-structure" design that enhances both energy storage and vehicle rigidity. The technology employs a multi-layer protection strategy with a reinforced outer casing made of high-strength steel alloys capable of withstanding impacts up to 60G without cell rupture. Volvo's certification methodology includes proprietary crash simulation algorithms that model both mechanical deformation and electrochemical responses simultaneously. Their structural batteries undergo extensive physical testing including rollover scenarios specific to heavy trucks, offset impact tests, and accelerated aging under mechanical stress. A key innovation is their "progressive deformation zones" that channel crash energy away from battery cells while maintaining structural integrity of the vehicle frame, allowing the battery to serve as both an energy source and a critical safety component.

Strengths: Exceptional integration with heavy-duty vehicle chassis design; superior protection against rollover incidents common in commercial transport; advanced simulation capabilities that accurately predict structural battery behavior under extreme conditions. Weaknesses: Higher weight compared to non-structural alternatives; limited flexibility for battery capacity upgrades; potentially higher repair costs following structural damage.

Key Patents and Research on Structural Battery Safety

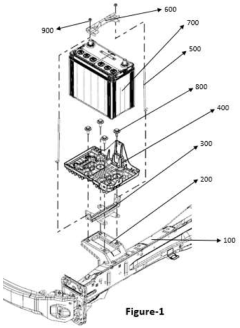

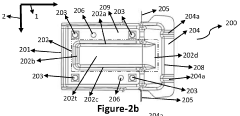

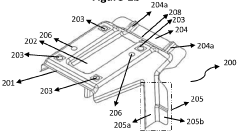

A reinforced battery assembly structure for a vehicle

PatentActiveIN201911047386A

Innovation

- A reinforced battery assembly comprising a battery bracket, a battery stay with a butterfly structure, a battery tray with depressions, and a U-shaped groove in the battery bracket to drain fluid leaks, secured with J-bolts and a battery band, enhancing structural integrity and fluid containment.

Certification Frameworks and Regulatory Requirements

The certification landscape for structural battery components presents a complex regulatory environment that manufacturers must navigate to ensure market acceptance. Current certification frameworks primarily follow traditional pathways established for either conventional vehicle structures or battery systems separately, creating a regulatory gap for integrated structural battery components. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established preliminary guidelines for aircraft applications, requiring dual certification under both structural integrity standards (such as FAR Part 25) and battery safety protocols (DO-311A).

For automotive applications, the United Nations Economic Commission for Europe (UNECE) regulations, particularly UN R100 for battery electric vehicles, provide baseline requirements but lack specific provisions for structural battery integration. Similarly, the National Highway Traffic Safety Administration (NHTSA) in the United States maintains Federal Motor Vehicle Safety Standards (FMVSS) that address crashworthiness and battery safety separately, requiring manufacturers to demonstrate compliance with both domains simultaneously.

The International Organization for Standardization (ISO) has begun developing specialized standards, with ISO 21782 addressing performance testing for electric vehicle components and ISO 12405 focusing on lithium-ion traction battery packs. However, these standards require significant adaptation to address the unique challenges of structural battery components where mechanical load paths and electrical functions are interdependent.

Maritime and rail sectors face even greater regulatory uncertainty, with classification societies like DNV GL developing provisional guidelines that attempt to bridge existing structural codes with emerging battery safety requirements. The International Maritime Organization (IMO) has incorporated limited provisions in the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code), but comprehensive frameworks remain under development.

A critical challenge across all sectors is the lack of standardized test methodologies that can simultaneously evaluate structural performance under crash conditions while monitoring electrical safety parameters. Regulatory bodies increasingly recognize this gap, with initiatives like the European Battery Alliance and the U.S. Department of Energy's Vehicle Technologies Office funding research to develop appropriate test protocols and certification methodologies.

The path toward harmonized global standards remains challenging, with different regions prioritizing various aspects of safety certification. While the European Union emphasizes lifecycle assessment and recycling requirements through the proposed Battery Regulation, North American frameworks focus more heavily on immediate safety performance and crashworthiness metrics. This regulatory divergence creates additional compliance burdens for manufacturers targeting global markets.

For automotive applications, the United Nations Economic Commission for Europe (UNECE) regulations, particularly UN R100 for battery electric vehicles, provide baseline requirements but lack specific provisions for structural battery integration. Similarly, the National Highway Traffic Safety Administration (NHTSA) in the United States maintains Federal Motor Vehicle Safety Standards (FMVSS) that address crashworthiness and battery safety separately, requiring manufacturers to demonstrate compliance with both domains simultaneously.

The International Organization for Standardization (ISO) has begun developing specialized standards, with ISO 21782 addressing performance testing for electric vehicle components and ISO 12405 focusing on lithium-ion traction battery packs. However, these standards require significant adaptation to address the unique challenges of structural battery components where mechanical load paths and electrical functions are interdependent.

Maritime and rail sectors face even greater regulatory uncertainty, with classification societies like DNV GL developing provisional guidelines that attempt to bridge existing structural codes with emerging battery safety requirements. The International Maritime Organization (IMO) has incorporated limited provisions in the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code), but comprehensive frameworks remain under development.

A critical challenge across all sectors is the lack of standardized test methodologies that can simultaneously evaluate structural performance under crash conditions while monitoring electrical safety parameters. Regulatory bodies increasingly recognize this gap, with initiatives like the European Battery Alliance and the U.S. Department of Energy's Vehicle Technologies Office funding research to develop appropriate test protocols and certification methodologies.

The path toward harmonized global standards remains challenging, with different regions prioritizing various aspects of safety certification. While the European Union emphasizes lifecycle assessment and recycling requirements through the proposed Battery Regulation, North American frameworks focus more heavily on immediate safety performance and crashworthiness metrics. This regulatory divergence creates additional compliance burdens for manufacturers targeting global markets.

Environmental Impact and End-of-Life Considerations

The integration of structural battery components into vehicle designs introduces significant environmental considerations that extend beyond traditional vehicle lifecycle assessments. These components represent a dual-purpose technology that serves both structural and energy storage functions, potentially reducing overall material usage and vehicle weight while increasing energy efficiency. However, their environmental impact must be carefully evaluated across the entire lifecycle.

Manufacturing structural battery components typically involves energy-intensive processes and specialized materials including carbon fiber composites, lithium-based compounds, and various electrolytes. The environmental footprint of these manufacturing processes currently exceeds that of conventional structural components due to higher energy requirements and more complex material processing. Quantitative lifecycle assessments indicate that the production phase accounts for approximately 40-60% of the total environmental impact of structural battery components.

During the operational phase, these components offer substantial environmental benefits through weight reduction and improved energy efficiency. Studies suggest that a 10% reduction in vehicle weight can result in 6-8% improvement in fuel economy for conventional vehicles and extended range for electric vehicles. This operational advantage may offset the higher initial environmental costs of manufacturing over the vehicle's service life.

End-of-life management presents unique challenges for structural battery components due to their integrated nature. Traditional recycling processes designed for either batteries or structural components are inadequate for these hybrid systems. Current recycling technologies can recover approximately 50-70% of valuable materials from conventional lithium-ion batteries, but this efficiency decreases significantly for structural battery components due to the difficulty in separating the integrated materials.

Developing specialized recycling protocols for structural battery components represents a critical research area. Advanced separation techniques utilizing mechanical, thermal, and chemical processes are being investigated to improve material recovery rates. Preliminary research indicates that hydrometallurgical processes combined with mechanical pre-treatment may achieve recovery rates of up to 80% for certain materials within structural battery components.

Regulatory frameworks worldwide are beginning to address the environmental implications of these components. The European Union's Battery Directive is being updated to include provisions for integrated battery systems, while the United States Environmental Protection Agency is developing guidelines for the disposal and recycling of multi-functional energy storage components. These regulations will significantly influence the design and implementation of structural battery technologies in the automotive sector.

Design for disassembly and recycling must become fundamental considerations in the development of structural battery components to minimize environmental impact. This includes incorporating features that facilitate separation of materials at end-of-life and selecting material combinations that are compatible with emerging recycling technologies.

Manufacturing structural battery components typically involves energy-intensive processes and specialized materials including carbon fiber composites, lithium-based compounds, and various electrolytes. The environmental footprint of these manufacturing processes currently exceeds that of conventional structural components due to higher energy requirements and more complex material processing. Quantitative lifecycle assessments indicate that the production phase accounts for approximately 40-60% of the total environmental impact of structural battery components.

During the operational phase, these components offer substantial environmental benefits through weight reduction and improved energy efficiency. Studies suggest that a 10% reduction in vehicle weight can result in 6-8% improvement in fuel economy for conventional vehicles and extended range for electric vehicles. This operational advantage may offset the higher initial environmental costs of manufacturing over the vehicle's service life.

End-of-life management presents unique challenges for structural battery components due to their integrated nature. Traditional recycling processes designed for either batteries or structural components are inadequate for these hybrid systems. Current recycling technologies can recover approximately 50-70% of valuable materials from conventional lithium-ion batteries, but this efficiency decreases significantly for structural battery components due to the difficulty in separating the integrated materials.

Developing specialized recycling protocols for structural battery components represents a critical research area. Advanced separation techniques utilizing mechanical, thermal, and chemical processes are being investigated to improve material recovery rates. Preliminary research indicates that hydrometallurgical processes combined with mechanical pre-treatment may achieve recovery rates of up to 80% for certain materials within structural battery components.

Regulatory frameworks worldwide are beginning to address the environmental implications of these components. The European Union's Battery Directive is being updated to include provisions for integrated battery systems, while the United States Environmental Protection Agency is developing guidelines for the disposal and recycling of multi-functional energy storage components. These regulations will significantly influence the design and implementation of structural battery technologies in the automotive sector.

Design for disassembly and recycling must become fundamental considerations in the development of structural battery components to minimize environmental impact. This includes incorporating features that facilitate separation of materials at end-of-life and selecting material combinations that are compatible with emerging recycling technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!