Automotive Body-In-White Integration With Structural Batteries

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Integration Background and Objectives

Structural batteries represent a revolutionary approach to energy storage in automotive design, combining load-bearing capabilities with energy storage functionality. The concept emerged in the early 2000s as researchers sought ways to address the inherent weight penalties associated with conventional battery systems in electric vehicles. By integrating energy storage directly into the vehicle structure, this technology promises to fundamentally transform automotive design paradigms, particularly in the Body-in-White (BiW) phase where the vehicle's structural framework is established.

The evolution of structural batteries has been driven by the automotive industry's push toward electrification coupled with demands for increased range and performance. Traditional approaches have treated batteries and structural components as separate entities, resulting in suboptimal weight distribution and space utilization. The structural battery concept aims to overcome these limitations by creating multifunctional materials that simultaneously serve mechanical and electrochemical functions.

The primary objective of structural battery integration in automotive BiW is to achieve significant weight reduction while maintaining or enhancing structural integrity and safety performance. Research indicates potential weight savings of 15-25% compared to conventional designs, translating to extended driving range and improved energy efficiency. Secondary objectives include optimizing space utilization, enhancing vehicle dynamics through better weight distribution, and reducing manufacturing complexity through parts consolidation.

Current technological trajectories suggest three main approaches to structural battery integration: true multifunctional materials where energy storage occurs within the structural material itself; semi-structural designs where battery packs contribute to vehicle stiffness; and hybrid approaches utilizing composite materials with embedded energy storage capabilities. Each pathway presents unique advantages and technical challenges that must be addressed through systematic research and development.

The integration of structural batteries into automotive BiW processes necessitates a fundamental rethinking of design methodologies, manufacturing techniques, and safety protocols. Achieving this integration requires interdisciplinary collaboration spanning materials science, electrochemistry, structural engineering, and manufacturing technology. The convergence of these disciplines represents both the greatest challenge and opportunity in advancing structural battery technology.

Looking forward, the successful implementation of structural batteries in automotive applications could establish new industry standards for electric vehicle design, potentially extending to aerospace, marine, and other transportation sectors. The technology promises not only performance improvements but also sustainability benefits through more efficient material utilization and potentially simplified end-of-life recycling processes.

The evolution of structural batteries has been driven by the automotive industry's push toward electrification coupled with demands for increased range and performance. Traditional approaches have treated batteries and structural components as separate entities, resulting in suboptimal weight distribution and space utilization. The structural battery concept aims to overcome these limitations by creating multifunctional materials that simultaneously serve mechanical and electrochemical functions.

The primary objective of structural battery integration in automotive BiW is to achieve significant weight reduction while maintaining or enhancing structural integrity and safety performance. Research indicates potential weight savings of 15-25% compared to conventional designs, translating to extended driving range and improved energy efficiency. Secondary objectives include optimizing space utilization, enhancing vehicle dynamics through better weight distribution, and reducing manufacturing complexity through parts consolidation.

Current technological trajectories suggest three main approaches to structural battery integration: true multifunctional materials where energy storage occurs within the structural material itself; semi-structural designs where battery packs contribute to vehicle stiffness; and hybrid approaches utilizing composite materials with embedded energy storage capabilities. Each pathway presents unique advantages and technical challenges that must be addressed through systematic research and development.

The integration of structural batteries into automotive BiW processes necessitates a fundamental rethinking of design methodologies, manufacturing techniques, and safety protocols. Achieving this integration requires interdisciplinary collaboration spanning materials science, electrochemistry, structural engineering, and manufacturing technology. The convergence of these disciplines represents both the greatest challenge and opportunity in advancing structural battery technology.

Looking forward, the successful implementation of structural batteries in automotive applications could establish new industry standards for electric vehicle design, potentially extending to aerospace, marine, and other transportation sectors. The technology promises not only performance improvements but also sustainability benefits through more efficient material utilization and potentially simplified end-of-life recycling processes.

Market Analysis for EV Lightweight Structures

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales reaching 10.5 million units in 2022, representing a 55% increase year-over-year. This surge is driving significant demand for lightweight structural solutions that can extend vehicle range while maintaining safety standards. The market for EV lightweight structures is projected to grow at a CAGR of 14.2% through 2030, reaching approximately $45 billion by the end of the forecast period.

Weight reduction has become a critical competitive factor in the EV industry, with manufacturers targeting 10-15% weight savings in next-generation platforms. This focus stems from the direct correlation between vehicle mass and energy consumption - for every 10% reduction in weight, energy efficiency typically improves by 6-8%. Consequently, the integration of structural batteries into the Body-in-White (BiW) represents a revolutionary approach to weight optimization.

Consumer preferences are increasingly favoring vehicles with longer range capabilities, with surveys indicating that 78% of potential EV buyers consider range anxiety a primary concern. This market pressure is compelling manufacturers to pursue innovative lightweight solutions, with structural battery integration emerging as a promising strategy to address both weight and range limitations simultaneously.

Regional market analysis reveals varying adoption rates for advanced lightweight technologies. European manufacturers lead in carbon fiber composite integration and structural battery research, driven by stringent emissions regulations. North American manufacturers are focusing on aluminum-intensive designs with growing investment in structural battery partnerships. Asian markets, particularly China, are rapidly scaling production capacity for lightweight materials while developing domestic supply chains for advanced battery technologies.

The competitive landscape shows traditional automotive suppliers expanding their capabilities in lightweight structures, while new entrants from the aerospace and advanced materials sectors are introducing disruptive technologies. Joint ventures between battery manufacturers and automotive OEMs are accelerating, with 23 major partnerships announced in the past two years specifically targeting structural battery integration.

Market segmentation analysis indicates that premium and luxury EV segments will likely see the first commercial applications of structural batteries in BiW, with mass-market adoption expected to follow as manufacturing costs decrease. The commercial vehicle segment is also showing increased interest, particularly for delivery vans and light trucks where payload capacity directly impacts operational efficiency.

Weight reduction has become a critical competitive factor in the EV industry, with manufacturers targeting 10-15% weight savings in next-generation platforms. This focus stems from the direct correlation between vehicle mass and energy consumption - for every 10% reduction in weight, energy efficiency typically improves by 6-8%. Consequently, the integration of structural batteries into the Body-in-White (BiW) represents a revolutionary approach to weight optimization.

Consumer preferences are increasingly favoring vehicles with longer range capabilities, with surveys indicating that 78% of potential EV buyers consider range anxiety a primary concern. This market pressure is compelling manufacturers to pursue innovative lightweight solutions, with structural battery integration emerging as a promising strategy to address both weight and range limitations simultaneously.

Regional market analysis reveals varying adoption rates for advanced lightweight technologies. European manufacturers lead in carbon fiber composite integration and structural battery research, driven by stringent emissions regulations. North American manufacturers are focusing on aluminum-intensive designs with growing investment in structural battery partnerships. Asian markets, particularly China, are rapidly scaling production capacity for lightweight materials while developing domestic supply chains for advanced battery technologies.

The competitive landscape shows traditional automotive suppliers expanding their capabilities in lightweight structures, while new entrants from the aerospace and advanced materials sectors are introducing disruptive technologies. Joint ventures between battery manufacturers and automotive OEMs are accelerating, with 23 major partnerships announced in the past two years specifically targeting structural battery integration.

Market segmentation analysis indicates that premium and luxury EV segments will likely see the first commercial applications of structural batteries in BiW, with mass-market adoption expected to follow as manufacturing costs decrease. The commercial vehicle segment is also showing increased interest, particularly for delivery vans and light trucks where payload capacity directly impacts operational efficiency.

Current Challenges in Body-In-White Battery Integration

The integration of structural batteries into automotive Body-in-White (BIW) structures presents significant technical challenges that must be overcome for successful implementation. One primary challenge is the inherent conflict between battery requirements and BIW structural demands. While BIW components must withstand high mechanical loads and crash forces, batteries require protection from physical damage and thermal stability. This fundamental contradiction creates complex design constraints that traditional automotive engineering approaches struggle to resolve.

Material compatibility issues further complicate integration efforts. Structural batteries typically incorporate carbon fiber composites and specialized electrolytes that may react adversely with traditional BIW materials like high-strength steel and aluminum alloys. These potential galvanic corrosion and chemical interaction concerns necessitate careful material selection and interface design to ensure long-term structural integrity and battery performance.

Manufacturing processes present another significant hurdle. Current automotive BIW assembly relies heavily on welding, stamping, and other high-temperature or high-pressure processes that could damage battery components. Developing new manufacturing techniques that can accommodate both structural requirements and battery sensitivity remains a critical challenge, potentially requiring substantial modifications to existing production lines and methodologies.

Thermal management represents a particularly complex challenge in structural battery integration. BIW components are frequently exposed to extreme temperature variations, while batteries require carefully controlled thermal conditions to operate safely and efficiently. Engineering solutions must address heat dissipation during charging/discharging while protecting batteries from external thermal influences, all without compromising structural performance.

Safety certification and regulatory compliance add another layer of complexity. Current automotive safety standards were not designed with structural batteries in mind, creating uncertainty around crash testing protocols, fire safety requirements, and end-of-life recycling procedures. Manufacturers must navigate evolving regulatory frameworks while developing new testing methodologies to validate these hybrid structural-energy systems.

Weight optimization remains a persistent challenge despite the theoretical weight advantages of structural batteries. Current prototypes often fail to achieve the ideal balance between energy density and structural performance, resulting in systems that are either too heavy or too limited in energy storage capacity. Breakthrough materials and design approaches are needed to realize the full weight-saving potential of this technology.

Finally, cost considerations present significant barriers to widespread adoption. The specialized materials, complex manufacturing processes, and extensive testing requirements for structural battery systems currently result in prohibitively high costs compared to conventional BIW structures with separate battery systems. Achieving economic viability will require innovations across the entire development and production chain.

Material compatibility issues further complicate integration efforts. Structural batteries typically incorporate carbon fiber composites and specialized electrolytes that may react adversely with traditional BIW materials like high-strength steel and aluminum alloys. These potential galvanic corrosion and chemical interaction concerns necessitate careful material selection and interface design to ensure long-term structural integrity and battery performance.

Manufacturing processes present another significant hurdle. Current automotive BIW assembly relies heavily on welding, stamping, and other high-temperature or high-pressure processes that could damage battery components. Developing new manufacturing techniques that can accommodate both structural requirements and battery sensitivity remains a critical challenge, potentially requiring substantial modifications to existing production lines and methodologies.

Thermal management represents a particularly complex challenge in structural battery integration. BIW components are frequently exposed to extreme temperature variations, while batteries require carefully controlled thermal conditions to operate safely and efficiently. Engineering solutions must address heat dissipation during charging/discharging while protecting batteries from external thermal influences, all without compromising structural performance.

Safety certification and regulatory compliance add another layer of complexity. Current automotive safety standards were not designed with structural batteries in mind, creating uncertainty around crash testing protocols, fire safety requirements, and end-of-life recycling procedures. Manufacturers must navigate evolving regulatory frameworks while developing new testing methodologies to validate these hybrid structural-energy systems.

Weight optimization remains a persistent challenge despite the theoretical weight advantages of structural batteries. Current prototypes often fail to achieve the ideal balance between energy density and structural performance, resulting in systems that are either too heavy or too limited in energy storage capacity. Breakthrough materials and design approaches are needed to realize the full weight-saving potential of this technology.

Finally, cost considerations present significant barriers to widespread adoption. The specialized materials, complex manufacturing processes, and extensive testing requirements for structural battery systems currently result in prohibitively high costs compared to conventional BIW structures with separate battery systems. Achieving economic viability will require innovations across the entire development and production chain.

Current Technical Solutions for BIW Battery Integration

01 Structural battery integration in vehicles

Structural batteries can be integrated into vehicle structures to serve dual purposes: providing energy storage while also contributing to the structural integrity of the vehicle. This approach reduces overall weight by eliminating the need for separate battery packs and structural components. The integration can be applied to various vehicle types including automobiles, aircraft, and spacecraft, offering improved energy efficiency and range while maintaining or enhancing structural performance.- Structural battery integration in vehicles: Structural batteries can be integrated into vehicle structures to serve dual purposes of energy storage and structural support. This approach reduces overall weight while maintaining or enhancing structural integrity. The integration involves embedding battery cells within load-bearing components such as chassis elements, body panels, or structural frames. This design strategy optimizes space utilization and improves energy efficiency by eliminating the need for separate battery housings.

- Multifunctional composite materials for structural batteries: Advanced composite materials are being developed that combine electrical energy storage capabilities with mechanical load-bearing properties. These multifunctional composites typically incorporate carbon fibers or other conductive materials as structural reinforcement while simultaneously serving as electrodes. The matrix material may contain electrolyte properties or house battery components. This approach enables the creation of lightweight structures with integrated energy storage functionality, particularly valuable for aerospace and automotive applications.

- Thermal management systems for structural batteries: Effective thermal management is critical for structural batteries to maintain optimal performance and safety. These systems incorporate cooling channels, heat-dissipating materials, or phase-change materials directly into the battery structure. The thermal management design must balance electrical performance with structural requirements while preventing thermal runaway conditions. Advanced solutions include integrated sensors for temperature monitoring and adaptive cooling mechanisms that respond to varying thermal loads.

- Manufacturing techniques for structural battery integration: Specialized manufacturing processes have been developed for producing structural batteries, including automated layup techniques, co-curing methods, and additive manufacturing approaches. These processes enable the precise positioning of battery components within structural elements while maintaining mechanical integrity. Advanced manufacturing methods address challenges such as ensuring uniform distribution of active materials, creating reliable electrical connections, and maintaining structural properties during the integration process.

- Structural battery management systems: Specialized battery management systems (BMS) are required for structural batteries to monitor and control both electrical and structural performance. These systems incorporate distributed sensors to track state of charge, temperature, and mechanical stress throughout the integrated structure. Advanced algorithms optimize energy usage while preventing conditions that could compromise structural integrity. The BMS must account for the unique characteristics of structural batteries, including non-uniform current distribution and mechanical load-dependent electrical performance.

02 Multifunctional composite structural batteries

Composite materials can be engineered to function both as structural components and energy storage devices. These multifunctional composites typically incorporate carbon fibers or other conductive materials as structural reinforcement while also serving as electrodes. The matrix material may contain electrolytes or be designed to accommodate them. This approach enables the creation of lightweight structures with integrated energy storage capabilities for applications in aerospace, automotive, and portable electronics.Expand Specific Solutions03 Battery integration in electronic device housings

Structural batteries can be integrated into the housings or frames of electronic devices such as smartphones, laptops, and wearables. This integration allows the device casing to double as an energy storage component, increasing the available battery capacity without increasing device dimensions. The approach involves designing battery components that can withstand mechanical stresses while maintaining electrochemical performance, often using specialized polymers and composite materials.Expand Specific Solutions04 Modeling and simulation of structural batteries

Advanced computational methods are used to model and simulate the behavior of structural batteries under various mechanical and electrical conditions. These simulations help optimize designs by predicting performance characteristics such as mechanical strength, energy density, and cycle life. Multiphysics modeling approaches account for the complex interactions between mechanical stresses, thermal effects, and electrochemical processes in structural battery systems, enabling more efficient development and testing.Expand Specific Solutions05 Manufacturing techniques for structural batteries

Specialized manufacturing techniques have been developed for producing structural batteries, including additive manufacturing, automated fiber placement, and novel lamination processes. These methods enable the precise integration of battery components within structural elements while maintaining both mechanical integrity and electrochemical functionality. Advanced manufacturing approaches also address challenges related to electrical connections, thermal management, and safety features in structural battery systems.Expand Specific Solutions

Key Automotive and Battery Technology Players

The automotive Body-In-White (BIW) integration with structural batteries market is in an early growth phase, characterized by significant R&D investments but limited commercial applications. The global market is projected to expand rapidly as electric vehicle adoption accelerates, with estimates suggesting a potential multi-billion dollar opportunity by 2030. Leading automotive manufacturers like Hyundai, Kia, Mercedes-Benz, and BYD are advancing this technology alongside specialized battery developers such as Contemporary Amperex Technology. Traditional tier-one suppliers including Magna International and Faurecia are also entering this space. Technical maturity varies significantly, with companies like Volvo/Polestar demonstrating advanced prototypes while others like Geely and Ford are still in early development phases. The technology represents a convergence point between automotive structural engineering and battery technology, with Asian manufacturers currently leading commercialization efforts.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative Cell-to-Body (CTB) integration technology that directly incorporates structural battery cells into the vehicle's body structure. Their Qilin Battery utilizes space more efficiently with an integration efficiency of 72%, enabling vehicles to achieve ranges of over 1000km. The structural battery cells serve dual purposes - energy storage and load-bearing components of the vehicle structure. CATL's approach involves specially designed battery cells with enhanced mechanical properties that can withstand structural loads while maintaining high energy density. The cells are integrated into the floor pan and other structural elements of the vehicle body using advanced bonding techniques and specialized interface materials that ensure proper load transfer between the battery and the body structure. This integration significantly reduces the number of parts and weight compared to conventional designs.

Strengths: Achieves significant weight reduction (up to 10%) and space optimization while maintaining structural integrity. The integrated design eliminates redundant structural components, resulting in improved energy efficiency and extended driving range. Weaknesses: Requires complete redesign of vehicle manufacturing processes and raises concerns about repairability and end-of-life recycling.

Ford Global Technologies LLC

Technical Solution: Ford has developed a multi-functional structural battery system that integrates directly with the vehicle's Body-in-White. Their approach utilizes a "cell-to-chassis" design philosophy where specially engineered battery cells are incorporated as load-bearing elements within the vehicle structure. Ford's system employs a novel battery cell housing design that distributes mechanical loads while providing thermal management and electrical isolation. The cells are arranged in a honeycomb-like structure that maximizes energy density while contributing to the vehicle's structural rigidity. Ford has developed proprietary joining methods that allow the battery structure to be securely integrated with the vehicle's steel or aluminum body components, creating a unified structure that enhances crash performance. This integration approach has been implemented in their electric vehicle platforms, where the battery pack forms part of the vehicle's floor structure, contributing significantly to torsional stiffness while eliminating the need for separate protective structures around the battery.

Strengths: Ford's approach achieves significant weight reduction (estimated 12-15%) compared to conventional designs with separate battery packs. The integrated structure enhances vehicle dynamics by lowering the center of gravity and improving weight distribution. Weaknesses: The highly integrated design may increase manufacturing complexity and potentially complicate battery service or replacement over the vehicle's lifetime.

Critical Patents and Research in Structural Battery Systems

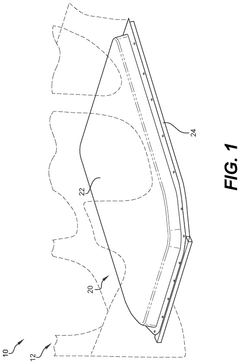

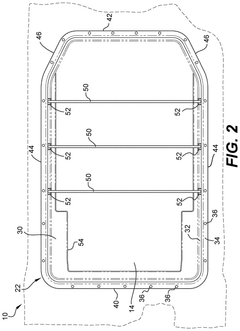

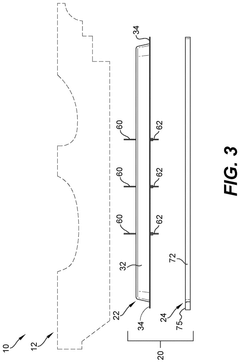

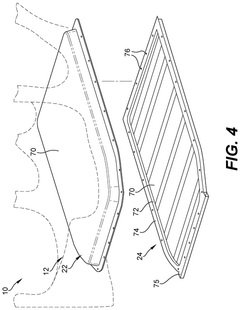

Body-in-white (BIW) integrated battery frame

PatentPendingUS20240336149A1

Innovation

- An integrated battery frame structure and body-in-white (BIW) design that eliminates redundant structures, optimizes load transfer, and increases battery space by integrating battery frame components directly into the BIW, providing enhanced crash protection and simplified installation.

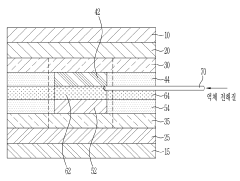

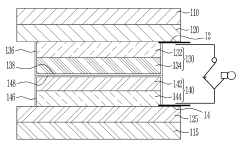

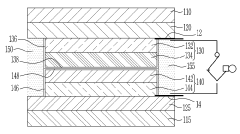

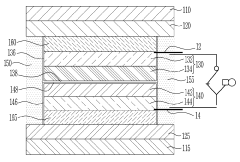

Structural battery for vehicle

PatentPendingKR1020240075016A

Innovation

- A structural battery design that eliminates the liquid electrolyte injection process by using solid electrolytes and carbon fiber current collectors, with insulating and sealing layers made of glass fiber prepreg and SUS material, respectively, to enhance mechanical strength and facilitate room temperature manufacturing.

Safety and Crash Performance Considerations

The integration of structural batteries into automotive Body-in-White (BIW) structures introduces significant safety and crash performance considerations that must be thoroughly addressed before widespread implementation. Traditional vehicle safety systems are designed around conventional BIW structures with predictable deformation patterns during collisions. Structural batteries fundamentally alter these patterns, requiring comprehensive reevaluation of crash dynamics.

Crash energy absorption pathways must be redesigned when battery cells become integral structural elements. Unlike conventional batteries housed in protected enclosures, structural batteries directly experience crash forces. This necessitates novel multi-objective design approaches that balance mechanical load-bearing capabilities with electrochemical performance and safety requirements. Computational modeling indicates that strategic placement of structural batteries away from primary crumple zones can maintain crash performance while maximizing weight reduction benefits.

Material selection for structural battery components presents unique challenges for crash safety. Carbon fiber composites commonly used as electrodes in structural batteries exhibit different failure modes compared to traditional automotive metals. These materials typically demonstrate brittle rather than ductile failure, potentially compromising controlled energy absorption during impacts. Advanced composite designs incorporating strategic fiber orientations and hybrid material systems show promise in addressing these concerns.

Thermal runaway prevention represents a critical safety consideration unique to structural battery integration. Unlike conventional battery packs with dedicated thermal management systems, structural batteries must incorporate intrinsic safety features. Research indicates that phase-change materials embedded within the battery structure can provide passive thermal protection during crash events. Additionally, self-healing polymer electrolytes that maintain integrity during deformation are being developed to prevent short circuits following impact.

Regulatory compliance presents significant hurdles for BIW-integrated structural batteries. Current automotive safety standards (FMVSS, Euro NCAP) do not specifically address structural energy storage components. Industry consortia are working with regulatory bodies to develop appropriate testing protocols that evaluate both mechanical integrity and electrochemical safety during crash events. Preliminary testing suggests that distributed structural battery arrays may actually enhance side-impact protection compared to conventional structures, though frontal crash performance requires careful optimization.

Post-crash safety considerations include emergency response protocols and battery state monitoring. Unlike conventional battery packs, structural batteries cannot be easily isolated or removed following accidents. Advanced sensing technologies embedded within the battery structure are being developed to detect damage and prevent delayed thermal events. These systems must maintain functionality even after significant structural deformation.

Crash energy absorption pathways must be redesigned when battery cells become integral structural elements. Unlike conventional batteries housed in protected enclosures, structural batteries directly experience crash forces. This necessitates novel multi-objective design approaches that balance mechanical load-bearing capabilities with electrochemical performance and safety requirements. Computational modeling indicates that strategic placement of structural batteries away from primary crumple zones can maintain crash performance while maximizing weight reduction benefits.

Material selection for structural battery components presents unique challenges for crash safety. Carbon fiber composites commonly used as electrodes in structural batteries exhibit different failure modes compared to traditional automotive metals. These materials typically demonstrate brittle rather than ductile failure, potentially compromising controlled energy absorption during impacts. Advanced composite designs incorporating strategic fiber orientations and hybrid material systems show promise in addressing these concerns.

Thermal runaway prevention represents a critical safety consideration unique to structural battery integration. Unlike conventional battery packs with dedicated thermal management systems, structural batteries must incorporate intrinsic safety features. Research indicates that phase-change materials embedded within the battery structure can provide passive thermal protection during crash events. Additionally, self-healing polymer electrolytes that maintain integrity during deformation are being developed to prevent short circuits following impact.

Regulatory compliance presents significant hurdles for BIW-integrated structural batteries. Current automotive safety standards (FMVSS, Euro NCAP) do not specifically address structural energy storage components. Industry consortia are working with regulatory bodies to develop appropriate testing protocols that evaluate both mechanical integrity and electrochemical safety during crash events. Preliminary testing suggests that distributed structural battery arrays may actually enhance side-impact protection compared to conventional structures, though frontal crash performance requires careful optimization.

Post-crash safety considerations include emergency response protocols and battery state monitoring. Unlike conventional battery packs, structural batteries cannot be easily isolated or removed following accidents. Advanced sensing technologies embedded within the battery structure are being developed to detect damage and prevent delayed thermal events. These systems must maintain functionality even after significant structural deformation.

Manufacturing Process Adaptations for Structural Batteries

The integration of structural batteries into automotive Body-in-White (BiW) manufacturing requires significant adaptations to existing production processes. Traditional automotive manufacturing relies on well-established methods for metal forming, joining, and assembly that must be reconsidered when incorporating multifunctional components like structural batteries.

Current BiW manufacturing typically involves stamping metal sheets, followed by joining operations using spot welding, adhesive bonding, or mechanical fastening. These processes often involve high temperatures, significant mechanical forces, and chemical treatments that could damage battery components. To accommodate structural batteries, manufacturers must develop lower-temperature joining methods and gentler handling procedures throughout the production line.

Automated assembly systems require reconfiguration to handle the more complex and sensitive nature of battery-integrated components. This includes specialized grippers and fixtures that can safely manipulate battery elements without causing damage to electrodes or separator materials. Vision systems and quality control measures must also be enhanced to detect potential defects specific to battery components, such as electrode misalignment or separator damage.

The introduction of composite materials, commonly used as substrates for structural batteries, presents additional manufacturing challenges. Unlike metal stamping, composite forming requires different equipment and expertise, including compression molding, resin transfer molding, or prepreg layup processes. These methods must be integrated into existing production lines while maintaining throughput rates comparable to conventional manufacturing.

Curing processes for structural battery components typically require precise temperature control and longer cycle times than traditional spot welding. This necessitates redesigned production flow and potentially parallel processing lines to prevent bottlenecks. Additionally, manufacturers must implement specialized testing stations throughout the production process to verify both structural integrity and electrochemical functionality of the integrated components.

Supply chain considerations also impact manufacturing adaptations. The introduction of new materials and components requires coordination with suppliers to ensure consistent quality and timely delivery. This may involve co-development of specialized materials and components that meet both automotive structural requirements and electrochemical performance specifications.

Environmental controls within manufacturing facilities must be enhanced when handling battery materials. Clean room conditions may be necessary for certain assembly operations to prevent contamination that could compromise battery performance or safety. Humidity and temperature control become more critical factors in production environments where battery components are exposed.

Current BiW manufacturing typically involves stamping metal sheets, followed by joining operations using spot welding, adhesive bonding, or mechanical fastening. These processes often involve high temperatures, significant mechanical forces, and chemical treatments that could damage battery components. To accommodate structural batteries, manufacturers must develop lower-temperature joining methods and gentler handling procedures throughout the production line.

Automated assembly systems require reconfiguration to handle the more complex and sensitive nature of battery-integrated components. This includes specialized grippers and fixtures that can safely manipulate battery elements without causing damage to electrodes or separator materials. Vision systems and quality control measures must also be enhanced to detect potential defects specific to battery components, such as electrode misalignment or separator damage.

The introduction of composite materials, commonly used as substrates for structural batteries, presents additional manufacturing challenges. Unlike metal stamping, composite forming requires different equipment and expertise, including compression molding, resin transfer molding, or prepreg layup processes. These methods must be integrated into existing production lines while maintaining throughput rates comparable to conventional manufacturing.

Curing processes for structural battery components typically require precise temperature control and longer cycle times than traditional spot welding. This necessitates redesigned production flow and potentially parallel processing lines to prevent bottlenecks. Additionally, manufacturers must implement specialized testing stations throughout the production process to verify both structural integrity and electrochemical functionality of the integrated components.

Supply chain considerations also impact manufacturing adaptations. The introduction of new materials and components requires coordination with suppliers to ensure consistent quality and timely delivery. This may involve co-development of specialized materials and components that meet both automotive structural requirements and electrochemical performance specifications.

Environmental controls within manufacturing facilities must be enhanced when handling battery materials. Clean room conditions may be necessary for certain assembly operations to prevent contamination that could compromise battery performance or safety. Humidity and temperature control become more critical factors in production environments where battery components are exposed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!