Embedded Sensing And SHM For Structural Battery Health

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Sensing Technology Background and Objectives

Structural batteries represent a revolutionary advancement in energy storage technology, combining load-bearing capabilities with energy storage functionalities. The concept emerged in the early 2000s as researchers sought to address the increasing demand for lightweight, multifunctional materials in aerospace, automotive, and portable electronics industries. The evolution of this technology has been driven by the limitations of conventional battery systems, which add significant weight to structures without contributing to mechanical performance.

The development trajectory of structural batteries has been marked by significant milestones, from initial proof-of-concept designs to increasingly sophisticated carbon fiber-based composites that serve dual functions. Early research focused primarily on embedding traditional battery components within structural materials, while more recent approaches have explored materials that inherently possess both mechanical and electrochemical properties.

Current technological trends indicate a shift toward fully integrated systems where the distinction between structural and energy storage components becomes increasingly blurred. This integration aims to optimize the weight-to-energy ratio while maintaining or enhancing structural integrity. The convergence of advanced materials science, electrochemistry, and structural engineering has accelerated innovation in this field, creating new possibilities for energy-efficient designs.

Embedded sensing and Structural Health Monitoring (SHM) technologies have emerged as critical components in the structural battery ecosystem. These technologies enable real-time monitoring of both mechanical stress and electrochemical performance, addressing the unique challenges posed by multifunctional energy storage systems. The integration of sensing capabilities within structural batteries represents a natural evolution toward smarter, more reliable energy systems.

The primary technical objectives in this field include developing robust sensing methodologies that can accurately detect and predict failure modes specific to structural batteries. These include mechanical degradation, electrochemical aging, thermal anomalies, and the complex interactions between these factors. Additionally, researchers aim to create minimally invasive sensing systems that do not compromise the structural or electrochemical performance of the battery.

Long-term goals encompass the development of self-diagnosing and potentially self-healing structural battery systems that can adapt to changing operational conditions and extend service life. The ultimate vision is to create energy storage solutions that seamlessly integrate with structural components across various applications, from electric vehicles to aerospace structures and wearable technology, while providing continuous health monitoring capabilities.

The advancement of this technology holds promise for significant weight reduction in transportation systems, extended operational range for electric vehicles, and new design possibilities for energy-efficient structures across multiple industries.

The development trajectory of structural batteries has been marked by significant milestones, from initial proof-of-concept designs to increasingly sophisticated carbon fiber-based composites that serve dual functions. Early research focused primarily on embedding traditional battery components within structural materials, while more recent approaches have explored materials that inherently possess both mechanical and electrochemical properties.

Current technological trends indicate a shift toward fully integrated systems where the distinction between structural and energy storage components becomes increasingly blurred. This integration aims to optimize the weight-to-energy ratio while maintaining or enhancing structural integrity. The convergence of advanced materials science, electrochemistry, and structural engineering has accelerated innovation in this field, creating new possibilities for energy-efficient designs.

Embedded sensing and Structural Health Monitoring (SHM) technologies have emerged as critical components in the structural battery ecosystem. These technologies enable real-time monitoring of both mechanical stress and electrochemical performance, addressing the unique challenges posed by multifunctional energy storage systems. The integration of sensing capabilities within structural batteries represents a natural evolution toward smarter, more reliable energy systems.

The primary technical objectives in this field include developing robust sensing methodologies that can accurately detect and predict failure modes specific to structural batteries. These include mechanical degradation, electrochemical aging, thermal anomalies, and the complex interactions between these factors. Additionally, researchers aim to create minimally invasive sensing systems that do not compromise the structural or electrochemical performance of the battery.

Long-term goals encompass the development of self-diagnosing and potentially self-healing structural battery systems that can adapt to changing operational conditions and extend service life. The ultimate vision is to create energy storage solutions that seamlessly integrate with structural components across various applications, from electric vehicles to aerospace structures and wearable technology, while providing continuous health monitoring capabilities.

The advancement of this technology holds promise for significant weight reduction in transportation systems, extended operational range for electric vehicles, and new design possibilities for energy-efficient structures across multiple industries.

Market Analysis for Structural Battery Health Monitoring

The structural battery health monitoring market is experiencing significant growth, driven by the increasing adoption of electric vehicles (EVs) and renewable energy storage systems. Current market valuations indicate that the global structural health monitoring market is projected to reach approximately 4.5 billion USD by 2027, with the battery-specific segment accounting for nearly 15% of this value. This specialized sector is growing at a compound annual growth rate of around 12%, outpacing the broader structural health monitoring market.

The demand for structural battery health monitoring solutions stems primarily from three key sectors: automotive, aerospace, and stationary energy storage. The automotive sector, particularly the EV segment, represents the largest market share at approximately 45% of the total demand. This is attributed to the critical nature of battery performance and safety in electric vehicles, where battery failures can lead to significant safety hazards and costly recalls.

Consumer expectations for longer battery life and enhanced safety features are driving manufacturers to implement more sophisticated monitoring systems. Market research indicates that consumers are willing to pay a premium of 5-8% for vehicles with advanced battery health monitoring capabilities, recognizing the long-term value proposition in terms of safety and battery longevity.

From a geographical perspective, Asia-Pacific currently leads the market with approximately 40% share, followed by North America (30%) and Europe (25%). China, Japan, and South Korea are particularly significant markets due to their robust EV manufacturing ecosystems and government initiatives promoting electric mobility. However, Europe is expected to witness the fastest growth rate in the coming years, driven by stringent environmental regulations and ambitious electrification targets.

The market is also seeing a shift from traditional periodic inspection methods to continuous real-time monitoring solutions. This transition is creating new revenue streams for service providers who offer data analytics and predictive maintenance services. The subscription-based model for these services is growing at approximately 18% annually, indicating strong market acceptance.

Regulatory factors are significantly influencing market dynamics. Safety standards such as UN ECE R100 and ISO 26262 are becoming more stringent regarding battery monitoring requirements, effectively mandating the implementation of advanced monitoring systems in new vehicles. Additionally, insurance companies are beginning to offer reduced premiums for vehicles and energy storage systems equipped with comprehensive battery health monitoring capabilities, further driving market adoption.

The demand for structural battery health monitoring solutions stems primarily from three key sectors: automotive, aerospace, and stationary energy storage. The automotive sector, particularly the EV segment, represents the largest market share at approximately 45% of the total demand. This is attributed to the critical nature of battery performance and safety in electric vehicles, where battery failures can lead to significant safety hazards and costly recalls.

Consumer expectations for longer battery life and enhanced safety features are driving manufacturers to implement more sophisticated monitoring systems. Market research indicates that consumers are willing to pay a premium of 5-8% for vehicles with advanced battery health monitoring capabilities, recognizing the long-term value proposition in terms of safety and battery longevity.

From a geographical perspective, Asia-Pacific currently leads the market with approximately 40% share, followed by North America (30%) and Europe (25%). China, Japan, and South Korea are particularly significant markets due to their robust EV manufacturing ecosystems and government initiatives promoting electric mobility. However, Europe is expected to witness the fastest growth rate in the coming years, driven by stringent environmental regulations and ambitious electrification targets.

The market is also seeing a shift from traditional periodic inspection methods to continuous real-time monitoring solutions. This transition is creating new revenue streams for service providers who offer data analytics and predictive maintenance services. The subscription-based model for these services is growing at approximately 18% annually, indicating strong market acceptance.

Regulatory factors are significantly influencing market dynamics. Safety standards such as UN ECE R100 and ISO 26262 are becoming more stringent regarding battery monitoring requirements, effectively mandating the implementation of advanced monitoring systems in new vehicles. Additionally, insurance companies are beginning to offer reduced premiums for vehicles and energy storage systems equipped with comprehensive battery health monitoring capabilities, further driving market adoption.

Current Challenges in Embedded Sensing for Structural Batteries

Despite significant advancements in embedded sensing technologies for structural health monitoring (SHM), the integration of these systems into structural batteries presents unique and complex challenges. The multifunctional nature of structural batteries, which simultaneously serve as energy storage devices and load-bearing components, creates an intricate environment for sensor implementation. Traditional sensing methods often disrupt the electrochemical performance or mechanical integrity of these batteries, necessitating novel approaches.

One primary challenge is the development of sensors that can withstand the harsh chemical environment within batteries. The electrolytes used in structural batteries are typically corrosive and can degrade conventional sensing materials over time. Additionally, the high voltage potential differences across battery components can interfere with electrical-based sensing systems, leading to signal distortion or sensor failure.

Spatial constraints represent another significant hurdle. Structural batteries are designed to maximize energy density while maintaining mechanical performance, leaving minimal space for sensor integration. Embedding sensors without compromising the battery's volumetric efficiency requires miniaturization beyond current technological capabilities for many sensing modalities.

The dynamic nature of structural batteries during charge-discharge cycles introduces further complications. These components undergo dimensional changes and property variations throughout their operational life, which can affect sensor readings and potentially damage the sensing elements themselves. Developing sensors that can accommodate these changes while maintaining measurement accuracy remains problematic.

Data interpretation presents yet another challenge. The complex interplay between mechanical stress, electrochemical reactions, and thermal effects creates multiphysics phenomena that are difficult to decouple in sensor readings. Current algorithms struggle to differentiate between signals indicating normal operational changes versus those indicating potential failure modes.

Power management for embedded sensors constitutes a paradoxical challenge. While the sensors are embedded within an energy storage device, drawing power from the battery for sensing operations creates a parasitic load that reduces the battery's effective capacity. Self-powered sensing solutions are still in their infancy and often cannot provide the continuous monitoring required for critical applications.

Manufacturing integration represents a significant barrier to widespread implementation. Current production methods for structural batteries are not easily compatible with sensor embedding processes. Introducing sensors during manufacturing can disrupt the carefully controlled fabrication environment, potentially introducing defects or reducing production yields.

Lastly, the long-term reliability of embedded sensors remains largely unproven. Structural batteries in aerospace or automotive applications may need to function reliably for decades, but accelerated aging tests for embedded sensing systems have not been standardized, making lifetime predictions highly uncertain.

One primary challenge is the development of sensors that can withstand the harsh chemical environment within batteries. The electrolytes used in structural batteries are typically corrosive and can degrade conventional sensing materials over time. Additionally, the high voltage potential differences across battery components can interfere with electrical-based sensing systems, leading to signal distortion or sensor failure.

Spatial constraints represent another significant hurdle. Structural batteries are designed to maximize energy density while maintaining mechanical performance, leaving minimal space for sensor integration. Embedding sensors without compromising the battery's volumetric efficiency requires miniaturization beyond current technological capabilities for many sensing modalities.

The dynamic nature of structural batteries during charge-discharge cycles introduces further complications. These components undergo dimensional changes and property variations throughout their operational life, which can affect sensor readings and potentially damage the sensing elements themselves. Developing sensors that can accommodate these changes while maintaining measurement accuracy remains problematic.

Data interpretation presents yet another challenge. The complex interplay between mechanical stress, electrochemical reactions, and thermal effects creates multiphysics phenomena that are difficult to decouple in sensor readings. Current algorithms struggle to differentiate between signals indicating normal operational changes versus those indicating potential failure modes.

Power management for embedded sensors constitutes a paradoxical challenge. While the sensors are embedded within an energy storage device, drawing power from the battery for sensing operations creates a parasitic load that reduces the battery's effective capacity. Self-powered sensing solutions are still in their infancy and often cannot provide the continuous monitoring required for critical applications.

Manufacturing integration represents a significant barrier to widespread implementation. Current production methods for structural batteries are not easily compatible with sensor embedding processes. Introducing sensors during manufacturing can disrupt the carefully controlled fabrication environment, potentially introducing defects or reducing production yields.

Lastly, the long-term reliability of embedded sensors remains largely unproven. Structural batteries in aerospace or automotive applications may need to function reliably for decades, but accelerated aging tests for embedded sensing systems have not been standardized, making lifetime predictions highly uncertain.

Current Embedded Sensing Solutions for Battery Structures

01 Battery health monitoring systems using embedded sensors

Embedded sensors can be integrated into battery systems to continuously monitor various parameters such as temperature, voltage, and current. These sensors provide real-time data on battery health, allowing for early detection of potential issues and preventing failures. The monitoring systems can use machine learning algorithms to analyze the collected data and predict battery degradation patterns, thereby extending battery life and improving overall system reliability.- Battery health monitoring systems: These systems are designed to monitor the health and performance of batteries in real-time. They utilize various sensors and algorithms to track parameters such as voltage, current, temperature, and state of charge. By continuously monitoring these parameters, the systems can detect early signs of battery degradation, predict remaining useful life, and prevent catastrophic failures. These monitoring systems are particularly important for critical applications where battery failure could lead to significant consequences.

- Structural health monitoring with embedded sensors: Embedded sensors are integrated into structural components to continuously monitor their health and integrity. These sensors can detect various parameters such as strain, vibration, temperature, and humidity. The data collected from these sensors is analyzed to assess the structural condition, identify potential damage, and predict maintenance needs. This approach enables proactive maintenance strategies, enhances safety, and extends the service life of structures by detecting issues before they become critical failures.

- Wireless sensor networks for battery monitoring: Wireless sensor networks provide a flexible and scalable solution for battery health monitoring. These networks consist of multiple sensor nodes that communicate wirelessly to collect and transmit data about battery parameters. The wireless nature eliminates the need for complex wiring, reduces installation costs, and allows for easy reconfiguration. These networks can be deployed in various environments, from individual battery cells to large battery banks, enabling comprehensive monitoring and management of battery systems.

- Data analytics and predictive algorithms for battery health: Advanced data analytics and predictive algorithms are employed to process the vast amounts of data collected from battery monitoring systems. These algorithms can identify patterns, detect anomalies, and predict future battery behavior. Machine learning techniques are often used to improve the accuracy of predictions over time. By analyzing historical data and current measurements, these systems can estimate remaining useful life, optimize charging strategies, and recommend maintenance actions to extend battery life and improve reliability.

- Integrated systems for vehicle and infrastructure monitoring: Integrated monitoring systems combine battery health monitoring with broader structural health monitoring for vehicles and infrastructure. These systems provide a comprehensive approach to maintenance and safety by simultaneously tracking multiple critical components. In vehicles, they monitor both the battery systems and structural integrity, while in infrastructure applications, they can monitor embedded power systems alongside structural elements. This integrated approach enables more efficient maintenance planning, reduces downtime, and enhances overall system reliability and safety.

02 Structural health monitoring for battery enclosures and components

Structural health monitoring techniques can be applied to battery enclosures and internal components to detect physical damage, deformation, or degradation. These systems utilize strain gauges, accelerometers, and acoustic sensors to monitor the structural integrity of battery systems. By detecting mechanical failures early, these monitoring systems help prevent catastrophic failures and enhance safety in battery applications, particularly in high-stress environments like electric vehicles and aerospace applications.Expand Specific Solutions03 Wireless and IoT-based battery monitoring networks

Wireless sensor networks and Internet of Things (IoT) technologies enable remote monitoring of battery health across distributed systems. These networks collect and transmit battery performance data to central monitoring stations without requiring physical connections. The wireless approach allows for monitoring batteries in hard-to-reach locations and enables fleet-wide battery management for applications like renewable energy storage systems and electric vehicle fleets.Expand Specific Solutions04 Predictive analytics and diagnostic algorithms for battery health

Advanced algorithms and predictive analytics techniques can be applied to battery monitoring data to forecast remaining useful life and identify potential failure modes. These systems analyze patterns in voltage, temperature, and impedance measurements to detect anomalies before they lead to failures. Machine learning models can be trained on historical battery performance data to improve prediction accuracy over time, enabling condition-based maintenance strategies rather than time-based replacement.Expand Specific Solutions05 Integration of battery health monitoring with broader structural systems

Battery health monitoring can be integrated with broader structural health monitoring systems in applications like smart buildings, aircraft, or infrastructure. This holistic approach allows for comprehensive monitoring of both power systems and the structures they support. Integrated systems can optimize energy usage based on structural demands and environmental conditions, while ensuring that battery systems maintain optimal performance throughout their operational life.Expand Specific Solutions

Leading Companies in Structural Battery Sensing Industry

The embedded sensing and structural health monitoring (SHM) for structural battery health market is currently in its growth phase, with increasing adoption across aerospace, automotive, and energy sectors. The market is projected to expand significantly as battery technologies become more critical in electric vehicles and renewable energy systems. Leading academic institutions like Nanjing University of Aeronautics & Astronautics, Johns Hopkins University, and RWTH Aachen University are advancing fundamental research, while industry players including Boeing, Bosch, and Dukosi are developing commercial applications. The technology maturity varies across segments, with companies like Honeywell and STMicroelectronics focusing on sensor integration, while automotive manufacturers such as Audi are implementing these systems in next-generation vehicles. Collaboration between research institutions and industry is accelerating technological advancement and standardization in this emerging field.

The Boeing Co.

Technical Solution: Boeing has pioneered advanced structural battery health monitoring systems specifically designed for aerospace applications where weight, reliability, and safety are paramount concerns. Their technology integrates a network of distributed piezoelectric sensors embedded within the battery structure that can both sense structural changes and harvest energy from vibrations to power the monitoring system itself. Boeing's approach uses guided wave propagation techniques to detect microscopic cracks and delamination in battery structures before they become critical failures. The system employs machine learning algorithms trained on extensive flight data to differentiate between normal operational stresses and actual structural degradation. Boeing's solution also incorporates thermal runaway prediction capabilities through differential thermal analysis and gas sensing to detect early signs of chemical decomposition within cells. The monitoring system is designed to withstand extreme aerospace environments including rapid pressure and temperature changes, high vibration, and radiation exposure.

Strengths: Aerospace-grade reliability and certification; energy harvesting capabilities reduce power requirements; extensive testing in actual flight conditions ensures real-world performance. Weaknesses: Higher cost implementation suitable primarily for high-value aerospace applications; proprietary nature limits broader industry adoption; complex installation requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive structural battery health monitoring system that combines multiple sensing technologies for enhanced reliability. Their solution integrates ultrasonic sensors, fiber optic strain gauges, and electrochemical impedance spectroscopy (EIS) to create a multi-modal monitoring approach. The ultrasonic sensors detect mechanical deformations and internal structural changes, while fiber optic sensors provide distributed temperature and strain measurements across the battery structure. The EIS component analyzes the electrochemical properties to identify capacity fade and internal resistance changes. Bosch's system employs edge computing capabilities to process sensor data locally, reducing latency for critical safety decisions. Their proprietary fusion algorithms correlate data from different sensor types to distinguish between normal aging patterns and potentially dangerous structural failures, enabling preventive maintenance interventions before catastrophic failures occur.

Strengths: Multi-modal sensing approach provides redundancy and comprehensive monitoring; edge computing capabilities enable real-time analysis and response; extensive automotive industry experience ensures robust implementation. Weaknesses: Complex integration of multiple sensing technologies increases system complexity; higher power consumption compared to simpler monitoring solutions; requires careful calibration across different sensor types.

Key Patents and Research in Structural Battery Monitoring

Structural Health Monitoring Apparatus and Methodology

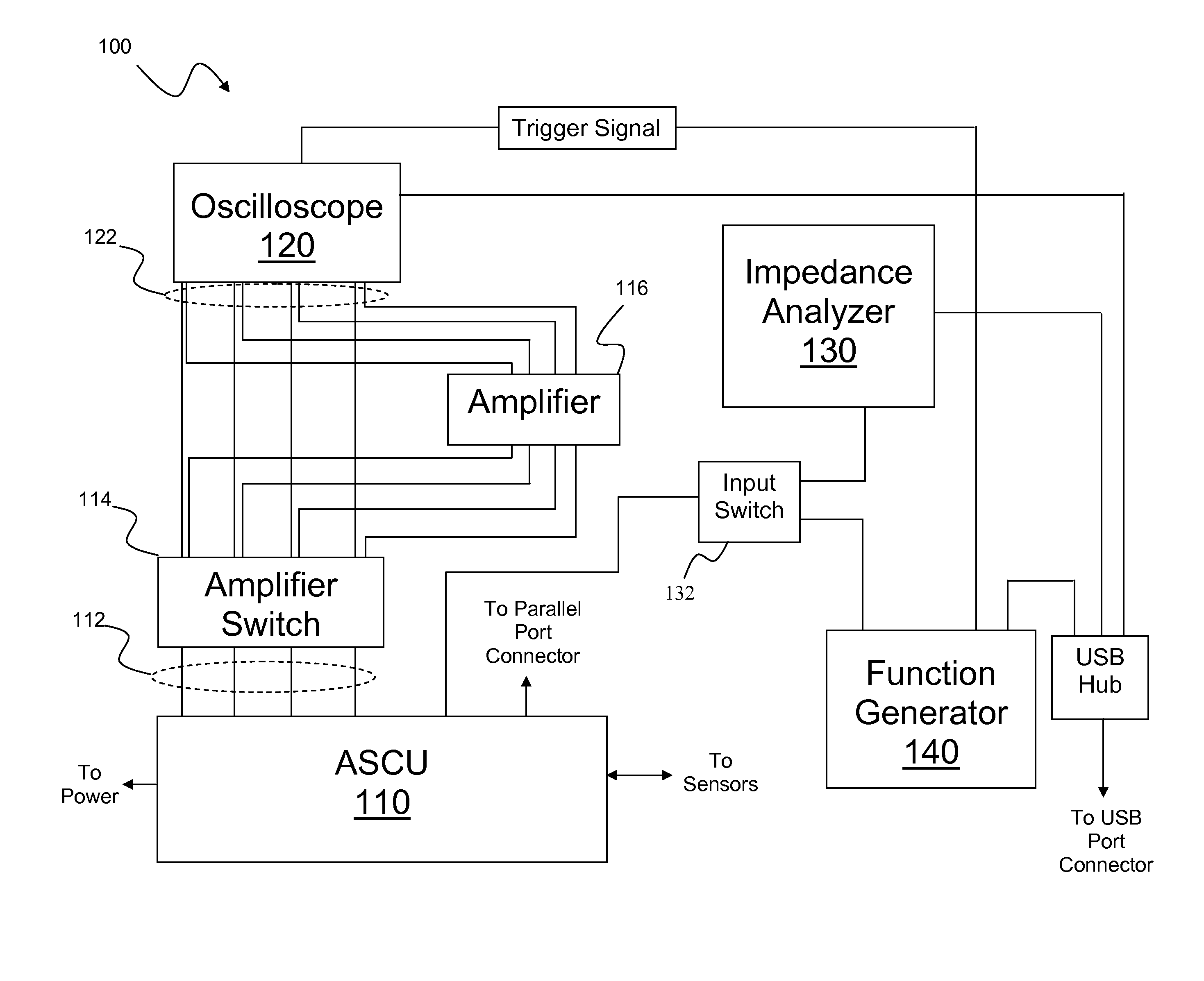

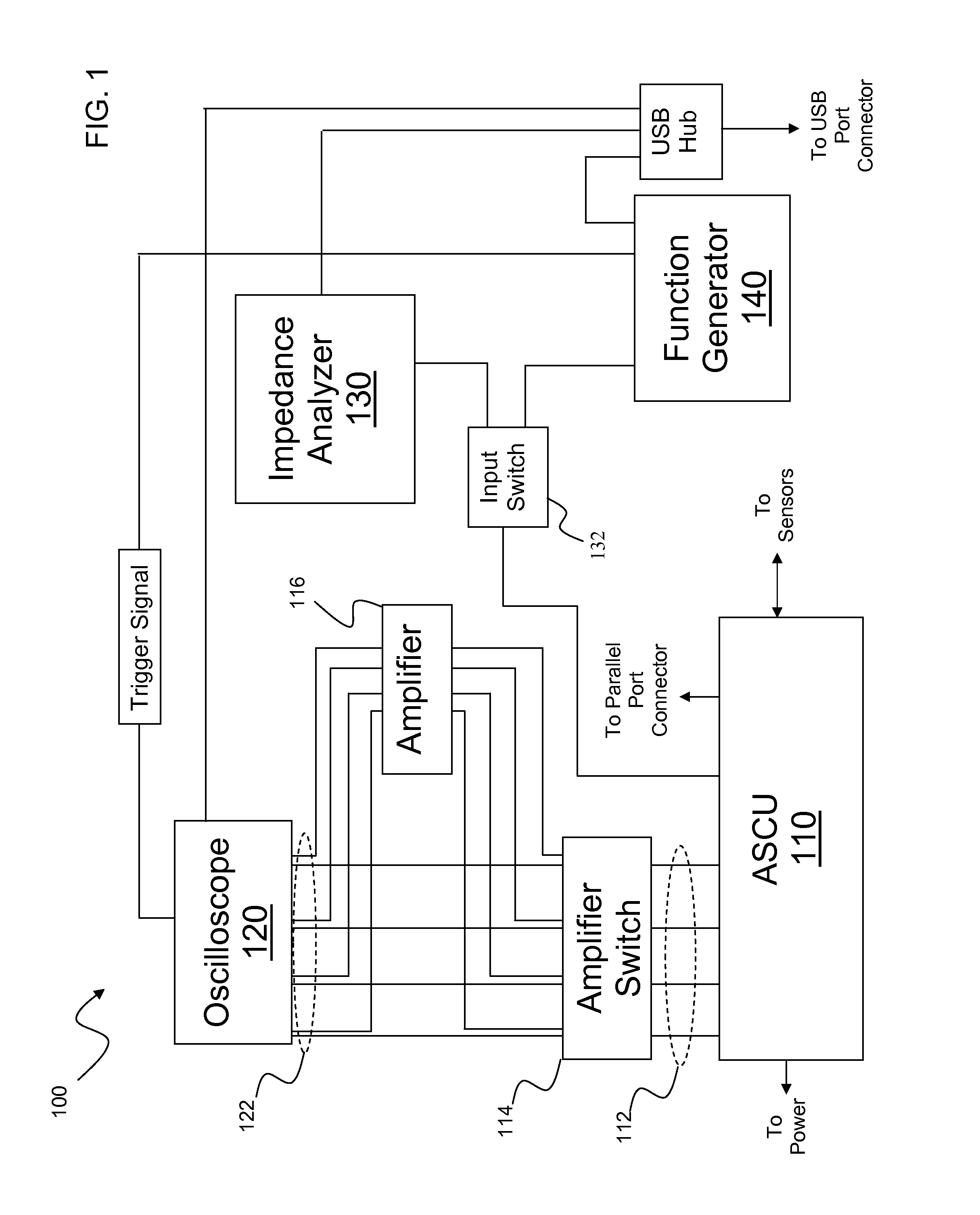

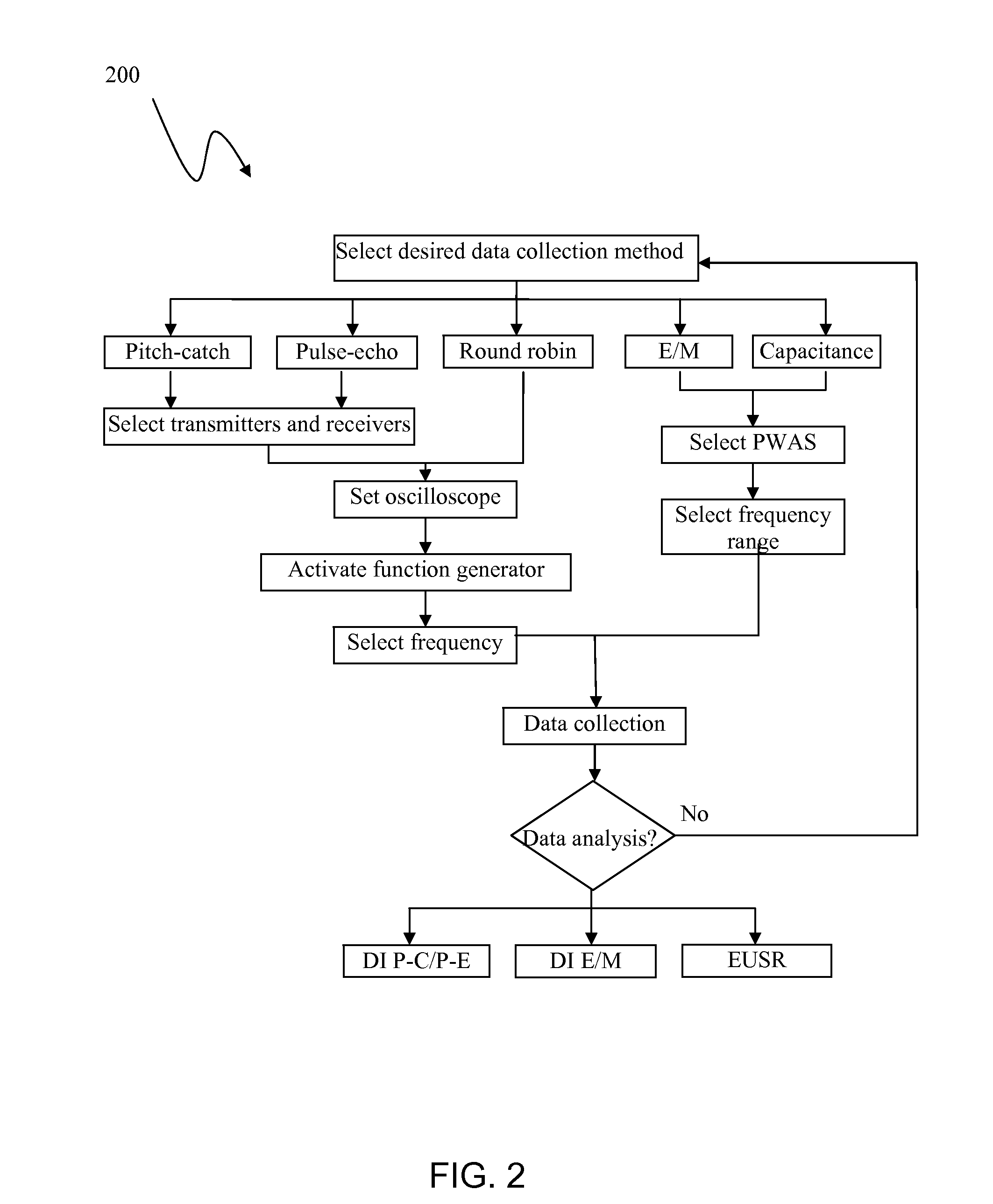

PatentActiveUS20100042338A1

Innovation

- An integrated hardware and software system that allows for automatic control and analysis of structural health data using pitch-catch, pulse-echo, electro/mechanical impedance, and phased array technologies, enabling simplified selection of monitoring aspects, direct calculation of a damage index, and automated data processing to produce scalar numbers representing relationships between data points.

Self-processing integrated damage assessment sensor for structural health monitoring

PatentWO2005048317A2

Innovation

- A self-processing integrated damage assessment sensor (SPIDAS) that embeds small sensor devices within structures to measure high-frequency local impedance spectra, integrating electronics for data acquisition, processing, and wireless communication, enabling compact, cost-effective, and portable structural health monitoring systems.

Safety Standards and Certification Requirements

The integration of structural batteries with embedded sensing and structural health monitoring (SHM) systems necessitates adherence to rigorous safety standards and certification requirements. Currently, this emerging technology operates at the intersection of multiple regulatory domains, including energy storage systems, structural materials, and electronic monitoring devices, creating a complex compliance landscape.

International standards organizations such as ISO, IEC, and ASTM are actively developing frameworks specifically addressing structural batteries with integrated sensing capabilities. ISO/TC 197 and IEC TC 21 have begun drafting guidelines that consider the dual functionality of these components. These standards emphasize the need for comprehensive testing protocols that simultaneously evaluate both energy storage performance and structural integrity under various operational conditions.

Certification requirements for structural battery systems with embedded sensing typically include electrical safety testing (IEC 62133), mechanical durability assessments (ASTM D7136), and environmental exposure evaluations (MIL-STD-810). Additionally, specialized testing for thermal runaway prevention becomes critical when sensors are embedded within battery structures, as these monitoring systems must maintain functionality even during potential failure modes.

Regulatory bodies including the FAA, EASA, and automotive safety organizations have established preliminary certification pathways for structural batteries in transportation applications. These frameworks mandate redundant safety systems and real-time monitoring capabilities, with particular emphasis on failure detection and containment strategies. The UL 1973 standard for batteries in light electric rail and stationary applications has been adapted to include provisions for structural battery systems with integrated health monitoring.

Risk assessment methodologies for these hybrid systems require evaluation across multiple failure domains. The IEC 61508 functional safety standard has been extended to address the unique challenges of embedded sensing in structural batteries, requiring manufacturers to demonstrate system reliability through fault tree analysis and failure mode effects analysis (FMEA) specific to the sensing-structure integration points.

Emerging certification approaches are increasingly adopting performance-based standards rather than prescriptive requirements, allowing for technological innovation while maintaining safety thresholds. This shift recognizes the rapid evolution of embedded sensing technologies and the need for flexible regulatory frameworks that can accommodate advances in materials science and sensor miniaturization without compromising safety objectives.

Harmonization efforts between different regulatory bodies remain ongoing, with international working groups focused on developing unified testing protocols and certification pathways that recognize the multifunctional nature of structural batteries with embedded sensing capabilities. These collaborative initiatives aim to establish globally recognized standards that facilitate market adoption while ensuring consistent safety performance across diverse applications and operating environments.

International standards organizations such as ISO, IEC, and ASTM are actively developing frameworks specifically addressing structural batteries with integrated sensing capabilities. ISO/TC 197 and IEC TC 21 have begun drafting guidelines that consider the dual functionality of these components. These standards emphasize the need for comprehensive testing protocols that simultaneously evaluate both energy storage performance and structural integrity under various operational conditions.

Certification requirements for structural battery systems with embedded sensing typically include electrical safety testing (IEC 62133), mechanical durability assessments (ASTM D7136), and environmental exposure evaluations (MIL-STD-810). Additionally, specialized testing for thermal runaway prevention becomes critical when sensors are embedded within battery structures, as these monitoring systems must maintain functionality even during potential failure modes.

Regulatory bodies including the FAA, EASA, and automotive safety organizations have established preliminary certification pathways for structural batteries in transportation applications. These frameworks mandate redundant safety systems and real-time monitoring capabilities, with particular emphasis on failure detection and containment strategies. The UL 1973 standard for batteries in light electric rail and stationary applications has been adapted to include provisions for structural battery systems with integrated health monitoring.

Risk assessment methodologies for these hybrid systems require evaluation across multiple failure domains. The IEC 61508 functional safety standard has been extended to address the unique challenges of embedded sensing in structural batteries, requiring manufacturers to demonstrate system reliability through fault tree analysis and failure mode effects analysis (FMEA) specific to the sensing-structure integration points.

Emerging certification approaches are increasingly adopting performance-based standards rather than prescriptive requirements, allowing for technological innovation while maintaining safety thresholds. This shift recognizes the rapid evolution of embedded sensing technologies and the need for flexible regulatory frameworks that can accommodate advances in materials science and sensor miniaturization without compromising safety objectives.

Harmonization efforts between different regulatory bodies remain ongoing, with international working groups focused on developing unified testing protocols and certification pathways that recognize the multifunctional nature of structural batteries with embedded sensing capabilities. These collaborative initiatives aim to establish globally recognized standards that facilitate market adoption while ensuring consistent safety performance across diverse applications and operating environments.

Environmental Impact and Sustainability Considerations

The integration of embedded sensing and structural health monitoring (SHM) systems in structural batteries presents significant environmental and sustainability implications that warrant careful consideration. These advanced monitoring technologies can substantially extend battery lifespan through early detection of degradation patterns, thereby reducing the frequency of replacements and associated waste generation. This lifecycle extension directly contributes to resource conservation by decreasing the demand for raw materials required in battery manufacturing, including critical minerals like lithium, cobalt, and nickel that often involve environmentally damaging extraction processes.

From a circular economy perspective, SHM systems enable more precise end-of-life determinations for structural batteries. Rather than relying on conservative replacement schedules, these systems allow batteries to remain in service until actual performance degradation occurs, maximizing useful life. Additionally, the detailed health data collected facilitates more effective recycling processes by providing precise information about battery composition and degradation state, potentially increasing recovery rates of valuable materials.

Energy efficiency represents another crucial environmental benefit of embedded sensing technologies. By optimizing charging cycles and operational parameters based on real-time health data, these systems can reduce energy consumption throughout the battery lifecycle. This optimization directly translates to lower carbon emissions, particularly when considering the energy-intensive nature of battery manufacturing and the potential for reduced charging inefficiencies.

The manufacturing processes for embedded sensors themselves must be evaluated for environmental impact. While miniaturized sensors generally require fewer materials than traditional monitoring equipment, their production may involve specialized materials with significant ecological footprints. Manufacturers are increasingly developing biodegradable or recyclable sensor components to address these concerns, though challenges remain in balancing performance requirements with environmental considerations.

When implemented in electric vehicles and renewable energy storage systems, structural battery monitoring technologies contribute to broader sustainability goals by enhancing the reliability and efficiency of clean energy technologies. The improved performance and safety profiles enabled by these systems accelerate the adoption of electric mobility and renewable energy integration, supporting the transition away from fossil fuel dependence.

Future research directions should focus on developing self-powered sensing systems that harvest energy from the battery's operational environment, eliminating the need for separate power sources and further reducing environmental impact. Additionally, designing monitoring systems with end-of-life considerations from the outset will ensure these technologies themselves don't create new waste streams as they become more widely deployed.

From a circular economy perspective, SHM systems enable more precise end-of-life determinations for structural batteries. Rather than relying on conservative replacement schedules, these systems allow batteries to remain in service until actual performance degradation occurs, maximizing useful life. Additionally, the detailed health data collected facilitates more effective recycling processes by providing precise information about battery composition and degradation state, potentially increasing recovery rates of valuable materials.

Energy efficiency represents another crucial environmental benefit of embedded sensing technologies. By optimizing charging cycles and operational parameters based on real-time health data, these systems can reduce energy consumption throughout the battery lifecycle. This optimization directly translates to lower carbon emissions, particularly when considering the energy-intensive nature of battery manufacturing and the potential for reduced charging inefficiencies.

The manufacturing processes for embedded sensors themselves must be evaluated for environmental impact. While miniaturized sensors generally require fewer materials than traditional monitoring equipment, their production may involve specialized materials with significant ecological footprints. Manufacturers are increasingly developing biodegradable or recyclable sensor components to address these concerns, though challenges remain in balancing performance requirements with environmental considerations.

When implemented in electric vehicles and renewable energy storage systems, structural battery monitoring technologies contribute to broader sustainability goals by enhancing the reliability and efficiency of clean energy technologies. The improved performance and safety profiles enabled by these systems accelerate the adoption of electric mobility and renewable energy integration, supporting the transition away from fossil fuel dependence.

Future research directions should focus on developing self-powered sensing systems that harvest energy from the battery's operational environment, eliminating the need for separate power sources and further reducing environmental impact. Additionally, designing monitoring systems with end-of-life considerations from the outset will ensure these technologies themselves don't create new waste streams as they become more widely deployed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!