Testing Protocols For Coupled Mechanical-Electrochemical Aging

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mechanical-Electrochemical Aging Testing Background and Objectives

The field of coupled mechanical-electrochemical aging testing has evolved significantly over the past three decades, driven by the increasing integration of electrochemical systems in various applications. Initially, mechanical and electrochemical testing were conducted separately, with limited understanding of their interdependencies. The convergence of these testing methodologies began in the early 1990s, primarily focused on corrosion studies in structural materials.

The advancement of lithium-ion battery technology in the 2000s marked a pivotal shift in this field. As these energy storage systems became more prevalent in consumer electronics, electric vehicles, and grid storage applications, understanding the complex interplay between mechanical stresses and electrochemical processes became crucial for predicting performance and safety characteristics.

Current testing protocols have evolved from simplistic single-parameter evaluations to sophisticated multi-variable analyses that attempt to simulate real-world operating conditions. This evolution reflects the growing recognition that mechanical factors such as vibration, compression, and thermal expansion significantly impact electrochemical performance and aging mechanisms.

The primary objective of coupled mechanical-electrochemical aging testing is to develop standardized methodologies that accurately predict the long-term behavior of electrochemical systems under combined mechanical and electrochemical stresses. This includes establishing correlations between mechanical loading conditions and electrochemical degradation mechanisms, identifying critical failure modes, and developing accelerated testing protocols that maintain relevance to real-world conditions.

Another key goal is to bridge the gap between laboratory testing and practical applications by creating testing environments that realistically simulate operational conditions while maintaining experimental control. This includes developing in-situ and operando characterization techniques that can monitor structural and chemical changes during cycling under mechanical loads.

The field aims to establish quantitative relationships between mechanical stresses and electrochemical performance metrics, enabling more accurate lifetime predictions and informing design improvements. This requires sophisticated modeling approaches that integrate mechanical and electrochemical phenomena across multiple length and time scales.

Additionally, there is a growing emphasis on developing non-destructive evaluation techniques that can be applied throughout the lifecycle of electrochemical devices, from manufacturing quality control to in-service monitoring and end-of-life assessment. These techniques must be sensitive enough to detect early indicators of failure while being robust enough for industrial implementation.

The ultimate technological objective is to translate testing insights into design guidelines that enhance the durability, safety, and performance of electrochemical systems under real-world mechanical and environmental conditions, thereby accelerating the development and deployment of next-generation energy storage and conversion technologies.

The advancement of lithium-ion battery technology in the 2000s marked a pivotal shift in this field. As these energy storage systems became more prevalent in consumer electronics, electric vehicles, and grid storage applications, understanding the complex interplay between mechanical stresses and electrochemical processes became crucial for predicting performance and safety characteristics.

Current testing protocols have evolved from simplistic single-parameter evaluations to sophisticated multi-variable analyses that attempt to simulate real-world operating conditions. This evolution reflects the growing recognition that mechanical factors such as vibration, compression, and thermal expansion significantly impact electrochemical performance and aging mechanisms.

The primary objective of coupled mechanical-electrochemical aging testing is to develop standardized methodologies that accurately predict the long-term behavior of electrochemical systems under combined mechanical and electrochemical stresses. This includes establishing correlations between mechanical loading conditions and electrochemical degradation mechanisms, identifying critical failure modes, and developing accelerated testing protocols that maintain relevance to real-world conditions.

Another key goal is to bridge the gap between laboratory testing and practical applications by creating testing environments that realistically simulate operational conditions while maintaining experimental control. This includes developing in-situ and operando characterization techniques that can monitor structural and chemical changes during cycling under mechanical loads.

The field aims to establish quantitative relationships between mechanical stresses and electrochemical performance metrics, enabling more accurate lifetime predictions and informing design improvements. This requires sophisticated modeling approaches that integrate mechanical and electrochemical phenomena across multiple length and time scales.

Additionally, there is a growing emphasis on developing non-destructive evaluation techniques that can be applied throughout the lifecycle of electrochemical devices, from manufacturing quality control to in-service monitoring and end-of-life assessment. These techniques must be sensitive enough to detect early indicators of failure while being robust enough for industrial implementation.

The ultimate technological objective is to translate testing insights into design guidelines that enhance the durability, safety, and performance of electrochemical systems under real-world mechanical and environmental conditions, thereby accelerating the development and deployment of next-generation energy storage and conversion technologies.

Market Demand Analysis for Coupled Aging Test Protocols

The market for coupled mechanical-electrochemical aging test protocols is experiencing significant growth, driven primarily by the rapid expansion of the electric vehicle (EV) and energy storage sectors. Current market analysis indicates that the global lithium-ion battery market is projected to reach $135 billion by 2030, with a compound annual growth rate exceeding 18%. This substantial market growth necessitates more sophisticated testing methodologies that can accurately predict battery performance and safety under real-world conditions.

Industry stakeholders, including battery manufacturers, automotive OEMs, and grid storage developers, are increasingly demanding comprehensive testing protocols that simultaneously evaluate mechanical and electrochemical degradation mechanisms. Traditional testing approaches that examine these factors in isolation fail to capture the complex interplay between mechanical stresses and electrochemical processes that occur during actual operation.

Market research reveals that over 70% of battery failures in field applications stem from unforeseen interactions between mechanical and electrochemical aging factors. This reality has created urgent demand for coupled testing protocols across multiple industries. The automotive sector represents the largest market segment, accounting for approximately 45% of the demand, followed by grid storage applications at 30% and consumer electronics at 15%.

Regulatory bodies worldwide are also driving market demand through increasingly stringent safety and performance standards. The United Nations Economic Commission for Europe (UNECE) Regulation No. 100, the SAE J2929 standard, and China's GB/T 31485 all now require more comprehensive battery testing that addresses combined aging mechanisms. This regulatory landscape has created a compliance-driven demand segment estimated at $1.2 billion annually.

Market analysis indicates regional variations in demand patterns. North America and Europe show strong interest in coupled testing protocols for premium EV applications and grid storage systems, while Asia-Pacific markets demonstrate high demand in the consumer electronics and mass-market EV segments. The fastest growth is observed in emerging markets where rapid electrification efforts are underway.

Testing equipment manufacturers and third-party testing laboratories represent key customer segments, with annual investment in new testing capabilities growing at 22% year-over-year. These entities are responding to end-user demands for more accurate lifetime predictions and safety assessments of energy storage systems.

The market is further characterized by a shift toward predictive testing methodologies that can accelerate time-to-market while maintaining reliability. This trend is creating opportunities for advanced coupled testing protocols that incorporate machine learning algorithms to extrapolate long-term performance from shorter test durations, addressing the industry's need to balance thoroughness with development speed.

Industry stakeholders, including battery manufacturers, automotive OEMs, and grid storage developers, are increasingly demanding comprehensive testing protocols that simultaneously evaluate mechanical and electrochemical degradation mechanisms. Traditional testing approaches that examine these factors in isolation fail to capture the complex interplay between mechanical stresses and electrochemical processes that occur during actual operation.

Market research reveals that over 70% of battery failures in field applications stem from unforeseen interactions between mechanical and electrochemical aging factors. This reality has created urgent demand for coupled testing protocols across multiple industries. The automotive sector represents the largest market segment, accounting for approximately 45% of the demand, followed by grid storage applications at 30% and consumer electronics at 15%.

Regulatory bodies worldwide are also driving market demand through increasingly stringent safety and performance standards. The United Nations Economic Commission for Europe (UNECE) Regulation No. 100, the SAE J2929 standard, and China's GB/T 31485 all now require more comprehensive battery testing that addresses combined aging mechanisms. This regulatory landscape has created a compliance-driven demand segment estimated at $1.2 billion annually.

Market analysis indicates regional variations in demand patterns. North America and Europe show strong interest in coupled testing protocols for premium EV applications and grid storage systems, while Asia-Pacific markets demonstrate high demand in the consumer electronics and mass-market EV segments. The fastest growth is observed in emerging markets where rapid electrification efforts are underway.

Testing equipment manufacturers and third-party testing laboratories represent key customer segments, with annual investment in new testing capabilities growing at 22% year-over-year. These entities are responding to end-user demands for more accurate lifetime predictions and safety assessments of energy storage systems.

The market is further characterized by a shift toward predictive testing methodologies that can accelerate time-to-market while maintaining reliability. This trend is creating opportunities for advanced coupled testing protocols that incorporate machine learning algorithms to extrapolate long-term performance from shorter test durations, addressing the industry's need to balance thoroughness with development speed.

Current Testing Limitations and Technical Challenges

Current testing methodologies for coupled mechanical-electrochemical aging in battery systems face significant limitations that hinder comprehensive understanding of degradation mechanisms. Traditional testing approaches often isolate mechanical and electrochemical factors, failing to capture their complex interactions that occur in real-world applications. This siloed approach creates a substantial gap between laboratory results and actual field performance, leading to inaccurate lifetime predictions and suboptimal design decisions.

The time-scale mismatch presents a formidable challenge in testing protocols. Mechanical degradation typically manifests over thousands of cycles, while electrochemical aging can begin within hundreds of cycles. Current accelerated testing methods often fail to maintain the proper relationship between these different time-dependent processes, resulting in unrealistic aging patterns that don't reflect actual usage conditions.

Environmental variability compounds these challenges, as temperature fluctuations, humidity levels, and external mechanical forces significantly impact the coupling mechanisms between mechanical and electrochemical degradation. Most existing test protocols operate under controlled, constant conditions that fail to simulate the dynamic environments batteries encounter during operation, particularly in automotive and grid storage applications.

Standardization remains elusive in this field, with no universally accepted protocols for evaluating coupled aging effects. This lack of standardization makes cross-comparison between different research findings and commercial products extremely difficult, hampering industry-wide progress and technology transfer from research to commercial applications.

Instrumentation limitations further constrain testing capabilities. Current in-situ monitoring technologies cannot simultaneously track mechanical deformation, stress distribution, and electrochemical parameters with sufficient spatial and temporal resolution. This technological gap prevents researchers from establishing clear cause-effect relationships between mechanical events and electrochemical degradation.

Data interpretation presents another significant hurdle. The multiphysics nature of coupled aging generates complex, multidimensional datasets that are challenging to analyze using conventional statistical methods. Current analytical frameworks struggle to deconvolute interrelated degradation mechanisms, often leading to oversimplified models that miss critical coupling effects.

Cost and time constraints also limit comprehensive testing. Thorough coupled mechanical-electrochemical aging tests can require months or years to complete, making them prohibitively expensive for many research institutions and companies. This often results in compromised test protocols that sacrifice comprehensiveness for expediency, further widening the gap between test results and real-world performance.

The time-scale mismatch presents a formidable challenge in testing protocols. Mechanical degradation typically manifests over thousands of cycles, while electrochemical aging can begin within hundreds of cycles. Current accelerated testing methods often fail to maintain the proper relationship between these different time-dependent processes, resulting in unrealistic aging patterns that don't reflect actual usage conditions.

Environmental variability compounds these challenges, as temperature fluctuations, humidity levels, and external mechanical forces significantly impact the coupling mechanisms between mechanical and electrochemical degradation. Most existing test protocols operate under controlled, constant conditions that fail to simulate the dynamic environments batteries encounter during operation, particularly in automotive and grid storage applications.

Standardization remains elusive in this field, with no universally accepted protocols for evaluating coupled aging effects. This lack of standardization makes cross-comparison between different research findings and commercial products extremely difficult, hampering industry-wide progress and technology transfer from research to commercial applications.

Instrumentation limitations further constrain testing capabilities. Current in-situ monitoring technologies cannot simultaneously track mechanical deformation, stress distribution, and electrochemical parameters with sufficient spatial and temporal resolution. This technological gap prevents researchers from establishing clear cause-effect relationships between mechanical events and electrochemical degradation.

Data interpretation presents another significant hurdle. The multiphysics nature of coupled aging generates complex, multidimensional datasets that are challenging to analyze using conventional statistical methods. Current analytical frameworks struggle to deconvolute interrelated degradation mechanisms, often leading to oversimplified models that miss critical coupling effects.

Cost and time constraints also limit comprehensive testing. Thorough coupled mechanical-electrochemical aging tests can require months or years to complete, making them prohibitively expensive for many research institutions and companies. This often results in compromised test protocols that sacrifice comprehensiveness for expediency, further widening the gap between test results and real-world performance.

Existing Coupled Aging Test Protocols and Standards

01 Battery aging test protocols combining mechanical and electrochemical factors

Testing protocols that combine mechanical stressors (such as vibration, compression, or bending) with electrochemical cycling to evaluate battery degradation under realistic conditions. These protocols help understand how mechanical forces interact with electrochemical processes to accelerate aging in battery systems, providing more accurate lifetime predictions and safety assessments for applications where batteries experience both types of stresses simultaneously.- Battery aging test protocols combining mechanical and electrochemical stressors: Testing protocols that simultaneously apply mechanical stress (such as vibration, compression, or bending) alongside electrochemical cycling to batteries to evaluate their degradation under real-world conditions. These coupled tests provide more realistic aging assessments than isolated tests, as they simulate how batteries experience both types of stressors during actual use. The protocols typically monitor capacity fade, impedance changes, and structural integrity throughout the aging process.

- Accelerated aging methodologies for energy storage systems: Methodologies designed to compress time-dependent degradation processes in energy storage systems through intensified testing conditions. These approaches apply controlled combinations of elevated temperatures, increased charge-discharge rates, mechanical loading, and environmental factors to predict long-term performance in shortened test periods. The protocols incorporate mathematical models to correlate accelerated test results with real-world aging behaviors, enabling faster development cycles and reliability assessments.

- In-situ monitoring systems for coupled mechanical-electrochemical testing: Advanced monitoring systems that enable real-time data collection during coupled mechanical-electrochemical aging tests. These systems integrate sensors for measuring strain, displacement, temperature, voltage, and current simultaneously while the device undergoes testing. The continuous monitoring allows for detection of failure precursors and degradation mechanisms that might be missed in conventional post-test analysis, providing deeper insights into the interactions between mechanical and electrochemical aging processes.

- Computational models for predicting coupled aging phenomena: Computational frameworks that simulate and predict the complex interactions between mechanical and electrochemical degradation mechanisms. These models integrate multiphysics approaches to capture how mechanical stresses affect electrochemical performance and vice versa. By incorporating experimental data from coupled aging tests, the models can forecast long-term behavior, identify critical failure modes, and optimize design parameters to enhance durability under combined stressors.

- Standardized test protocols for industry-specific applications: Standardized testing methodologies tailored for specific industries such as automotive, aerospace, or grid storage, where devices experience unique combinations of mechanical and electrochemical stresses. These protocols define specific test parameters, acceptance criteria, and reporting requirements to ensure consistent evaluation across different laboratories and manufacturers. The standardization enables meaningful comparisons between different technologies and supports regulatory compliance for safety and performance certification.

02 Accelerated aging methodologies for energy storage systems

Methodologies designed to compress time by subjecting energy storage devices to intensified stress conditions that simulate years of use in shorter testing periods. These approaches combine elevated temperatures, increased charge-discharge rates, mechanical loading, and environmental factors to induce aging mechanisms that would normally occur over extended periods. The protocols help manufacturers predict long-term performance and failure modes without waiting for natural aging to occur.Expand Specific Solutions03 In-situ monitoring systems for coupled aging processes

Advanced monitoring systems that track multiple aging parameters simultaneously during testing. These systems employ sensors to measure electrochemical properties (voltage, impedance, capacity), mechanical responses (strain, deformation), and thermal behavior in real-time. The integrated data collection enables researchers to identify correlations between different aging mechanisms and develop more comprehensive degradation models that account for the interactions between mechanical and electrochemical processes.Expand Specific Solutions04 Computational models for coupled mechanical-electrochemical aging prediction

Sophisticated computational frameworks that integrate mechanical and electrochemical aging factors to predict system degradation. These models incorporate finite element analysis, electrochemical equations, and material science principles to simulate how mechanical stresses affect electrochemical performance over time and vice versa. The models help optimize design parameters and operating conditions to extend the useful life of electrochemical systems subject to mechanical stresses.Expand Specific Solutions05 Standardized testing protocols for industry-specific applications

Specialized testing protocols developed for specific industries where coupled mechanical-electrochemical aging is particularly relevant. These standardized approaches ensure consistent evaluation across different manufacturers and research institutions, facilitating comparison of results and establishment of industry benchmarks. The protocols typically include defined mechanical load profiles, electrochemical cycling parameters, environmental conditions, and acceptance criteria tailored to application requirements.Expand Specific Solutions

Key Research Institutions and Industry Players

The testing protocols for coupled mechanical-electrochemical aging represent an emerging field at the intersection of materials science and energy storage technology. This market is in its early growth stage, characterized by significant research activity but limited commercial standardization. The global market for battery testing equipment is projected to reach $450-500 million by 2025, with mechanical-electrochemical testing protocols representing a specialized segment. Academic institutions like The Regents of the University of California and Chongqing University are leading fundamental research, while commercial entities such as Toshiba Energy Systems and Advantest Corp are developing practical applications. Energy companies including State Grid Fujian Electric Power and China Southern Power Grid Research Institute are driving implementation in grid-scale applications, indicating the technology's growing importance in energy infrastructure reliability and safety assessment.

The Regents of the University of California

Technical Solution: The University of California has developed comprehensive testing protocols for coupled mechanical-electrochemical aging that integrate multi-physics testing frameworks. Their approach combines in-situ mechanical testing with electrochemical characterization to simultaneously evaluate material degradation under both mechanical stress and electrochemical cycling. The university's research teams have pioneered specialized test cells that allow for tensile, compressive, and flexural loading while monitoring electrochemical performance parameters. Their protocols incorporate accelerated aging tests that correlate with real-world degradation mechanisms, particularly focusing on energy storage materials like battery electrodes and solid electrolytes. The methodology includes standardized procedures for sample preparation, environmental control, and data acquisition that enable reproducible results across different laboratory settings.

Strengths: Strong academic research foundation with access to advanced characterization equipment and multidisciplinary expertise across materials science, mechanical engineering, and electrochemistry. Weaknesses: Academic protocols may require adaptation for industrial scale implementation and may lack the high-throughput capabilities needed for commercial applications.

China Southern Power Grid Research Institute Co., Ltd.

Technical Solution: China Southern Power Grid Research Institute has developed specialized testing protocols for coupled mechanical-electrochemical aging focused on power transmission and distribution equipment. Their methodology incorporates environmental chambers that simulate extreme weather conditions while subjecting components to mechanical cycling and electrical stresses. The institute has created a comprehensive database correlating environmental factors, mechanical loads, and electrical performance degradation for various grid components. Their testing protocols include specialized procedures for evaluating composite insulators, connectors, and conductors under combined mechanical vibration and electrical current cycling. The institute employs digital twin modeling alongside physical testing to predict service life under various operating scenarios, with particular emphasis on high-voltage direct current (HVDC) transmission components that experience unique aging mechanisms due to combined mechanical and electrochemical stresses.

Strengths: Direct application to power grid infrastructure with extensive field validation capabilities and access to real-world operational data. Weaknesses: Testing protocols may be overly specialized for power grid applications and less applicable to other industries requiring mechanical-electrochemical aging assessment.

Critical Technologies for Mechanical-Electrochemical Interface Analysis

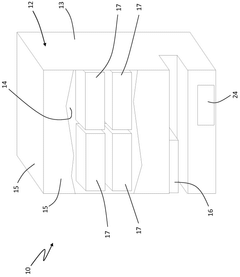

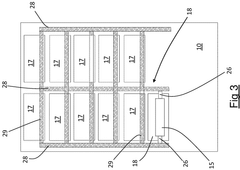

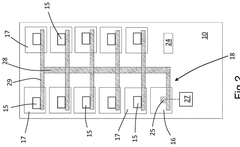

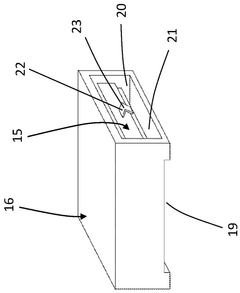

Storage for the process of aging electrochemical cells and method for implementing an aging process on electrochemical cells

PatentWO2025120525A1

Innovation

- A self-contained aging warehouse with a containment structure, transfer station, transport system, and conditioning system that allows for independent thermal conditioning of trays within the warehouse, eliminating the need for cell transfer between racks.

Method and device for determining degradation variables of an electrochemical device, in particular a fuel cell or electrolysis cell

PatentWO2025132181A1

Innovation

- A hybrid method that combines physical models with advanced data methods to determine degradation variables of electrochemical devices. This method involves selecting a time window with consistent operating conditions, using measured data to estimate the values of degradation variables, and applying a physical model to determine the performance impact of these variables.

Regulatory Framework for Materials Aging Certification

The regulatory landscape for materials aging certification is evolving rapidly in response to the growing complexity of coupled mechanical-electrochemical aging phenomena. International standards organizations such as ISO, ASTM, and IEC have established foundational frameworks that govern testing protocols for various materials and components subjected to combined mechanical and electrochemical stressors. These standards typically specify minimum requirements for test conditions, data collection methodologies, and acceptance criteria.

In the energy storage sector, particularly for lithium-ion batteries, regulatory bodies like UL (Underwriters Laboratories) and IEC have developed specific testing protocols (UL 1642, IEC 62133) that address mechanical abuse in conjunction with electrochemical performance. These standards mandate sequential and simultaneous testing of mechanical integrity under various electrochemical states, recognizing the interdependence of these aging mechanisms.

The aerospace and automotive industries face particularly stringent certification requirements due to safety-critical applications. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented comprehensive certification processes that require manufacturers to demonstrate material resilience under combined mechanical-electrochemical stress conditions representative of actual service environments. Similarly, automotive standards like SAE J2380 address the durability of electric vehicle battery systems under combined mechanical vibration and charge-discharge cycling.

Regulatory frameworks increasingly emphasize accelerated aging protocols that can reliably predict long-term performance. The challenge lies in establishing correlation factors between accelerated test results and real-world aging processes. Organizations like NIST (National Institute of Standards and Technology) are working to standardize these correlation methodologies to ensure consistency across certification processes.

Recent regulatory trends show movement toward performance-based rather than prescriptive requirements, allowing manufacturers greater flexibility in demonstrating compliance while maintaining safety standards. This shift acknowledges the rapid pace of materials innovation and the need for regulatory frameworks that can adapt to emerging technologies without impeding innovation.

Cross-border harmonization of certification standards remains a significant challenge, with different jurisdictions maintaining varying requirements. The International Electrotechnical Commission's Conformity Assessment Systems (IECEE) represents one effort to streamline global certification processes through mutual recognition agreements, reducing redundant testing while maintaining rigorous standards for materials aging certification.

In the energy storage sector, particularly for lithium-ion batteries, regulatory bodies like UL (Underwriters Laboratories) and IEC have developed specific testing protocols (UL 1642, IEC 62133) that address mechanical abuse in conjunction with electrochemical performance. These standards mandate sequential and simultaneous testing of mechanical integrity under various electrochemical states, recognizing the interdependence of these aging mechanisms.

The aerospace and automotive industries face particularly stringent certification requirements due to safety-critical applications. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have implemented comprehensive certification processes that require manufacturers to demonstrate material resilience under combined mechanical-electrochemical stress conditions representative of actual service environments. Similarly, automotive standards like SAE J2380 address the durability of electric vehicle battery systems under combined mechanical vibration and charge-discharge cycling.

Regulatory frameworks increasingly emphasize accelerated aging protocols that can reliably predict long-term performance. The challenge lies in establishing correlation factors between accelerated test results and real-world aging processes. Organizations like NIST (National Institute of Standards and Technology) are working to standardize these correlation methodologies to ensure consistency across certification processes.

Recent regulatory trends show movement toward performance-based rather than prescriptive requirements, allowing manufacturers greater flexibility in demonstrating compliance while maintaining safety standards. This shift acknowledges the rapid pace of materials innovation and the need for regulatory frameworks that can adapt to emerging technologies without impeding innovation.

Cross-border harmonization of certification standards remains a significant challenge, with different jurisdictions maintaining varying requirements. The International Electrotechnical Commission's Conformity Assessment Systems (IECEE) represents one effort to streamline global certification processes through mutual recognition agreements, reducing redundant testing while maintaining rigorous standards for materials aging certification.

Data Acquisition and Processing Techniques

The acquisition and processing of data in coupled mechanical-electrochemical aging tests require sophisticated methodologies to capture the complex interplay between mechanical stresses and electrochemical processes. High-precision data acquisition systems are essential for monitoring multiple parameters simultaneously, including mechanical strain, stress, electrochemical potential, current density, and temperature variations. These systems typically employ multi-channel data loggers with sampling rates of at least 1 kHz to ensure accurate capture of transient phenomena that occur during cycling.

Signal conditioning plays a crucial role in enhancing data quality by filtering noise and amplifying weak signals, particularly important for electrochemical impedance spectroscopy (EIS) measurements where small signal changes can contain significant information about degradation mechanisms. Modern testing protocols increasingly incorporate digital signal processing techniques such as wavelet transforms and Fourier analysis to separate mechanical and electrochemical responses in the frequency domain.

Real-time data processing algorithms have become standard in advanced testing protocols, enabling immediate detection of anomalies and potential failure precursors. These algorithms typically implement statistical methods such as principal component analysis (PCA) and machine learning approaches to identify patterns in the multidimensional data space that correlate with specific aging mechanisms. The integration of digital image correlation techniques with electrochemical measurements has emerged as a powerful approach for visualizing localized deformation and its relationship to electrochemical activity.

Data synchronization between mechanical and electrochemical measurements presents significant challenges due to different time constants and response characteristics. Current best practices involve hardware-level synchronization using master clock signals and software-based post-processing techniques to align data streams accurately. Time-stamping with microsecond precision ensures proper correlation between mechanical events and electrochemical responses.

Calibration protocols must address both mechanical and electrochemical measurement systems, accounting for cross-sensitivities and environmental factors. This typically involves multi-point calibration procedures performed before each test series and periodic verification during extended aging studies. Temperature compensation algorithms are particularly important as both mechanical properties and electrochemical kinetics exhibit strong temperature dependence.

Data storage and management systems for coupled aging tests must handle large datasets efficiently while maintaining data integrity. Hierarchical database structures with appropriate metadata tagging facilitate subsequent analysis and ensure experimental reproducibility. The emerging trend toward standardized data formats and open-access repositories is enhancing collaboration and enabling meta-analyses across multiple studies, accelerating progress in understanding coupled aging phenomena.

Signal conditioning plays a crucial role in enhancing data quality by filtering noise and amplifying weak signals, particularly important for electrochemical impedance spectroscopy (EIS) measurements where small signal changes can contain significant information about degradation mechanisms. Modern testing protocols increasingly incorporate digital signal processing techniques such as wavelet transforms and Fourier analysis to separate mechanical and electrochemical responses in the frequency domain.

Real-time data processing algorithms have become standard in advanced testing protocols, enabling immediate detection of anomalies and potential failure precursors. These algorithms typically implement statistical methods such as principal component analysis (PCA) and machine learning approaches to identify patterns in the multidimensional data space that correlate with specific aging mechanisms. The integration of digital image correlation techniques with electrochemical measurements has emerged as a powerful approach for visualizing localized deformation and its relationship to electrochemical activity.

Data synchronization between mechanical and electrochemical measurements presents significant challenges due to different time constants and response characteristics. Current best practices involve hardware-level synchronization using master clock signals and software-based post-processing techniques to align data streams accurately. Time-stamping with microsecond precision ensures proper correlation between mechanical events and electrochemical responses.

Calibration protocols must address both mechanical and electrochemical measurement systems, accounting for cross-sensitivities and environmental factors. This typically involves multi-point calibration procedures performed before each test series and periodic verification during extended aging studies. Temperature compensation algorithms are particularly important as both mechanical properties and electrochemical kinetics exhibit strong temperature dependence.

Data storage and management systems for coupled aging tests must handle large datasets efficiently while maintaining data integrity. Hierarchical database structures with appropriate metadata tagging facilitate subsequent analysis and ensure experimental reproducibility. The emerging trend toward standardized data formats and open-access repositories is enhancing collaboration and enabling meta-analyses across multiple studies, accelerating progress in understanding coupled aging phenomena.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!