Recyclability And End-Of-Life Options For Structural Composites

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Composite Recycling Background and Objectives

Composite materials, particularly fiber-reinforced polymers (FRPs), have revolutionized multiple industries including aerospace, automotive, construction, and renewable energy due to their exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. However, the widespread adoption of these materials has created a significant end-of-life challenge that demands urgent attention. The global composite materials market has grown exponentially, projected to reach $160.54 billion by 2027, with a corresponding increase in composite waste generation.

Historically, composite materials were designed without consideration for their end-of-life management, resulting in most composite waste being landfilled or incinerated. This approach is increasingly untenable due to tightening environmental regulations, landfill restrictions, and growing corporate sustainability commitments. The European Union's End-of-Life Vehicle Directive and similar regulations worldwide are driving the need for recyclable composite solutions.

The technical evolution of composite recycling has progressed through several phases. Initial efforts in the 1990s focused primarily on mechanical recycling methods that yielded low-value products. The 2000s saw increased research into thermal processes like pyrolysis and solvolysis, while the 2010s brought advancements in fiber recovery techniques and remanufacturing processes. Current research is increasingly focused on designing composites for circularity from the outset.

The primary objective of this technical research is to comprehensively evaluate existing and emerging technologies for structural composite recycling and end-of-life management. Specifically, we aim to assess the technical feasibility, economic viability, and environmental impact of various recycling methods including mechanical, thermal, and chemical processes. Additionally, we seek to identify potential innovations in material design that could facilitate more efficient recycling.

Secondary objectives include mapping the current global infrastructure for composite recycling, analyzing the quality and potential applications of recycled composite materials, and developing a framework for life cycle assessment of different recycling pathways. We will also explore the regulatory landscape affecting composite waste management and identify potential policy drivers that could accelerate the adoption of recycling technologies.

This research is strategically important as it addresses both environmental imperatives and economic opportunities. Effective recycling technologies could transform composite waste from a liability into a valuable resource stream, creating new business models and reducing dependency on virgin materials. Furthermore, advances in this field could position early adopters as leaders in the circular economy for advanced materials.

Historically, composite materials were designed without consideration for their end-of-life management, resulting in most composite waste being landfilled or incinerated. This approach is increasingly untenable due to tightening environmental regulations, landfill restrictions, and growing corporate sustainability commitments. The European Union's End-of-Life Vehicle Directive and similar regulations worldwide are driving the need for recyclable composite solutions.

The technical evolution of composite recycling has progressed through several phases. Initial efforts in the 1990s focused primarily on mechanical recycling methods that yielded low-value products. The 2000s saw increased research into thermal processes like pyrolysis and solvolysis, while the 2010s brought advancements in fiber recovery techniques and remanufacturing processes. Current research is increasingly focused on designing composites for circularity from the outset.

The primary objective of this technical research is to comprehensively evaluate existing and emerging technologies for structural composite recycling and end-of-life management. Specifically, we aim to assess the technical feasibility, economic viability, and environmental impact of various recycling methods including mechanical, thermal, and chemical processes. Additionally, we seek to identify potential innovations in material design that could facilitate more efficient recycling.

Secondary objectives include mapping the current global infrastructure for composite recycling, analyzing the quality and potential applications of recycled composite materials, and developing a framework for life cycle assessment of different recycling pathways. We will also explore the regulatory landscape affecting composite waste management and identify potential policy drivers that could accelerate the adoption of recycling technologies.

This research is strategically important as it addresses both environmental imperatives and economic opportunities. Effective recycling technologies could transform composite waste from a liability into a valuable resource stream, creating new business models and reducing dependency on virgin materials. Furthermore, advances in this field could position early adopters as leaders in the circular economy for advanced materials.

Market Analysis for Recyclable Composites

The global market for recyclable composites is experiencing significant growth, driven by increasing environmental regulations and sustainability initiatives across industries. The composite materials market, valued at approximately $90 billion in 2022, is projected to reach $160 billion by 2030, with recyclable composites representing a rapidly expanding segment within this space. This growth trajectory is particularly evident in automotive, aerospace, construction, and wind energy sectors, where structural composites are extensively utilized.

In the automotive industry, the push for lightweight vehicles to improve fuel efficiency and reduce emissions has accelerated the adoption of composite materials. However, end-of-life vehicle directives, particularly in Europe, mandate that 85% of vehicle materials must be recyclable, creating substantial market pressure for recyclable composite solutions. Similarly, the aerospace sector, which consumes premium-grade composites, faces mounting challenges with the disposal of decommissioned aircraft, estimated at 12,000 aircraft reaching end-of-life in the next two decades.

The wind energy sector represents another significant market for recyclable composites, with approximately 2.5 million tons of composite materials in wind turbine blades expected to reach end-of-life by 2030. This has created an urgent need for recyclable alternatives to conventional glass and carbon fiber composites, as landfill bans for composite waste are increasingly implemented across developed economies.

Consumer preferences are also reshaping market dynamics, with surveys indicating that 73% of global consumers are willing to pay premium prices for sustainable products. This consumer sentiment is influencing procurement decisions across supply chains, creating market pull for recyclable composite materials despite their currently higher production costs compared to traditional composites.

Regionally, Europe leads the market for recyclable composites due to stringent waste management regulations and circular economy initiatives. North America follows with growing adoption rates, while Asia-Pacific represents the fastest-growing market, driven by rapid industrialization and increasing environmental awareness in countries like China, Japan, and South Korea.

The economic viability of recyclable composites is improving as recycling technologies mature and achieve economies of scale. The cost differential between virgin and recycled carbon fiber has decreased from 70% to approximately 30% over the past decade, making recycled composite materials increasingly competitive in price-sensitive applications. Market analysts project that the recyclable composites segment will grow at a CAGR of 8.5% through 2030, outpacing the broader composites market growth rate of 6.2%.

In the automotive industry, the push for lightweight vehicles to improve fuel efficiency and reduce emissions has accelerated the adoption of composite materials. However, end-of-life vehicle directives, particularly in Europe, mandate that 85% of vehicle materials must be recyclable, creating substantial market pressure for recyclable composite solutions. Similarly, the aerospace sector, which consumes premium-grade composites, faces mounting challenges with the disposal of decommissioned aircraft, estimated at 12,000 aircraft reaching end-of-life in the next two decades.

The wind energy sector represents another significant market for recyclable composites, with approximately 2.5 million tons of composite materials in wind turbine blades expected to reach end-of-life by 2030. This has created an urgent need for recyclable alternatives to conventional glass and carbon fiber composites, as landfill bans for composite waste are increasingly implemented across developed economies.

Consumer preferences are also reshaping market dynamics, with surveys indicating that 73% of global consumers are willing to pay premium prices for sustainable products. This consumer sentiment is influencing procurement decisions across supply chains, creating market pull for recyclable composite materials despite their currently higher production costs compared to traditional composites.

Regionally, Europe leads the market for recyclable composites due to stringent waste management regulations and circular economy initiatives. North America follows with growing adoption rates, while Asia-Pacific represents the fastest-growing market, driven by rapid industrialization and increasing environmental awareness in countries like China, Japan, and South Korea.

The economic viability of recyclable composites is improving as recycling technologies mature and achieve economies of scale. The cost differential between virgin and recycled carbon fiber has decreased from 70% to approximately 30% over the past decade, making recycled composite materials increasingly competitive in price-sensitive applications. Market analysts project that the recyclable composites segment will grow at a CAGR of 8.5% through 2030, outpacing the broader composites market growth rate of 6.2%.

Current Challenges in Composite Recycling

Despite significant advancements in composite materials technology, the recycling of structural composites remains one of the most challenging aspects of their life cycle management. The inherent heterogeneity of composite materials—typically consisting of reinforcement fibers embedded in a polymer matrix—creates fundamental obstacles to conventional recycling approaches. Unlike metals or pure polymers, composites cannot be simply melted down and reformed without significant degradation of their mechanical properties.

The thermoset matrices commonly used in high-performance structural applications present a particular challenge, as they undergo irreversible chemical reactions during curing. This cross-linked molecular structure, while providing excellent mechanical properties and environmental resistance, makes these materials inherently difficult to break down into their constituent components. Current mechanical recycling methods often result in significant downgrading of material properties, limiting the applications for recycled composite materials.

Energy recovery through incineration offers an alternative end-of-life option, but raises environmental concerns regarding emissions and represents a loss of valuable materials. Chemical recycling approaches using solvolysis or pyrolysis show promise for fiber recovery but are energy-intensive and often involve hazardous chemicals, creating additional environmental challenges and economic barriers to widespread implementation.

The economic viability of composite recycling remains problematic due to high processing costs relative to virgin material production. The lack of established collection and sorting infrastructure specifically designed for composite waste compounds this issue. Additionally, the geographic dispersion of composite waste sources—ranging from decommissioned wind turbines to end-of-life aircraft and automobiles—creates logistical challenges for centralized recycling operations.

Regulatory frameworks worldwide are increasingly demanding improved end-of-life management for composites, with the European Union's End-of-Life Vehicle Directive and Waste Framework Directive setting ambitious recovery and recycling targets. However, technical solutions have not kept pace with these regulatory requirements, creating compliance challenges for industries reliant on composite materials.

Quality assurance represents another significant hurdle, as recycled composite materials often exhibit inconsistent properties due to contamination, fiber damage during processing, and variations in the original material composition. This inconsistency limits market acceptance and integration into new high-performance applications, creating a cycle where recycled composites are relegated to non-structural applications with lower value.

The absence of standardized testing and certification protocols for recycled composite materials further complicates their market adoption. Without reliable methods to verify performance characteristics, designers and engineers remain hesitant to specify recycled composites for critical applications, limiting potential market growth and circular economy development in this sector.

The thermoset matrices commonly used in high-performance structural applications present a particular challenge, as they undergo irreversible chemical reactions during curing. This cross-linked molecular structure, while providing excellent mechanical properties and environmental resistance, makes these materials inherently difficult to break down into their constituent components. Current mechanical recycling methods often result in significant downgrading of material properties, limiting the applications for recycled composite materials.

Energy recovery through incineration offers an alternative end-of-life option, but raises environmental concerns regarding emissions and represents a loss of valuable materials. Chemical recycling approaches using solvolysis or pyrolysis show promise for fiber recovery but are energy-intensive and often involve hazardous chemicals, creating additional environmental challenges and economic barriers to widespread implementation.

The economic viability of composite recycling remains problematic due to high processing costs relative to virgin material production. The lack of established collection and sorting infrastructure specifically designed for composite waste compounds this issue. Additionally, the geographic dispersion of composite waste sources—ranging from decommissioned wind turbines to end-of-life aircraft and automobiles—creates logistical challenges for centralized recycling operations.

Regulatory frameworks worldwide are increasingly demanding improved end-of-life management for composites, with the European Union's End-of-Life Vehicle Directive and Waste Framework Directive setting ambitious recovery and recycling targets. However, technical solutions have not kept pace with these regulatory requirements, creating compliance challenges for industries reliant on composite materials.

Quality assurance represents another significant hurdle, as recycled composite materials often exhibit inconsistent properties due to contamination, fiber damage during processing, and variations in the original material composition. This inconsistency limits market acceptance and integration into new high-performance applications, creating a cycle where recycled composites are relegated to non-structural applications with lower value.

The absence of standardized testing and certification protocols for recycled composite materials further complicates their market adoption. Without reliable methods to verify performance characteristics, designers and engineers remain hesitant to specify recycled composites for critical applications, limiting potential market growth and circular economy development in this sector.

Existing End-of-Life Management Solutions

01 Thermoplastic-based recyclable composites

Thermoplastic materials are used as matrices in structural composites to enable recyclability. Unlike thermoset composites, thermoplastic-based composites can be melted and reformed multiple times, allowing for easier recycling processes. These composites maintain structural integrity while providing the environmental benefit of being reprocessable at end-of-life. The thermoplastic matrices can be combined with various reinforcement materials to create composites with tailored mechanical properties suitable for different applications.- Recyclable thermoplastic composites: Thermoplastic composites offer significant advantages for recyclability compared to thermoset materials. These composites can be melted and reformed multiple times without significant degradation of mechanical properties. By using thermoplastic matrices such as polyethylene, polypropylene, or polyamide, structural composites can be designed for end-of-life recycling. The recyclability is enhanced through proper material selection and processing techniques that maintain fiber integrity during recycling processes.

- Disassembly and separation techniques: Advanced disassembly and separation techniques are crucial for effective recycling of structural composites. These methods include chemical dissolution processes that selectively dissolve matrix materials while preserving valuable fibers, mechanical separation techniques that break down composites into reusable components, and thermal processes that facilitate material recovery. Innovative joining methods are also designed to allow for easier disassembly at end-of-life, improving the overall recyclability of composite structures.

- Bio-based and biodegradable composites: Bio-based and biodegradable composites represent an environmentally friendly approach to structural materials. These composites incorporate natural fibers such as flax, hemp, or jute, combined with biodegradable polymer matrices. The resulting materials can maintain structural integrity during their service life while being designed to decompose under specific conditions after disposal. This approach reduces environmental impact and offers alternative end-of-life scenarios beyond traditional recycling methods.

- Fiber recovery and reuse systems: Advanced systems for recovering and reusing high-value fibers from composite materials are essential for closed-loop recycling. These systems employ various technologies including pyrolysis, solvolysis, and mechanical grinding to extract carbon, glass, or aramid fibers from end-of-life composites. The recovered fibers, though sometimes shorter or with slightly reduced mechanical properties, can be reincorporated into new composite materials for secondary applications, significantly reducing waste and resource consumption.

- Design for recyclability approaches: Design for recyclability involves creating structural composites with end-of-life considerations from the initial design phase. This approach includes material selection strategies that favor recyclable constituents, modular design principles that facilitate disassembly, and structural optimization that minimizes material usage while maintaining performance requirements. Additionally, computational tools and lifecycle assessment methodologies are employed to evaluate and improve the recyclability potential of composite structures before manufacturing.

02 Disassembly and separation techniques for composite recycling

Various methods have been developed to facilitate the disassembly and separation of composite components for recycling. These techniques include the use of specialized adhesives that can be triggered to release, mechanical fastening systems designed for easy disassembly, and chemical processes that selectively dissolve certain components. By enabling effective separation of different materials in a composite structure, these methods improve the recyclability of structural composites and allow for the recovery of valuable constituent materials.Expand Specific Solutions03 Bio-based and biodegradable composite materials

Bio-based and biodegradable materials are increasingly being used in structural composites to improve end-of-life recyclability and environmental impact. These composites incorporate natural fibers, biopolymers, or biodegradable synthetic polymers that can break down under specific conditions. While maintaining necessary mechanical properties for structural applications, these materials offer advantages in terms of sustainability, reduced carbon footprint, and alternative end-of-life options such as composting for certain applications.Expand Specific Solutions04 Recycling processes for fiber-reinforced composites

Specialized recycling processes have been developed specifically for fiber-reinforced composites to recover valuable fibers and other materials. These processes include mechanical grinding, pyrolysis, solvolysis, and fluidized bed techniques. The recovered fibers, while sometimes experiencing some degradation in properties, can be reincorporated into new composite materials. These recycling methods help address the challenge of recycling traditionally difficult-to-recycle composite materials like carbon fiber reinforced polymers.Expand Specific Solutions05 Design for recyclability in structural composites

Design strategies that specifically consider end-of-life recyclability are being implemented in structural composite development. These approaches include material selection based on compatibility for recycling, modular designs that facilitate disassembly, and structural configurations that allow for easy separation of different materials. By incorporating recyclability considerations at the design stage, these methods improve the overall lifecycle sustainability of structural composites while maintaining their performance characteristics.Expand Specific Solutions

Leading Organizations in Structural Composite Recycling

The recyclability and end-of-life options for structural composites market is in a growth phase, with increasing regulatory pressure driving innovation. The global market is projected to expand significantly as sustainability becomes a priority across industries. Leading chemical companies like BASF and Eastman Chemical are developing recyclable resins, while aerospace giants Boeing and Airbus are investing in composite recycling technologies to address end-of-life challenges. Academic institutions including Rutgers and Caltech are collaborating with industry partners to advance recycling methods. Companies like Ecogensus are creating specialized technologies for waste processing, while materials manufacturers such as LM Wind Power are focusing on sustainable composite solutions for renewable energy applications. The technology is advancing rapidly but still faces commercialization challenges.

BASF Corp.

Technical Solution: BASF has developed a chemical recycling technology called "ChemCycling" that can be applied to composite materials. Their approach uses thermochemical processes to break down composite waste into pyrolysis oil, which serves as a feedstock for new chemical production. For structural composites specifically, BASF has engineered recyclable thermoset resins with cleavable chemical bonds that can be triggered under specific conditions, allowing separation of fibers from the matrix. Their "Baxxodur" system incorporates reversible crosslinking technology that enables the composite to be broken down at end-of-life while maintaining high performance during use. BASF has also developed compatibilizers that allow recycled composite materials to be incorporated into virgin polymer systems without significant property degradation. Their life cycle analysis shows that their chemical recycling approach can reduce CO2 emissions by 50-80% compared to incineration of composite waste.

Strengths: Strong chemical expertise enabling molecular-level solutions; integrated approach from material design to recycling; global infrastructure for implementation. Weaknesses: Energy-intensive chemical processes; economic viability dependent on oil prices; technology more suited to thermoplastic than thermoset composites.

The Boeing Co.

Technical Solution: Boeing has developed a comprehensive approach to composite recycling through their "Boeing Composite Recycling Program". Their technology involves a solvolysis process that breaks down thermoset composites using specialized solvents under controlled temperature and pressure conditions. This enables the recovery of carbon fibers with minimal degradation of mechanical properties (retaining up to 95% of virgin fiber strength). Boeing has also implemented a closed-loop manufacturing system where composite manufacturing scrap is collected, processed, and the recovered fibers are reincorporated into non-critical aerospace components and secondary structures. Their research extends to pyrolysis methods for end-of-life aircraft components, allowing for fiber recovery while generating syngas as a byproduct that can be used for energy recovery.

Strengths: Industry-leading expertise in high-performance aerospace composites; established infrastructure for collection and processing; ability to reintegrate recovered materials into aerospace supply chain. Weaknesses: High energy requirements for processing; recovered fibers typically have some degradation in mechanical properties; processes primarily optimized for carbon fiber rather than glass fiber composites.

Key Recycling Technologies and Patents

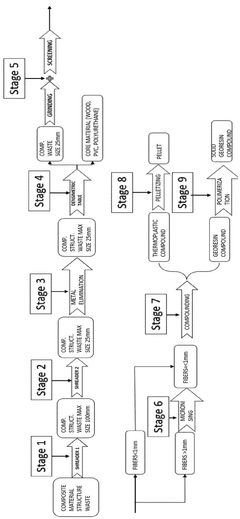

Secondary raw materials obtaining method from composite materials structures

PatentWO2025003515A1

Innovation

- A mechanical method involving ripping, densiometric separation, shredding, sieving, micronizing, and reformulation with thermoplastic or georesin compounds to produce pellet-shaped or solid georesin secondary raw materials from fibre-resin composite materials, including core materials like foam, allowing for the recycling of both monolithic and sandwich-type composite structures.

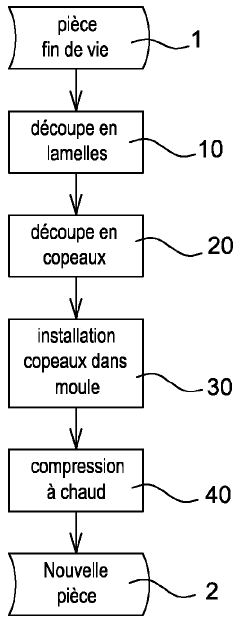

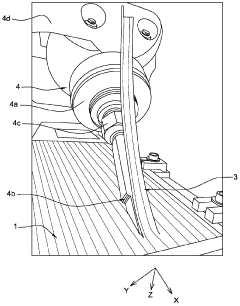

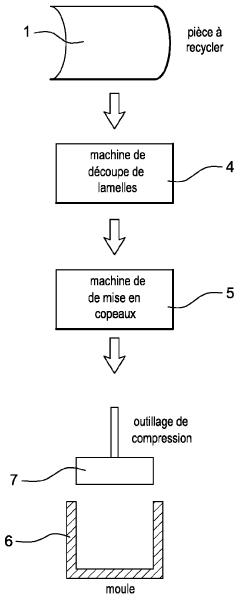

Process for recycling a composite material part and system for the implementation thereof

PatentWO2012085000A1

Innovation

- A process involving cutting composite parts into strips, then into chips of predefined dimensions, which are inserted into a mold and subjected to hot compression to form new parts, allowing for the recycling of all composite material parts and maintaining long fiber lengths for improved mechanical properties.

Environmental Impact Assessment

The environmental impact of structural composites extends throughout their entire lifecycle, with particular concerns arising during production, use, and disposal phases. Traditional composite materials, especially carbon fiber reinforced polymers (CFRP) and glass fiber reinforced polymers (GFRP), present significant environmental challenges due to their energy-intensive manufacturing processes and limited end-of-life options. Life Cycle Assessment (LCA) studies indicate that the production of virgin carbon fiber can consume up to 30 times more energy than conventional steel manufacturing, with corresponding increases in greenhouse gas emissions.

The disposal of composite materials presents particularly acute environmental challenges. When landfilled, these materials can persist for centuries without degrading, contributing to long-term waste management issues. Incineration of composites, while reducing volume, often releases harmful substances including volatile organic compounds (VOCs), particulate matter, and potentially toxic gases from resin decomposition. These emissions contribute to air pollution and may pose health risks to surrounding communities.

Water systems are also affected by composite waste through microplastic pollution. As composite materials gradually break down, they release microparticles that can enter aquatic ecosystems, potentially affecting marine life through ingestion and bioaccumulation processes. Research indicates these particles may persist in the environment for decades, with potential long-term ecological consequences that remain incompletely understood.

Land use impacts arise from both the extraction of raw materials for composite production and the space required for disposal. Mining operations for materials like bauxite (for aluminum in certain composites) can lead to habitat destruction, soil erosion, and water contamination. Additionally, the growing volume of composite waste requires increasing landfill capacity, competing with other land use priorities.

Recent environmental impact assessments have begun quantifying the benefits of various recycling and recovery methods. Mechanical recycling of composites can reduce environmental impact by 30-40% compared to virgin material production, while advanced thermal recovery processes like pyrolysis show potential for 50-70% reductions in carbon footprint when recovering carbon fibers. These findings underscore the environmental imperative for developing effective recycling technologies.

The regulatory landscape is evolving in response to these environmental concerns. The European Union's End-of-Life Vehicle Directive and similar regulations worldwide are increasingly targeting composite materials, mandating higher recovery and recycling rates. This regulatory pressure, combined with growing corporate sustainability commitments, is accelerating research into environmentally preferable end-of-life options for structural composites.

The disposal of composite materials presents particularly acute environmental challenges. When landfilled, these materials can persist for centuries without degrading, contributing to long-term waste management issues. Incineration of composites, while reducing volume, often releases harmful substances including volatile organic compounds (VOCs), particulate matter, and potentially toxic gases from resin decomposition. These emissions contribute to air pollution and may pose health risks to surrounding communities.

Water systems are also affected by composite waste through microplastic pollution. As composite materials gradually break down, they release microparticles that can enter aquatic ecosystems, potentially affecting marine life through ingestion and bioaccumulation processes. Research indicates these particles may persist in the environment for decades, with potential long-term ecological consequences that remain incompletely understood.

Land use impacts arise from both the extraction of raw materials for composite production and the space required for disposal. Mining operations for materials like bauxite (for aluminum in certain composites) can lead to habitat destruction, soil erosion, and water contamination. Additionally, the growing volume of composite waste requires increasing landfill capacity, competing with other land use priorities.

Recent environmental impact assessments have begun quantifying the benefits of various recycling and recovery methods. Mechanical recycling of composites can reduce environmental impact by 30-40% compared to virgin material production, while advanced thermal recovery processes like pyrolysis show potential for 50-70% reductions in carbon footprint when recovering carbon fibers. These findings underscore the environmental imperative for developing effective recycling technologies.

The regulatory landscape is evolving in response to these environmental concerns. The European Union's End-of-Life Vehicle Directive and similar regulations worldwide are increasingly targeting composite materials, mandating higher recovery and recycling rates. This regulatory pressure, combined with growing corporate sustainability commitments, is accelerating research into environmentally preferable end-of-life options for structural composites.

Regulatory Framework and Compliance

The regulatory landscape governing composite materials recycling and end-of-life management has evolved significantly in recent years, driven by increasing environmental concerns and sustainability goals. The European Union leads global efforts with its comprehensive framework, particularly through the Waste Framework Directive (2008/98/EC) which establishes waste hierarchy principles prioritizing prevention, reuse, recycling, and recovery over disposal. This directive has been instrumental in pushing manufacturers toward designing composites with end-of-life considerations.

The End-of-Life Vehicle (ELV) Directive (2000/53/EC) specifically targets the automotive sector, mandating 95% recovery and 85% recycling rates for vehicles, creating significant challenges for composite-intensive components. Similarly, the aerospace industry faces regulatory pressure through the Aircraft Fleet Recycling Association (AFRA) guidelines, which although voluntary, have become industry standards for responsible aircraft decommissioning.

Extended Producer Responsibility (EPR) schemes have emerged as powerful regulatory tools across multiple jurisdictions, shifting the financial and operational burden of waste management back to manufacturers. This approach has catalyzed innovation in recyclable composite design, particularly in wind energy where blade disposal presents significant environmental challenges.

Compliance with these regulations requires sophisticated tracking and documentation systems. Life Cycle Assessment (LCA) methodologies have become essential for manufacturers to demonstrate regulatory adherence and quantify environmental impacts across the entire product lifecycle. The ISO 14040 series provides standardized frameworks for conducting these assessments, ensuring consistency and comparability across different composite applications.

Regional variations in regulatory approaches create compliance complexities for global manufacturers. While the EU maintains the most stringent requirements, North America has adopted a more fragmented approach with regulations varying significantly between states and provinces. Emerging economies are increasingly implementing their own frameworks, often modeled after European standards but adapted to local conditions and capabilities.

Looking forward, regulatory trends indicate movement toward circular economy principles with stricter recycling targets and potential bans on landfilling composite materials. The EU's Circular Economy Action Plan signals this direction, with proposed measures to further incentivize design for recyclability and penalize non-recyclable composite structures. Companies investing in recyclable composite technologies now may gain competitive advantages as regulatory requirements intensify globally.

The End-of-Life Vehicle (ELV) Directive (2000/53/EC) specifically targets the automotive sector, mandating 95% recovery and 85% recycling rates for vehicles, creating significant challenges for composite-intensive components. Similarly, the aerospace industry faces regulatory pressure through the Aircraft Fleet Recycling Association (AFRA) guidelines, which although voluntary, have become industry standards for responsible aircraft decommissioning.

Extended Producer Responsibility (EPR) schemes have emerged as powerful regulatory tools across multiple jurisdictions, shifting the financial and operational burden of waste management back to manufacturers. This approach has catalyzed innovation in recyclable composite design, particularly in wind energy where blade disposal presents significant environmental challenges.

Compliance with these regulations requires sophisticated tracking and documentation systems. Life Cycle Assessment (LCA) methodologies have become essential for manufacturers to demonstrate regulatory adherence and quantify environmental impacts across the entire product lifecycle. The ISO 14040 series provides standardized frameworks for conducting these assessments, ensuring consistency and comparability across different composite applications.

Regional variations in regulatory approaches create compliance complexities for global manufacturers. While the EU maintains the most stringent requirements, North America has adopted a more fragmented approach with regulations varying significantly between states and provinces. Emerging economies are increasingly implementing their own frameworks, often modeled after European standards but adapted to local conditions and capabilities.

Looking forward, regulatory trends indicate movement toward circular economy principles with stricter recycling targets and potential bans on landfilling composite materials. The EU's Circular Economy Action Plan signals this direction, with proposed measures to further incentivize design for recyclability and penalize non-recyclable composite structures. Companies investing in recyclable composite technologies now may gain competitive advantages as regulatory requirements intensify globally.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!