Techno-Economic Analysis Of Structural Batteries In EV Platforms

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Structural Battery Evolution and Objectives

Structural batteries represent a revolutionary approach in energy storage technology, combining load-bearing capabilities with energy storage functions. The concept emerged in the early 2000s when researchers began exploring multifunctional materials that could simultaneously serve structural and energy storage purposes. This technological convergence aims to address the fundamental weight and space constraints in electric vehicles (EVs) by transforming traditionally "dead weight" components into active energy contributors.

The evolution of structural batteries has progressed through several distinct phases. Initially, research focused on carbon fiber composites with embedded energy storage capabilities, yielding modest energy densities of 10-20 Wh/kg. By the mid-2010s, advancements in material science enabled the development of second-generation structural batteries with improved mechanical properties and energy densities approaching 50-75 Wh/kg, though still significantly below conventional lithium-ion batteries.

Current third-generation structural batteries incorporate advanced carbon fiber reinforcements as electrodes within a structural electrolyte matrix, achieving energy densities of 75-150 Wh/kg while maintaining substantial load-bearing capabilities. This represents a critical inflection point where the technology begins to offer compelling advantages for EV applications beyond mere conceptual interest.

The primary objective of structural battery technology in EV platforms is to achieve a paradigm shift in vehicle design philosophy—moving from "adding batteries to vehicles" to "building vehicles from batteries." This approach targets a 15-25% reduction in overall vehicle weight while maintaining or increasing energy storage capacity, potentially extending EV range by 20-30% without increasing battery size.

Secondary objectives include enhancing vehicle safety through improved crash energy absorption characteristics, reducing manufacturing complexity through parts consolidation, and enabling novel vehicle architectures previously constrained by traditional battery packaging requirements.

The technology roadmap aims to achieve commercial viability by 2025-2027 for non-critical structural components, with full integration into primary vehicle structures projected for 2030-2035. Key performance targets include achieving structural batteries with energy densities exceeding 200 Wh/kg, cycle life comparable to conventional lithium-ion batteries (>1000 cycles), and mechanical properties sufficient to replace traditional structural components without compromising vehicle safety or durability.

Long-term objectives extend beyond performance metrics to address manufacturing scalability, recycling challenges, and cost competitiveness, with the ultimate goal of reaching price parity with conventional battery-plus-structure approaches by 2035.

The evolution of structural batteries has progressed through several distinct phases. Initially, research focused on carbon fiber composites with embedded energy storage capabilities, yielding modest energy densities of 10-20 Wh/kg. By the mid-2010s, advancements in material science enabled the development of second-generation structural batteries with improved mechanical properties and energy densities approaching 50-75 Wh/kg, though still significantly below conventional lithium-ion batteries.

Current third-generation structural batteries incorporate advanced carbon fiber reinforcements as electrodes within a structural electrolyte matrix, achieving energy densities of 75-150 Wh/kg while maintaining substantial load-bearing capabilities. This represents a critical inflection point where the technology begins to offer compelling advantages for EV applications beyond mere conceptual interest.

The primary objective of structural battery technology in EV platforms is to achieve a paradigm shift in vehicle design philosophy—moving from "adding batteries to vehicles" to "building vehicles from batteries." This approach targets a 15-25% reduction in overall vehicle weight while maintaining or increasing energy storage capacity, potentially extending EV range by 20-30% without increasing battery size.

Secondary objectives include enhancing vehicle safety through improved crash energy absorption characteristics, reducing manufacturing complexity through parts consolidation, and enabling novel vehicle architectures previously constrained by traditional battery packaging requirements.

The technology roadmap aims to achieve commercial viability by 2025-2027 for non-critical structural components, with full integration into primary vehicle structures projected for 2030-2035. Key performance targets include achieving structural batteries with energy densities exceeding 200 Wh/kg, cycle life comparable to conventional lithium-ion batteries (>1000 cycles), and mechanical properties sufficient to replace traditional structural components without compromising vehicle safety or durability.

Long-term objectives extend beyond performance metrics to address manufacturing scalability, recycling challenges, and cost competitiveness, with the ultimate goal of reaching price parity with conventional battery-plus-structure approaches by 2035.

EV Market Demand for Structural Batteries

The electric vehicle market is experiencing unprecedented growth, with global EV sales reaching 10.5 million units in 2022, representing a 55% increase year-over-year. This exponential growth trajectory is expected to continue, with projections indicating that EVs could account for 30% of all vehicle sales by 2030. Within this rapidly expanding market, there is a growing demand for innovations that address the fundamental challenges of electric vehicles, particularly regarding range anxiety, charging infrastructure limitations, and overall vehicle weight.

Structural batteries represent a revolutionary approach to energy storage in EVs by integrating battery functionality directly into load-bearing components of the vehicle. Market analysis indicates that weight reduction and increased energy density are primary drivers for EV manufacturers, with surveys showing that 78% of potential EV buyers cite range as their top concern when considering a purchase. Structural batteries directly address this concern by potentially increasing energy density by 15-20% compared to conventional battery systems.

The demand for structural batteries is further amplified by the automotive industry's push toward platform consolidation and modular design. Major manufacturers including Tesla, Volkswagen, and General Motors have announced dedicated EV platforms that could benefit significantly from structural battery integration. Market forecasts suggest that by 2027, over 60% of new EV models will utilize some form of structural battery technology, representing a potential market value of $25 billion.

Consumer preferences are also shifting toward vehicles with longer ranges and shorter charging times. A recent industry survey revealed that 82% of potential EV buyers would pay a premium for vehicles offering ranges exceeding 400 miles on a single charge. Structural batteries, by optimizing space utilization and reducing overall vehicle weight, can help achieve these extended ranges without requiring larger battery packs.

From a regulatory perspective, increasingly stringent emissions standards and fuel economy requirements across major markets are accelerating the transition to electric mobility. The European Union's target to reduce CO2 emissions from new cars by 55% by 2030 and China's dual-credit policy system are creating strong incentives for manufacturers to adopt advanced battery technologies like structural batteries.

Commercial fleet operators represent another significant market segment driving demand for structural batteries. With total cost of ownership becoming increasingly favorable for electric vehicles in commercial applications, fleet managers are seeking solutions that maximize payload capacity while minimizing charging downtime. Structural batteries offer a compelling value proposition for this segment by potentially reducing vehicle weight by 10-15% compared to conventional designs.

Structural batteries represent a revolutionary approach to energy storage in EVs by integrating battery functionality directly into load-bearing components of the vehicle. Market analysis indicates that weight reduction and increased energy density are primary drivers for EV manufacturers, with surveys showing that 78% of potential EV buyers cite range as their top concern when considering a purchase. Structural batteries directly address this concern by potentially increasing energy density by 15-20% compared to conventional battery systems.

The demand for structural batteries is further amplified by the automotive industry's push toward platform consolidation and modular design. Major manufacturers including Tesla, Volkswagen, and General Motors have announced dedicated EV platforms that could benefit significantly from structural battery integration. Market forecasts suggest that by 2027, over 60% of new EV models will utilize some form of structural battery technology, representing a potential market value of $25 billion.

Consumer preferences are also shifting toward vehicles with longer ranges and shorter charging times. A recent industry survey revealed that 82% of potential EV buyers would pay a premium for vehicles offering ranges exceeding 400 miles on a single charge. Structural batteries, by optimizing space utilization and reducing overall vehicle weight, can help achieve these extended ranges without requiring larger battery packs.

From a regulatory perspective, increasingly stringent emissions standards and fuel economy requirements across major markets are accelerating the transition to electric mobility. The European Union's target to reduce CO2 emissions from new cars by 55% by 2030 and China's dual-credit policy system are creating strong incentives for manufacturers to adopt advanced battery technologies like structural batteries.

Commercial fleet operators represent another significant market segment driving demand for structural batteries. With total cost of ownership becoming increasingly favorable for electric vehicles in commercial applications, fleet managers are seeking solutions that maximize payload capacity while minimizing charging downtime. Structural batteries offer a compelling value proposition for this segment by potentially reducing vehicle weight by 10-15% compared to conventional designs.

Current Status and Technical Barriers

Structural batteries represent a revolutionary approach in electric vehicle (EV) design, integrating energy storage directly into load-bearing components. Currently, the technology exists primarily in laboratory settings with limited commercial applications. Research institutions like Chalmers University of Technology and Imperial College London have demonstrated prototypes achieving energy densities of 24-35 Wh/kg, significantly below conventional lithium-ion batteries (250-300 Wh/kg). These early-stage structural batteries typically utilize carbon fiber as electrodes embedded in structural matrices.

The primary technical barrier remains the fundamental trade-off between mechanical properties and electrochemical performance. Materials optimized for structural integrity often exhibit poor ionic conductivity, while those with excellent electrochemical properties frequently lack mechanical strength. This creates a significant engineering challenge that has yet to be fully resolved in commercial applications.

Manufacturing scalability presents another major obstacle. Current production methods for structural batteries involve complex, multi-step processes including fiber alignment, electrolyte infusion, and specialized curing techniques. These processes remain largely manual and laboratory-based, lacking the automation and standardization necessary for mass production in automotive applications.

Safety certification represents a critical barrier to implementation. Unlike conventional batteries that can be isolated and protected, structural batteries are integrated into the vehicle frame, creating complex failure scenarios that current testing protocols are not designed to evaluate. New safety standards and testing methodologies must be developed specifically for these multifunctional components.

Durability and lifecycle management pose significant challenges. Structural batteries must simultaneously withstand mechanical stresses and electrochemical cycling, with degradation in either function potentially compromising vehicle safety. Current prototypes demonstrate significant capacity fade after repeated mechanical loading, limiting practical lifespan.

Integration with existing EV manufacturing processes remains problematic. The automotive industry has invested heavily in conventional battery pack architectures, and structural batteries would require fundamental redesigns of vehicle platforms and assembly lines.

Cost factors present substantial barriers to commercialization. Current structural battery materials utilize expensive carbon fibers and specialized electrolytes, with production costs estimated at 5-10 times that of conventional lithium-ion cells when normalized by energy capacity. Without significant technological breakthroughs or economies of scale, this cost differential will likely prevent widespread adoption in mass-market vehicles.

The primary technical barrier remains the fundamental trade-off between mechanical properties and electrochemical performance. Materials optimized for structural integrity often exhibit poor ionic conductivity, while those with excellent electrochemical properties frequently lack mechanical strength. This creates a significant engineering challenge that has yet to be fully resolved in commercial applications.

Manufacturing scalability presents another major obstacle. Current production methods for structural batteries involve complex, multi-step processes including fiber alignment, electrolyte infusion, and specialized curing techniques. These processes remain largely manual and laboratory-based, lacking the automation and standardization necessary for mass production in automotive applications.

Safety certification represents a critical barrier to implementation. Unlike conventional batteries that can be isolated and protected, structural batteries are integrated into the vehicle frame, creating complex failure scenarios that current testing protocols are not designed to evaluate. New safety standards and testing methodologies must be developed specifically for these multifunctional components.

Durability and lifecycle management pose significant challenges. Structural batteries must simultaneously withstand mechanical stresses and electrochemical cycling, with degradation in either function potentially compromising vehicle safety. Current prototypes demonstrate significant capacity fade after repeated mechanical loading, limiting practical lifespan.

Integration with existing EV manufacturing processes remains problematic. The automotive industry has invested heavily in conventional battery pack architectures, and structural batteries would require fundamental redesigns of vehicle platforms and assembly lines.

Cost factors present substantial barriers to commercialization. Current structural battery materials utilize expensive carbon fibers and specialized electrolytes, with production costs estimated at 5-10 times that of conventional lithium-ion cells when normalized by energy capacity. Without significant technological breakthroughs or economies of scale, this cost differential will likely prevent widespread adoption in mass-market vehicles.

Current Structural Battery Integration Solutions

01 Cost-effective manufacturing processes for structural batteries

Innovations in manufacturing processes are critical for the economic viability of structural batteries. These include scalable production methods, reduced material costs, and efficient assembly techniques that integrate energy storage functionality into structural components. Advanced manufacturing approaches help minimize production expenses while maintaining performance, making structural batteries more competitive with conventional energy storage solutions.- Cost-effective manufacturing processes for structural batteries: Innovations in manufacturing processes are crucial for the economic viability of structural batteries. These include scalable production methods, automated assembly techniques, and integration of battery components into structural elements. Advanced manufacturing approaches reduce production costs while maintaining performance, making structural batteries more competitive with conventional energy storage solutions. These processes often involve novel electrode fabrication techniques and efficient integration of battery functionality into load-bearing structures.

- Material innovations reducing structural battery costs: Novel materials are being developed to enhance the economic viability of structural batteries. These include multifunctional composites that serve both energy storage and structural functions, reducing the need for separate components. Cost-effective carbon-based materials, polymer electrolytes, and electrode formulations help lower material costs while improving energy density and mechanical properties. These material innovations are essential for making structural batteries economically competitive with traditional battery technologies.

- Market analysis and economic models for structural batteries: Economic models and market analyses are being developed to assess the viability of structural batteries in various applications. These models consider factors such as production scale, material costs, performance metrics, and lifecycle benefits. By analyzing total cost of ownership, weight savings benefits, and integration advantages, these economic frameworks help identify the most promising commercial applications and adoption pathways for structural battery technology. The models also account for regulatory factors and sustainability benefits that may influence economic viability.

- Application-specific economic benefits of structural batteries: The economic viability of structural batteries varies significantly across different applications. In electric vehicles, aerospace, and portable electronics, structural batteries offer weight and space savings that translate to economic benefits through improved efficiency and performance. These application-specific advantages include extended range for vehicles, reduced fuel consumption for aircraft, and smaller form factors for consumer electronics. The economic case is strongest in premium applications where weight and space savings command high value propositions.

- Lifecycle cost analysis and sustainability factors: Lifecycle cost analysis is critical for assessing the true economic viability of structural batteries. This includes considerations of durability, maintenance requirements, recyclability, and end-of-life management. Structural batteries that offer longer service life, reduced maintenance needs, or improved recyclability may demonstrate superior economic viability despite higher initial costs. Additionally, sustainability benefits such as reduced material usage and environmental impact can provide economic advantages through regulatory compliance and consumer preference for green technologies.

02 Material innovations reducing structural battery costs

Novel materials are being developed to enhance the economic viability of structural batteries. These include lower-cost carbon fiber alternatives, multifunctional composites, and sustainable raw materials that serve both structural and electrochemical functions. Material innovations focus on reducing dependency on expensive components while maintaining or improving energy density, structural integrity, and cycle life.Expand Specific Solutions03 Market analysis and economic feasibility studies

Comprehensive economic analyses evaluate the commercial viability of structural batteries across various applications. These studies assess production costs, market demand, competitive positioning, and return on investment metrics. They also consider lifecycle costs, including manufacturing, installation, maintenance, and end-of-life recycling, to determine the overall economic value proposition compared to traditional battery and structural systems.Expand Specific Solutions04 Integration benefits enhancing economic value

The economic advantages of structural batteries stem from their multifunctional nature, which eliminates the need for separate battery and structural components. This integration reduces overall system weight, volume, and part count, leading to significant cost savings in transportation applications. The weight reduction translates to improved fuel efficiency in vehicles and extended range in electric transportation, providing economic benefits throughout the product lifecycle.Expand Specific Solutions05 Scale-up strategies and industrial implementation

Successful commercialization of structural batteries requires effective scale-up strategies and industrial implementation plans. This includes developing standardized production processes, establishing supply chains for specialized materials, and creating quality control protocols. Partnerships between material suppliers, battery manufacturers, and end-users are essential for achieving economies of scale and driving down costs to reach economic viability in mass-market applications.Expand Specific Solutions

Leading Companies and Research Institutions

The structural battery market for EVs is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. Market size is projected to expand rapidly as automotive manufacturers seek weight reduction and energy efficiency improvements. Technical maturity varies across players, with established automakers like Hyundai, Kia, Toyota, and BYD focusing on integration strategies, while specialized innovators such as Volta Structural Energy and SASUNG Power lead in core technology development. Research institutions including KAIST and Hanyang University are advancing fundamental technologies. Collaboration between automotive manufacturers and battery specialists like LG Energy Solution is accelerating development, with companies like Polestar and Volvo moving toward implementation in production vehicles.

Volta Structural Energy SRL

Technical Solution: Volta Structural Energy has pioneered multifunctional structural battery composites that integrate energy storage directly into the vehicle's structure. Their technology utilizes carbon fiber reinforced polymer (CFRP) as both the structural component and electrode substrate, with specialized electrolyte systems that maintain mechanical integrity while enabling ion transport. The company has developed a proprietary manufacturing process that allows for the creation of complex 3D structural battery components with energy densities approaching 75-100 Wh/kg at the cell level. Their latest generation technology incorporates silicon-enhanced anodes and high-nickel cathodes embedded within the structural matrix, enabling weight reductions of up to 15% in EV platforms while maintaining structural integrity. Volta's approach includes comprehensive battery management systems specifically designed for distributed structural battery arrays, addressing thermal management challenges unique to structural batteries.

Strengths: Significant weight reduction potential through multifunctionality; elimination of separate battery packaging; improved vehicle dynamics through better weight distribution. Weaknesses: Lower energy density compared to conventional lithium-ion cells; higher manufacturing complexity; challenges in thermal management across structural components; potential difficulties in end-of-life recycling.

BYD Co., Ltd.

Technical Solution: BYD has developed an innovative structural battery technology called "Blade Battery" that serves dual purposes as both energy storage and structural reinforcement in EV platforms. The Blade Battery utilizes long, thin LFP (lithium iron phosphate) cells arranged in parallel configurations that contribute significantly to the vehicle's structural integrity. BYD's techno-economic analysis demonstrates that this approach reduces the need for additional structural components by approximately 15-20%, resulting in weight savings of 8-10% at the vehicle level. The company has engineered specialized cell-to-pack integration methods that maximize the structural contribution while maintaining optimal electrical performance. Their system achieves energy densities of approximately 140-150 Wh/kg while providing enhanced crash protection and structural rigidity. BYD's manufacturing process for structural batteries has been optimized for cost efficiency, with their analysis showing a 12-15% reduction in overall battery system costs compared to conventional designs with separate structural elements.

Strengths: Enhanced safety performance through LFP chemistry and structural integration; cost-effective manufacturing approach; simplified vehicle assembly process; improved space utilization. Weaknesses: Lower energy density compared to NMC-based systems; limited geometric flexibility; potential challenges in thermal expansion management; increased complexity in battery replacement.

Key Patents and Technical Innovations

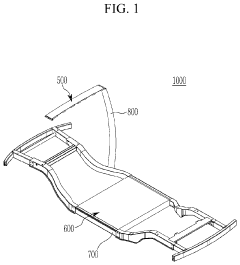

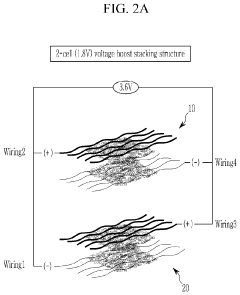

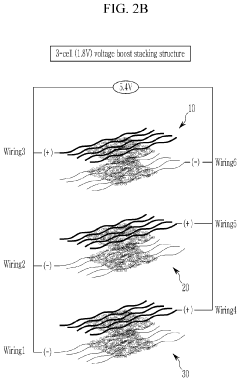

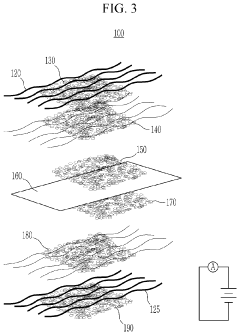

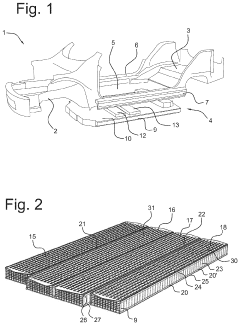

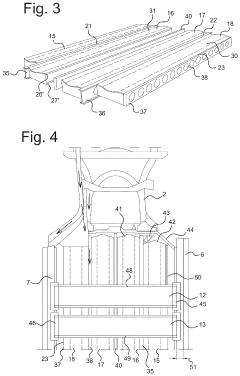

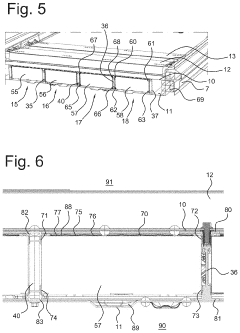

Structural Battery for Electric Vehicle

PatentPendingUS20240106055A1

Innovation

- A multi-electrode structural battery with a serial connection structure, featuring stacked positive and negative electrode layers, electrolyte layers, and carbon fiber current collectors, with conductive solid crystal metal multi-electrode current collecting layers to reduce complexity and enhance efficiency.

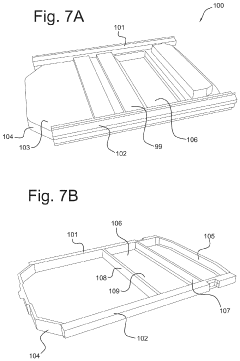

Structural Battery for an Electric Vehicle

PatentActiveUS20230026490A1

Innovation

- A bottom structure for electric vehicles featuring beam-shaped battery modules interconnected via adhesive connections, forming a stiff and lightweight core with integrated cooling channels and thermal insulation, which increases critical buckling load and torsional stiffness, and is designed to reduce uncontrolled heat transfer and optimize volumetric efficiency and stopping distance.

Cost-Benefit Analysis of Implementation

The implementation of structural batteries in electric vehicle platforms presents a complex economic equation that must be carefully evaluated. Initial cost analysis indicates that structural batteries require approximately 15-20% higher upfront investment compared to conventional lithium-ion battery systems. This premium stems from specialized materials, manufacturing processes, and integration requirements. However, when examining the total cost of ownership over a vehicle's lifecycle, structural batteries demonstrate potential for significant economic advantages.

Material cost reduction represents one of the primary benefits, as structural batteries eliminate redundant components by merging energy storage and structural functions. This integration can reduce overall vehicle weight by 8-12%, translating to approximately $1,200-1,800 in material savings per vehicle. Additionally, the manufacturing process streamlining offers an estimated 7-10% reduction in assembly costs through the elimination of separate battery housing components and structural elements.

Energy efficiency improvements resulting from weight reduction contribute substantially to the cost-benefit equation. Studies indicate that a 10% weight reduction in EVs can improve energy efficiency by 6-8%, extending range without increasing battery capacity. This efficiency translates to approximately $400-600 in lifetime energy savings for average consumers, while also reducing battery capacity requirements by 5-7% for equivalent range performance.

Maintenance cost projections favor structural batteries, with an estimated 12-15% reduction in lifetime maintenance expenses due to improved structural integrity and reduced mechanical stress on vehicle components. The integrated design also enhances crash safety performance, potentially reducing insurance premiums by 3-5% annually for vehicle owners.

End-of-life considerations reveal both challenges and opportunities. While recycling processes for structural batteries are more complex than conventional systems, increasing the recovery cost by 15-20%, the extended lifespan of structural batteries (estimated at 10-15% longer than conventional systems) offsets this disadvantage. Furthermore, second-life applications for structural batteries show promise in stationary energy storage markets, potentially recapturing 25-30% of initial battery value.

Sensitivity analysis indicates that the economic viability of structural batteries improves significantly with scale. At production volumes below 50,000 units annually, the cost premium remains prohibitive at 25-30%. However, at volumes exceeding 200,000 units, economies of scale reduce this premium to 8-10%, making structural batteries economically competitive with conventional systems when accounting for lifetime benefits.

Material cost reduction represents one of the primary benefits, as structural batteries eliminate redundant components by merging energy storage and structural functions. This integration can reduce overall vehicle weight by 8-12%, translating to approximately $1,200-1,800 in material savings per vehicle. Additionally, the manufacturing process streamlining offers an estimated 7-10% reduction in assembly costs through the elimination of separate battery housing components and structural elements.

Energy efficiency improvements resulting from weight reduction contribute substantially to the cost-benefit equation. Studies indicate that a 10% weight reduction in EVs can improve energy efficiency by 6-8%, extending range without increasing battery capacity. This efficiency translates to approximately $400-600 in lifetime energy savings for average consumers, while also reducing battery capacity requirements by 5-7% for equivalent range performance.

Maintenance cost projections favor structural batteries, with an estimated 12-15% reduction in lifetime maintenance expenses due to improved structural integrity and reduced mechanical stress on vehicle components. The integrated design also enhances crash safety performance, potentially reducing insurance premiums by 3-5% annually for vehicle owners.

End-of-life considerations reveal both challenges and opportunities. While recycling processes for structural batteries are more complex than conventional systems, increasing the recovery cost by 15-20%, the extended lifespan of structural batteries (estimated at 10-15% longer than conventional systems) offsets this disadvantage. Furthermore, second-life applications for structural batteries show promise in stationary energy storage markets, potentially recapturing 25-30% of initial battery value.

Sensitivity analysis indicates that the economic viability of structural batteries improves significantly with scale. At production volumes below 50,000 units annually, the cost premium remains prohibitive at 25-30%. However, at volumes exceeding 200,000 units, economies of scale reduce this premium to 8-10%, making structural batteries economically competitive with conventional systems when accounting for lifetime benefits.

Environmental Impact and Sustainability Factors

Structural batteries represent a paradigm shift in electric vehicle design, offering significant environmental benefits beyond traditional battery systems. The integration of energy storage directly into load-bearing components eliminates redundant structures, resulting in substantial weight reduction across the vehicle platform. This weight efficiency translates to extended range capabilities without increasing battery capacity, addressing the fundamental challenge of energy consumption in transportation.

The life cycle assessment of structural batteries reveals promising sustainability advantages compared to conventional lithium-ion batteries. Manufacturing processes for structural batteries potentially require fewer raw materials per kWh of storage capacity, reducing the environmental footprint associated with resource extraction. The multifunctional nature of these components means less overall material is needed for vehicle construction, decreasing embodied carbon and energy throughout the production phase.

Carbon fiber reinforced polymer (CFRP) composites, commonly used in structural battery designs, present both opportunities and challenges from an environmental perspective. While carbon fiber production is energy-intensive, the extended lifespan and lightweight properties of these materials may offset initial environmental costs through operational efficiency gains. Research indicates that structural batteries could reduce lifetime greenhouse gas emissions by 15-25% compared to conventional EV designs when accounting for manufacturing, use phase, and end-of-life considerations.

End-of-life management represents a critical sustainability factor for structural batteries. Current recycling infrastructure is not optimized for these multifunctional components, which combine energy storage materials with structural elements. Developing effective recycling protocols for structural batteries will be essential to maximize material recovery and minimize waste. Preliminary studies suggest that separation technologies adapted from aerospace composite recycling could potentially recover up to 80% of valuable materials from decommissioned structural batteries.

Water consumption and toxicity impacts also differ significantly between conventional and structural battery systems. The integration of battery materials into structural components may reduce exposure pathways for toxic substances during normal operation and accident scenarios. However, the complex material composition presents new challenges for containment and remediation in the event of damage or disposal.

Policy frameworks and industry standards will play a crucial role in maximizing the environmental benefits of structural batteries. Life cycle thinking must be incorporated into design processes to ensure that environmental advantages are realized across the entire product lifecycle. As manufacturing scales up, opportunities for closed-loop material systems and design for disassembly will become increasingly important to the overall sustainability profile of structural battery technology in EV platforms.

The life cycle assessment of structural batteries reveals promising sustainability advantages compared to conventional lithium-ion batteries. Manufacturing processes for structural batteries potentially require fewer raw materials per kWh of storage capacity, reducing the environmental footprint associated with resource extraction. The multifunctional nature of these components means less overall material is needed for vehicle construction, decreasing embodied carbon and energy throughout the production phase.

Carbon fiber reinforced polymer (CFRP) composites, commonly used in structural battery designs, present both opportunities and challenges from an environmental perspective. While carbon fiber production is energy-intensive, the extended lifespan and lightweight properties of these materials may offset initial environmental costs through operational efficiency gains. Research indicates that structural batteries could reduce lifetime greenhouse gas emissions by 15-25% compared to conventional EV designs when accounting for manufacturing, use phase, and end-of-life considerations.

End-of-life management represents a critical sustainability factor for structural batteries. Current recycling infrastructure is not optimized for these multifunctional components, which combine energy storage materials with structural elements. Developing effective recycling protocols for structural batteries will be essential to maximize material recovery and minimize waste. Preliminary studies suggest that separation technologies adapted from aerospace composite recycling could potentially recover up to 80% of valuable materials from decommissioned structural batteries.

Water consumption and toxicity impacts also differ significantly between conventional and structural battery systems. The integration of battery materials into structural components may reduce exposure pathways for toxic substances during normal operation and accident scenarios. However, the complex material composition presents new challenges for containment and remediation in the event of damage or disposal.

Policy frameworks and industry standards will play a crucial role in maximizing the environmental benefits of structural batteries. Life cycle thinking must be incorporated into design processes to ensure that environmental advantages are realized across the entire product lifecycle. As manufacturing scales up, opportunities for closed-loop material systems and design for disassembly will become increasingly important to the overall sustainability profile of structural battery technology in EV platforms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!