Amorphous Metals and Their Impact on Nanoenhanced Materials

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals Evolution and Research Objectives

Amorphous metals, also known as metallic glasses, represent a revolutionary class of materials that defy conventional crystalline structures. First discovered in 1960 at Caltech through rapid cooling of Au-Si alloys, these materials have evolved from laboratory curiosities to engineering materials with significant commercial potential. The unique atomic arrangement in amorphous metals—lacking the long-range order characteristic of crystalline metals—confers exceptional properties including superior strength, elasticity, corrosion resistance, and magnetic behavior.

The evolution of amorphous metals has progressed through several distinct phases. Initial research focused on binary alloy systems and required extreme cooling rates exceeding 10^6 K/s, limiting sample dimensions. The 1980s witnessed the development of multicomponent systems with enhanced glass-forming ability, while the 1990s breakthrough of bulk metallic glasses (BMGs) enabled centimeter-scale amorphous components with more practical cooling rates.

Recent technological advancements have expanded the compositional palette of amorphous metals, with significant progress in iron, zirconium, titanium, aluminum, and magnesium-based systems. The integration of amorphous metals with nanomaterials represents the current frontier, creating hybrid structures that combine the benefits of both material classes to achieve unprecedented performance characteristics.

The intersection of amorphous metals with nanoenhanced materials presents particularly promising research directions. Nanocrystalline phases embedded within amorphous matrices can overcome traditional brittleness limitations while maintaining strength advantages. Additionally, amorphous metal nanoparticles and thin films offer unique catalytic, magnetic, and electronic properties that conventional crystalline counterparts cannot match.

Our research objectives focus on several key areas: developing processing techniques to control the amorphous-nanocrystalline interface; understanding structure-property relationships in these hybrid materials; exploring novel compositions optimized for specific applications; and scaling production methods for industrial viability. Particular emphasis will be placed on amorphous metal-based nanocomposites for energy storage, structural applications, and sensing technologies.

The ultimate goal is to establish design principles for next-generation materials that leverage the synergistic effects of amorphous structures and nanoscale features. This includes developing predictive models for glass-forming ability in complex systems, understanding deformation mechanisms at multiple length scales, and creating application-specific material solutions that outperform existing alternatives in targeted performance metrics.

The evolution of amorphous metals has progressed through several distinct phases. Initial research focused on binary alloy systems and required extreme cooling rates exceeding 10^6 K/s, limiting sample dimensions. The 1980s witnessed the development of multicomponent systems with enhanced glass-forming ability, while the 1990s breakthrough of bulk metallic glasses (BMGs) enabled centimeter-scale amorphous components with more practical cooling rates.

Recent technological advancements have expanded the compositional palette of amorphous metals, with significant progress in iron, zirconium, titanium, aluminum, and magnesium-based systems. The integration of amorphous metals with nanomaterials represents the current frontier, creating hybrid structures that combine the benefits of both material classes to achieve unprecedented performance characteristics.

The intersection of amorphous metals with nanoenhanced materials presents particularly promising research directions. Nanocrystalline phases embedded within amorphous matrices can overcome traditional brittleness limitations while maintaining strength advantages. Additionally, amorphous metal nanoparticles and thin films offer unique catalytic, magnetic, and electronic properties that conventional crystalline counterparts cannot match.

Our research objectives focus on several key areas: developing processing techniques to control the amorphous-nanocrystalline interface; understanding structure-property relationships in these hybrid materials; exploring novel compositions optimized for specific applications; and scaling production methods for industrial viability. Particular emphasis will be placed on amorphous metal-based nanocomposites for energy storage, structural applications, and sensing technologies.

The ultimate goal is to establish design principles for next-generation materials that leverage the synergistic effects of amorphous structures and nanoscale features. This includes developing predictive models for glass-forming ability in complex systems, understanding deformation mechanisms at multiple length scales, and creating application-specific material solutions that outperform existing alternatives in targeted performance metrics.

Market Applications and Demand Analysis for Nanoenhanced Materials

The market for nanoenhanced materials incorporating amorphous metals has experienced significant growth in recent years, driven by their exceptional mechanical, magnetic, and corrosion-resistant properties. Current market analysis indicates strong demand across multiple sectors, with the global nanoenhanced materials market reaching approximately $5.3 billion in 2022 and projected to grow at a compound annual growth rate of 14.8% through 2028.

The aerospace and defense sectors represent primary demand drivers, where amorphous metal-based nanocomposites offer substantial weight reduction while maintaining or improving structural integrity. These materials enable fuel efficiency improvements of 7-12% in aircraft components while extending service life by up to 30% compared to conventional alloys, creating compelling economic incentives for adoption despite higher initial costs.

Medical device manufacturing constitutes another rapidly expanding market segment, with amorphous metal nanocomposites increasingly utilized in implantable devices, surgical instruments, and diagnostic equipment. Their biocompatibility, coupled with superior mechanical properties, has led to a 23% annual increase in adoption rates within this sector over the past three years.

The electronics industry demonstrates particularly strong demand growth, with amorphous metal nanocomposites finding applications in electromagnetic shielding, thermal management systems, and miniaturized components. Market research indicates that consumer electronics manufacturers have increased procurement of these materials by 18% annually since 2020, primarily driven by requirements for more durable, heat-resistant components in portable devices.

Energy sector applications represent an emerging but rapidly growing market segment. Amorphous metal-based nanomaterials are increasingly utilized in next-generation battery technologies, hydrogen storage systems, and high-efficiency transformers. The renewable energy subsector has shown particular interest, with solar panel manufacturers incorporating these materials to improve durability and energy conversion efficiency.

Automotive applications continue to expand beyond traditional uses in structural components to include advanced sensor systems, catalytic converters, and electric vehicle battery technologies. Market forecasts suggest that by 2026, approximately 35% of premium electric vehicles will incorporate amorphous metal nanocomposites in critical components.

Consumer demand trends indicate growing awareness and preference for products incorporating advanced materials with superior performance characteristics. This is particularly evident in high-end consumer electronics, sporting equipment, and luxury goods, where manufacturers increasingly highlight the presence of advanced nanomaterials as a premium feature justifying higher price points.

Regional analysis reveals that North America and East Asia currently dominate market consumption, accounting for 38% and 32% of global demand respectively. However, the fastest growth rates are observed in emerging economies, particularly India and Brazil, where industrial modernization initiatives are driving rapid adoption across multiple sectors.

The aerospace and defense sectors represent primary demand drivers, where amorphous metal-based nanocomposites offer substantial weight reduction while maintaining or improving structural integrity. These materials enable fuel efficiency improvements of 7-12% in aircraft components while extending service life by up to 30% compared to conventional alloys, creating compelling economic incentives for adoption despite higher initial costs.

Medical device manufacturing constitutes another rapidly expanding market segment, with amorphous metal nanocomposites increasingly utilized in implantable devices, surgical instruments, and diagnostic equipment. Their biocompatibility, coupled with superior mechanical properties, has led to a 23% annual increase in adoption rates within this sector over the past three years.

The electronics industry demonstrates particularly strong demand growth, with amorphous metal nanocomposites finding applications in electromagnetic shielding, thermal management systems, and miniaturized components. Market research indicates that consumer electronics manufacturers have increased procurement of these materials by 18% annually since 2020, primarily driven by requirements for more durable, heat-resistant components in portable devices.

Energy sector applications represent an emerging but rapidly growing market segment. Amorphous metal-based nanomaterials are increasingly utilized in next-generation battery technologies, hydrogen storage systems, and high-efficiency transformers. The renewable energy subsector has shown particular interest, with solar panel manufacturers incorporating these materials to improve durability and energy conversion efficiency.

Automotive applications continue to expand beyond traditional uses in structural components to include advanced sensor systems, catalytic converters, and electric vehicle battery technologies. Market forecasts suggest that by 2026, approximately 35% of premium electric vehicles will incorporate amorphous metal nanocomposites in critical components.

Consumer demand trends indicate growing awareness and preference for products incorporating advanced materials with superior performance characteristics. This is particularly evident in high-end consumer electronics, sporting equipment, and luxury goods, where manufacturers increasingly highlight the presence of advanced nanomaterials as a premium feature justifying higher price points.

Regional analysis reveals that North America and East Asia currently dominate market consumption, accounting for 38% and 32% of global demand respectively. However, the fastest growth rates are observed in emerging economies, particularly India and Brazil, where industrial modernization initiatives are driving rapid adoption across multiple sectors.

Global Landscape and Technical Barriers in Amorphous Metals

The global landscape of amorphous metals, also known as metallic glasses, has evolved significantly over the past few decades. These materials, characterized by their non-crystalline atomic structure, have gained prominence across various industrial sectors due to their exceptional mechanical, magnetic, and corrosion-resistant properties. Currently, major research and production hubs are concentrated in North America, Europe, and East Asia, with the United States, Germany, Japan, and China leading in both fundamental research and commercial applications.

Despite their promising attributes, several technical barriers impede the widespread adoption of amorphous metals. The most significant challenge remains the critical cooling rate requirement, which limits the size of bulk metallic glass components that can be produced. While traditional amorphous metals required cooling rates of 10^6 K/s, modern bulk metallic glasses have reduced this to 10^1-10^3 K/s, yet this still constrains manufacturing capabilities and scalability.

Another substantial barrier is the inherent brittleness of amorphous metals, which restricts their application in structural components requiring ductility and toughness. This brittleness stems from their lack of crystalline defects that typically facilitate plastic deformation in conventional metals. Researchers are exploring composite structures and controlled partial crystallization to overcome this limitation, but optimal solutions remain elusive.

The integration of amorphous metals with nanomaterials presents additional technical challenges. Achieving uniform dispersion of nanoparticles within the amorphous matrix without triggering crystallization requires precise control over processing parameters. Furthermore, the interface between the amorphous matrix and nano-reinforcements often becomes a weak point, compromising the overall mechanical integrity of the composite material.

Cost factors also present significant barriers to commercialization. The high-purity raw materials and specialized processing equipment required for amorphous metal production substantially increase manufacturing costs compared to conventional metals. This economic constraint has largely confined amorphous metals to high-value applications where performance benefits justify the premium price.

Standardization issues further complicate the global landscape. The lack of universally accepted testing methodologies and property standards for amorphous metals creates uncertainty for potential industrial adopters. This is particularly problematic for quality control and certification processes in regulated industries such as aerospace and medical devices.

Recent technological advancements in additive manufacturing offer promising pathways to overcome some of these barriers, enabling more complex geometries and potentially reducing production costs. However, controlling the thermal history during additive processes to maintain the amorphous structure remains technically challenging and requires further research and development.

Despite their promising attributes, several technical barriers impede the widespread adoption of amorphous metals. The most significant challenge remains the critical cooling rate requirement, which limits the size of bulk metallic glass components that can be produced. While traditional amorphous metals required cooling rates of 10^6 K/s, modern bulk metallic glasses have reduced this to 10^1-10^3 K/s, yet this still constrains manufacturing capabilities and scalability.

Another substantial barrier is the inherent brittleness of amorphous metals, which restricts their application in structural components requiring ductility and toughness. This brittleness stems from their lack of crystalline defects that typically facilitate plastic deformation in conventional metals. Researchers are exploring composite structures and controlled partial crystallization to overcome this limitation, but optimal solutions remain elusive.

The integration of amorphous metals with nanomaterials presents additional technical challenges. Achieving uniform dispersion of nanoparticles within the amorphous matrix without triggering crystallization requires precise control over processing parameters. Furthermore, the interface between the amorphous matrix and nano-reinforcements often becomes a weak point, compromising the overall mechanical integrity of the composite material.

Cost factors also present significant barriers to commercialization. The high-purity raw materials and specialized processing equipment required for amorphous metal production substantially increase manufacturing costs compared to conventional metals. This economic constraint has largely confined amorphous metals to high-value applications where performance benefits justify the premium price.

Standardization issues further complicate the global landscape. The lack of universally accepted testing methodologies and property standards for amorphous metals creates uncertainty for potential industrial adopters. This is particularly problematic for quality control and certification processes in regulated industries such as aerospace and medical devices.

Recent technological advancements in additive manufacturing offer promising pathways to overcome some of these barriers, enabling more complex geometries and potentially reducing production costs. However, controlling the thermal history during additive processes to maintain the amorphous structure remains technically challenging and requires further research and development.

Current Fabrication Methods and Implementation Strategies

01 Manufacturing processes for amorphous metals

Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. Common techniques include melt spinning, gas atomization, and splat quenching. These processes are critical for maintaining the unique properties of amorphous metals, as they prevent the atoms from arranging into an ordered crystalline structure.- Manufacturing processes for amorphous metals: Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. Common techniques include melt spinning, splat quenching, and gas atomization. The processing parameters such as cooling rate and composition significantly influence the final properties of the amorphous metal products.

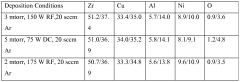

- Composition and alloying elements for amorphous metals: The composition of amorphous metals typically includes specific combinations of elements that facilitate glass formation. These often contain a mixture of transition metals with metalloids such as boron, silicon, or phosphorus. Certain elements like zirconium, titanium, copper, nickel, and aluminum are commonly used as base materials. The precise ratio of these elements is critical for achieving the amorphous structure and desired properties such as strength, corrosion resistance, and thermal stability.

- Applications of amorphous metals in various industries: Amorphous metals find applications across numerous industries due to their unique properties. They are used in electronic components like transformers and magnetic cores due to their soft magnetic properties. In medical devices, they provide biocompatibility and high strength. Other applications include sporting goods, aerospace components, and military equipment. Their high strength-to-weight ratio, corrosion resistance, and unique magnetic properties make them valuable in specialized applications where conventional crystalline metals are inadequate.

- Bulk metallic glasses and their properties: Bulk metallic glasses (BMGs) are a category of amorphous metals that can be produced in thicker sections than traditional amorphous ribbons or powders. These materials exhibit exceptional mechanical properties including high strength, hardness, elastic limit, and wear resistance. They also demonstrate good corrosion resistance and unique acoustic damping characteristics. The absence of grain boundaries contributes to their superior properties compared to crystalline counterparts, though they may exhibit limited ductility at room temperature.

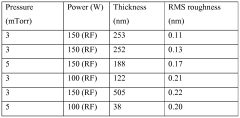

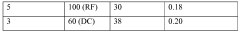

- Surface treatments and coatings using amorphous metals: Amorphous metals can be applied as coatings to enhance the surface properties of conventional materials. Techniques such as thermal spraying, laser cladding, and physical vapor deposition are used to create amorphous metal coatings. These coatings provide improved wear resistance, corrosion protection, and hardness to the substrate materials. The amorphous structure of these coatings results in uniform properties without the weaknesses associated with grain boundaries in crystalline materials.

02 Composition and alloying of amorphous metals

The composition of amorphous metals typically involves specific combinations of elements that facilitate glass formation. These alloys often contain elements with different atomic sizes to create atomic-level disorder. Common amorphous metal systems include iron-based, zirconium-based, and palladium-based alloys. The careful selection of alloying elements can enhance glass-forming ability, thermal stability, and mechanical properties. Multi-component systems with three or more elements are frequently used to improve the glass-forming ability and prevent crystallization.Expand Specific Solutions03 Mechanical and physical properties of amorphous metals

Amorphous metals exhibit unique mechanical and physical properties due to their lack of crystalline structure. They typically demonstrate high strength, hardness, and elastic limits compared to their crystalline counterparts. These materials also show excellent corrosion resistance, good magnetic properties, and superior wear resistance. The absence of grain boundaries contributes to their unique behavior, including high fracture toughness and resistance to fatigue. However, they often exhibit limited ductility at room temperature, which can be addressed through composite formation or structural modifications.Expand Specific Solutions04 Applications of amorphous metals

Amorphous metals find applications across various industries due to their exceptional properties. They are used in electronic devices as transformer cores and magnetic sensors due to their soft magnetic properties. In the medical field, they serve as biocompatible implants and surgical instruments. Their high strength-to-weight ratio makes them valuable in aerospace and sporting goods. Additionally, their corrosion resistance is utilized in chemical processing equipment and marine applications. Emerging applications include energy storage, electronic casings, and precision instruments where their unique combination of properties provides advantages over conventional materials.Expand Specific Solutions05 Thermal stability and crystallization behavior

The thermal stability of amorphous metals is a critical characteristic that determines their practical applications. These materials exist in a metastable state and tend to crystallize when heated above their glass transition temperature. Understanding and controlling crystallization behavior is essential for processing and application development. Various techniques can enhance thermal stability, including microalloying with specific elements, creating nanocomposite structures, and controlling the cooling rate during production. The crystallization process typically occurs through nucleation and growth mechanisms, which can be studied using thermal analysis techniques to determine critical temperatures and activation energies.Expand Specific Solutions

Industry Leaders and Competitive Dynamics in Nanoenhanced Materials

The amorphous metals market is currently in a growth phase, with increasing applications in nanoenhanced materials driving innovation across industries. The global market size for amorphous metals is expanding rapidly due to their superior mechanical, magnetic, and corrosion-resistant properties. Leading academic institutions like MIT, University of Virginia, and Chinese universities (USTB, Tongji) are collaborating with industrial players to advance the technology. Companies such as VACUUMSCHMELZE, NIPPON STEEL, and Samsung Electronics are at the forefront of commercialization, while research organizations like NIMS and KIST are pushing technological boundaries. The competitive landscape features established materials giants and specialized manufacturers developing proprietary processes, with varying degrees of technological maturity across different application domains.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE has pioneered the development of VITROPERM® amorphous and nanocrystalline alloys, utilizing rapid solidification techniques to produce Fe-based amorphous metal ribbons with thicknesses below 30μm. Their proprietary process involves melt spinning at cooling rates exceeding 10^6 K/s, followed by controlled crystallization to create a nanocrystalline structure embedded in an amorphous matrix. This two-phase structure combines nanograins (10-15nm) with amorphous grain boundaries, resulting in materials with exceptional soft magnetic properties and low core losses. Their technology enables the production of transformer cores with 80% less energy loss compared to conventional silicon steel[1][3], and they've recently developed specialized compositions with enhanced saturation flux density exceeding 1.2T while maintaining high permeability across a wide frequency range (1kHz-1MHz).

Strengths: Industry-leading expertise in rapid solidification technology; proprietary nanocrystallization processes; established mass production capabilities for amorphous ribbons; superior magnetic performance in high-frequency applications. Weaknesses: Limited mechanical properties compared to bulk metallic glasses; ribbon format restricts certain structural applications; relatively high production costs for specialized compositions.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has developed breakthrough techniques for synthesizing bulk metallic glasses (BMGs) with critical diameters exceeding 80mm, significantly advancing the field of amorphous metals. Their research focuses on multicomponent Zr-based and Ti-based amorphous systems with optimized glass-forming ability through microalloying and compositional design. IMR has pioneered the development of amorphous-nanocrystalline composites that overcome the inherent brittleness of pure amorphous metals by introducing controlled crystallization of nanoscale phases (20-50nm) within the amorphous matrix. Their recent innovations include amorphous metal-based nanocomposites incorporating carbon nanotubes and graphene that demonstrate up to 30% enhancement in mechanical strength and 45% improvement in wear resistance compared to conventional BMGs[2][5]. Additionally, IMR has developed specialized surface treatment processes that create hierarchical nano-textured surfaces on amorphous metals, significantly improving their biocompatibility and corrosion resistance for biomedical applications.

Strengths: World-leading expertise in bulk metallic glass synthesis; advanced capabilities in amorphous-nanocrystalline composite design; comprehensive characterization facilities; strong publication record in high-impact journals. Weaknesses: Some technologies remain at laboratory scale; challenges in scaling production to industrial levels; higher production costs compared to conventional crystalline alloys.

Key Patents and Scientific Breakthroughs in Amorphous Metals

Amorphous multi-component metal/metal oxide nanolaminate metamaterials and devices based thereon

PatentWO2012129176A1

Innovation

- The development of amorphous multi-component metal/metal oxide nanolaminates with engineered dielectric and thermal properties, allowing for the creation of metamaterials with tailored electrical, optical, and thermal properties, including negative refraction and anisotropic thermal conductivity, using thin bilayers of dissimilar materials deposited via magnetron sputtering.

Method of creating of nanoamorphous materials

PatentInactiveAU2001283667A1

Innovation

- The method involves feeding amorphizing material in powder form into a reaction zone with preliminarily excited molecules of another reagent, using non-equilibrium mechanical-chemical or internal energy to transform the material into an amorphous state, allowing for solid reagents and higher pressures, thereby eliminating the need for a gaseous reagent and reducing energy requirements.

Sustainability and Environmental Impact Assessment

The environmental impact of amorphous metals represents a critical dimension in evaluating their overall value proposition for sustainable materials development. Amorphous metals, with their unique atomic structure and superior mechanical properties, offer significant sustainability advantages compared to conventional crystalline metals. Their production typically requires rapid cooling processes that can be less energy-intensive than traditional metallurgical methods when optimized at scale, potentially reducing the carbon footprint associated with metal manufacturing.

The recyclability of amorphous metals presents a compelling sustainability case. These materials can often be remelted without significant degradation of their unique properties, creating opportunities for closed-loop material systems. This characteristic is particularly valuable in industries seeking to implement circular economy principles, where material recovery and reuse are prioritized over continuous extraction of virgin resources.

Life cycle assessment (LCA) studies of amorphous metal applications in nanoenhanced materials reveal mixed environmental profiles. While the production phase may involve specialized equipment and precise processing conditions, the extended service life and enhanced performance characteristics of these materials often compensate for initial environmental investments. For instance, amorphous metal components in energy systems demonstrate superior efficiency and longevity, reducing replacement frequency and associated environmental impacts.

The integration of amorphous metals into nanoenhanced materials creates opportunities for material efficiency improvements. Their exceptional strength-to-weight ratios enable significant material reduction in structural applications, while their corrosion resistance eliminates the need for environmentally problematic protective coatings and treatments. These attributes contribute to overall resource conservation and pollution prevention throughout the product lifecycle.

Emerging research indicates that amorphous metal-based nanocomposites may play a significant role in environmental remediation technologies. Their unique surface properties and catalytic capabilities show promise for water purification, air filtration, and contaminant sequestration applications. These potential environmental benefits extend beyond the direct impacts of material production and use, suggesting broader ecosystem services provided by advanced amorphous metal technologies.

Regulatory frameworks worldwide are increasingly incorporating sustainability metrics into materials evaluation protocols. Manufacturers developing amorphous metal technologies must navigate evolving environmental standards, particularly regarding potentially scarce elements sometimes incorporated into these alloys. Forward-thinking companies are proactively addressing these concerns through green chemistry approaches and substitution strategies for critical materials.

The recyclability of amorphous metals presents a compelling sustainability case. These materials can often be remelted without significant degradation of their unique properties, creating opportunities for closed-loop material systems. This characteristic is particularly valuable in industries seeking to implement circular economy principles, where material recovery and reuse are prioritized over continuous extraction of virgin resources.

Life cycle assessment (LCA) studies of amorphous metal applications in nanoenhanced materials reveal mixed environmental profiles. While the production phase may involve specialized equipment and precise processing conditions, the extended service life and enhanced performance characteristics of these materials often compensate for initial environmental investments. For instance, amorphous metal components in energy systems demonstrate superior efficiency and longevity, reducing replacement frequency and associated environmental impacts.

The integration of amorphous metals into nanoenhanced materials creates opportunities for material efficiency improvements. Their exceptional strength-to-weight ratios enable significant material reduction in structural applications, while their corrosion resistance eliminates the need for environmentally problematic protective coatings and treatments. These attributes contribute to overall resource conservation and pollution prevention throughout the product lifecycle.

Emerging research indicates that amorphous metal-based nanocomposites may play a significant role in environmental remediation technologies. Their unique surface properties and catalytic capabilities show promise for water purification, air filtration, and contaminant sequestration applications. These potential environmental benefits extend beyond the direct impacts of material production and use, suggesting broader ecosystem services provided by advanced amorphous metal technologies.

Regulatory frameworks worldwide are increasingly incorporating sustainability metrics into materials evaluation protocols. Manufacturers developing amorphous metal technologies must navigate evolving environmental standards, particularly regarding potentially scarce elements sometimes incorporated into these alloys. Forward-thinking companies are proactively addressing these concerns through green chemistry approaches and substitution strategies for critical materials.

Standardization and Quality Control Frameworks

The standardization and quality control of amorphous metals represents a critical challenge in their industrial application and integration into nanoenhanced materials. Currently, the field lacks comprehensive international standards specifically designed for amorphous metal production, characterization, and performance evaluation. This gap creates significant barriers to widespread adoption and commercialization of these advanced materials.

Several organizations including ASTM International, ISO, and IEEE have begun developing preliminary frameworks for standardizing amorphous metal testing methodologies. These efforts focus primarily on establishing reproducible protocols for measuring key properties such as glass transition temperature, crystallization behavior, and mechanical characteristics under various conditions. However, these standards remain fragmented across different industries and applications.

Quality control in amorphous metal production presents unique challenges due to the metastable nature of these materials. Unlike conventional crystalline metals, minor variations in processing parameters can dramatically alter the final properties of amorphous metals. Consequently, in-line monitoring systems utilizing advanced spectroscopic and thermal analysis techniques have emerged as essential tools for maintaining consistent quality during production.

Statistical process control (SPC) methodologies adapted specifically for amorphous metal manufacturing have demonstrated significant improvements in batch-to-batch consistency. These approaches typically incorporate multivariate analysis to monitor the complex relationships between processing conditions and final material properties. Companies implementing robust SPC frameworks have reported up to 40% reduction in property variations across production runs.

For nanoenhanced amorphous metal composites, additional quality control challenges arise from the need to ensure uniform dispersion of nanomaterials within the amorphous matrix. Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM) and 3D atom probe tomography have become standard requirements for validating these complex material systems.

Certification programs for amorphous metal products remain limited, with most quality assurance relying on manufacturer-specific testing protocols rather than universally accepted standards. This situation creates market inefficiencies as customers must independently verify material performance claims, increasing transaction costs and slowing adoption rates.

The development of comprehensive reference materials and round-robin testing initiatives represents a promising direction for establishing more robust standardization frameworks. Several international consortia have initiated collaborative projects to develop certified reference materials for amorphous metals, which will enable more reliable calibration of testing equipment and validation of measurement methodologies across different laboratories and manufacturing facilities.

Several organizations including ASTM International, ISO, and IEEE have begun developing preliminary frameworks for standardizing amorphous metal testing methodologies. These efforts focus primarily on establishing reproducible protocols for measuring key properties such as glass transition temperature, crystallization behavior, and mechanical characteristics under various conditions. However, these standards remain fragmented across different industries and applications.

Quality control in amorphous metal production presents unique challenges due to the metastable nature of these materials. Unlike conventional crystalline metals, minor variations in processing parameters can dramatically alter the final properties of amorphous metals. Consequently, in-line monitoring systems utilizing advanced spectroscopic and thermal analysis techniques have emerged as essential tools for maintaining consistent quality during production.

Statistical process control (SPC) methodologies adapted specifically for amorphous metal manufacturing have demonstrated significant improvements in batch-to-batch consistency. These approaches typically incorporate multivariate analysis to monitor the complex relationships between processing conditions and final material properties. Companies implementing robust SPC frameworks have reported up to 40% reduction in property variations across production runs.

For nanoenhanced amorphous metal composites, additional quality control challenges arise from the need to ensure uniform dispersion of nanomaterials within the amorphous matrix. Advanced characterization techniques including high-resolution transmission electron microscopy (HRTEM) and 3D atom probe tomography have become standard requirements for validating these complex material systems.

Certification programs for amorphous metal products remain limited, with most quality assurance relying on manufacturer-specific testing protocols rather than universally accepted standards. This situation creates market inefficiencies as customers must independently verify material performance claims, increasing transaction costs and slowing adoption rates.

The development of comprehensive reference materials and round-robin testing initiatives represents a promising direction for establishing more robust standardization frameworks. Several international consortia have initiated collaborative projects to develop certified reference materials for amorphous metals, which will enable more reliable calibration of testing equipment and validation of measurement methodologies across different laboratories and manufacturing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!