The Role of Amorphous Metals in Liquid Metal Battery Design

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals in Energy Storage: Background and Objectives

Amorphous metals, also known as metallic glasses, represent a revolutionary class of materials that have emerged as potential game-changers in energy storage technologies, particularly in liquid metal battery design. The evolution of these materials dates back to the 1960s when the first amorphous metal alloys were produced through rapid cooling techniques. Since then, significant advancements in manufacturing processes have enabled the production of amorphous metals with tailored properties, expanding their potential applications across various industries.

The trajectory of amorphous metals in energy storage has been marked by incremental improvements in their structural stability, electrical conductivity, and corrosion resistance. These unique properties stem from their disordered atomic structure, which lacks the crystalline grain boundaries found in conventional metals. This distinctive characteristic contributes to their exceptional mechanical properties, enhanced corrosion resistance, and superior electromagnetic performance.

In the context of liquid metal batteries, amorphous metals present compelling advantages over traditional crystalline materials. Liquid metal batteries operate at elevated temperatures and involve highly reactive molten metal electrodes separated by a molten salt electrolyte. The harsh operating conditions demand materials with exceptional thermal stability and corrosion resistance—attributes inherently present in amorphous metals.

The technical objectives for incorporating amorphous metals in liquid metal battery design encompass several critical aspects. Primary among these is enhancing the longevity and reliability of battery components exposed to corrosive molten metals and salts. Amorphous metals, with their superior resistance to chemical degradation, offer promising solutions to this persistent challenge.

Another key objective involves improving the energy efficiency of liquid metal batteries through the utilization of amorphous metal current collectors and containment structures. The reduced electrical resistance of these materials can minimize energy losses during charge-discharge cycles, thereby enhancing overall battery performance.

Furthermore, the research aims to leverage the unique mechanical properties of amorphous metals to develop more robust battery architectures capable of withstanding thermal cycling and mechanical stresses. This could potentially extend the operational lifespan of liquid metal batteries, making them more economically viable for grid-scale energy storage applications.

The technological trend indicates a growing interest in developing specialized amorphous metal alloys specifically tailored for energy storage applications. This includes compositions optimized for high-temperature stability, enhanced electrical conductivity, and compatibility with specific electrode materials used in liquid metal batteries.

The trajectory of amorphous metals in energy storage has been marked by incremental improvements in their structural stability, electrical conductivity, and corrosion resistance. These unique properties stem from their disordered atomic structure, which lacks the crystalline grain boundaries found in conventional metals. This distinctive characteristic contributes to their exceptional mechanical properties, enhanced corrosion resistance, and superior electromagnetic performance.

In the context of liquid metal batteries, amorphous metals present compelling advantages over traditional crystalline materials. Liquid metal batteries operate at elevated temperatures and involve highly reactive molten metal electrodes separated by a molten salt electrolyte. The harsh operating conditions demand materials with exceptional thermal stability and corrosion resistance—attributes inherently present in amorphous metals.

The technical objectives for incorporating amorphous metals in liquid metal battery design encompass several critical aspects. Primary among these is enhancing the longevity and reliability of battery components exposed to corrosive molten metals and salts. Amorphous metals, with their superior resistance to chemical degradation, offer promising solutions to this persistent challenge.

Another key objective involves improving the energy efficiency of liquid metal batteries through the utilization of amorphous metal current collectors and containment structures. The reduced electrical resistance of these materials can minimize energy losses during charge-discharge cycles, thereby enhancing overall battery performance.

Furthermore, the research aims to leverage the unique mechanical properties of amorphous metals to develop more robust battery architectures capable of withstanding thermal cycling and mechanical stresses. This could potentially extend the operational lifespan of liquid metal batteries, making them more economically viable for grid-scale energy storage applications.

The technological trend indicates a growing interest in developing specialized amorphous metal alloys specifically tailored for energy storage applications. This includes compositions optimized for high-temperature stability, enhanced electrical conductivity, and compatibility with specific electrode materials used in liquid metal batteries.

Market Analysis for Liquid Metal Battery Technologies

The liquid metal battery market is experiencing significant growth driven by the increasing demand for grid-scale energy storage solutions. As renewable energy sources like solar and wind continue to expand their market share, the need for efficient, large-scale energy storage systems becomes critical to address intermittency issues. Liquid metal batteries (LMBs) are emerging as a promising technology in this space due to their potential for long cycle life, high energy density, and relatively low cost compared to other grid-scale storage technologies.

Current market projections indicate that the global grid-scale energy storage market will reach approximately $15 billion by 2025, with liquid metal batteries potentially capturing a growing segment of this market. The technology's ability to provide long-duration storage (8+ hours) positions it favorably against lithium-ion batteries, which typically operate most efficiently in the 1-4 hour range.

The market for LMBs is currently segmented into several key application areas. Utility-scale grid storage represents the largest potential market, particularly in regions with high renewable energy penetration. Microgrids and island power systems form another significant segment, where the technology's durability and minimal maintenance requirements provide distinct advantages. Industrial applications requiring stable power supply constitute the third major market segment.

Geographically, North America and Europe lead in LMB adoption, primarily due to their aggressive renewable energy targets and supportive regulatory frameworks. However, Asia-Pacific markets, particularly China and India, are expected to show the highest growth rates as these countries rapidly expand their renewable energy capacity while facing grid stability challenges.

The integration of amorphous metals in LMB design represents a potential market differentiator. Batteries utilizing amorphous metal components may offer enhanced performance characteristics, including improved corrosion resistance, better thermal stability, and potentially longer operational lifetimes. These advantages could translate to lower levelized cost of storage (LCOS), a critical metric for market adoption.

Market barriers include competition from established technologies like lithium-ion, flow batteries, and compressed air energy storage. Additionally, the high upfront capital costs and limited commercial deployment history create adoption hesitancy among conservative utility operators. Regulatory uncertainties regarding long-term energy storage valuation also impact market growth potential.

Customer requirements in this market emphasize reliability, safety, scalability, and total cost of ownership. The ability of amorphous metal-enhanced LMBs to address these requirements will significantly influence their market penetration rate and commercial success in the evolving energy storage landscape.

Current market projections indicate that the global grid-scale energy storage market will reach approximately $15 billion by 2025, with liquid metal batteries potentially capturing a growing segment of this market. The technology's ability to provide long-duration storage (8+ hours) positions it favorably against lithium-ion batteries, which typically operate most efficiently in the 1-4 hour range.

The market for LMBs is currently segmented into several key application areas. Utility-scale grid storage represents the largest potential market, particularly in regions with high renewable energy penetration. Microgrids and island power systems form another significant segment, where the technology's durability and minimal maintenance requirements provide distinct advantages. Industrial applications requiring stable power supply constitute the third major market segment.

Geographically, North America and Europe lead in LMB adoption, primarily due to their aggressive renewable energy targets and supportive regulatory frameworks. However, Asia-Pacific markets, particularly China and India, are expected to show the highest growth rates as these countries rapidly expand their renewable energy capacity while facing grid stability challenges.

The integration of amorphous metals in LMB design represents a potential market differentiator. Batteries utilizing amorphous metal components may offer enhanced performance characteristics, including improved corrosion resistance, better thermal stability, and potentially longer operational lifetimes. These advantages could translate to lower levelized cost of storage (LCOS), a critical metric for market adoption.

Market barriers include competition from established technologies like lithium-ion, flow batteries, and compressed air energy storage. Additionally, the high upfront capital costs and limited commercial deployment history create adoption hesitancy among conservative utility operators. Regulatory uncertainties regarding long-term energy storage valuation also impact market growth potential.

Customer requirements in this market emphasize reliability, safety, scalability, and total cost of ownership. The ability of amorphous metal-enhanced LMBs to address these requirements will significantly influence their market penetration rate and commercial success in the evolving energy storage landscape.

Current Status and Technical Barriers in Amorphous Metal Implementation

Amorphous metals, also known as metallic glasses, have gained significant attention in liquid metal battery (LMB) design due to their unique structural and electrochemical properties. Currently, these materials are being explored as potential components in various battery elements, including electrodes, current collectors, and containment vessels. Research institutions across North America, Europe, and Asia have demonstrated promising results in laboratory settings, with several pilot-scale implementations showing enhanced battery performance.

The implementation of amorphous metals in commercial LMB systems faces several technical barriers. Foremost among these is the scalability challenge - while amorphous metals can be produced in small quantities with consistent properties, mass production techniques often introduce structural inconsistencies that compromise performance. The rapid cooling rates (typically 10^4-10^6 K/s) required for amorphization present significant manufacturing hurdles when scaling beyond laboratory dimensions.

Cost factors represent another substantial barrier. Current production methods for high-quality amorphous metals remain expensive compared to conventional crystalline alternatives, with prices approximately 3-5 times higher per unit weight. This cost differential makes widespread adoption economically challenging despite performance advantages.

Thermal stability issues also constrain implementation. Many amorphous metal compositions undergo crystallization at operating temperatures typical for LMBs (400-700°C), which can degrade their beneficial properties over time. Research shows that most commercially available amorphous alloys begin to crystallize after 500-1000 hours of exposure to typical LMB operating conditions.

Corrosion resistance presents a complex challenge. While amorphous metals generally exhibit superior corrosion resistance compared to their crystalline counterparts, the extreme chemical environment within LMBs—particularly with molten alkali metals—can still cause degradation. Recent studies indicate that certain zirconium and iron-based amorphous alloys show promising resistance, but long-term stability remains unproven.

Joining and integration difficulties further complicate implementation. Traditional welding and bonding techniques often induce crystallization at joint interfaces, creating potential failure points. Alternative joining methods such as diffusion bonding show promise but add complexity and cost to manufacturing processes.

Geographically, research leadership in amorphous metals for LMB applications is distributed unevenly. The United States and China lead in patent filings (accounting for approximately 65% of relevant patents), while significant research contributions also emerge from Germany, Japan, and South Korea. This distribution creates potential supply chain vulnerabilities for widespread commercial implementation.

The implementation of amorphous metals in commercial LMB systems faces several technical barriers. Foremost among these is the scalability challenge - while amorphous metals can be produced in small quantities with consistent properties, mass production techniques often introduce structural inconsistencies that compromise performance. The rapid cooling rates (typically 10^4-10^6 K/s) required for amorphization present significant manufacturing hurdles when scaling beyond laboratory dimensions.

Cost factors represent another substantial barrier. Current production methods for high-quality amorphous metals remain expensive compared to conventional crystalline alternatives, with prices approximately 3-5 times higher per unit weight. This cost differential makes widespread adoption economically challenging despite performance advantages.

Thermal stability issues also constrain implementation. Many amorphous metal compositions undergo crystallization at operating temperatures typical for LMBs (400-700°C), which can degrade their beneficial properties over time. Research shows that most commercially available amorphous alloys begin to crystallize after 500-1000 hours of exposure to typical LMB operating conditions.

Corrosion resistance presents a complex challenge. While amorphous metals generally exhibit superior corrosion resistance compared to their crystalline counterparts, the extreme chemical environment within LMBs—particularly with molten alkali metals—can still cause degradation. Recent studies indicate that certain zirconium and iron-based amorphous alloys show promising resistance, but long-term stability remains unproven.

Joining and integration difficulties further complicate implementation. Traditional welding and bonding techniques often induce crystallization at joint interfaces, creating potential failure points. Alternative joining methods such as diffusion bonding show promise but add complexity and cost to manufacturing processes.

Geographically, research leadership in amorphous metals for LMB applications is distributed unevenly. The United States and China lead in patent filings (accounting for approximately 65% of relevant patents), while significant research contributions also emerge from Germany, Japan, and South Korea. This distribution creates potential supply chain vulnerabilities for widespread commercial implementation.

Contemporary Amorphous Metal Integration Approaches

01 Manufacturing methods for amorphous metals

Various techniques are employed to produce amorphous metals, including rapid solidification processes that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. Common manufacturing approaches include melt spinning, gas atomization, and mechanical alloying, which enable the production of amorphous metals with unique properties not achievable in conventional crystalline metals.- Manufacturing methods for amorphous metals: Various techniques are employed to produce amorphous metals, including rapid solidification processes that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. Common manufacturing approaches include melt spinning, gas atomization, and mechanical alloying, which enable the production of amorphous metals with unique properties not achievable in conventional crystalline metals.

- Composition and alloying of amorphous metals: The composition of amorphous metals significantly influences their properties and glass-forming ability. These alloys typically contain multiple elements with different atomic sizes to disrupt crystallization. Common amorphous metal systems include iron-based, zirconium-based, and palladium-based alloys, often incorporating elements like boron, silicon, and phosphorus as glass formers. The specific elemental ratios are carefully designed to enhance thermal stability, mechanical properties, and other functional characteristics.

- Properties and applications of amorphous metals: Amorphous metals exhibit exceptional properties including high strength, hardness, corrosion resistance, and unique magnetic characteristics. Their lack of grain boundaries contributes to superior mechanical performance compared to crystalline counterparts. These materials find applications in transformer cores, electronic devices, sporting equipment, biomedical implants, and aerospace components. The combination of high elastic limit, wear resistance, and processability makes amorphous metals valuable in industries requiring high-performance materials.

- Bulk metallic glasses and their processing: Bulk metallic glasses (BMGs) are amorphous metals that can be produced in thicker sections than traditional amorphous ribbons. These materials possess exceptional glass-forming ability, allowing them to be cast into three-dimensional shapes while maintaining their amorphous structure. Processing techniques for BMGs include suction casting, injection molding, and thermoplastic forming. The development of BMGs has expanded the potential applications of amorphous metals by enabling the production of larger components with complex geometries.

- Surface treatments and coatings of amorphous metals: Surface modification techniques enhance the performance of amorphous metals for specific applications. These include laser surface treatments, thermal spraying, and vapor deposition methods to create amorphous metal coatings on conventional substrates. Such treatments can improve wear resistance, corrosion protection, and biocompatibility. Amorphous metal coatings combine the advantages of the substrate material with the superior surface properties of amorphous metals, offering cost-effective solutions for enhancing component performance in aggressive environments.

02 Composition and alloying of amorphous metals

The composition of amorphous metals significantly influences their properties and glass-forming ability. These alloys typically contain multiple elements with different atomic sizes to create atomic mismatch that inhibits crystallization. Common amorphous metal systems include iron-based, zirconium-based, and palladium-based alloys. The specific combination and proportion of elements determine characteristics such as thermal stability, mechanical properties, and magnetic behavior of the resulting amorphous structure.Expand Specific Solutions03 Applications of amorphous metals

Amorphous metals find applications across various industries due to their unique combination of properties. They are used in transformer cores and magnetic sensors due to their soft magnetic properties with low core losses. Their high strength and corrosion resistance make them suitable for structural components, medical implants, and sporting goods. Additionally, their unique elastic properties enable applications in springs, pressure sensors, and energy absorption systems where conventional metals would fail.Expand Specific Solutions04 Bulk metallic glasses and processing techniques

Bulk metallic glasses (BMGs) are amorphous metals that can be produced in thicker sections than traditional amorphous ribbons or powders. These materials exhibit exceptional glass-forming ability, allowing them to be cast into complex shapes while maintaining their amorphous structure. Processing techniques for BMGs include suction casting, injection molding, and thermoplastic forming. The ability to process BMGs in bulk form has expanded their potential applications in structural components, consumer electronics, and medical devices.Expand Specific Solutions05 Properties and characterization of amorphous metals

Amorphous metals exhibit distinctive properties that differentiate them from their crystalline counterparts. They typically display high strength, hardness, and elastic limit due to the absence of crystalline defects. Their isotropic structure results in uniform properties in all directions and enhanced corrosion resistance. Characterization techniques such as X-ray diffraction, differential scanning calorimetry, and transmission electron microscopy are employed to confirm the amorphous structure and evaluate thermal stability, crystallization behavior, and mechanical properties of these materials.Expand Specific Solutions

Leading Companies and Research Institutions in Liquid Metal Battery Field

The liquid metal battery market is in an early growth phase, characterized by increasing research activity and strategic investments. The global market size is expanding as energy storage demands rise, with projections showing significant growth potential over the next decade. Technologically, amorphous metals represent an emerging innovation in this field, with varying degrees of maturity across applications. Leading players like Toyota, Panasonic Energy, and LG Energy Solution are advancing commercial applications, while research institutions such as Kyushu University and Rutgers are driving fundamental innovations. Companies like Lyten and Advano are developing specialized materials that could accelerate adoption. The competitive landscape features both established battery manufacturers and specialized materials science companies working to overcome technical challenges related to thermal stability and longevity.

Panasonic Energy Co. Ltd.

Technical Solution: Panasonic Energy has developed sophisticated liquid metal battery systems utilizing titanium-based amorphous metal alloys as critical interface components. Their technology employs Ti-Zr-Cu-Ni amorphous compositions that provide exceptional resistance to corrosion by molten electrode materials while maintaining electrical conductivity at operating temperatures between 450-650°C. Panasonic's approach incorporates these amorphous metals as protective layers on conventional current collectors, creating composite structures that combine the mechanical strength of traditional materials with the chemical stability of amorphous alloys. Their liquid metal battery design features a lithium-lead negative electrode paired with a bismuth-antimony positive electrode, separated by a lithium-containing molten salt electrolyte. The amorphous metal components serve as critical interface materials that prevent unwanted reactions between the molten metals and container materials while facilitating efficient charge transfer.

Strengths: Exceptional chemical stability in contact with reactive molten metals; excellent electrical properties maintained throughout battery lifetime; enables simplified battery management systems due to inherent thermal stability. Weaknesses: Complex manufacturing processes increase production costs; requires specialized equipment for amorphous metal production and integration into battery systems.

International Business Machines Corp.

Technical Solution: IBM has developed innovative liquid metal battery technology utilizing iron-based amorphous metal alloys as structural components and current collectors. Their approach leverages the unique properties of Fe-B-Si-C amorphous systems that maintain structural integrity at the high operating temperatures (500-700°C) required for liquid metal batteries. IBM's research has focused on creating self-healing interfaces between the amorphous metal components and the active molten electrode materials, allowing for accommodation of volume changes during cycling. Their battery architecture employs a sodium-bismuth electrode system with specialized molten salt electrolytes, where the amorphous metal components provide both structural support and electrical pathways. IBM has also pioneered advanced manufacturing techniques for these materials, including melt spinning and vapor deposition methods that enable precise control of composition and microstructure.

Strengths: Advanced self-healing interfaces minimize degradation during thermal cycling; superior electrical conductivity compared to crystalline alternatives; innovative manufacturing techniques enable complex geometries. Weaknesses: High energy requirements for manufacturing processes increase production costs; challenges in scaling production to commercial volumes while maintaining material quality.

Critical Patents and Research on Amorphous Metal Electrodes

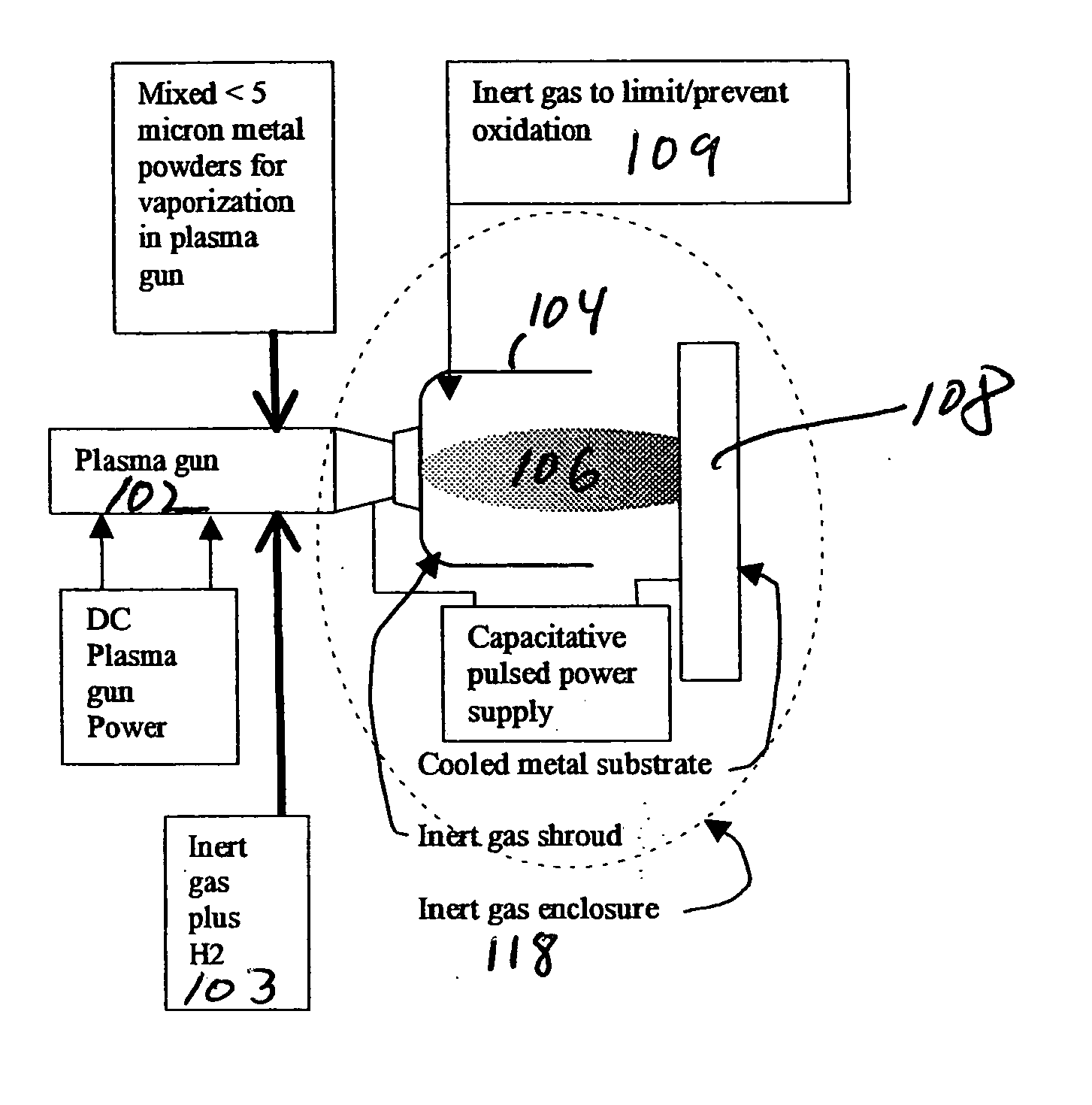

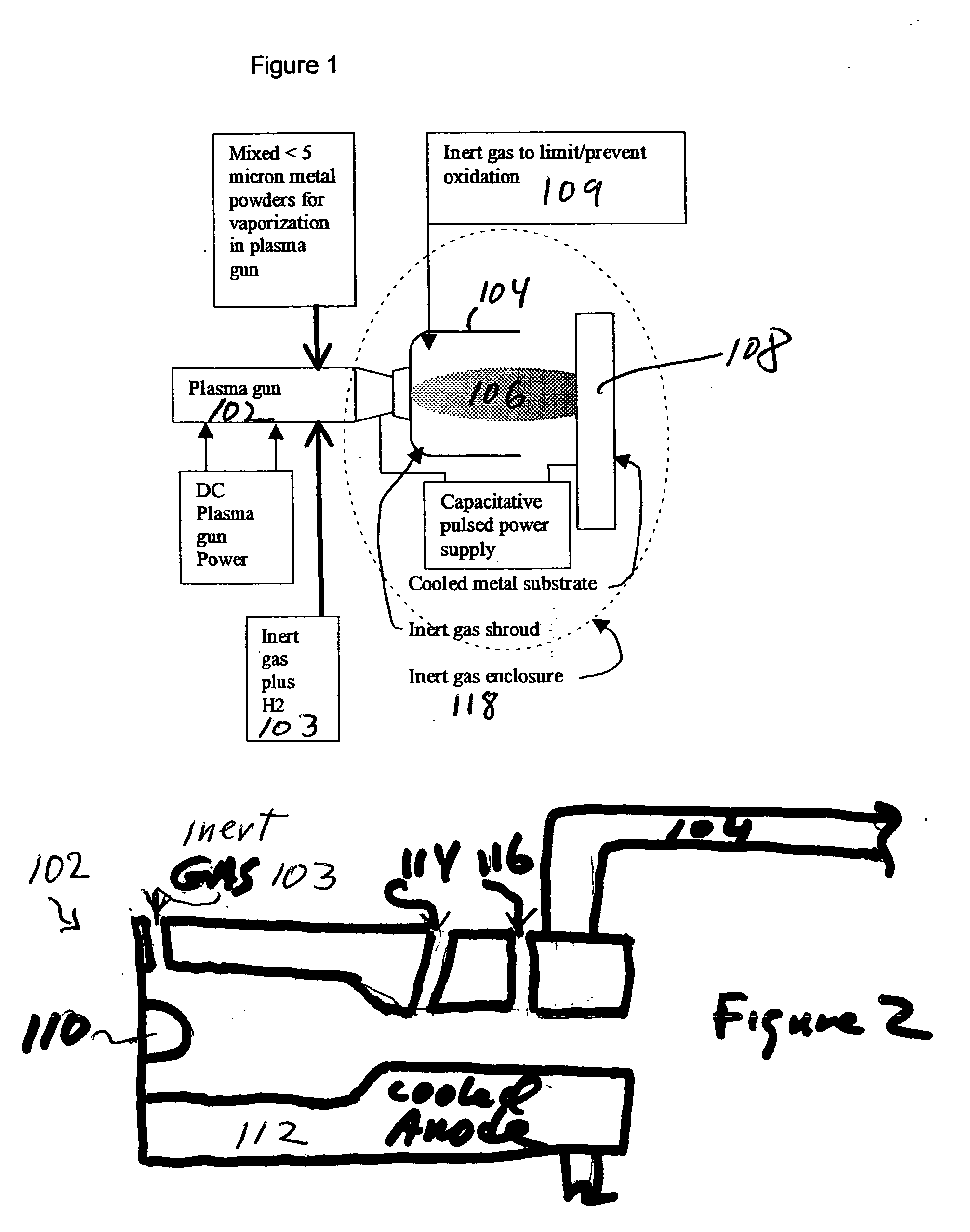

Amorphous metal deposition and new aluminum-based amorphous metals

PatentInactiveUS20050123686A1

Innovation

- The method involves vaporizing small powders of specific metal/metalloid compositions using plasma processing to form amorphous metal alloys, condensing the vapor on a substrate below the crystallization temperature, and using a chemically reducing plasma to prevent oxidation and enhance bonding, allowing for the formation of dense, amorphous metal coatings with improved mechanical properties.

Liquid metal battery

PatentWO2025010472A1

Innovation

- A liquid metal battery design incorporating a flow inducer that generates a swirl flow in the positive electrode using a magnetic field, effectively reducing mass transport overpotentials and homogenizing concentration within the cathode by inducing a rotational Lorentz force, enhancing mixing and reducing concentration stratification.

Sustainability Impact of Amorphous Metals in Energy Storage

The integration of amorphous metals in energy storage systems, particularly liquid metal batteries, represents a significant advancement in sustainable energy technology. These materials offer exceptional corrosion resistance and durability in harsh chemical environments, substantially extending battery lifespans compared to conventional crystalline metals. This longevity directly translates to reduced material consumption and waste generation over time, addressing critical sustainability concerns in the energy storage sector.

From a lifecycle perspective, amorphous metals demonstrate favorable environmental profiles. Their production typically requires less energy than traditional crystalline counterparts due to the elimination of multiple heat treatment steps. Additionally, the absence of grain boundaries in their structure enhances recyclability, as these materials maintain consistent properties throughout their service life and can be more efficiently reprocessed at end-of-life stages.

The carbon footprint reduction potential of amorphous metal-based liquid metal batteries is particularly noteworthy. By enabling more efficient energy storage solutions with longer operational lifespans, these systems can significantly decrease the embodied carbon associated with battery manufacturing and replacement cycles. Studies indicate that amorphous metal components can reduce lifecycle emissions by up to 30% compared to conventional materials in similar applications.

Resource efficiency represents another sustainability advantage of amorphous metals in energy storage. These materials often allow for thinner structural components due to their superior mechanical properties, reducing overall material requirements. Furthermore, some amorphous metal formulations utilize more abundant elements, potentially decreasing reliance on critical raw materials that face supply constraints or ethical sourcing challenges.

In grid-scale applications, liquid metal batteries incorporating amorphous metals contribute to broader sustainability goals by facilitating renewable energy integration. Their thermal stability and high cycling efficiency make them ideal candidates for load-leveling and peak-shaving applications, enabling greater penetration of intermittent renewable sources like solar and wind power.

Economic sustainability aspects must also be considered. While initial manufacturing costs for amorphous metals typically exceed those of conventional materials, their extended service life and reduced maintenance requirements often result in favorable total cost of ownership calculations. This economic advantage strengthens the business case for widespread adoption of these advanced materials in next-generation energy storage systems.

From a lifecycle perspective, amorphous metals demonstrate favorable environmental profiles. Their production typically requires less energy than traditional crystalline counterparts due to the elimination of multiple heat treatment steps. Additionally, the absence of grain boundaries in their structure enhances recyclability, as these materials maintain consistent properties throughout their service life and can be more efficiently reprocessed at end-of-life stages.

The carbon footprint reduction potential of amorphous metal-based liquid metal batteries is particularly noteworthy. By enabling more efficient energy storage solutions with longer operational lifespans, these systems can significantly decrease the embodied carbon associated with battery manufacturing and replacement cycles. Studies indicate that amorphous metal components can reduce lifecycle emissions by up to 30% compared to conventional materials in similar applications.

Resource efficiency represents another sustainability advantage of amorphous metals in energy storage. These materials often allow for thinner structural components due to their superior mechanical properties, reducing overall material requirements. Furthermore, some amorphous metal formulations utilize more abundant elements, potentially decreasing reliance on critical raw materials that face supply constraints or ethical sourcing challenges.

In grid-scale applications, liquid metal batteries incorporating amorphous metals contribute to broader sustainability goals by facilitating renewable energy integration. Their thermal stability and high cycling efficiency make them ideal candidates for load-leveling and peak-shaving applications, enabling greater penetration of intermittent renewable sources like solar and wind power.

Economic sustainability aspects must also be considered. While initial manufacturing costs for amorphous metals typically exceed those of conventional materials, their extended service life and reduced maintenance requirements often result in favorable total cost of ownership calculations. This economic advantage strengthens the business case for widespread adoption of these advanced materials in next-generation energy storage systems.

Safety and Scalability Considerations for Commercial Deployment

The commercial deployment of liquid metal batteries incorporating amorphous metals presents significant safety and scalability considerations that must be addressed before widespread adoption. Safety concerns primarily revolve around the high operating temperatures (typically 400-700°C) required for these batteries, which introduce thermal management challenges and potential fire hazards. The reactive nature of liquid metals, particularly when exposed to moisture or air, necessitates robust containment systems to prevent leakage and subsequent chemical reactions that could lead to safety incidents.

Amorphous metals offer potential safety advantages through their superior mechanical properties and corrosion resistance. Their unique atomic structure provides enhanced resistance to cracking and fatigue, reducing the risk of containment failures during thermal cycling. Additionally, certain amorphous metal compositions demonstrate exceptional chemical stability against molten electrode materials, minimizing degradation over extended operational periods.

Scalability considerations for commercial deployment focus on manufacturing processes, material availability, and system integration. The production of amorphous metals typically requires rapid cooling techniques such as melt spinning or splat quenching, which present challenges for large-scale manufacturing. Current production methods limit the thickness and dimensions of amorphous metal components, potentially constraining battery design and capacity scaling.

Material cost and availability represent another critical factor in commercial viability. While amorphous metals can be formulated using various elemental compositions, certain formulations rely on relatively scarce or expensive elements. Developing compositions that balance performance requirements with material accessibility will be essential for cost-effective scaling.

System integration considerations include the development of standardized designs that can be efficiently manufactured, transported, and installed. The weight and volume of thermal management systems required for maintaining operating temperatures must be optimized to improve energy density at the system level. Furthermore, safety certification and regulatory compliance pathways need to be established for these novel energy storage systems.

Grid integration presents additional challenges, including the development of appropriate power electronics and control systems capable of managing the unique operational characteristics of liquid metal batteries. The thermal inertia of these systems affects response times and cycling capabilities, requiring specialized grid interface solutions to maximize value in various application scenarios.

Long-term reliability testing under real-world conditions remains limited, creating uncertainty regarding lifetime performance and degradation mechanisms. Accelerated testing protocols must be developed to validate expected operational lifetimes of 10-20 years, particularly focusing on the stability of amorphous metal components under repeated thermal and electrochemical cycling.

Amorphous metals offer potential safety advantages through their superior mechanical properties and corrosion resistance. Their unique atomic structure provides enhanced resistance to cracking and fatigue, reducing the risk of containment failures during thermal cycling. Additionally, certain amorphous metal compositions demonstrate exceptional chemical stability against molten electrode materials, minimizing degradation over extended operational periods.

Scalability considerations for commercial deployment focus on manufacturing processes, material availability, and system integration. The production of amorphous metals typically requires rapid cooling techniques such as melt spinning or splat quenching, which present challenges for large-scale manufacturing. Current production methods limit the thickness and dimensions of amorphous metal components, potentially constraining battery design and capacity scaling.

Material cost and availability represent another critical factor in commercial viability. While amorphous metals can be formulated using various elemental compositions, certain formulations rely on relatively scarce or expensive elements. Developing compositions that balance performance requirements with material accessibility will be essential for cost-effective scaling.

System integration considerations include the development of standardized designs that can be efficiently manufactured, transported, and installed. The weight and volume of thermal management systems required for maintaining operating temperatures must be optimized to improve energy density at the system level. Furthermore, safety certification and regulatory compliance pathways need to be established for these novel energy storage systems.

Grid integration presents additional challenges, including the development of appropriate power electronics and control systems capable of managing the unique operational characteristics of liquid metal batteries. The thermal inertia of these systems affects response times and cycling capabilities, requiring specialized grid interface solutions to maximize value in various application scenarios.

Long-term reliability testing under real-world conditions remains limited, creating uncertainty regarding lifetime performance and degradation mechanisms. Accelerated testing protocols must be developed to validate expected operational lifetimes of 10-20 years, particularly focusing on the stability of amorphous metal components under repeated thermal and electrochemical cycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!