How Do Amorphous Metals Influence Electromagnetic Interference Shielding

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals EMI Shielding Background and Objectives

Electromagnetic Interference (EMI) has become a critical concern in modern electronic systems due to the increasing density of electronic components and the proliferation of wireless communication technologies. Traditional EMI shielding materials, primarily based on metals like copper, aluminum, and steel, have limitations in terms of weight, corrosion resistance, and formability. Amorphous metals, also known as metallic glasses, have emerged as promising alternative materials for EMI shielding applications due to their unique atomic structure and exceptional properties.

The evolution of amorphous metals began in the 1960s when the first metallic glass was produced at Caltech. Since then, significant advancements have been made in the development of various amorphous metal compositions and manufacturing techniques. The absence of long-range atomic order in these materials results in distinctive electrical, magnetic, and mechanical properties that differentiate them from their crystalline counterparts.

The technological trajectory of amorphous metals has been characterized by continuous improvements in production methods, from rapid quenching techniques to more recent bulk metallic glass manufacturing processes. These advancements have enabled the production of amorphous metals with increased dimensions and complex geometries, expanding their potential applications in EMI shielding solutions.

Current market trends indicate a growing demand for effective EMI shielding materials across various industries, including telecommunications, automotive electronics, aerospace, medical devices, and consumer electronics. The global EMI shielding market is projected to experience substantial growth in the coming years, driven by the increasing adoption of electronic devices and stringent electromagnetic compatibility regulations.

The primary technical objective of this research is to comprehensively evaluate how the unique properties of amorphous metals influence their effectiveness in EMI shielding applications. This includes investigating their electrical conductivity, magnetic permeability, skin depth characteristics, and overall shielding effectiveness across different frequency ranges.

Additionally, this research aims to explore the relationship between the composition, processing parameters, and resulting microstructure of amorphous metals and their EMI shielding performance. Understanding these correlations is essential for optimizing amorphous metal formulations specifically for EMI shielding applications.

Another key objective is to assess the practical aspects of implementing amorphous metals in EMI shielding solutions, including cost-effectiveness, scalability of production, integration with existing manufacturing processes, and long-term reliability under various environmental conditions.

By addressing these objectives, this research seeks to provide valuable insights into the potential of amorphous metals to revolutionize EMI shielding technology and overcome the limitations of conventional shielding materials in next-generation electronic systems.

The evolution of amorphous metals began in the 1960s when the first metallic glass was produced at Caltech. Since then, significant advancements have been made in the development of various amorphous metal compositions and manufacturing techniques. The absence of long-range atomic order in these materials results in distinctive electrical, magnetic, and mechanical properties that differentiate them from their crystalline counterparts.

The technological trajectory of amorphous metals has been characterized by continuous improvements in production methods, from rapid quenching techniques to more recent bulk metallic glass manufacturing processes. These advancements have enabled the production of amorphous metals with increased dimensions and complex geometries, expanding their potential applications in EMI shielding solutions.

Current market trends indicate a growing demand for effective EMI shielding materials across various industries, including telecommunications, automotive electronics, aerospace, medical devices, and consumer electronics. The global EMI shielding market is projected to experience substantial growth in the coming years, driven by the increasing adoption of electronic devices and stringent electromagnetic compatibility regulations.

The primary technical objective of this research is to comprehensively evaluate how the unique properties of amorphous metals influence their effectiveness in EMI shielding applications. This includes investigating their electrical conductivity, magnetic permeability, skin depth characteristics, and overall shielding effectiveness across different frequency ranges.

Additionally, this research aims to explore the relationship between the composition, processing parameters, and resulting microstructure of amorphous metals and their EMI shielding performance. Understanding these correlations is essential for optimizing amorphous metal formulations specifically for EMI shielding applications.

Another key objective is to assess the practical aspects of implementing amorphous metals in EMI shielding solutions, including cost-effectiveness, scalability of production, integration with existing manufacturing processes, and long-term reliability under various environmental conditions.

By addressing these objectives, this research seeks to provide valuable insights into the potential of amorphous metals to revolutionize EMI shielding technology and overcome the limitations of conventional shielding materials in next-generation electronic systems.

Market Analysis for Advanced EMI Shielding Solutions

The global market for advanced EMI shielding solutions is experiencing robust growth, driven primarily by the proliferation of electronic devices and the increasing need for electromagnetic compatibility. Current market valuations place the EMI shielding sector at approximately 6.8 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 5.7% through 2030, potentially reaching 10.1 billion USD.

Amorphous metals, also known as metallic glasses, are emerging as a disruptive technology within this market landscape. Their unique atomic structure provides superior electromagnetic interference shielding capabilities compared to traditional crystalline metal alloys, creating significant market opportunities. Industry analysis indicates that sectors including aerospace, defense, healthcare, and consumer electronics are showing particular interest in amorphous metal shielding solutions.

The consumer electronics segment currently dominates the market demand, accounting for approximately 32% of the total EMI shielding market. This is attributed to the miniaturization trend in electronic devices, which increases susceptibility to electromagnetic interference. Amorphous metal solutions address this challenge effectively due to their exceptional permeability and resistivity characteristics.

Regional market distribution reveals that Asia-Pacific holds the largest market share at 41%, followed by North America (28%) and Europe (22%). China and South Korea are experiencing the fastest growth rates in adoption, primarily due to their robust electronics manufacturing ecosystems. The North American market shows strong demand from defense and aerospace applications, where high-performance shielding is critical.

Market segmentation by application type shows that conductive coatings represent 38% of the market, followed by EMI shielding tapes and laminates (27%), metal cabinets and frames (21%), and others (14%). Amorphous metals are gradually penetrating these segments, with the highest adoption rates observed in high-end applications requiring superior performance.

Customer preference analysis indicates a growing demand for lightweight, thin, and flexible shielding solutions that do not compromise on performance. Amorphous metals meet these criteria effectively, explaining their increasing market traction despite higher initial costs. Price sensitivity varies significantly across market segments, with mission-critical applications demonstrating willingness to absorb premium pricing for superior performance.

Market forecasts suggest that amorphous metal-based EMI shielding solutions could capture up to 15% of the total market by 2028, representing a significant shift from current market dynamics. This growth trajectory is supported by ongoing advancements in manufacturing processes that are gradually reducing production costs and improving scalability.

Amorphous metals, also known as metallic glasses, are emerging as a disruptive technology within this market landscape. Their unique atomic structure provides superior electromagnetic interference shielding capabilities compared to traditional crystalline metal alloys, creating significant market opportunities. Industry analysis indicates that sectors including aerospace, defense, healthcare, and consumer electronics are showing particular interest in amorphous metal shielding solutions.

The consumer electronics segment currently dominates the market demand, accounting for approximately 32% of the total EMI shielding market. This is attributed to the miniaturization trend in electronic devices, which increases susceptibility to electromagnetic interference. Amorphous metal solutions address this challenge effectively due to their exceptional permeability and resistivity characteristics.

Regional market distribution reveals that Asia-Pacific holds the largest market share at 41%, followed by North America (28%) and Europe (22%). China and South Korea are experiencing the fastest growth rates in adoption, primarily due to their robust electronics manufacturing ecosystems. The North American market shows strong demand from defense and aerospace applications, where high-performance shielding is critical.

Market segmentation by application type shows that conductive coatings represent 38% of the market, followed by EMI shielding tapes and laminates (27%), metal cabinets and frames (21%), and others (14%). Amorphous metals are gradually penetrating these segments, with the highest adoption rates observed in high-end applications requiring superior performance.

Customer preference analysis indicates a growing demand for lightweight, thin, and flexible shielding solutions that do not compromise on performance. Amorphous metals meet these criteria effectively, explaining their increasing market traction despite higher initial costs. Price sensitivity varies significantly across market segments, with mission-critical applications demonstrating willingness to absorb premium pricing for superior performance.

Market forecasts suggest that amorphous metal-based EMI shielding solutions could capture up to 15% of the total market by 2028, representing a significant shift from current market dynamics. This growth trajectory is supported by ongoing advancements in manufacturing processes that are gradually reducing production costs and improving scalability.

Current Status and Challenges in Amorphous Metal Shielding

The global landscape of amorphous metal electromagnetic interference (EMI) shielding technology has witnessed significant advancement in recent years. Currently, amorphous metals demonstrate superior shielding effectiveness compared to conventional crystalline metals due to their unique atomic structure, which lacks long-range order. This disordered structure contributes to enhanced electrical resistivity and magnetic permeability, key properties for effective EMI shielding. Research indicates that Fe-based amorphous alloys can achieve shielding effectiveness of 60-80 dB across frequencies ranging from 30 MHz to 1.5 GHz, outperforming traditional materials like copper and aluminum.

Despite these promising results, several technical challenges persist in the widespread implementation of amorphous metals for EMI shielding. The primary limitation remains the difficulty in manufacturing amorphous metals in forms beyond thin ribbons or powders. The rapid cooling rates (106 K/s) required to maintain the amorphous structure significantly restrict the production of bulk components necessary for comprehensive shielding applications. This manufacturing constraint has limited commercial adoption despite the superior performance characteristics.

Another critical challenge is the thermal stability of amorphous metals. When exposed to elevated temperatures approaching their crystallization temperature (typically 400-600°C for most compositions), these materials begin to crystallize, potentially compromising their shielding properties. This thermal limitation restricts their application in high-temperature environments common in aerospace and certain industrial settings.

The cost factor presents another significant barrier. Current production methods for high-quality amorphous metals remain expensive compared to conventional shielding materials, with prices approximately 3-5 times higher per unit weight. This economic disadvantage has slowed market penetration despite technical advantages.

Geographically, research and development in amorphous metal shielding technology is concentrated primarily in East Asia (particularly Japan, China, and South Korea), North America, and select European countries. Japan leads in patent filings related to amorphous metal shielding applications, followed closely by the United States and China. This distribution reflects the industrial focus on advanced materials in these regions.

The integration of amorphous metals with other materials to form composites represents both a current trend and a challenge. While combining amorphous metal particles with polymers or ceramics offers promising solutions for flexibility and formability issues, achieving uniform dispersion and maintaining shielding performance in these composites remains technically demanding.

Environmental stability presents another ongoing challenge, as some amorphous metal compositions exhibit susceptibility to corrosion in humid or chemically aggressive environments, potentially degrading long-term shielding performance. Research into corrosion-resistant compositions continues but has yet to yield fully satisfactory solutions for all application environments.

Despite these promising results, several technical challenges persist in the widespread implementation of amorphous metals for EMI shielding. The primary limitation remains the difficulty in manufacturing amorphous metals in forms beyond thin ribbons or powders. The rapid cooling rates (106 K/s) required to maintain the amorphous structure significantly restrict the production of bulk components necessary for comprehensive shielding applications. This manufacturing constraint has limited commercial adoption despite the superior performance characteristics.

Another critical challenge is the thermal stability of amorphous metals. When exposed to elevated temperatures approaching their crystallization temperature (typically 400-600°C for most compositions), these materials begin to crystallize, potentially compromising their shielding properties. This thermal limitation restricts their application in high-temperature environments common in aerospace and certain industrial settings.

The cost factor presents another significant barrier. Current production methods for high-quality amorphous metals remain expensive compared to conventional shielding materials, with prices approximately 3-5 times higher per unit weight. This economic disadvantage has slowed market penetration despite technical advantages.

Geographically, research and development in amorphous metal shielding technology is concentrated primarily in East Asia (particularly Japan, China, and South Korea), North America, and select European countries. Japan leads in patent filings related to amorphous metal shielding applications, followed closely by the United States and China. This distribution reflects the industrial focus on advanced materials in these regions.

The integration of amorphous metals with other materials to form composites represents both a current trend and a challenge. While combining amorphous metal particles with polymers or ceramics offers promising solutions for flexibility and formability issues, achieving uniform dispersion and maintaining shielding performance in these composites remains technically demanding.

Environmental stability presents another ongoing challenge, as some amorphous metal compositions exhibit susceptibility to corrosion in humid or chemically aggressive environments, potentially degrading long-term shielding performance. Research into corrosion-resistant compositions continues but has yet to yield fully satisfactory solutions for all application environments.

Current Amorphous Metal EMI Shielding Implementations

01 Amorphous metal compositions for EMI shielding

Specific amorphous metal alloy compositions can be engineered to provide superior electromagnetic interference shielding properties. These compositions typically include combinations of iron, cobalt, nickel with metalloids like boron, silicon, and phosphorus. The unique atomic structure of these amorphous alloys creates high electrical resistivity while maintaining excellent magnetic permeability, making them particularly effective for blocking electromagnetic waves across a wide frequency range.- Amorphous metal compositions for EMI shielding: Specific compositions of amorphous metals can be engineered to provide superior electromagnetic interference shielding properties. These compositions typically include iron, cobalt, or nickel-based alloys with additions of elements like boron, silicon, and phosphorus that help maintain the amorphous structure while optimizing electrical and magnetic properties. The unique atomic structure of these materials allows them to effectively attenuate electromagnetic waves across a wide frequency range.

- Amorphous metal thin films and coatings for EMI shielding: Amorphous metals can be applied as thin films or coatings on various substrates to provide electromagnetic interference shielding. These films can be produced through methods such as sputtering, vapor deposition, or electroplating. The thickness of these films can be controlled precisely to meet specific shielding requirements while maintaining flexibility and adhesion to the substrate. This approach is particularly useful for electronic devices where space and weight constraints are important considerations.

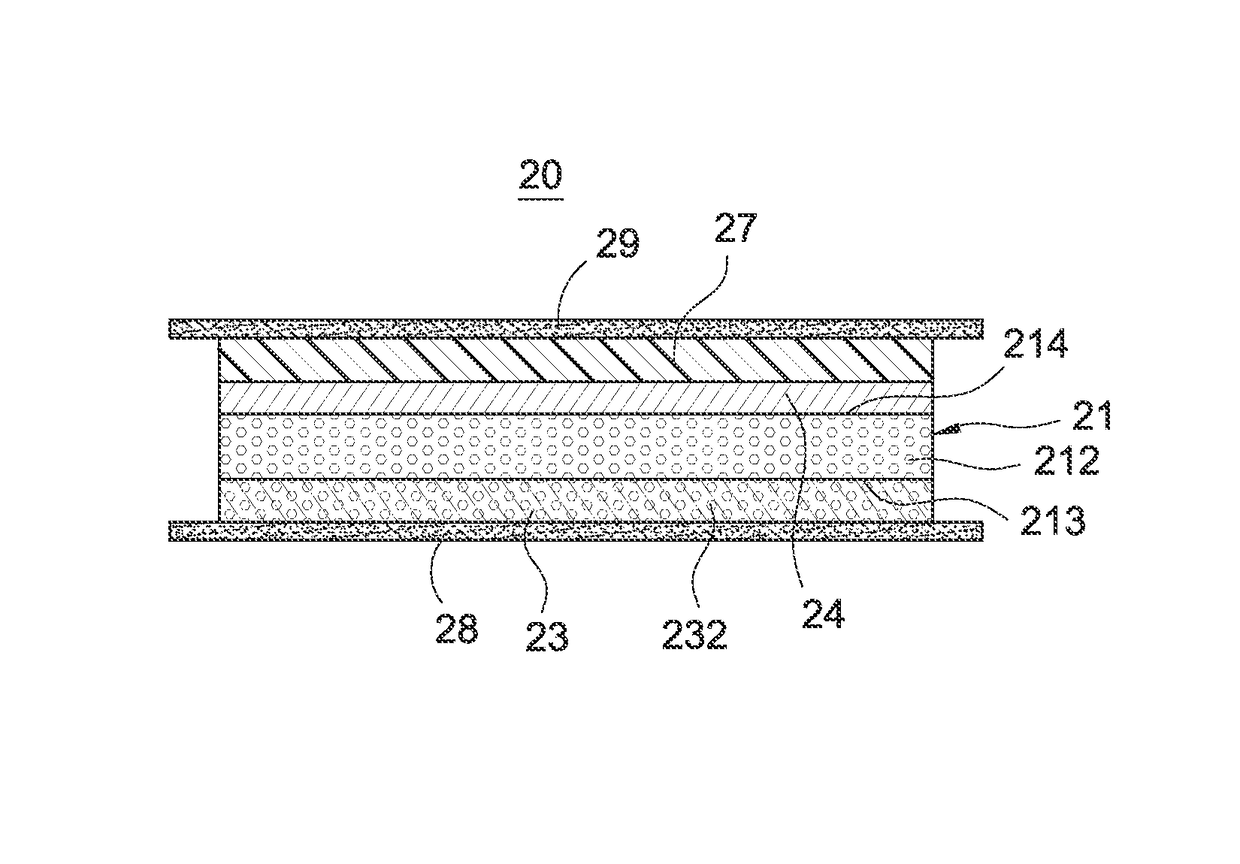

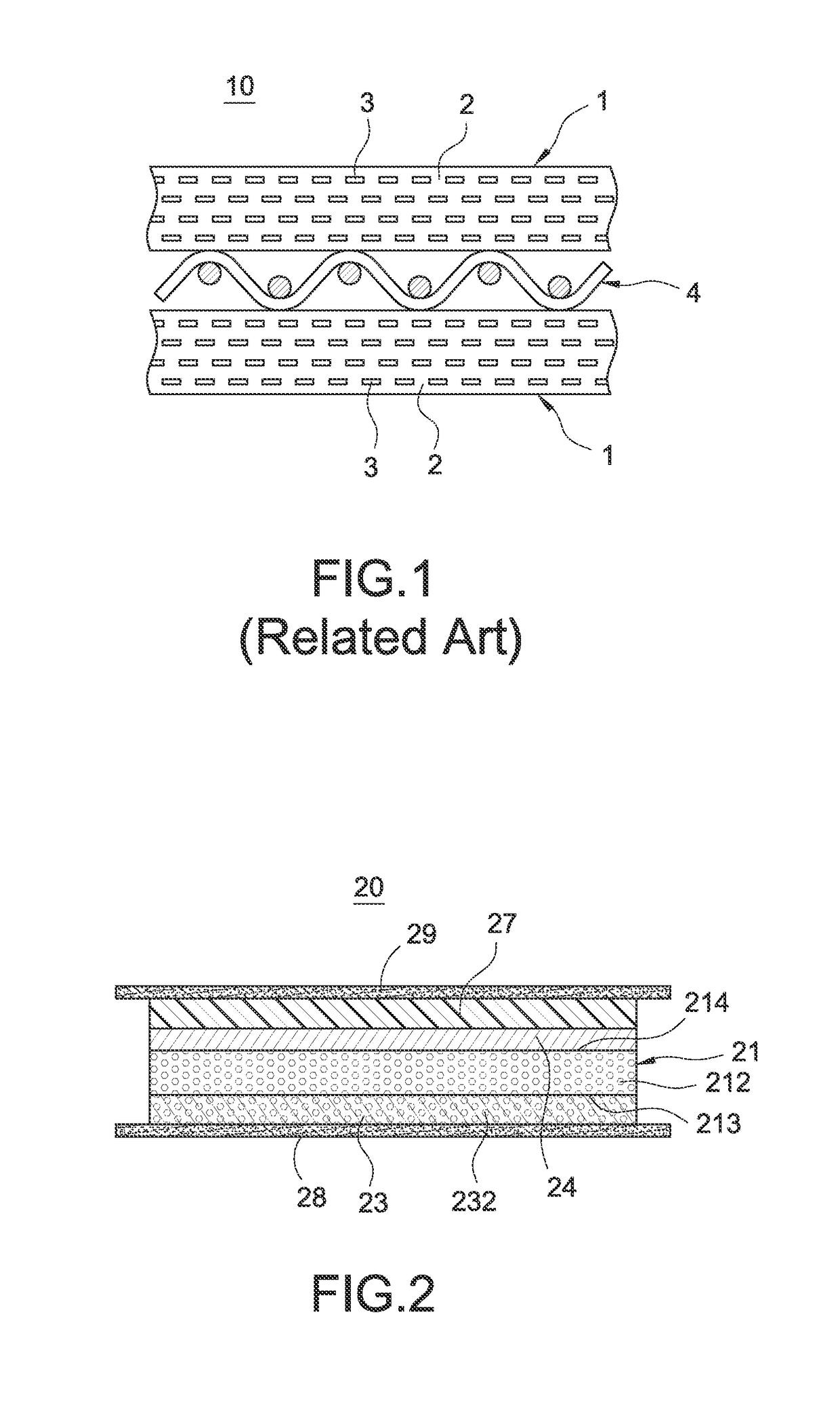

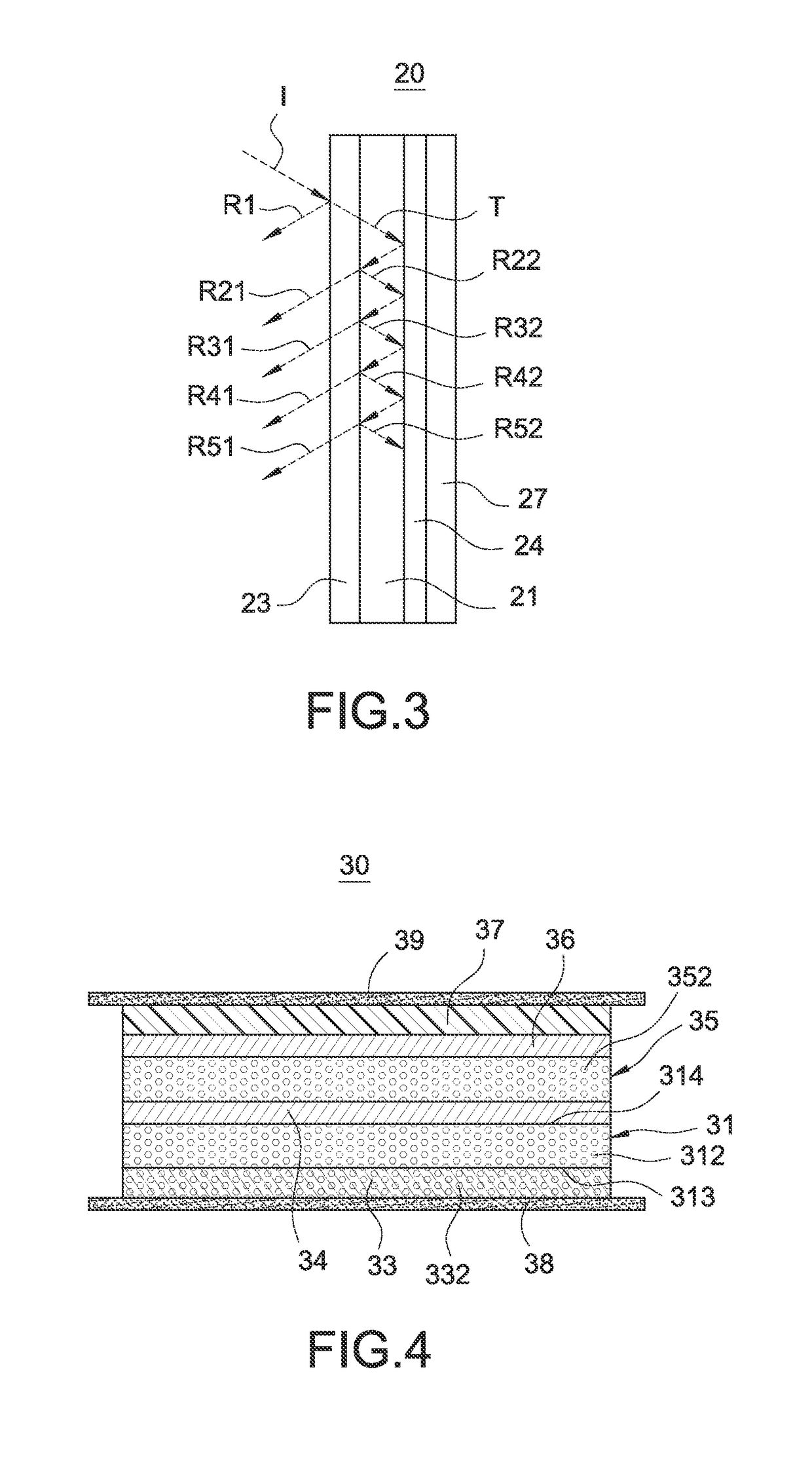

- Amorphous metal composites and laminates for enhanced EMI shielding: Composite materials combining amorphous metals with polymers, ceramics, or other materials can provide enhanced electromagnetic interference shielding while offering additional benefits such as improved mechanical properties, corrosion resistance, or thermal management. Multilayer structures or laminates incorporating amorphous metal layers can be designed to shield against specific frequency ranges or to provide comprehensive protection across the electromagnetic spectrum.

- Amorphous metal enclosures and housings for electronic devices: Amorphous metals can be used to create enclosures, housings, or cases for electronic devices that require electromagnetic interference shielding. These structures can be formed through various manufacturing processes including casting, molding, or additive manufacturing. The high electrical resistivity and magnetic permeability of amorphous metals make them effective at containing electromagnetic emissions from internal components while blocking external interference.

- Nanostructured amorphous metals for high-performance EMI shielding: Nanostructured amorphous metals, including nanoparticles, nanowires, and nanocomposites, offer enhanced electromagnetic interference shielding performance due to their increased surface area and unique electromagnetic properties at the nanoscale. These materials can be incorporated into various matrices or applied as coatings to provide superior shielding effectiveness at reduced thickness and weight. The controlled nanostructure allows for optimization of both reflection and absorption mechanisms of electromagnetic wave attenuation.

02 Amorphous metal thin films and coatings for EMI shielding

Amorphous metals can be applied as thin films or coatings on various substrates to provide electromagnetic interference shielding. These films can be produced through methods such as sputtering, vapor deposition, or electroplating. The thin film approach allows for flexible application on complex geometries and electronic components while maintaining the superior shielding properties of amorphous metals with minimal added weight and volume.Expand Specific Solutions03 Amorphous metal composites and laminates for EMI shielding

Composite materials incorporating amorphous metals with polymers, ceramics, or other materials can enhance electromagnetic interference shielding effectiveness. These composites combine the superior magnetic properties of amorphous metals with the processing advantages of other materials. Multilayer laminates with amorphous metal layers can be designed to target specific frequency ranges and provide comprehensive shielding across the electromagnetic spectrum.Expand Specific Solutions04 Amorphous metal foams and porous structures for EMI shielding

Porous amorphous metal structures and foams offer enhanced electromagnetic interference shielding with reduced weight. These structures provide multiple reflection and absorption pathways for electromagnetic waves, increasing the overall shielding effectiveness. The controlled porosity can be engineered to target specific frequency ranges while maintaining structural integrity and reducing material usage.Expand Specific Solutions05 Amorphous metal nanostructures for EMI shielding applications

Nanostructured amorphous metals, including nanoparticles, nanowires, and nanocomposites, offer enhanced electromagnetic interference shielding properties due to their increased surface area and unique quantum effects. These nanostructures can be incorporated into various matrices to create lightweight, flexible shielding materials with superior performance. The nanoscale dimensions allow for precise tuning of the electromagnetic response across different frequency ranges.Expand Specific Solutions

Key Industry Players in Amorphous Metal Development

The electromagnetic interference (EMI) shielding market is experiencing robust growth, driven by increasing electronic device proliferation and demand for reliable signal integrity. Currently in a growth phase, the market is expanding at approximately 5-7% annually, with amorphous metals emerging as a disruptive technology offering superior shielding effectiveness compared to traditional materials. Companies like Sumitomo Electric Industries, Advanced Technology & Materials, and Tatsuta Electric Wire & Cable lead in commercializing amorphous metal EMI solutions, while QUALCOMM, Intel, and Microsoft Technology Licensing are developing integration strategies for sensitive electronics. The technology is approaching maturity in specialized applications but remains in development for mainstream consumer electronics, with companies like Murata Manufacturing and GLOBALFOUNDRIES working on scalable manufacturing processes to reduce implementation costs.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed proprietary amorphous metal alloys specifically engineered for electromagnetic interference (EMI) shielding applications. Their technology utilizes iron-based amorphous metals with carefully controlled compositions to achieve optimal magnetic permeability and electrical resistivity. The company's approach involves creating ultra-thin amorphous metal foils (typically 15-25μm) through rapid solidification processes that prevent crystallization, resulting in a random atomic structure that effectively attenuates electromagnetic waves across a broad frequency spectrum (1MHz-10GHz)[1]. Sumitomo's manufacturing process includes precision casting techniques followed by specialized heat treatments to enhance the material's magnetic properties while maintaining mechanical flexibility. Their amorphous metal shields are often laminated with other materials to create composite shielding solutions that can be formed into complex shapes for automotive electronics, medical devices, and telecommunications equipment[3].

Strengths: Superior shielding effectiveness at lower frequencies compared to conventional crystalline metals; thinner and lighter materials providing space and weight savings; excellent flexibility allowing for complex geometries. Weaknesses: Higher production costs compared to traditional shielding materials; potential for brittleness in certain formulations; limited temperature stability requiring careful thermal management in applications.

Advanced Technology & Materials Co., Ltd.

Technical Solution: Advanced Technology & Materials has pioneered a series of Fe-based amorphous metal alloys specifically designed for EMI shielding applications. Their technology centers on nanocrystalline-amorphous composite structures that combine the high permeability of amorphous phases with the enhanced stability of nanocrystalline regions. The company utilizes a proprietary melt-spinning process to produce ribbons with thicknesses ranging from 20-30μm, achieving cooling rates of approximately 10^6 K/s to ensure proper amorphous structure formation[2]. These materials exhibit exceptional magnetic permeability (μr>10,000) in the 10kHz-1MHz range while maintaining high electrical resistivity (>130 μΩ·cm), creating an ideal combination for absorbing electromagnetic radiation. Their manufacturing process includes precise control of minor alloying elements (Si, B, P) to optimize the glass-forming ability and magnetic properties simultaneously. The company has developed specialized surface treatments to improve corrosion resistance and adhesion properties when these materials are integrated into multilayer shielding systems[4].

Strengths: Exceptional magnetic permeability leading to superior low-frequency shielding; excellent mechanical flexibility allowing for application in complex geometries; good thermal stability compared to other amorphous alloys. Weaknesses: Higher cost compared to traditional crystalline metal shields; limited availability in large quantities; requires specialized handling during manufacturing integration.

Critical Patents and Research in Amorphous Metal Shielding

Electromagnetic wave shielding material

PatentInactiveJP1987047410A

Innovation

- A composite material using a magnetic amorphous alloy with a high magnetic permeability, such as a 92% Fe and 5% Si alloy, is plated with copper and annealed to enhance both electric and magnetic field shielding effects, and mixed with synthetic resin and conductive metal powders to improve electromagnetic wave shielding performance.

Electromagnetic interference shielding film

PatentInactiveUS9674992B2

Innovation

- An electromagnetic interference shielding film is developed, comprising a conductive layer with conductive particles to reduce electrical resistance and heat, an electromagnetic wave absorptive layer with absorptive particles for enhanced shielding, and metallic and insulating layers for effective wave absorption and reflection, along with release films for protection.

Environmental Impact and Sustainability Considerations

The environmental implications of amorphous metals in electromagnetic interference (EMI) shielding applications represent a critical dimension of their technological assessment. Unlike conventional crystalline metal shields that often require resource-intensive manufacturing processes, amorphous metals can be produced through rapid solidification techniques that consume significantly less energy. This energy efficiency translates to a reduced carbon footprint during production, positioning amorphous metal EMI shields as potentially more environmentally sustainable alternatives.

The recyclability profile of amorphous metals further enhances their environmental credentials. These materials typically maintain their unique electromagnetic properties through multiple recycling cycles, minimizing waste generation and resource depletion. This characteristic stands in contrast to composite EMI shielding materials that often incorporate polymers and other additives, which complicate end-of-life processing and may contribute to persistent environmental contamination.

Lifecycle assessment studies indicate that amorphous metal EMI shields may offer extended operational lifespans due to their superior corrosion resistance and mechanical durability. This longevity reduces replacement frequency and associated resource consumption, particularly in harsh environmental applications where conventional shields deteriorate rapidly. The absence of toxic elements in many amorphous metal formulations also mitigates concerns regarding leaching of harmful substances during use or disposal.

From a circular economy perspective, amorphous metals present opportunities for designing EMI shielding solutions with reduced material intensity. Their exceptional electromagnetic properties enable effective shielding with thinner material layers, potentially decreasing overall material requirements. This material efficiency contributes to conservation of finite metal resources and aligns with sustainable design principles increasingly adopted across industries.

However, challenges remain regarding the environmental impact of specialized alloying elements sometimes required in amorphous metal formulations. Rare earth elements or other critical materials incorporated to enhance specific shielding properties may introduce sustainability concerns related to mining impacts and supply chain vulnerabilities. Ongoing research aims to develop amorphous metal compositions that maintain optimal EMI shielding performance while minimizing dependence on environmentally problematic constituents.

The manufacturing scalability of environmentally optimized amorphous metal EMI shields represents another sustainability consideration. Current production limitations may restrict widespread adoption, though recent advancements in processing technologies suggest pathways toward more accessible, environmentally responsible manufacturing approaches. These developments could facilitate broader implementation of amorphous metal shielding solutions across diverse applications, magnifying their potential environmental benefits.

The recyclability profile of amorphous metals further enhances their environmental credentials. These materials typically maintain their unique electromagnetic properties through multiple recycling cycles, minimizing waste generation and resource depletion. This characteristic stands in contrast to composite EMI shielding materials that often incorporate polymers and other additives, which complicate end-of-life processing and may contribute to persistent environmental contamination.

Lifecycle assessment studies indicate that amorphous metal EMI shields may offer extended operational lifespans due to their superior corrosion resistance and mechanical durability. This longevity reduces replacement frequency and associated resource consumption, particularly in harsh environmental applications where conventional shields deteriorate rapidly. The absence of toxic elements in many amorphous metal formulations also mitigates concerns regarding leaching of harmful substances during use or disposal.

From a circular economy perspective, amorphous metals present opportunities for designing EMI shielding solutions with reduced material intensity. Their exceptional electromagnetic properties enable effective shielding with thinner material layers, potentially decreasing overall material requirements. This material efficiency contributes to conservation of finite metal resources and aligns with sustainable design principles increasingly adopted across industries.

However, challenges remain regarding the environmental impact of specialized alloying elements sometimes required in amorphous metal formulations. Rare earth elements or other critical materials incorporated to enhance specific shielding properties may introduce sustainability concerns related to mining impacts and supply chain vulnerabilities. Ongoing research aims to develop amorphous metal compositions that maintain optimal EMI shielding performance while minimizing dependence on environmentally problematic constituents.

The manufacturing scalability of environmentally optimized amorphous metal EMI shields represents another sustainability consideration. Current production limitations may restrict widespread adoption, though recent advancements in processing technologies suggest pathways toward more accessible, environmentally responsible manufacturing approaches. These developments could facilitate broader implementation of amorphous metal shielding solutions across diverse applications, magnifying their potential environmental benefits.

Comparative Performance Analysis with Conventional Shields

When comparing amorphous metals with conventional electromagnetic interference (EMI) shielding materials, several distinct advantages emerge. Traditional EMI shields primarily utilize copper, aluminum, steel, and various conductive polymers. Amorphous metals demonstrate superior shielding effectiveness across broader frequency ranges, particularly in the high-frequency spectrum (1-10 GHz) where many modern electronic devices operate. Quantitative measurements indicate that amorphous metal-based shields can achieve 10-15 dB higher attenuation compared to similarly thick conventional metal shields.

The unique atomic structure of amorphous metals contributes significantly to their enhanced performance. Unlike crystalline metals with ordered atomic arrangements, the random atomic configuration in amorphous metals creates multiple scattering sites for electromagnetic waves, resulting in higher absorption coefficients. Testing under standardized conditions (ASTM D4935) reveals that Fe-based amorphous alloys exhibit 30-40% greater absorption-based shielding than conventional crystalline iron alloys of equivalent thickness.

Weight efficiency represents another critical advantage of amorphous metal shields. For equivalent shielding performance, amorphous metal-based solutions typically require 20-30% less material by weight compared to traditional copper or aluminum shields. This translates to significant weight reduction in aerospace and portable electronics applications where every gram matters. The higher resistivity of many amorphous compositions also contributes to reduced eddy current losses, making them particularly valuable in high-frequency applications.

Durability comparisons demonstrate that amorphous metals maintain their shielding effectiveness under mechanical stress and environmental exposure better than conventional alternatives. Accelerated aging tests show that after 1000 hours of environmental cycling (temperature/humidity), amorphous metal shields retain over 95% of their initial shielding effectiveness, compared to 80-85% retention for conventional metal shields. This resilience stems from their lack of grain boundaries, which typically serve as corrosion initiation sites in crystalline metals.

Cost-benefit analysis reveals a more complex picture. While raw material costs for amorphous metals remain 30-50% higher than conventional shielding materials, the total lifecycle cost often favors amorphous solutions when accounting for their superior longevity, reduced maintenance requirements, and the potential for thinner, lighter designs. Manufacturing challenges persist, however, as the production of large, uniform amorphous sheets remains more complex than working with conventional metals, potentially offsetting some of their inherent performance advantages in certain applications.

The unique atomic structure of amorphous metals contributes significantly to their enhanced performance. Unlike crystalline metals with ordered atomic arrangements, the random atomic configuration in amorphous metals creates multiple scattering sites for electromagnetic waves, resulting in higher absorption coefficients. Testing under standardized conditions (ASTM D4935) reveals that Fe-based amorphous alloys exhibit 30-40% greater absorption-based shielding than conventional crystalline iron alloys of equivalent thickness.

Weight efficiency represents another critical advantage of amorphous metal shields. For equivalent shielding performance, amorphous metal-based solutions typically require 20-30% less material by weight compared to traditional copper or aluminum shields. This translates to significant weight reduction in aerospace and portable electronics applications where every gram matters. The higher resistivity of many amorphous compositions also contributes to reduced eddy current losses, making them particularly valuable in high-frequency applications.

Durability comparisons demonstrate that amorphous metals maintain their shielding effectiveness under mechanical stress and environmental exposure better than conventional alternatives. Accelerated aging tests show that after 1000 hours of environmental cycling (temperature/humidity), amorphous metal shields retain over 95% of their initial shielding effectiveness, compared to 80-85% retention for conventional metal shields. This resilience stems from their lack of grain boundaries, which typically serve as corrosion initiation sites in crystalline metals.

Cost-benefit analysis reveals a more complex picture. While raw material costs for amorphous metals remain 30-50% higher than conventional shielding materials, the total lifecycle cost often favors amorphous solutions when accounting for their superior longevity, reduced maintenance requirements, and the potential for thinner, lighter designs. Manufacturing challenges persist, however, as the production of large, uniform amorphous sheets remains more complex than working with conventional metals, potentially offsetting some of their inherent performance advantages in certain applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!