Exploring the Role of Amorphous Metals in Advanced Robotics

OCT 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals in Robotics: Background and Objectives

Amorphous metals, also known as metallic glasses, represent a revolutionary class of materials that have emerged as potential game-changers in the field of robotics. Unlike conventional crystalline metals with ordered atomic structures, amorphous metals possess a non-crystalline, disordered atomic arrangement that confers unique mechanical, electrical, and magnetic properties. The development of these materials dates back to the 1960s when the first metallic glass was produced at Caltech, but their application in advanced robotics has gained significant momentum only in the past decade.

The evolution of amorphous metals has followed a trajectory from laboratory curiosities to commercially viable materials. Early limitations in size and production capabilities restricted their practical applications. However, recent advancements in manufacturing techniques, particularly bulk metallic glass (BMG) production methods, have overcome these constraints, enabling the creation of amorphous metal components with dimensions suitable for robotic applications.

Current technological trends indicate a growing integration of amorphous metals in robotics, driven by demands for higher performance, durability, and efficiency. These materials offer exceptional strength-to-weight ratios, superior elastic limits, and remarkable wear resistance—characteristics that address critical challenges in modern robotics design. Additionally, their unique combination of metallic bonding and glassy structure provides excellent corrosion resistance and magnetic properties that conventional materials cannot match.

The primary objective of exploring amorphous metals in advanced robotics is to leverage these exceptional properties to overcome existing limitations in robotic systems. Specifically, the goals include developing more resilient and lightweight robotic components, enhancing energy efficiency through reduced mechanical losses, and enabling new functionalities through the materials' unique electromagnetic properties. There is also significant interest in utilizing the biocompatibility of certain amorphous metal compositions for medical robotics applications.

Looking forward, the trajectory of amorphous metals in robotics appears poised for acceleration as manufacturing techniques continue to mature and material costs decrease. Research efforts are increasingly focused on tailoring amorphous metal compositions for specific robotic applications, from micro-electromechanical systems (MEMS) to large-scale industrial robots. The potential for these materials to enable next-generation soft robotics, biomimetic designs, and adaptive structures represents a frontier in robotics engineering that promises to reshape the capabilities and applications of robotic systems across industries.

The evolution of amorphous metals has followed a trajectory from laboratory curiosities to commercially viable materials. Early limitations in size and production capabilities restricted their practical applications. However, recent advancements in manufacturing techniques, particularly bulk metallic glass (BMG) production methods, have overcome these constraints, enabling the creation of amorphous metal components with dimensions suitable for robotic applications.

Current technological trends indicate a growing integration of amorphous metals in robotics, driven by demands for higher performance, durability, and efficiency. These materials offer exceptional strength-to-weight ratios, superior elastic limits, and remarkable wear resistance—characteristics that address critical challenges in modern robotics design. Additionally, their unique combination of metallic bonding and glassy structure provides excellent corrosion resistance and magnetic properties that conventional materials cannot match.

The primary objective of exploring amorphous metals in advanced robotics is to leverage these exceptional properties to overcome existing limitations in robotic systems. Specifically, the goals include developing more resilient and lightweight robotic components, enhancing energy efficiency through reduced mechanical losses, and enabling new functionalities through the materials' unique electromagnetic properties. There is also significant interest in utilizing the biocompatibility of certain amorphous metal compositions for medical robotics applications.

Looking forward, the trajectory of amorphous metals in robotics appears poised for acceleration as manufacturing techniques continue to mature and material costs decrease. Research efforts are increasingly focused on tailoring amorphous metal compositions for specific robotic applications, from micro-electromechanical systems (MEMS) to large-scale industrial robots. The potential for these materials to enable next-generation soft robotics, biomimetic designs, and adaptive structures represents a frontier in robotics engineering that promises to reshape the capabilities and applications of robotic systems across industries.

Market Demand Analysis for Advanced Robotic Materials

The global robotics market is experiencing unprecedented growth, with advanced materials playing a crucial role in this expansion. The demand for amorphous metals in robotics is primarily driven by the increasing need for robots with enhanced durability, precision, and performance capabilities across various industries. According to recent market analyses, the global advanced robotics market is projected to reach $189 billion by 2027, with materials innovation representing a significant growth factor.

Manufacturing sectors, particularly automotive and electronics, are showing the strongest demand for robots incorporating advanced materials like amorphous metals. These industries require robots that can perform high-precision tasks while withstanding harsh operational environments. The automotive industry alone accounts for approximately 30% of industrial robot deployments worldwide, with manufacturers seeking materials that can improve robot longevity and reduce maintenance costs.

Healthcare robotics represents another rapidly expanding market segment, with surgical and rehabilitation robots requiring materials that combine strength with biocompatibility. The medical robotics market is growing at an annual rate of 21%, creating substantial opportunities for amorphous metals that can meet strict medical-grade requirements while offering superior mechanical properties.

Consumer robotics is emerging as a promising market for amorphous metal applications, particularly in high-end service robots where durability and aesthetic appeal are equally important. This sector is expected to grow by 25% annually over the next five years, driven by increasing consumer acceptance and technological advancements.

Geographically, East Asia continues to lead in robotics adoption, with China, Japan, and South Korea collectively accounting for over 50% of global industrial robot installations. However, North America and Europe are showing accelerated growth rates in specialized robotics applications where advanced materials provide competitive advantages.

The market demand is further shaped by evolving regulatory standards for robot safety and performance. As regulations become more stringent, particularly in collaborative robotics where humans and robots work in close proximity, materials that can absorb impact energy while maintaining structural integrity become increasingly valuable.

Cost considerations remain a significant factor influencing market adoption. Currently, the price premium for amorphous metal components ranges from 40-200% compared to conventional materials, depending on complexity and production volume. However, as manufacturing processes mature and economies of scale improve, this price differential is expected to narrow, potentially accelerating market penetration.

Manufacturing sectors, particularly automotive and electronics, are showing the strongest demand for robots incorporating advanced materials like amorphous metals. These industries require robots that can perform high-precision tasks while withstanding harsh operational environments. The automotive industry alone accounts for approximately 30% of industrial robot deployments worldwide, with manufacturers seeking materials that can improve robot longevity and reduce maintenance costs.

Healthcare robotics represents another rapidly expanding market segment, with surgical and rehabilitation robots requiring materials that combine strength with biocompatibility. The medical robotics market is growing at an annual rate of 21%, creating substantial opportunities for amorphous metals that can meet strict medical-grade requirements while offering superior mechanical properties.

Consumer robotics is emerging as a promising market for amorphous metal applications, particularly in high-end service robots where durability and aesthetic appeal are equally important. This sector is expected to grow by 25% annually over the next five years, driven by increasing consumer acceptance and technological advancements.

Geographically, East Asia continues to lead in robotics adoption, with China, Japan, and South Korea collectively accounting for over 50% of global industrial robot installations. However, North America and Europe are showing accelerated growth rates in specialized robotics applications where advanced materials provide competitive advantages.

The market demand is further shaped by evolving regulatory standards for robot safety and performance. As regulations become more stringent, particularly in collaborative robotics where humans and robots work in close proximity, materials that can absorb impact energy while maintaining structural integrity become increasingly valuable.

Cost considerations remain a significant factor influencing market adoption. Currently, the price premium for amorphous metal components ranges from 40-200% compared to conventional materials, depending on complexity and production volume. However, as manufacturing processes mature and economies of scale improve, this price differential is expected to narrow, potentially accelerating market penetration.

Current Status and Challenges of Amorphous Metals

Amorphous metals, also known as metallic glasses, represent a unique class of materials that lack the crystalline structure typical of conventional metals. Globally, research into these materials has accelerated significantly over the past decade, with major centers of development concentrated in the United States, China, Japan, and Germany. The current technological landscape shows varying levels of maturity across different applications, with some sectors already commercializing amorphous metal components while others remain in early experimental stages.

In robotics applications specifically, amorphous metals have demonstrated exceptional mechanical properties including high strength-to-weight ratios, superior elastic limits, and excellent wear resistance. These characteristics make them particularly valuable for precision components in advanced robotic systems. However, widespread adoption faces several significant challenges that require innovative solutions.

The primary technical hurdle remains the manufacturing constraints associated with amorphous metals. The critical cooling rates required to maintain the amorphous structure severely limit the maximum thickness of components, typically restricting them to dimensions below 10mm. This "critical casting thickness" limitation presents a substantial barrier for structural robotic applications that require larger components.

Cost factors also present considerable challenges, as the specialized processing techniques and equipment needed for amorphous metal production significantly increase manufacturing expenses compared to conventional metals. This economic barrier has confined their use primarily to high-value applications where performance benefits can justify the premium costs.

Another significant technical challenge involves joining and integration issues. Traditional welding methods often crystallize the amorphous structure, negating the material's unique properties. This necessitates the development of specialized bonding techniques compatible with maintaining the amorphous state during assembly of robotic systems.

The mechanical behavior of amorphous metals under dynamic loading conditions relevant to robotics applications remains incompletely characterized. While static properties are well documented, the response to cyclic loading, impact resistance, and long-term fatigue performance requires further investigation to enable confident engineering design.

Environmental stability presents another concern, particularly for robotics operating in extreme conditions. Research indicates that some amorphous metal compositions may experience structural relaxation or partial crystallization at elevated temperatures or under certain chemical exposures, potentially compromising their performance characteristics over time.

Despite these challenges, recent breakthroughs in processing techniques, including additive manufacturing approaches and novel rapid solidification methods, are gradually expanding the practical applications of amorphous metals in robotics. These advances suggest that many current limitations may be overcome through continued research and development efforts.

In robotics applications specifically, amorphous metals have demonstrated exceptional mechanical properties including high strength-to-weight ratios, superior elastic limits, and excellent wear resistance. These characteristics make them particularly valuable for precision components in advanced robotic systems. However, widespread adoption faces several significant challenges that require innovative solutions.

The primary technical hurdle remains the manufacturing constraints associated with amorphous metals. The critical cooling rates required to maintain the amorphous structure severely limit the maximum thickness of components, typically restricting them to dimensions below 10mm. This "critical casting thickness" limitation presents a substantial barrier for structural robotic applications that require larger components.

Cost factors also present considerable challenges, as the specialized processing techniques and equipment needed for amorphous metal production significantly increase manufacturing expenses compared to conventional metals. This economic barrier has confined their use primarily to high-value applications where performance benefits can justify the premium costs.

Another significant technical challenge involves joining and integration issues. Traditional welding methods often crystallize the amorphous structure, negating the material's unique properties. This necessitates the development of specialized bonding techniques compatible with maintaining the amorphous state during assembly of robotic systems.

The mechanical behavior of amorphous metals under dynamic loading conditions relevant to robotics applications remains incompletely characterized. While static properties are well documented, the response to cyclic loading, impact resistance, and long-term fatigue performance requires further investigation to enable confident engineering design.

Environmental stability presents another concern, particularly for robotics operating in extreme conditions. Research indicates that some amorphous metal compositions may experience structural relaxation or partial crystallization at elevated temperatures or under certain chemical exposures, potentially compromising their performance characteristics over time.

Despite these challenges, recent breakthroughs in processing techniques, including additive manufacturing approaches and novel rapid solidification methods, are gradually expanding the practical applications of amorphous metals in robotics. These advances suggest that many current limitations may be overcome through continued research and development efforts.

Current Technical Solutions for Implementing Amorphous Metals

01 Manufacturing processes for amorphous metals

Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation, resulting in a disordered atomic structure. Common techniques include melt spinning, splat quenching, and gas atomization. The processing parameters must be carefully controlled to achieve the desired amorphous structure and properties.- Manufacturing processes for amorphous metals: Various manufacturing processes can be employed to produce amorphous metals, including rapid solidification techniques that prevent crystallization. These methods involve cooling molten metal at extremely high rates to bypass crystal formation. Techniques such as melt spinning, gas atomization, and splat quenching are commonly used to achieve the necessary cooling rates. These processes allow for the production of amorphous metals with unique structural properties that differ significantly from their crystalline counterparts.

- Composition and alloying elements for amorphous metals: The composition of amorphous metals typically includes specific combinations of elements that facilitate glass formation. These often contain a mixture of transition metals with metalloids such as boron, silicon, or phosphorus. The selection of alloying elements significantly influences the glass-forming ability, thermal stability, and mechanical properties of the resulting amorphous metal. Multi-component systems with elements of different atomic sizes tend to have better glass-forming ability due to increased atomic packing density and complexity.

- Applications of amorphous metals in various industries: Amorphous metals find applications across numerous industries due to their unique combination of properties. They are used in transformer cores and electronic devices due to their soft magnetic properties and low core losses. Their high strength and corrosion resistance make them suitable for structural components, medical implants, and sporting goods. Additionally, their unique surface properties and biocompatibility enable applications in biomedical fields. The absence of grain boundaries contributes to their superior performance in many specialized applications.

- Mechanical and physical properties of amorphous metals: Amorphous metals exhibit exceptional mechanical and physical properties compared to their crystalline counterparts. They typically display high strength, hardness, and elastic limits due to the absence of crystalline defects like dislocations. Their lack of grain boundaries results in superior corrosion resistance and unique magnetic properties. However, they often show limited ductility at room temperature. The combination of high strength-to-weight ratio, wear resistance, and elastic energy storage capacity makes these materials attractive for various engineering applications.

- Thermal stability and crystallization behavior: The thermal stability of amorphous metals is a critical property that determines their practical applications. When heated, amorphous metals eventually crystallize, transforming from a metastable amorphous state to a more thermodynamically stable crystalline state. This crystallization process can be controlled through careful heat treatment to develop partially crystallized structures with enhanced properties. Understanding and controlling the crystallization behavior is essential for processing these materials and developing amorphous metal composites with tailored properties.

02 Composition and alloying elements for amorphous metals

The composition of amorphous metals significantly influences their glass-forming ability and resulting properties. Specific alloying elements can enhance the stability of the amorphous structure by creating atomic size mismatches that inhibit crystallization. Common amorphous metal systems include iron-based, zirconium-based, and palladium-based alloys. The careful selection of composition can yield materials with superior mechanical properties, corrosion resistance, and magnetic characteristics.Expand Specific Solutions03 Applications of amorphous metals

Amorphous metals find applications across various industries due to their unique combination of properties. They are used in transformer cores and magnetic sensors due to their soft magnetic properties with low coercivity and high permeability. Their high strength and corrosion resistance make them suitable for structural components, sporting goods, and medical implants. Additionally, their biocompatibility enables applications in medical devices, while their unique acoustic properties are utilized in high-end audio equipment.Expand Specific Solutions04 Thermal stability and crystallization behavior

The thermal stability of amorphous metals is crucial for their practical applications. These materials exist in a metastable state and will crystallize when heated above their crystallization temperature. Understanding and controlling this crystallization behavior is essential for processing and application development. Techniques such as differential scanning calorimetry are used to characterize the glass transition and crystallization temperatures. Various methods, including the addition of specific elements, can enhance thermal stability and extend the temperature range for applications.Expand Specific Solutions05 Mechanical properties and deformation mechanisms

Amorphous metals exhibit unique mechanical properties compared to their crystalline counterparts. They typically display high strength, hardness, and elastic limits but often suffer from limited ductility at room temperature. Their deformation mechanisms differ from crystalline materials, as they lack dislocations and grain boundaries. Instead, deformation occurs through shear band formation. Understanding these mechanisms is crucial for designing amorphous metals with improved ductility and toughness for structural applications.Expand Specific Solutions

Key Industry Players in Amorphous Metals for Robotics

The amorphous metals market in advanced robotics is currently in a growth phase, characterized by increasing applications in precision components and mechanical systems. The market size is expanding as these materials offer superior mechanical properties and corrosion resistance compared to conventional metals. Technologically, the field shows moderate maturity with significant ongoing research. Leading players include academic institutions like Tsinghua University and University of Science & Technology Beijing conducting fundamental research, while companies such as VACUUMSCHMELZE, Heraeus Amloy Technologies, and Liquidmetal Coatings Enterprises are commercializing applications. Amorphyx Incorporated specifically focuses on amorphous metals for electronic devices. Research organizations like National Institute for Materials Science and NASA are exploring advanced applications, indicating strong future potential in robotics systems requiring high performance materials.

Heraeus Amloy Technologies GmbH

Technical Solution: Heraeus Amloy has developed proprietary amorphous metal alloys specifically engineered for advanced robotics applications. Their technology focuses on zirconium-based bulk metallic glasses (BMGs) that can be processed through injection molding to create complex robotic components with exceptional precision[1]. The company has pioneered a specialized manufacturing process that allows for the production of amorphous metal parts with thickness up to 50mm while maintaining their non-crystalline structure[2]. Their robotic components exhibit superior elastic strain limits (up to 2%) compared to conventional metals (0.2%), enabling the development of high-performance actuators and flexible joints that can withstand repeated deformation cycles without fatigue[3]. Heraeus Amloy's materials demonstrate exceptional wear resistance with surface hardness values exceeding 500 HV, making them ideal for robotic applications requiring durability in moving parts and gears[4].

Strengths: Superior elastic properties allow for design of flexible robotic components with excellent spring-back characteristics; exceptional wear resistance extends operational lifespan of robotic parts; precision manufacturing capability enables complex geometries impossible with traditional metals. Weaknesses: Higher production costs compared to conventional metals; limited maximum size of components due to critical cooling rate requirements; potential challenges in joining amorphous metals to other materials in complex robotic assemblies.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has pioneered innovative amorphous metal alloys specifically designed for advanced robotic applications. Their research team has developed titanium-based bulk metallic glasses with exceptional mechanical properties, achieving tensile strengths exceeding 2000 MPa while maintaining elastic strain limits above 2%[1]. IMR's proprietary manufacturing process combines electromagnetic levitation melting with copper mold casting to produce amorphous metal components with dimensions up to 80mm while preserving their non-crystalline structure[2]. For robotics applications, they've engineered specialized compositions that exhibit self-lubricating properties through the controlled formation of oxide layers, reducing friction coefficients to below 0.1 in robotic joints and actuators[3]. Their most significant breakthrough involves the development of gradient amorphous-crystalline structures that provide optimized performance characteristics across different regions of the same component, enabling robotic parts that combine the wear resistance of amorphous metals with the ductility of crystalline alloys[4]. IMR has successfully implemented these materials in prototype humanoid robots, where the amorphous metal components demonstrated a 40% reduction in weight while increasing operational lifespan by an estimated 300% compared to traditional materials[5].

Strengths: Cutting-edge research capabilities have produced amorphous metals with industry-leading mechanical properties; gradient structure technology enables optimized performance across different regions of the same component; comprehensive understanding of processing-structure-property relationships allows for tailored solutions. Weaknesses: Limited large-scale manufacturing capabilities compared to industrial entities; focus on research may result in solutions that face commercialization challenges; potential intellectual property constraints when collaborating with international partners.

Critical Patents and Research on Amorphous Metal Applications

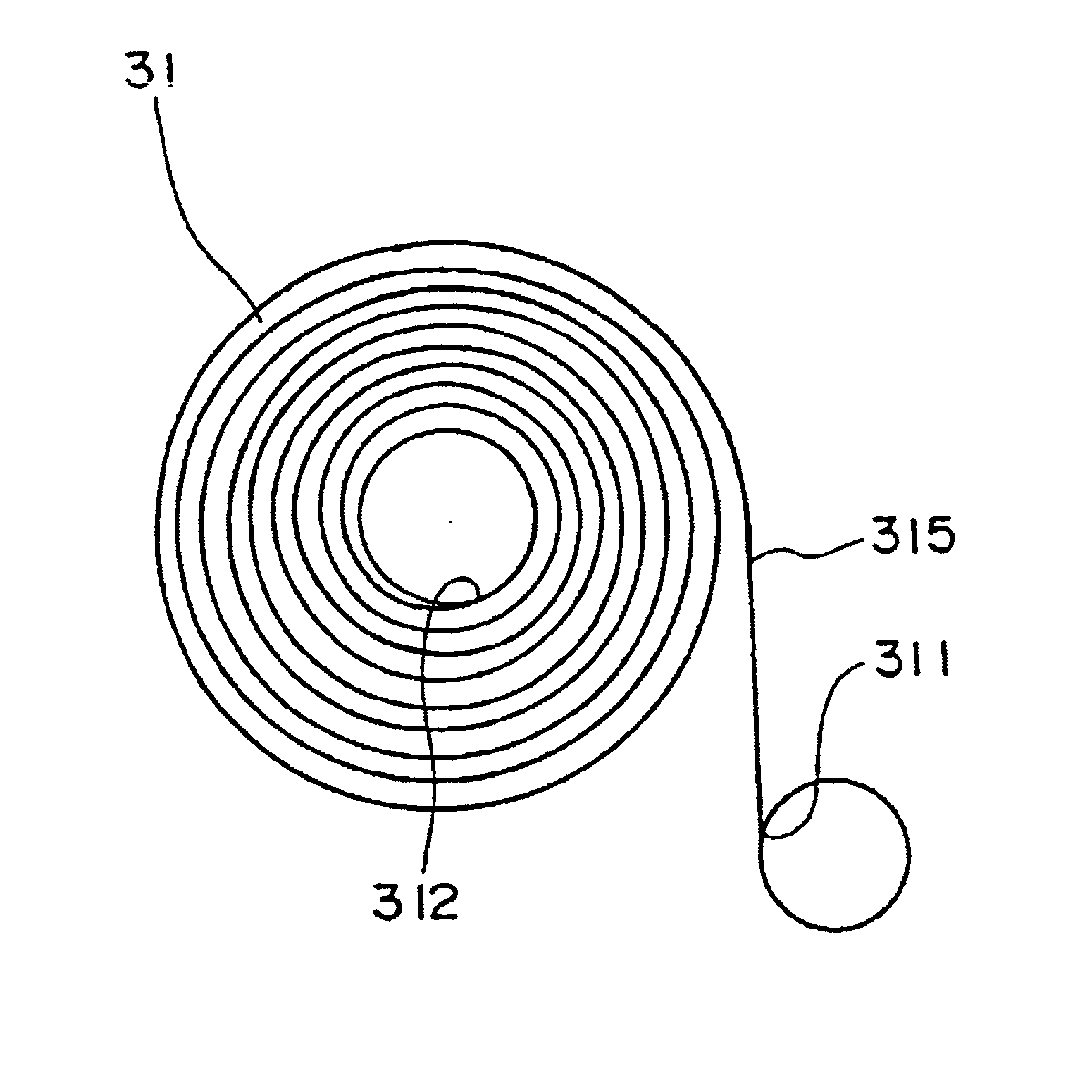

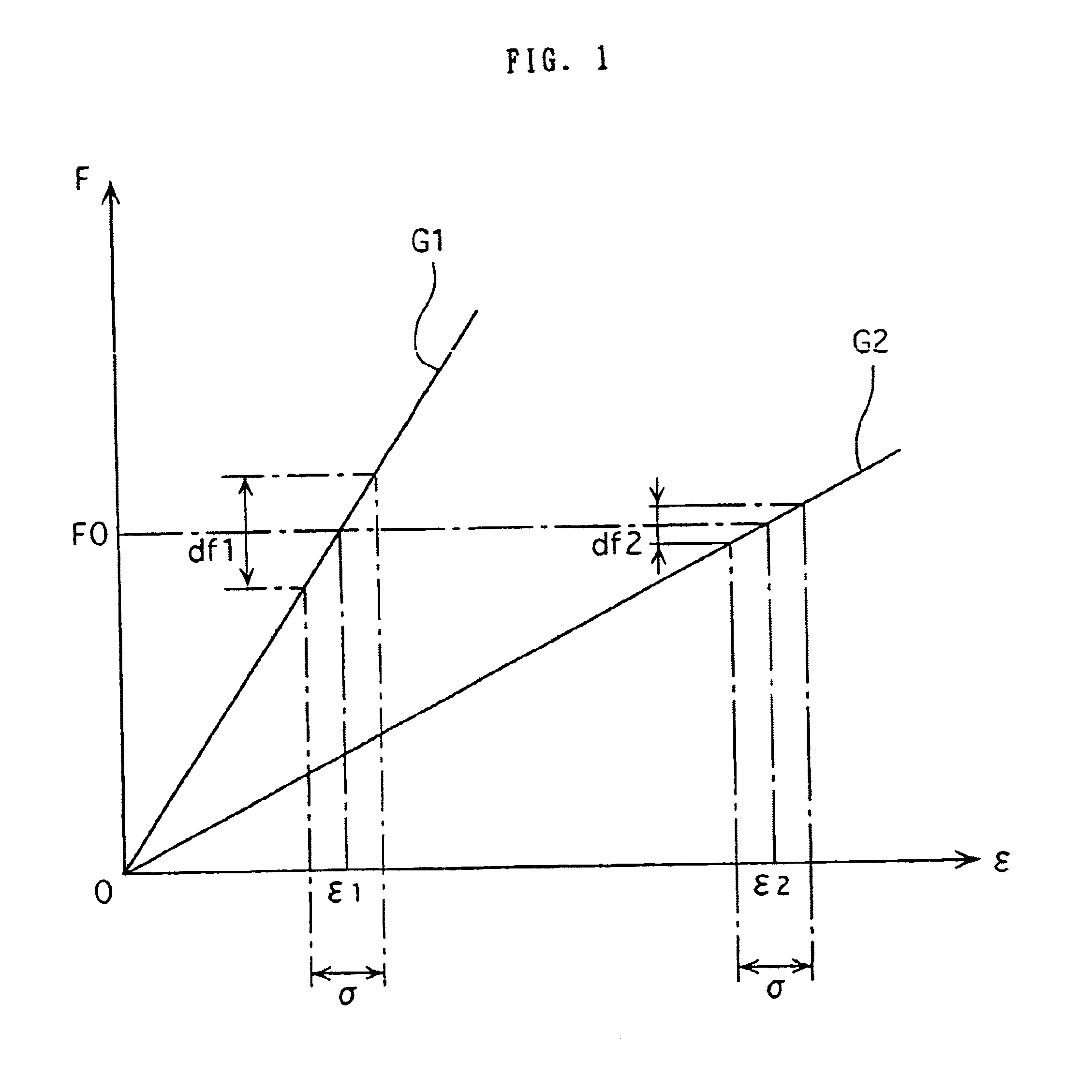

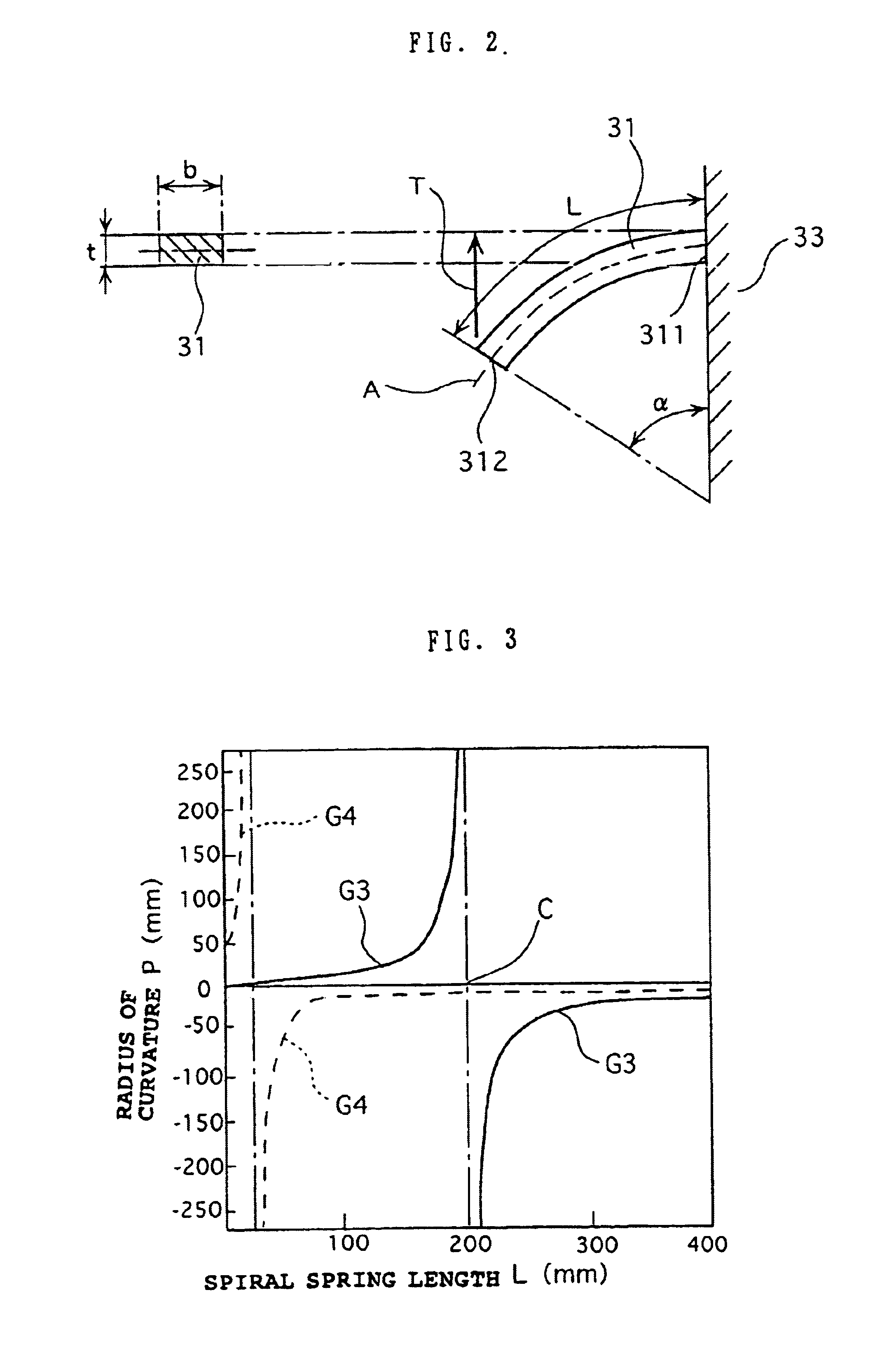

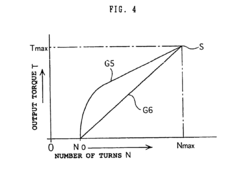

Spring, power spring, hair spring, driving mechanism utilizing them, and timepiece

PatentInactiveUS6843594B1

Innovation

- The use of amorphous metal springs with high tensile stress and low Young's modulus, allowing for reduced dispersion of wielding force, improved temperature stability, and increased energy storage capacity without modifying the geometry of the driving mechanism, while also offering corrosion resistance and magnetic resistance when necessary.

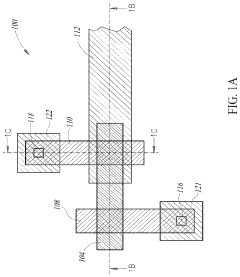

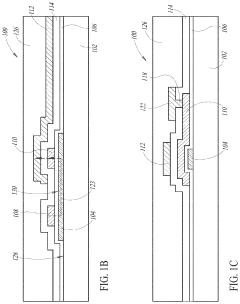

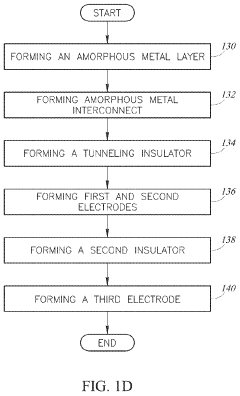

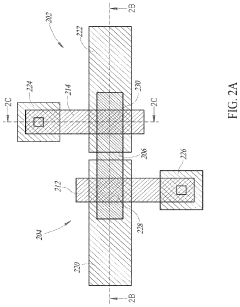

Amorphous metal hot electron transistor

PatentActiveUS20200259008A1

Innovation

- A co-planar amorphous hot electron transistor design with emitter and base electrodes in the same upper layer, separated by a gap, allowing for two-way Fowler-Nordheim tunneling and independent control of hot electron generation and collection, which is extended to a three-terminal device with adjustable I-V performance characteristics without modifying the tunneling dielectric.

Manufacturing Processes and Scalability Considerations

The manufacturing of amorphous metals for robotics applications presents unique challenges and opportunities that significantly impact their industrial adoption. Traditional manufacturing methods for crystalline metals are often incompatible with amorphous metals due to their distinct atomic structure. The primary production technique for amorphous metals involves rapid solidification processes, where cooling rates exceed 10^6 K/s to prevent crystallization. Methods such as melt spinning, which produces thin ribbons, and copper mold casting for bulk metallic glasses (BMGs) have become industry standards, though each has specific limitations regarding component size and geometry.

Recent advancements in additive manufacturing have opened new possibilities for amorphous metal implementation in robotics. Selective laser melting (SLM) and direct metal laser sintering (DMLS) enable the production of complex geometries with localized amorphous structures. These techniques allow for the creation of robotic components with gradient properties—crystalline where strength is needed and amorphous where elasticity and wear resistance are priorities. However, maintaining the necessary cooling rates during these processes remains technically challenging and often requires specialized equipment.

Scalability considerations represent a significant barrier to widespread adoption of amorphous metals in robotics. The critical cooling rate requirement inherently limits the maximum thickness of fully amorphous components, commonly referred to as the "critical casting thickness." This limitation has historically restricted amorphous metals to applications requiring only thin sections or small components. For larger robotic structures, manufacturers have developed composite approaches, where amorphous metal elements are integrated with conventional materials to leverage their respective advantages.

Cost factors also influence scalability, with specialized manufacturing equipment and precise process control adding significant expense compared to conventional metal fabrication. The high raw material costs of elements commonly used in amorphous alloys (such as palladium, platinum, or rare earth elements) further impact economic viability. However, lifecycle cost analyses suggest that the extended service life and reduced maintenance requirements of amorphous metal components may offset these initial investments, particularly in high-performance robotics applications.

Quality control presents another manufacturing challenge, as detecting defects or partial crystallization in amorphous structures requires sophisticated characterization techniques. X-ray diffraction, differential scanning calorimetry, and transmission electron microscopy are commonly employed but add complexity to production workflows. The development of in-situ monitoring systems during manufacturing represents an active research area that could significantly improve production reliability and reduce costs.

Recent advancements in additive manufacturing have opened new possibilities for amorphous metal implementation in robotics. Selective laser melting (SLM) and direct metal laser sintering (DMLS) enable the production of complex geometries with localized amorphous structures. These techniques allow for the creation of robotic components with gradient properties—crystalline where strength is needed and amorphous where elasticity and wear resistance are priorities. However, maintaining the necessary cooling rates during these processes remains technically challenging and often requires specialized equipment.

Scalability considerations represent a significant barrier to widespread adoption of amorphous metals in robotics. The critical cooling rate requirement inherently limits the maximum thickness of fully amorphous components, commonly referred to as the "critical casting thickness." This limitation has historically restricted amorphous metals to applications requiring only thin sections or small components. For larger robotic structures, manufacturers have developed composite approaches, where amorphous metal elements are integrated with conventional materials to leverage their respective advantages.

Cost factors also influence scalability, with specialized manufacturing equipment and precise process control adding significant expense compared to conventional metal fabrication. The high raw material costs of elements commonly used in amorphous alloys (such as palladium, platinum, or rare earth elements) further impact economic viability. However, lifecycle cost analyses suggest that the extended service life and reduced maintenance requirements of amorphous metal components may offset these initial investments, particularly in high-performance robotics applications.

Quality control presents another manufacturing challenge, as detecting defects or partial crystallization in amorphous structures requires sophisticated characterization techniques. X-ray diffraction, differential scanning calorimetry, and transmission electron microscopy are commonly employed but add complexity to production workflows. The development of in-situ monitoring systems during manufacturing represents an active research area that could significantly improve production reliability and reduce costs.

Performance Metrics and Comparative Material Analysis

When evaluating amorphous metals for robotic applications, standardized performance metrics are essential for meaningful comparisons with conventional materials. Key mechanical metrics include yield strength (typically 1.5-2.5 GPa for amorphous metals versus 0.5-1.2 GPa for high-strength steels), elastic limit (2% for amorphous metals compared to 0.2% for crystalline metals), and hardness (Vickers hardness of 700-1200 HV for amorphous metals versus 150-600 HV for conventional alloys). These superior mechanical properties translate directly to enhanced wear resistance and structural durability in robotic components.

Thermal performance metrics reveal that while amorphous metals exhibit lower thermal conductivity (10-20 W/m·K compared to 50-400 W/m·K for crystalline metals), they maintain structural integrity across wider temperature ranges before crystallization occurs. This characteristic proves advantageous for robots operating in extreme environments where thermal stability is critical.

Electrical properties analysis shows that amorphous metals typically demonstrate higher electrical resistivity than their crystalline counterparts, making them suitable for electromagnetic shielding and specialized sensor applications in robotics. Their unique magnetic properties, particularly low coercivity and high permeability, enable more efficient electromagnetic actuators and sensors.

Comparative lifecycle assessment indicates that amorphous metal components can achieve 30-50% longer operational lifespans than traditional materials in high-stress robotic applications. This extended durability stems from superior fatigue resistance, with amorphous metals demonstrating fatigue limits approaching 90% of their tensile strength compared to 35-50% for conventional alloys.

Cost-benefit analysis reveals that while amorphous metals typically cost 3-5 times more per unit weight than conventional engineering alloys, the total cost of ownership can be lower when accounting for extended service life, reduced maintenance requirements, and performance advantages. For high-precision robotic applications, the enhanced dimensional stability of amorphous metals (with thermal expansion coefficients 20-30% lower than conventional alloys) provides significant performance benefits that justify the higher initial investment.

Weight-to-performance ratios demonstrate that amorphous metal components can achieve equivalent mechanical performance at 15-25% lower weight compared to steel alternatives, contributing to energy efficiency in mobile robotic systems. This weight reduction becomes particularly significant in aerial and humanoid robotics where mass distribution directly impacts dynamic performance and energy consumption.

Thermal performance metrics reveal that while amorphous metals exhibit lower thermal conductivity (10-20 W/m·K compared to 50-400 W/m·K for crystalline metals), they maintain structural integrity across wider temperature ranges before crystallization occurs. This characteristic proves advantageous for robots operating in extreme environments where thermal stability is critical.

Electrical properties analysis shows that amorphous metals typically demonstrate higher electrical resistivity than their crystalline counterparts, making them suitable for electromagnetic shielding and specialized sensor applications in robotics. Their unique magnetic properties, particularly low coercivity and high permeability, enable more efficient electromagnetic actuators and sensors.

Comparative lifecycle assessment indicates that amorphous metal components can achieve 30-50% longer operational lifespans than traditional materials in high-stress robotic applications. This extended durability stems from superior fatigue resistance, with amorphous metals demonstrating fatigue limits approaching 90% of their tensile strength compared to 35-50% for conventional alloys.

Cost-benefit analysis reveals that while amorphous metals typically cost 3-5 times more per unit weight than conventional engineering alloys, the total cost of ownership can be lower when accounting for extended service life, reduced maintenance requirements, and performance advantages. For high-precision robotic applications, the enhanced dimensional stability of amorphous metals (with thermal expansion coefficients 20-30% lower than conventional alloys) provides significant performance benefits that justify the higher initial investment.

Weight-to-performance ratios demonstrate that amorphous metal components can achieve equivalent mechanical performance at 15-25% lower weight compared to steel alternatives, contributing to energy efficiency in mobile robotic systems. This weight reduction becomes particularly significant in aerial and humanoid robotics where mass distribution directly impacts dynamic performance and energy consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!