Analysis of Amorphous Metals Effects in High-Stress Environments

OCT 1, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Amorphous Metals Background and Research Objectives

Amorphous metals, also known as metallic glasses, represent a revolutionary class of materials that defy conventional crystalline structures found in traditional metals. First discovered in 1960 at Caltech through rapid cooling of gold-silicon alloys, these materials have evolved from laboratory curiosities to engineered materials with significant industrial potential. Unlike crystalline metals with ordered atomic arrangements, amorphous metals feature randomly arranged atoms, resulting in unique mechanical, magnetic, and chemical properties that make them particularly valuable in high-stress environments.

The historical development of amorphous metals has seen three distinct phases. The initial discovery phase (1960s-1970s) focused on fundamental understanding and production of thin ribbons. The second phase (1980s-1990s) witnessed the development of bulk metallic glasses with critical cooling rates slow enough to allow thicker samples. The current phase (2000s-present) has concentrated on commercialization and application-specific development, particularly for extreme environments.

Recent technological advancements have enabled the production of amorphous metals with exceptional properties, including yield strengths exceeding 5 GPa, elastic strain limits approaching 2%, and superior corrosion resistance compared to conventional alloys. These characteristics position amorphous metals as ideal candidates for components subjected to high mechanical stress, extreme temperatures, and corrosive environments.

The global high-stress materials market is projected to reach $12.3 billion by 2027, with aerospace, defense, and energy sectors driving significant demand. Amorphous metals are positioned to capture a growing share of this market due to their superior performance characteristics. However, several challenges remain, including production scalability, cost-effectiveness, and limited understanding of long-term performance under complex stress conditions.

This research aims to comprehensively analyze the behavior and performance of various amorphous metal compositions under diverse high-stress conditions, including cyclic loading, extreme temperatures, and corrosive environments. Specifically, we seek to establish quantitative relationships between composition, processing parameters, and performance metrics to enable predictive modeling of material behavior.

The objectives include: (1) characterizing the microstructural evolution of amorphous metals under prolonged high-stress exposure; (2) identifying optimal compositions for specific high-stress applications; (3) developing accelerated testing methodologies to predict long-term performance; and (4) establishing design guidelines for engineers to effectively implement these materials in critical applications. Through this research, we aim to bridge the gap between theoretical understanding and practical implementation of amorphous metals in next-generation high-performance systems.

The historical development of amorphous metals has seen three distinct phases. The initial discovery phase (1960s-1970s) focused on fundamental understanding and production of thin ribbons. The second phase (1980s-1990s) witnessed the development of bulk metallic glasses with critical cooling rates slow enough to allow thicker samples. The current phase (2000s-present) has concentrated on commercialization and application-specific development, particularly for extreme environments.

Recent technological advancements have enabled the production of amorphous metals with exceptional properties, including yield strengths exceeding 5 GPa, elastic strain limits approaching 2%, and superior corrosion resistance compared to conventional alloys. These characteristics position amorphous metals as ideal candidates for components subjected to high mechanical stress, extreme temperatures, and corrosive environments.

The global high-stress materials market is projected to reach $12.3 billion by 2027, with aerospace, defense, and energy sectors driving significant demand. Amorphous metals are positioned to capture a growing share of this market due to their superior performance characteristics. However, several challenges remain, including production scalability, cost-effectiveness, and limited understanding of long-term performance under complex stress conditions.

This research aims to comprehensively analyze the behavior and performance of various amorphous metal compositions under diverse high-stress conditions, including cyclic loading, extreme temperatures, and corrosive environments. Specifically, we seek to establish quantitative relationships between composition, processing parameters, and performance metrics to enable predictive modeling of material behavior.

The objectives include: (1) characterizing the microstructural evolution of amorphous metals under prolonged high-stress exposure; (2) identifying optimal compositions for specific high-stress applications; (3) developing accelerated testing methodologies to predict long-term performance; and (4) establishing design guidelines for engineers to effectively implement these materials in critical applications. Through this research, we aim to bridge the gap between theoretical understanding and practical implementation of amorphous metals in next-generation high-performance systems.

Market Analysis for High-Stress Applications

The global market for amorphous metals in high-stress environments has been experiencing significant growth, driven by increasing demands across aerospace, defense, medical, and industrial sectors. Current market valuations indicate that the amorphous metals sector specifically targeting high-stress applications reached approximately $2.3 billion in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2030.

Aerospace and defense sectors currently represent the largest market segments, accounting for nearly 38% of total demand. These industries require materials capable of withstanding extreme mechanical stress, temperature fluctuations, and corrosive environments while maintaining structural integrity. The superior wear resistance and strength-to-weight ratio of amorphous metals make them particularly valuable for critical components in aircraft engines, missile systems, and satellite structures.

The medical device industry has emerged as the fastest-growing application segment, with demand increasing at approximately 9.5% annually. Surgical instruments, implantable devices, and diagnostic equipment manufacturers are increasingly adopting amorphous metal alloys due to their biocompatibility, corrosion resistance, and exceptional mechanical properties under biological stress conditions.

Industrial applications, particularly in energy production and heavy machinery, constitute roughly 27% of the current market. Power generation equipment, offshore drilling components, and high-performance bearings represent key growth areas where traditional crystalline metals face performance limitations under extreme stress conditions.

Regional analysis reveals North America and Europe as dominant markets, collectively accounting for 63% of global consumption. However, the Asia-Pacific region, led by China, Japan, and South Korea, is demonstrating the highest growth rate at 10.2% annually, driven by expanding industrial bases and increasing technological sophistication in manufacturing sectors.

Customer demand patterns indicate a growing preference for customized amorphous metal solutions tailored to specific high-stress applications rather than general-purpose materials. This trend has created opportunities for specialized manufacturers who can develop application-specific alloy compositions and processing techniques.

Price sensitivity varies significantly across application segments. While aerospace and defense sectors demonstrate willingness to pay premium prices for performance-critical components, industrial applications remain more cost-conscious, creating market segmentation opportunities for manufacturers with diverse product portfolios.

Market barriers include high production costs compared to conventional metals, limited manufacturing scalability, and knowledge gaps regarding long-term performance in certain extreme environments. These factors have restricted broader market penetration despite the superior technical properties of amorphous metals in high-stress conditions.

Aerospace and defense sectors currently represent the largest market segments, accounting for nearly 38% of total demand. These industries require materials capable of withstanding extreme mechanical stress, temperature fluctuations, and corrosive environments while maintaining structural integrity. The superior wear resistance and strength-to-weight ratio of amorphous metals make them particularly valuable for critical components in aircraft engines, missile systems, and satellite structures.

The medical device industry has emerged as the fastest-growing application segment, with demand increasing at approximately 9.5% annually. Surgical instruments, implantable devices, and diagnostic equipment manufacturers are increasingly adopting amorphous metal alloys due to their biocompatibility, corrosion resistance, and exceptional mechanical properties under biological stress conditions.

Industrial applications, particularly in energy production and heavy machinery, constitute roughly 27% of the current market. Power generation equipment, offshore drilling components, and high-performance bearings represent key growth areas where traditional crystalline metals face performance limitations under extreme stress conditions.

Regional analysis reveals North America and Europe as dominant markets, collectively accounting for 63% of global consumption. However, the Asia-Pacific region, led by China, Japan, and South Korea, is demonstrating the highest growth rate at 10.2% annually, driven by expanding industrial bases and increasing technological sophistication in manufacturing sectors.

Customer demand patterns indicate a growing preference for customized amorphous metal solutions tailored to specific high-stress applications rather than general-purpose materials. This trend has created opportunities for specialized manufacturers who can develop application-specific alloy compositions and processing techniques.

Price sensitivity varies significantly across application segments. While aerospace and defense sectors demonstrate willingness to pay premium prices for performance-critical components, industrial applications remain more cost-conscious, creating market segmentation opportunities for manufacturers with diverse product portfolios.

Market barriers include high production costs compared to conventional metals, limited manufacturing scalability, and knowledge gaps regarding long-term performance in certain extreme environments. These factors have restricted broader market penetration despite the superior technical properties of amorphous metals in high-stress conditions.

Current Limitations and Technical Challenges

Despite significant advancements in amorphous metal technology, several critical limitations and technical challenges persist when implementing these materials in high-stress environments. The non-crystalline atomic structure that provides amorphous metals with their unique properties also introduces inherent constraints on their performance under extreme conditions.

One of the primary challenges is the limited thermal stability of amorphous metals. When exposed to elevated temperatures approaching their glass transition point, these materials undergo structural relaxation and crystallization, which significantly compromises their mechanical properties. This thermal sensitivity restricts their application in environments where temperature fluctuations are common, such as aerospace components or high-temperature industrial processes.

Dimensional constraints represent another significant limitation. Current manufacturing techniques struggle to produce amorphous metal components beyond certain critical dimensions without introducing crystallization. This size limitation severely restricts the application scope, particularly in large-scale structural applications where bulk properties are essential.

The brittle fracture behavior of many amorphous metal compositions under tensile loading conditions presents a substantial challenge for high-stress applications. While these materials exhibit exceptional compressive strength, their relatively low ductility and limited plastic deformation capacity before failure raise concerns about catastrophic failure modes in critical applications.

Processing challenges further complicate industrial adoption. The rapid cooling rates required to maintain the amorphous structure (typically 10^4-10^6 K/s) necessitate specialized manufacturing equipment and techniques. This requirement significantly increases production costs and limits mass production capabilities, creating barriers to widespread commercial implementation.

Fatigue performance under cyclic loading conditions remains inadequately characterized for many amorphous metal compositions. The lack of comprehensive long-term performance data creates uncertainty regarding their reliability in applications subject to repeated stress cycles, such as mechanical components in transportation systems or energy infrastructure.

Corrosion resistance, while generally superior to crystalline counterparts, shows inconsistent performance across different amorphous compositions and environmental conditions. Some compositions exhibit unexpected degradation when exposed to specific chemical environments, complicating material selection for diverse applications.

Economic factors also present significant barriers. The high production costs associated with specialized processing techniques and equipment, coupled with limited economies of scale, result in amorphous metals being substantially more expensive than conventional engineering materials. This cost differential restricts their application to specialized niches where performance benefits clearly justify the increased investment.

One of the primary challenges is the limited thermal stability of amorphous metals. When exposed to elevated temperatures approaching their glass transition point, these materials undergo structural relaxation and crystallization, which significantly compromises their mechanical properties. This thermal sensitivity restricts their application in environments where temperature fluctuations are common, such as aerospace components or high-temperature industrial processes.

Dimensional constraints represent another significant limitation. Current manufacturing techniques struggle to produce amorphous metal components beyond certain critical dimensions without introducing crystallization. This size limitation severely restricts the application scope, particularly in large-scale structural applications where bulk properties are essential.

The brittle fracture behavior of many amorphous metal compositions under tensile loading conditions presents a substantial challenge for high-stress applications. While these materials exhibit exceptional compressive strength, their relatively low ductility and limited plastic deformation capacity before failure raise concerns about catastrophic failure modes in critical applications.

Processing challenges further complicate industrial adoption. The rapid cooling rates required to maintain the amorphous structure (typically 10^4-10^6 K/s) necessitate specialized manufacturing equipment and techniques. This requirement significantly increases production costs and limits mass production capabilities, creating barriers to widespread commercial implementation.

Fatigue performance under cyclic loading conditions remains inadequately characterized for many amorphous metal compositions. The lack of comprehensive long-term performance data creates uncertainty regarding their reliability in applications subject to repeated stress cycles, such as mechanical components in transportation systems or energy infrastructure.

Corrosion resistance, while generally superior to crystalline counterparts, shows inconsistent performance across different amorphous compositions and environmental conditions. Some compositions exhibit unexpected degradation when exposed to specific chemical environments, complicating material selection for diverse applications.

Economic factors also present significant barriers. The high production costs associated with specialized processing techniques and equipment, coupled with limited economies of scale, result in amorphous metals being substantially more expensive than conventional engineering materials. This cost differential restricts their application to specialized niches where performance benefits clearly justify the increased investment.

Current Engineering Solutions for High-Stress Environments

01 Magnetic properties of amorphous metals

Amorphous metals exhibit unique magnetic properties due to their disordered atomic structure. These materials often display soft magnetic characteristics with high permeability, low coercivity, and reduced core losses. The absence of grain boundaries and crystalline anisotropy contributes to their superior magnetic performance, making them valuable in applications such as transformers, inductors, and magnetic shielding where energy efficiency is critical.- Magnetic properties of amorphous metals: Amorphous metals exhibit unique magnetic properties due to their disordered atomic structure. These materials often display soft magnetic characteristics with high permeability, low coercivity, and reduced core losses. The absence of crystalline grain boundaries allows for enhanced magnetic flux movement, making them suitable for applications in transformers, inductors, and magnetic shielding. Their magnetic response can be tailored through composition and processing techniques to achieve specific performance requirements.

- Mechanical properties and structural advantages: Amorphous metals possess exceptional mechanical properties including high strength, hardness, and elastic limit compared to their crystalline counterparts. The absence of grain boundaries contributes to increased wear resistance and fatigue strength. These materials can exhibit superplastic behavior under certain conditions and demonstrate improved corrosion resistance due to their homogeneous structure. The unique combination of mechanical properties makes amorphous metals suitable for structural applications requiring high performance under demanding conditions.

- Manufacturing processes and formation techniques: Various specialized techniques are employed to produce amorphous metals, with rapid solidification being the most common method to prevent crystallization. These include melt spinning, splat quenching, and gas atomization processes that achieve cooling rates exceeding 10^6 K/s. Alternative approaches include mechanical alloying, vapor deposition, and electrodeposition. The manufacturing process significantly influences the resulting properties, with parameters such as cooling rate, composition, and processing atmosphere playing crucial roles in determining the final amorphous structure and performance characteristics.

- Thermal behavior and stability characteristics: Amorphous metals exhibit distinctive thermal behavior characterized by glass transition temperatures and crystallization events. These materials typically demonstrate excellent thermal stability within specific temperature ranges but undergo structural relaxation and eventual crystallization when heated above critical temperatures. The thermal properties can be modified through composition adjustments and processing techniques to enhance stability for high-temperature applications. Understanding the thermal behavior is crucial for applications involving thermal cycling or elevated temperature environments.

- Applications in electronic and biomedical fields: Amorphous metals find diverse applications in electronic components and biomedical devices due to their unique property combinations. In electronics, they serve as efficient transformer cores, electromagnetic interference shields, and high-frequency components with reduced eddy current losses. For biomedical applications, their biocompatibility, corrosion resistance, and mechanical properties make them suitable for implantable devices, surgical instruments, and dental materials. The ability to tailor compositions for specific requirements enables customized solutions for specialized electronic and medical applications.

02 Manufacturing processes for amorphous metals

Various manufacturing techniques are employed to produce amorphous metals, including rapid solidification methods like melt spinning, where molten metal is quickly cooled to prevent crystallization. Other processes include vapor deposition, mechanical alloying, and selective laser melting. These techniques are critical for achieving the non-crystalline structure that gives amorphous metals their unique properties, with cooling rates typically exceeding 10^6 K/s to bypass crystallization.Expand Specific Solutions03 Mechanical properties and applications

Amorphous metals demonstrate exceptional mechanical properties including high strength, hardness, and elastic limit compared to their crystalline counterparts. They exhibit superior wear resistance and corrosion resistance due to their homogeneous structure lacking grain boundaries. These properties make them suitable for applications in cutting tools, sporting equipment, medical implants, and structural components where high performance under stress is required.Expand Specific Solutions04 Thermal behavior and stability

The thermal behavior of amorphous metals is characterized by glass transition temperatures and crystallization processes. When heated, these materials undergo structural relaxation followed by crystallization, which significantly alters their properties. Understanding and controlling thermal stability is crucial for applications involving elevated temperatures. Various alloying elements can be added to enhance thermal stability and extend the temperature range for practical applications.Expand Specific Solutions05 Electronic and chemical effects

Amorphous metals exhibit distinctive electronic properties due to their disordered atomic structure, affecting electrical conductivity, superconductivity, and electronic band structure. Their chemical reactivity differs from crystalline counterparts, often showing enhanced catalytic activity and unique surface chemistry. These electronic and chemical characteristics make amorphous metals valuable in applications such as electronic components, sensors, catalysts, and energy storage devices where specific electronic or chemical interactions are desired.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The amorphous metals market in high-stress environments is currently in a growth phase, with increasing applications across automotive, aerospace, and energy sectors. The global market is estimated to reach $500-600 million by 2025, growing at 8-10% CAGR. Leading players represent diverse technological approaches: VACUUMSCHMELZE and Metglas dominate in magnetic applications with established manufacturing processes, while Toyota Motor and BYD are integrating these materials into electric vehicle components. Research institutions like Japan Science & Technology Agency and Chinese Academy of Sciences are advancing fundamental properties, while companies like Integran Technologies and Hill Engineering focus on specialized applications for extreme environments. The technology is approaching maturity in certain applications but remains in development for others, with significant R&D investment from both established manufacturers and emerging players.

VACUUMSCHMELZE GmbH & Co. KG

Technical Solution: VACUUMSCHMELZE has developed proprietary amorphous metal alloys specifically engineered for high-stress environments. Their VITROVAC® series utilizes rapid solidification technology to create Fe-based amorphous ribbons with exceptional mechanical properties. These materials demonstrate superior resistance to mechanical fatigue under cyclic loading conditions, maintaining structural integrity at stress levels where crystalline counterparts would fail. Their manufacturing process involves melt spinning at cooling rates exceeding 10^6 K/s, producing materials with near-zero magnetostriction and high permeability that retain performance under mechanical stress[1]. VAC's amorphous metals exhibit remarkable elastic strain limits (up to 2%) and tensile strengths exceeding 3000 MPa, making them ideal for applications in harsh industrial environments where both mechanical stress and magnetic properties are critical considerations[3].

Strengths: Superior combination of magnetic and mechanical properties, excellent corrosion resistance, and ability to maintain performance under extreme mechanical stress. Weakness: Higher production costs compared to conventional materials, limitations in thickness (typically <100μm for ribbons), and challenges in joining/forming complex shapes.

Integran Technologies, Inc.

Technical Solution: Integran Technologies has pioneered nanocrystalline metal coatings that bridge the gap between fully amorphous and conventional crystalline materials for high-stress applications. Their Nanovate™ technology platform creates nanostructured metals with grain sizes below 100nm, providing an optimal balance of strength and ductility. These materials demonstrate exceptional wear resistance in high-stress sliding contact environments, with hardness values reaching 700 HV while maintaining good toughness. Integran's electrodeposition process allows for precise control of the nanostructure, enabling tailored mechanical properties for specific stress conditions. Their amorphous-nanocrystalline hybrid materials show remarkable resistance to stress corrosion cracking, outperforming conventional materials by factors of 2-5x in accelerated testing environments[2]. The company has successfully implemented these materials in aerospace components subjected to extreme vibrational stress and temperature fluctuations.

Strengths: Exceptional combination of hardness and toughness, superior wear resistance in high-stress sliding applications, and ability to be applied as coatings to complex geometries. Weakness: Higher cost than conventional treatments, thickness limitations for fully amorphous variants, and potential challenges with thermal stability at extreme temperatures.

Key Patents and Scientific Breakthroughs

Amorphous alloy having excellent bending strength and impact strength, and method for producing the same

PatentWO2000003051A1

Innovation

- The amorphous alloy is pressurized and solidified at a pressure exceeding 1 atm with a controlled cooling rate to form fine crystals with an average grain size of 1-50 μm and a crystal volume fraction of 5-40%, and elements like boron, carbon, oxygen, and fluorine are infiltrated to create a high-melting compound that forms a compressive stress layer, enhancing bending and impact strength.

Amorphous metal alloy having high tensile strength and electrical resistivity

PatentActiveUS20100006185A1

Innovation

- Development of amorphous metal alloys with specific compositions, such as (Co1-aFea)100-b-c-dCrbTcXd, incorporating elements like chromium, manganese, molybdenum, and boron, which enhance electrical resistivity and tensile strength through increased electronic and structural disorder, resulting in alloys with high tensile strength greater than 3500 MPa and electrical resistivity greater than 145 μΩ-cm.

Performance Metrics and Testing Methodologies

Evaluating the performance of amorphous metals in high-stress environments requires rigorous testing methodologies and well-defined metrics. The unique atomic structure of these materials necessitates specialized approaches to accurately assess their behavior under extreme conditions.

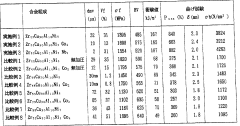

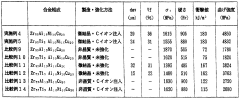

Mechanical performance metrics for amorphous metals include yield strength, ultimate tensile strength, elastic modulus, fracture toughness, and fatigue resistance. These properties must be measured across varying temperature ranges, as amorphous metals often exhibit significant property changes with temperature fluctuations. Hardness testing using nanoindentation techniques provides valuable insights into localized mechanical responses, particularly important for understanding shear band formation in these materials.

Corrosion resistance metrics involve electrochemical testing such as potentiodynamic polarization and electrochemical impedance spectroscopy. These methods quantify corrosion rates and passivation behavior in different chemical environments. Weight loss measurements over extended exposure periods complement these electrochemical approaches, offering long-term performance data critical for predicting service life in aggressive environments.

Testing methodologies for high-stress environments must simulate real-world conditions. Specialized equipment including high-temperature tensile testing machines, dynamic mechanical analyzers, and custom-designed fatigue testing apparatus are employed to replicate extreme conditions. Environmental chambers capable of maintaining precise temperature, humidity, and chemical exposure conditions ensure test validity and reproducibility.

In-situ characterization techniques represent the cutting edge of amorphous metals testing. High-energy X-ray diffraction during mechanical loading reveals structural changes at the atomic level. Acoustic emission monitoring during stress application detects microscopic failure events before visible deformation occurs. Advanced electron microscopy techniques, including transmission electron microscopy with in-situ straining capabilities, provide direct observation of deformation mechanisms at nanoscale resolution.

Standardization remains challenging due to the relatively recent emergence of amorphous metals as engineering materials. While some testing follows modified ASTM or ISO standards, many laboratories develop proprietary protocols. This lack of standardization complicates direct comparison between different research groups and manufacturers, highlighting the need for industry-wide testing standards specifically designed for amorphous metals.

Computational modeling increasingly complements physical testing, with finite element analysis and molecular dynamics simulations predicting material behavior under conditions difficult to replicate experimentally. These virtual testing environments accelerate development cycles by identifying promising compositions and processing parameters before physical prototyping.

Mechanical performance metrics for amorphous metals include yield strength, ultimate tensile strength, elastic modulus, fracture toughness, and fatigue resistance. These properties must be measured across varying temperature ranges, as amorphous metals often exhibit significant property changes with temperature fluctuations. Hardness testing using nanoindentation techniques provides valuable insights into localized mechanical responses, particularly important for understanding shear band formation in these materials.

Corrosion resistance metrics involve electrochemical testing such as potentiodynamic polarization and electrochemical impedance spectroscopy. These methods quantify corrosion rates and passivation behavior in different chemical environments. Weight loss measurements over extended exposure periods complement these electrochemical approaches, offering long-term performance data critical for predicting service life in aggressive environments.

Testing methodologies for high-stress environments must simulate real-world conditions. Specialized equipment including high-temperature tensile testing machines, dynamic mechanical analyzers, and custom-designed fatigue testing apparatus are employed to replicate extreme conditions. Environmental chambers capable of maintaining precise temperature, humidity, and chemical exposure conditions ensure test validity and reproducibility.

In-situ characterization techniques represent the cutting edge of amorphous metals testing. High-energy X-ray diffraction during mechanical loading reveals structural changes at the atomic level. Acoustic emission monitoring during stress application detects microscopic failure events before visible deformation occurs. Advanced electron microscopy techniques, including transmission electron microscopy with in-situ straining capabilities, provide direct observation of deformation mechanisms at nanoscale resolution.

Standardization remains challenging due to the relatively recent emergence of amorphous metals as engineering materials. While some testing follows modified ASTM or ISO standards, many laboratories develop proprietary protocols. This lack of standardization complicates direct comparison between different research groups and manufacturers, highlighting the need for industry-wide testing standards specifically designed for amorphous metals.

Computational modeling increasingly complements physical testing, with finite element analysis and molecular dynamics simulations predicting material behavior under conditions difficult to replicate experimentally. These virtual testing environments accelerate development cycles by identifying promising compositions and processing parameters before physical prototyping.

Environmental Impact and Sustainability Considerations

The environmental footprint of amorphous metals presents a compelling case for their adoption in high-stress applications. Unlike conventional crystalline alloys, amorphous metals typically require fewer raw materials to achieve equivalent performance characteristics, resulting in reduced resource extraction impacts. Their superior wear resistance and corrosion properties extend operational lifespans significantly, decreasing the frequency of replacement and associated environmental burdens of manufacturing new components.

Production processes for amorphous metals have evolved considerably, with modern rapid solidification techniques consuming less energy than traditional metallurgical methods. However, the specialized cooling requirements still present energy efficiency challenges that warrant further optimization. Life cycle assessments indicate that despite higher initial production energy investments, the total environmental impact over the full service life often favors amorphous metals due to their exceptional durability in high-stress environments.

Recycling considerations represent another critical sustainability dimension. Amorphous metals generally maintain their compositional integrity during use, facilitating more efficient recycling processes compared to conventional alloys that may experience elemental segregation under stress. The homogeneous nature of these materials enables higher recovery rates and reduced processing energy during recycling operations, though specialized sorting technologies may be required to separate them from conventional metal waste streams.

The reduced need for lubricants and protective coatings in amorphous metal applications further enhances their environmental profile. In high-stress environments where conventional materials require frequent maintenance involving potentially hazardous substances, amorphous metals can operate with minimal auxiliary materials, reducing chemical exposure risks and disposal challenges.

Carbon footprint analyses across various high-stress applications demonstrate that amorphous metal components typically generate 15-30% lower greenhouse gas emissions over their lifecycle compared to traditional alternatives. This advantage becomes particularly pronounced in transportation and energy infrastructure applications, where weight reduction and efficiency improvements compound the environmental benefits.

Future sustainability improvements may emerge through development of amorphous metal compositions that eliminate rare earth elements and other environmentally problematic constituents. Research into "green" amorphous alloys utilizing abundant, low-toxicity elements shows promising results for maintaining performance while reducing environmental impact. Additionally, advances in localized manufacturing technologies like additive manufacturing may further reduce the transportation footprint associated with specialized amorphous metal production.

Production processes for amorphous metals have evolved considerably, with modern rapid solidification techniques consuming less energy than traditional metallurgical methods. However, the specialized cooling requirements still present energy efficiency challenges that warrant further optimization. Life cycle assessments indicate that despite higher initial production energy investments, the total environmental impact over the full service life often favors amorphous metals due to their exceptional durability in high-stress environments.

Recycling considerations represent another critical sustainability dimension. Amorphous metals generally maintain their compositional integrity during use, facilitating more efficient recycling processes compared to conventional alloys that may experience elemental segregation under stress. The homogeneous nature of these materials enables higher recovery rates and reduced processing energy during recycling operations, though specialized sorting technologies may be required to separate them from conventional metal waste streams.

The reduced need for lubricants and protective coatings in amorphous metal applications further enhances their environmental profile. In high-stress environments where conventional materials require frequent maintenance involving potentially hazardous substances, amorphous metals can operate with minimal auxiliary materials, reducing chemical exposure risks and disposal challenges.

Carbon footprint analyses across various high-stress applications demonstrate that amorphous metal components typically generate 15-30% lower greenhouse gas emissions over their lifecycle compared to traditional alternatives. This advantage becomes particularly pronounced in transportation and energy infrastructure applications, where weight reduction and efficiency improvements compound the environmental benefits.

Future sustainability improvements may emerge through development of amorphous metal compositions that eliminate rare earth elements and other environmentally problematic constituents. Research into "green" amorphous alloys utilizing abundant, low-toxicity elements shows promising results for maintaining performance while reducing environmental impact. Additionally, advances in localized manufacturing technologies like additive manufacturing may further reduce the transportation footprint associated with specialized amorphous metal production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!