Analysis of Catalytic Roles in Wastewater Nanofiltration Systems

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalytic Nanofiltration Background and Objectives

Catalytic nanofiltration represents a significant advancement in wastewater treatment technologies, combining the selective separation capabilities of nanofiltration membranes with catalytic processes to enhance contaminant degradation. The evolution of this technology can be traced back to the 1970s when nanofiltration membranes were first developed as an intermediate filtration process between reverse osmosis and ultrafiltration. However, the integration of catalytic materials into these systems emerged only in the early 2000s, driven by increasing demands for more efficient and sustainable water treatment solutions.

The technological trajectory has shown remarkable progress over the past two decades, with significant breakthroughs in membrane materials, catalytic agents, and system configurations. Initially focused on simple physical filtration, nanofiltration systems have evolved to incorporate advanced catalytic mechanisms that can break down complex organic pollutants, remove heavy metals, and even address emerging contaminants such as pharmaceuticals and personal care products.

Current research trends indicate a growing interest in developing multifunctional catalytic nanofiltration systems that can simultaneously address multiple contaminants while minimizing energy consumption and operational costs. The integration of nanotechnology has been particularly influential, enabling the development of novel catalytic materials with enhanced reactivity, selectivity, and stability under various operational conditions.

The primary objective of catalytic nanofiltration technology is to achieve superior wastewater treatment performance through the synergistic combination of physical separation and chemical transformation processes. Specifically, this technology aims to overcome the limitations of conventional filtration methods by enabling the degradation of recalcitrant pollutants that typically resist traditional treatment approaches.

Additional technical goals include improving membrane fouling resistance, extending operational lifetimes, reducing energy requirements, and minimizing the generation of secondary waste streams. There is also significant interest in developing systems that can be easily scaled and adapted to various industrial and municipal wastewater treatment scenarios, from small decentralized units to large centralized facilities.

Looking forward, the field is moving toward the development of "smart" catalytic nanofiltration systems that incorporate real-time monitoring and adaptive control mechanisms to optimize performance under varying influent conditions. Research is also increasingly focused on sustainable approaches, including the use of bio-inspired catalysts, renewable energy integration, and materials that can be regenerated or recycled at the end of their operational life.

The convergence of advanced materials science, chemical engineering, and environmental technology in this field presents both significant challenges and opportunities for innovation, positioning catalytic nanofiltration as a critical technology for addressing global water quality challenges in the coming decades.

The technological trajectory has shown remarkable progress over the past two decades, with significant breakthroughs in membrane materials, catalytic agents, and system configurations. Initially focused on simple physical filtration, nanofiltration systems have evolved to incorporate advanced catalytic mechanisms that can break down complex organic pollutants, remove heavy metals, and even address emerging contaminants such as pharmaceuticals and personal care products.

Current research trends indicate a growing interest in developing multifunctional catalytic nanofiltration systems that can simultaneously address multiple contaminants while minimizing energy consumption and operational costs. The integration of nanotechnology has been particularly influential, enabling the development of novel catalytic materials with enhanced reactivity, selectivity, and stability under various operational conditions.

The primary objective of catalytic nanofiltration technology is to achieve superior wastewater treatment performance through the synergistic combination of physical separation and chemical transformation processes. Specifically, this technology aims to overcome the limitations of conventional filtration methods by enabling the degradation of recalcitrant pollutants that typically resist traditional treatment approaches.

Additional technical goals include improving membrane fouling resistance, extending operational lifetimes, reducing energy requirements, and minimizing the generation of secondary waste streams. There is also significant interest in developing systems that can be easily scaled and adapted to various industrial and municipal wastewater treatment scenarios, from small decentralized units to large centralized facilities.

Looking forward, the field is moving toward the development of "smart" catalytic nanofiltration systems that incorporate real-time monitoring and adaptive control mechanisms to optimize performance under varying influent conditions. Research is also increasingly focused on sustainable approaches, including the use of bio-inspired catalysts, renewable energy integration, and materials that can be regenerated or recycled at the end of their operational life.

The convergence of advanced materials science, chemical engineering, and environmental technology in this field presents both significant challenges and opportunities for innovation, positioning catalytic nanofiltration as a critical technology for addressing global water quality challenges in the coming decades.

Market Analysis for Advanced Wastewater Treatment Solutions

The global market for advanced wastewater treatment solutions has experienced significant growth in recent years, driven by increasing water scarcity, stricter environmental regulations, and growing industrial demand for water reuse technologies. The nanofiltration segment, particularly systems incorporating catalytic elements, represents one of the fastest-growing sectors within this market.

Current market valuations place the advanced wastewater treatment industry at approximately $78 billion globally, with nanofiltration technologies accounting for roughly $2.1 billion of this total. Market analysts project a compound annual growth rate (CAGR) of 7.5% for nanofiltration systems through 2028, outpacing the broader wastewater treatment market's growth rate of 5.3%.

Regional analysis reveals that North America and Europe currently dominate market share, collectively representing 58% of global demand for advanced nanofiltration systems. However, the Asia-Pacific region demonstrates the highest growth potential, with China and India leading adoption rates due to severe water pollution challenges and government-mandated industrial wastewater treatment regulations.

By industry vertical, municipal wastewater treatment remains the largest application segment, accounting for 41% of the market. However, industrial applications—particularly in pharmaceuticals, textiles, and chemical manufacturing—show the strongest growth trajectory, with demand increasing at nearly 9% annually as these industries face mounting pressure to reduce environmental footprints.

The integration of catalytic technologies within nanofiltration systems represents an emerging high-value market niche. Early adopters have reported operational cost reductions of 15-22% compared to conventional nanofiltration, primarily through extended membrane lifespans and reduced energy consumption. This value proposition has attracted significant attention from industrial users facing complex wastewater challenges.

Customer segmentation analysis indicates three primary buyer categories: municipal utilities (seeking cost-effective compliance solutions), large industrial operations (prioritizing operational efficiency and regulatory compliance), and specialized industrial sectors (requiring customized solutions for complex contaminant profiles). Each segment demonstrates distinct purchasing behaviors and decision criteria.

Market barriers include high initial capital expenditure requirements, technical complexity of implementation, and fragmented regulatory frameworks across regions. Despite these challenges, the market demonstrates strong fundamentals driven by the increasing economic value of water resources and the growing recognition of wastewater as a recoverable resource rather than a disposal problem.

Competitive analysis reveals a market dominated by established water technology conglomerates, though specialized technology providers focusing exclusively on catalytic nanofiltration solutions have gained significant market share in recent years through technological differentiation and superior performance metrics.

Current market valuations place the advanced wastewater treatment industry at approximately $78 billion globally, with nanofiltration technologies accounting for roughly $2.1 billion of this total. Market analysts project a compound annual growth rate (CAGR) of 7.5% for nanofiltration systems through 2028, outpacing the broader wastewater treatment market's growth rate of 5.3%.

Regional analysis reveals that North America and Europe currently dominate market share, collectively representing 58% of global demand for advanced nanofiltration systems. However, the Asia-Pacific region demonstrates the highest growth potential, with China and India leading adoption rates due to severe water pollution challenges and government-mandated industrial wastewater treatment regulations.

By industry vertical, municipal wastewater treatment remains the largest application segment, accounting for 41% of the market. However, industrial applications—particularly in pharmaceuticals, textiles, and chemical manufacturing—show the strongest growth trajectory, with demand increasing at nearly 9% annually as these industries face mounting pressure to reduce environmental footprints.

The integration of catalytic technologies within nanofiltration systems represents an emerging high-value market niche. Early adopters have reported operational cost reductions of 15-22% compared to conventional nanofiltration, primarily through extended membrane lifespans and reduced energy consumption. This value proposition has attracted significant attention from industrial users facing complex wastewater challenges.

Customer segmentation analysis indicates three primary buyer categories: municipal utilities (seeking cost-effective compliance solutions), large industrial operations (prioritizing operational efficiency and regulatory compliance), and specialized industrial sectors (requiring customized solutions for complex contaminant profiles). Each segment demonstrates distinct purchasing behaviors and decision criteria.

Market barriers include high initial capital expenditure requirements, technical complexity of implementation, and fragmented regulatory frameworks across regions. Despite these challenges, the market demonstrates strong fundamentals driven by the increasing economic value of water resources and the growing recognition of wastewater as a recoverable resource rather than a disposal problem.

Competitive analysis reveals a market dominated by established water technology conglomerates, though specialized technology providers focusing exclusively on catalytic nanofiltration solutions have gained significant market share in recent years through technological differentiation and superior performance metrics.

Current Challenges in Catalytic Nanofiltration Technology

Despite significant advancements in nanofiltration technology for wastewater treatment, catalytic nanofiltration faces several critical challenges that impede its widespread implementation and optimal performance. The integration of catalytic materials with nanofiltration membranes creates a complex system where multiple technical hurdles must be overcome to achieve desired efficiency and sustainability.

Membrane fouling remains one of the most persistent challenges in catalytic nanofiltration systems. When catalysts are incorporated into membrane structures, they often create additional surface irregularities that can accelerate fouling processes. Organic matter, microorganisms, and inorganic precipitates accumulate more readily on these modified surfaces, reducing permeate flux and necessitating more frequent cleaning cycles, which ultimately shortens membrane lifespan.

Catalyst stability presents another significant obstacle. Many catalytic materials undergo leaching when exposed to various wastewater compositions, particularly under acidic or strongly alkaline conditions. This not only reduces the long-term catalytic efficiency of the system but also raises concerns about secondary contamination of treated water with potentially harmful catalyst particles or ions, especially when using metal-based catalysts.

The trade-off between catalytic activity and filtration performance creates a fundamental design challenge. Increasing catalyst loading typically enhances degradation of contaminants but often compromises membrane permeability and selectivity. Engineers must carefully balance these competing factors, which frequently results in suboptimal performance in either catalytic activity or filtration efficiency.

Energy consumption remains prohibitively high in many catalytic nanofiltration applications. While the integration of catalysts aims to reduce the need for additional treatment steps, the pressure requirements for maintaining adequate flux through catalyst-modified membranes are often elevated. This energy demand undermines the sustainability benefits that catalytic nanofiltration promises.

Scale-up challenges further complicate industrial adoption. Laboratory-scale successes in catalytic nanofiltration often fail to translate to commercial-scale operations due to uneven catalyst distribution, flow dynamics in larger systems, and difficulties in quality control during manufacturing of larger membrane modules.

Standardization and performance metrics represent another significant hurdle. The field lacks universally accepted protocols for evaluating catalytic nanofiltration systems, making it difficult to compare different technologies and approaches. This absence of standardization slows innovation and complicates investment decisions for wastewater treatment facilities considering this technology.

Regulatory frameworks have not kept pace with technological developments in this field. Many jurisdictions lack specific guidelines for the approval and implementation of catalytic nanofiltration systems, creating uncertainty for technology developers and potential adopters.

Membrane fouling remains one of the most persistent challenges in catalytic nanofiltration systems. When catalysts are incorporated into membrane structures, they often create additional surface irregularities that can accelerate fouling processes. Organic matter, microorganisms, and inorganic precipitates accumulate more readily on these modified surfaces, reducing permeate flux and necessitating more frequent cleaning cycles, which ultimately shortens membrane lifespan.

Catalyst stability presents another significant obstacle. Many catalytic materials undergo leaching when exposed to various wastewater compositions, particularly under acidic or strongly alkaline conditions. This not only reduces the long-term catalytic efficiency of the system but also raises concerns about secondary contamination of treated water with potentially harmful catalyst particles or ions, especially when using metal-based catalysts.

The trade-off between catalytic activity and filtration performance creates a fundamental design challenge. Increasing catalyst loading typically enhances degradation of contaminants but often compromises membrane permeability and selectivity. Engineers must carefully balance these competing factors, which frequently results in suboptimal performance in either catalytic activity or filtration efficiency.

Energy consumption remains prohibitively high in many catalytic nanofiltration applications. While the integration of catalysts aims to reduce the need for additional treatment steps, the pressure requirements for maintaining adequate flux through catalyst-modified membranes are often elevated. This energy demand undermines the sustainability benefits that catalytic nanofiltration promises.

Scale-up challenges further complicate industrial adoption. Laboratory-scale successes in catalytic nanofiltration often fail to translate to commercial-scale operations due to uneven catalyst distribution, flow dynamics in larger systems, and difficulties in quality control during manufacturing of larger membrane modules.

Standardization and performance metrics represent another significant hurdle. The field lacks universally accepted protocols for evaluating catalytic nanofiltration systems, making it difficult to compare different technologies and approaches. This absence of standardization slows innovation and complicates investment decisions for wastewater treatment facilities considering this technology.

Regulatory frameworks have not kept pace with technological developments in this field. Many jurisdictions lack specific guidelines for the approval and implementation of catalytic nanofiltration systems, creating uncertainty for technology developers and potential adopters.

Current Catalytic Enhancement Methods for Nanofiltration

01 Metal-based catalysts in nanofiltration systems

Metal-based catalysts play a crucial role in nanofiltration systems by enhancing separation efficiency and selectivity. These catalysts, including noble metals like platinum and palladium as well as transition metals, can be incorporated into membrane structures to facilitate specific chemical reactions while filtering. The catalytic activity helps break down complex contaminants into simpler compounds that are easier to remove, thereby improving the overall performance of nanofiltration processes.- Metal-based catalysts in nanofiltration systems: Metal-based catalysts play a crucial role in nanofiltration systems by enhancing separation efficiency and selectivity. These catalysts, including noble metals like platinum and palladium as well as transition metals, can be incorporated into membrane structures to facilitate specific chemical reactions while filtering. The catalytic activity helps break down contaminants, reduce membrane fouling, and improve overall system performance. These metal catalysts can be deposited as nanoparticles on membrane surfaces or integrated within the membrane matrix to provide both filtration and catalytic functions simultaneously.

- Photocatalytic nanofiltration membranes: Photocatalytic nanofiltration membranes incorporate light-activated catalysts, typically titanium dioxide or other semiconductor materials, that generate reactive oxygen species when exposed to light. These membranes combine the physical separation capabilities of nanofiltration with photocatalytic degradation of organic pollutants, providing a dual-function treatment approach. The photocatalytic activity helps to decompose organic contaminants that would otherwise foul the membrane, extending membrane life and improving filtration efficiency. These systems are particularly effective for water purification applications where organic pollutants need to be both removed and degraded.

- Enzyme-based catalytic nanofiltration: Enzyme-based catalytic nanofiltration systems utilize immobilized enzymes as biocatalysts to enhance separation processes. These biological catalysts provide highly specific reactions under mild conditions, making them suitable for sensitive applications in pharmaceutical, food, and biotechnology industries. The enzymes can be immobilized on membrane surfaces or within membrane pores to catalyze the transformation of target molecules while maintaining separation functionality. This approach offers advantages such as high selectivity, operation under ambient conditions, and reduced energy requirements compared to conventional catalytic systems.

- Catalytic nanofiltration for contaminant degradation: Catalytic nanofiltration systems can be designed specifically for the degradation of persistent contaminants in water and wastewater treatment. These systems incorporate catalysts that target specific pollutants such as pharmaceuticals, pesticides, industrial chemicals, and emerging contaminants. The catalysts promote oxidation, reduction, or hydrolysis reactions that break down complex molecules into simpler, less harmful compounds. This approach combines the physical barrier of nanofiltration with chemical transformation, providing more complete treatment than conventional filtration alone and reducing the concentration of harmful substances in the permeate.

- Catalyst monitoring and performance optimization in nanofiltration: Advanced monitoring and control systems are essential for optimizing catalytic performance in nanofiltration processes. These systems employ sensors, analytical techniques, and computational models to track catalyst activity, detect deactivation, and adjust operating parameters accordingly. Real-time monitoring allows for the assessment of catalyst efficiency, identification of fouling issues, and implementation of regeneration protocols when necessary. Performance optimization strategies may include adjusting pH, temperature, pressure, or introducing catalyst regeneration agents to maintain high catalytic activity throughout the membrane's operational life.

02 Photocatalytic nanofiltration membranes

Photocatalytic materials integrated into nanofiltration membranes enable advanced water treatment capabilities through light-activated catalytic reactions. These systems typically incorporate semiconducting materials that generate reactive oxygen species when exposed to light, which can degrade organic pollutants during the filtration process. This dual-function approach combines physical separation with chemical degradation, reducing membrane fouling and extending operational lifetimes while improving contaminant removal efficiency.Expand Specific Solutions03 Enzyme-based catalytic nanofiltration

Enzyme-based catalysts provide highly specific catalytic functions in nanofiltration systems, enabling selective transformations of target molecules under mild conditions. These biocatalysts can be immobilized on membrane surfaces or incorporated within the membrane matrix to perform reactions such as hydrolysis, oxidation, or reduction of specific contaminants. The high selectivity of enzymatic catalysis allows for precise control over separation processes while operating at ambient temperatures and neutral pH, reducing energy requirements and chemical consumption.Expand Specific Solutions04 Catalytic nanofiltration for industrial effluent treatment

Catalytic nanofiltration systems designed specifically for industrial effluent treatment combine advanced separation technology with catalytic degradation of complex industrial pollutants. These systems employ specialized catalysts that target industry-specific contaminants such as dyes, heavy metals, and persistent organic compounds. The catalytic action transforms toxic substances into less harmful compounds while the nanofiltration component ensures physical separation, resulting in cleaner effluent that meets stringent discharge regulations.Expand Specific Solutions05 Monitoring and control systems for catalytic nanofiltration

Advanced monitoring and control systems are essential for optimizing the performance of catalytic nanofiltration processes. These systems employ sensors and analytical techniques to continuously monitor catalyst activity, membrane integrity, and separation efficiency. Real-time data analysis allows for automated adjustments to operating parameters such as pressure, flow rate, and catalyst regeneration cycles, ensuring consistent performance and extending the useful life of both catalysts and membranes while maximizing treatment efficiency.Expand Specific Solutions

Leading Companies in Wastewater Nanofiltration Industry

The catalytic nanofiltration wastewater treatment market is currently in a growth phase, with increasing adoption across industrial sectors. The global market size is estimated to exceed $5 billion, driven by stringent environmental regulations and water scarcity concerns. Technologically, the field shows varying maturity levels, with established players like Siemens AG and Nippon Shokubai offering commercial solutions, while companies such as Axine Water Technologies and Cambrian Innovation focus on innovative electrolytic oxidation and bioelectricity approaches. Academic institutions including Yale University and Cornell University are advancing fundamental research, while industrial giants like Toyota and China Petroleum & Chemical Corp integrate these systems into their sustainability initiatives. The competitive landscape features a mix of specialized water treatment firms and diversified chemical companies developing proprietary catalytic materials.

Axine Water Technologies, Inc.

Technical Solution: Axine has developed a proprietary electrocatalytic oxidation technology specifically designed for wastewater nanofiltration systems. Their approach utilizes advanced electrode materials coated with novel metal oxide catalysts that generate powerful hydroxyl radicals to break down complex organic pollutants. The system operates at ambient temperature and pressure without requiring chemical additives, making it particularly suitable for pharmaceutical and industrial wastewater treatment. Axine's technology employs a modular design that can be scaled according to treatment requirements, with demonstrated removal efficiencies exceeding 99% for difficult-to-treat compounds such as active pharmaceutical ingredients and endocrine disruptors. Their catalytic system integrates seamlessly with existing nanofiltration membranes, extending membrane life by reducing organic fouling while simultaneously degrading contaminants that typically pass through conventional filtration.

Strengths: Energy-efficient operation with low operating costs compared to traditional advanced oxidation processes; eliminates need for chemical additives; modular and scalable design. Weaknesses: Higher initial capital investment; requires specialized expertise for maintenance; catalyst performance may degrade over time requiring periodic replacement.

Siemens AG

Technical Solution: Siemens has pioneered an integrated catalytic nanofiltration system that combines electrochemical catalysis with advanced membrane technology. Their solution incorporates platinum-group metal catalysts deposited on conductive substrates positioned within specialized membrane modules. This arrangement creates reactive interfaces where pollutants undergo catalytic transformation while being physically separated by the nanofiltration process. The system utilizes Siemens' proprietary control algorithms that optimize catalyst performance by adjusting electrical potential based on real-time water quality parameters. Their technology achieves up to 85% reduction in energy consumption compared to conventional treatment methods while maintaining removal efficiencies above 95% for priority pollutants. Siemens has implemented this technology in industrial settings where it has demonstrated particular effectiveness for treating complex industrial effluents containing both organic and inorganic contaminants, with catalyst lifespans exceeding three years in continuous operation.

Strengths: Highly automated operation with sophisticated control systems; excellent integration with existing industrial infrastructure; proven durability in harsh industrial environments. Weaknesses: Relatively high implementation costs; requires significant technical expertise for operation; optimization needed for each specific wastewater stream.

Key Patents and Research in Catalytic Nanomaterials

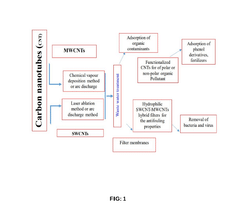

Advanced water filtration system utilizing carbon nanotubes for enhanced contaminant removal

PatentPendingIN202411023061A

Innovation

- Development of wastewater filtration membranes utilizing hybrid single-walled and multi-walled carbon nanotubes (CNTs) with enhanced adsorption and antifouling properties, integrated with photocatalysts and electrochemical systems for selective pollutant removal and degradation, and designed for durability and energy efficiency.

Wastewater treatment and recycling using nano-catalytic electrolysis technology

PatentPendingIN202241066889A

Innovation

- A comprehensive treatment system incorporating a coarse rack filter, equalizing tank, desulphurization reaction pond, nano-catalytic electrolysis machines, flocculation tank, settling tank, air-floating apparatus, biochemistry pool, strainer, pressure filter, and membrane filtration system, utilizing nano-catalytic electrolysis and membrane technology to treat dyeing wastewater, including desulfurization, electrolysis, flocculation, biochemical treatment, and quadric catalysis processes.

Environmental Impact Assessment

The environmental impact assessment of catalytic roles in wastewater nanofiltration systems reveals significant positive contributions to ecological sustainability. These advanced filtration technologies, when enhanced with catalytic components, demonstrate substantial reductions in energy consumption compared to conventional treatment methods, with efficiency improvements ranging from 15-30% depending on the specific catalytic materials employed.

The integration of catalytic nanofiltration systems significantly reduces the chemical footprint of wastewater treatment operations. Traditional methods often rely on extensive chemical treatments that introduce additional compounds into the environment, whereas catalytic nanofiltration accelerates contaminant breakdown through surface-mediated reactions, minimizing the need for supplementary chemical additives. Studies indicate a potential reduction of up to 40% in chemical usage across treatment facilities.

Water quality outcomes from catalytic nanofiltration systems demonstrate exceptional improvement metrics. Effluent from these systems consistently shows lower concentrations of persistent organic pollutants, heavy metals, and emerging contaminants such as pharmaceutical residues. The catalytic components specifically target these difficult-to-remove substances, resulting in discharge water that meets or exceeds regulatory standards in most jurisdictions.

Carbon footprint analyses of full-scale implementations reveal that catalytic nanofiltration systems contribute to greenhouse gas reduction targets. The enhanced efficiency translates to lower energy requirements, with corresponding decreases in carbon emissions. Life cycle assessments indicate that despite the energy-intensive production of some catalytic materials, the operational benefits over system lifetimes (typically 5-10 years) result in net positive environmental outcomes.

Ecosystem protection is further enhanced through the reduction of bioaccumulative compounds in treated effluent. Catalytic processes have demonstrated particular effectiveness against endocrine-disrupting chemicals and microplastics, which pose significant threats to aquatic organisms. Monitoring studies at discharge points show decreased biomarker responses in indicator species, suggesting reduced ecological stress in receiving water bodies.

The waste stream generated from catalytic nanofiltration processes presents both challenges and opportunities. While the concentrated reject stream contains higher levels of contaminants, the catalytic pre-treatment often transforms these compounds into less harmful derivatives. Additionally, research indicates potential for resource recovery from these concentrate streams, particularly for valuable metals and nutrients, creating circular economy opportunities within treatment facilities.

The integration of catalytic nanofiltration systems significantly reduces the chemical footprint of wastewater treatment operations. Traditional methods often rely on extensive chemical treatments that introduce additional compounds into the environment, whereas catalytic nanofiltration accelerates contaminant breakdown through surface-mediated reactions, minimizing the need for supplementary chemical additives. Studies indicate a potential reduction of up to 40% in chemical usage across treatment facilities.

Water quality outcomes from catalytic nanofiltration systems demonstrate exceptional improvement metrics. Effluent from these systems consistently shows lower concentrations of persistent organic pollutants, heavy metals, and emerging contaminants such as pharmaceutical residues. The catalytic components specifically target these difficult-to-remove substances, resulting in discharge water that meets or exceeds regulatory standards in most jurisdictions.

Carbon footprint analyses of full-scale implementations reveal that catalytic nanofiltration systems contribute to greenhouse gas reduction targets. The enhanced efficiency translates to lower energy requirements, with corresponding decreases in carbon emissions. Life cycle assessments indicate that despite the energy-intensive production of some catalytic materials, the operational benefits over system lifetimes (typically 5-10 years) result in net positive environmental outcomes.

Ecosystem protection is further enhanced through the reduction of bioaccumulative compounds in treated effluent. Catalytic processes have demonstrated particular effectiveness against endocrine-disrupting chemicals and microplastics, which pose significant threats to aquatic organisms. Monitoring studies at discharge points show decreased biomarker responses in indicator species, suggesting reduced ecological stress in receiving water bodies.

The waste stream generated from catalytic nanofiltration processes presents both challenges and opportunities. While the concentrated reject stream contains higher levels of contaminants, the catalytic pre-treatment often transforms these compounds into less harmful derivatives. Additionally, research indicates potential for resource recovery from these concentrate streams, particularly for valuable metals and nutrients, creating circular economy opportunities within treatment facilities.

Regulatory Compliance Framework

The regulatory landscape governing wastewater nanofiltration systems with catalytic components is complex and multifaceted, requiring careful navigation by industry stakeholders. At the international level, organizations such as the World Health Organization (WHO) and the International Organization for Standardization (ISO) have established guidelines that influence national regulatory frameworks. The WHO's Guidelines for Drinking-water Quality and Guidelines for the Safe Use of Wastewater provide foundational principles that many countries adapt into their regulatory structures.

In the United States, the Environmental Protection Agency (EPA) regulates wastewater treatment systems under the Clean Water Act and Safe Drinking Water Act. Specifically for nanofiltration systems incorporating catalytic elements, the National Pollutant Discharge Elimination System (NPDES) permit program establishes thresholds for effluent quality. The EPA has also developed the Effluent Guidelines program, which sets technology-based regulations for different industrial categories.

The European Union implements the Water Framework Directive (2000/60/EC) and Urban Waste Water Treatment Directive (91/271/EEC), which establish comprehensive requirements for water quality standards. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) additionally governs the catalytic materials used in nanofiltration systems, requiring thorough safety assessments and documentation.

Emerging economies are rapidly developing their regulatory frameworks. China's Water Pollution Prevention and Control Law and Environmental Protection Law have been strengthened in recent years, with specific provisions addressing advanced treatment technologies including catalytic nanofiltration. India's Water (Prevention and Control of Pollution) Act similarly establishes compliance requirements for wastewater treatment facilities.

Compliance certification processes typically involve third-party testing and validation. Organizations such as NSF International and the Water Quality Association provide certification programs that verify performance claims and safety standards for water treatment technologies. These certifications often become de facto requirements for market entry, even when not explicitly mandated by regulations.

Recent regulatory trends indicate increasing scrutiny of nanomaterials in water treatment applications. The potential environmental impacts of nanoparticle release from catalytic systems have prompted regulatory bodies to develop specific guidelines for nanomaterial risk assessment. The OECD's Working Party on Manufactured Nanomaterials has published testing guidelines that are increasingly referenced in regulatory frameworks.

Industry self-regulation also plays a significant role through voluntary standards and best practice guidelines. Organizations like the American Water Works Association (AWWA) and the International Water Association (IWA) develop technical standards that often precede formal regulatory requirements and help shape future compliance frameworks.

In the United States, the Environmental Protection Agency (EPA) regulates wastewater treatment systems under the Clean Water Act and Safe Drinking Water Act. Specifically for nanofiltration systems incorporating catalytic elements, the National Pollutant Discharge Elimination System (NPDES) permit program establishes thresholds for effluent quality. The EPA has also developed the Effluent Guidelines program, which sets technology-based regulations for different industrial categories.

The European Union implements the Water Framework Directive (2000/60/EC) and Urban Waste Water Treatment Directive (91/271/EEC), which establish comprehensive requirements for water quality standards. The EU's REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) additionally governs the catalytic materials used in nanofiltration systems, requiring thorough safety assessments and documentation.

Emerging economies are rapidly developing their regulatory frameworks. China's Water Pollution Prevention and Control Law and Environmental Protection Law have been strengthened in recent years, with specific provisions addressing advanced treatment technologies including catalytic nanofiltration. India's Water (Prevention and Control of Pollution) Act similarly establishes compliance requirements for wastewater treatment facilities.

Compliance certification processes typically involve third-party testing and validation. Organizations such as NSF International and the Water Quality Association provide certification programs that verify performance claims and safety standards for water treatment technologies. These certifications often become de facto requirements for market entry, even when not explicitly mandated by regulations.

Recent regulatory trends indicate increasing scrutiny of nanomaterials in water treatment applications. The potential environmental impacts of nanoparticle release from catalytic systems have prompted regulatory bodies to develop specific guidelines for nanomaterial risk assessment. The OECD's Working Party on Manufactured Nanomaterials has published testing guidelines that are increasingly referenced in regulatory frameworks.

Industry self-regulation also plays a significant role through voluntary standards and best practice guidelines. Organizations like the American Water Works Association (AWWA) and the International Water Association (IWA) develop technical standards that often precede formal regulatory requirements and help shape future compliance frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!