Catalyst Developments for Optimized Wastewater Nanofiltration

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Catalyst Evolution and Objectives

Nanofiltration technology has evolved significantly over the past three decades, transforming from a niche separation process to a critical component in advanced wastewater treatment systems. Initially developed in the late 1980s as an intermediate filtration technology between reverse osmosis and ultrafiltration, nanofiltration has gained prominence due to its unique ability to selectively remove multivalent ions, organic compounds, and micropollutants while operating at lower pressures than reverse osmosis.

The evolution of catalysts for nanofiltration represents a particularly dynamic area of development. Early nanofiltration membranes relied primarily on physical separation mechanisms, with limited chemical selectivity. The introduction of catalytic materials in the 1990s marked a significant turning point, enabling enhanced removal of specific contaminants through chemical transformation rather than mere physical rejection.

By the early 2000s, researchers began incorporating metal-based catalysts, particularly titanium dioxide and iron oxides, into nanofiltration membranes to facilitate photocatalytic degradation of organic pollutants. This approach addressed a fundamental limitation of conventional membranes: their tendency to become fouled by organic matter. The integration of catalytic functionality with separation capability represented a paradigm shift in membrane technology design philosophy.

Recent years have witnessed the emergence of advanced nanostructured catalysts, including metal-organic frameworks (MOFs), graphene-based materials, and engineered nanoparticles with precisely controlled morphologies. These materials offer unprecedented surface area-to-volume ratios and can be tailored to target specific contaminants with remarkable selectivity. The development of dual-function catalytic nanofiltration membranes that simultaneously remove and degrade contaminants has been particularly noteworthy.

The primary objective of current catalyst development for wastewater nanofiltration is to create systems that combine high permeability with excellent selectivity while maintaining long-term operational stability. Researchers aim to develop catalysts that can effectively degrade recalcitrant organic pollutants, remove heavy metals, and inactivate pathogens in a single treatment step. Additionally, there is growing interest in catalysts that can operate efficiently under ambient conditions without requiring additional energy inputs.

Another critical objective is addressing the challenge of membrane fouling, which remains a significant operational constraint. Novel anti-fouling catalysts that prevent biofilm formation and organic matter accumulation are being actively pursued. The development of self-cleaning membranes that utilize catalytic reactions to periodically regenerate the membrane surface represents an ambitious but potentially transformative goal in this field.

Looking forward, the integration of smart materials that can adapt their catalytic activity in response to changing wastewater compositions represents the frontier of research in this domain. The ultimate objective is to develop sustainable, energy-efficient nanofiltration systems that can be deployed at various scales, from decentralized point-of-use applications to large municipal treatment facilities.

The evolution of catalysts for nanofiltration represents a particularly dynamic area of development. Early nanofiltration membranes relied primarily on physical separation mechanisms, with limited chemical selectivity. The introduction of catalytic materials in the 1990s marked a significant turning point, enabling enhanced removal of specific contaminants through chemical transformation rather than mere physical rejection.

By the early 2000s, researchers began incorporating metal-based catalysts, particularly titanium dioxide and iron oxides, into nanofiltration membranes to facilitate photocatalytic degradation of organic pollutants. This approach addressed a fundamental limitation of conventional membranes: their tendency to become fouled by organic matter. The integration of catalytic functionality with separation capability represented a paradigm shift in membrane technology design philosophy.

Recent years have witnessed the emergence of advanced nanostructured catalysts, including metal-organic frameworks (MOFs), graphene-based materials, and engineered nanoparticles with precisely controlled morphologies. These materials offer unprecedented surface area-to-volume ratios and can be tailored to target specific contaminants with remarkable selectivity. The development of dual-function catalytic nanofiltration membranes that simultaneously remove and degrade contaminants has been particularly noteworthy.

The primary objective of current catalyst development for wastewater nanofiltration is to create systems that combine high permeability with excellent selectivity while maintaining long-term operational stability. Researchers aim to develop catalysts that can effectively degrade recalcitrant organic pollutants, remove heavy metals, and inactivate pathogens in a single treatment step. Additionally, there is growing interest in catalysts that can operate efficiently under ambient conditions without requiring additional energy inputs.

Another critical objective is addressing the challenge of membrane fouling, which remains a significant operational constraint. Novel anti-fouling catalysts that prevent biofilm formation and organic matter accumulation are being actively pursued. The development of self-cleaning membranes that utilize catalytic reactions to periodically regenerate the membrane surface represents an ambitious but potentially transformative goal in this field.

Looking forward, the integration of smart materials that can adapt their catalytic activity in response to changing wastewater compositions represents the frontier of research in this domain. The ultimate objective is to develop sustainable, energy-efficient nanofiltration systems that can be deployed at various scales, from decentralized point-of-use applications to large municipal treatment facilities.

Wastewater Treatment Market Analysis

The global wastewater treatment market has experienced significant growth in recent years, driven by increasing water scarcity, stringent environmental regulations, and growing industrialization. As of 2023, the market was valued at approximately 250 billion USD, with projections indicating a compound annual growth rate (CAGR) of 6.5% through 2030. The nanofiltration segment specifically has been expanding at an accelerated rate of 8.2% annually, outpacing conventional filtration technologies.

Regional analysis reveals that North America and Europe currently dominate the wastewater treatment market, accounting for over 60% of global revenue. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth due to rapid industrialization, urbanization, and increasing government investments in water infrastructure. Latin America and Africa represent emerging markets with substantial growth potential as these regions address critical water quality challenges.

Industry segmentation shows that municipal wastewater treatment constitutes approximately 65% of the market, while industrial applications make up the remaining 35%. Within industrial applications, the chemical, pharmaceutical, food and beverage, and textile sectors are the primary contributors to market demand. Catalyst-enhanced nanofiltration technologies are gaining particular traction in these industries due to their ability to remove specific contaminants while maintaining operational efficiency.

Market drivers for advanced wastewater treatment solutions include increasingly stringent discharge regulations, growing water reuse initiatives, and rising costs of freshwater. The European Union's Water Framework Directive and the United States EPA's Clean Water Act continue to push industries toward adopting more effective treatment technologies. Additionally, corporate sustainability goals and ESG (Environmental, Social, and Governance) reporting requirements are incentivizing businesses to invest in advanced wastewater treatment solutions.

Consumer trends indicate a growing preference for treatment technologies that minimize chemical usage, reduce energy consumption, and generate less waste. Catalyst-enhanced nanofiltration addresses these concerns by improving filtration efficiency while reducing operational costs. Market research indicates that solutions offering a demonstrable return on investment through energy savings or recovered resources are particularly attractive to both municipal and industrial customers.

Competitive analysis reveals that the market remains fragmented, with numerous specialized players alongside major water treatment corporations. Recent merger and acquisition activity suggests market consolidation is underway, with technology-focused startups being primary acquisition targets for established companies seeking to enhance their technological capabilities in specialized areas such as catalytic nanofiltration.

Regional analysis reveals that North America and Europe currently dominate the wastewater treatment market, accounting for over 60% of global revenue. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth due to rapid industrialization, urbanization, and increasing government investments in water infrastructure. Latin America and Africa represent emerging markets with substantial growth potential as these regions address critical water quality challenges.

Industry segmentation shows that municipal wastewater treatment constitutes approximately 65% of the market, while industrial applications make up the remaining 35%. Within industrial applications, the chemical, pharmaceutical, food and beverage, and textile sectors are the primary contributors to market demand. Catalyst-enhanced nanofiltration technologies are gaining particular traction in these industries due to their ability to remove specific contaminants while maintaining operational efficiency.

Market drivers for advanced wastewater treatment solutions include increasingly stringent discharge regulations, growing water reuse initiatives, and rising costs of freshwater. The European Union's Water Framework Directive and the United States EPA's Clean Water Act continue to push industries toward adopting more effective treatment technologies. Additionally, corporate sustainability goals and ESG (Environmental, Social, and Governance) reporting requirements are incentivizing businesses to invest in advanced wastewater treatment solutions.

Consumer trends indicate a growing preference for treatment technologies that minimize chemical usage, reduce energy consumption, and generate less waste. Catalyst-enhanced nanofiltration addresses these concerns by improving filtration efficiency while reducing operational costs. Market research indicates that solutions offering a demonstrable return on investment through energy savings or recovered resources are particularly attractive to both municipal and industrial customers.

Competitive analysis reveals that the market remains fragmented, with numerous specialized players alongside major water treatment corporations. Recent merger and acquisition activity suggests market consolidation is underway, with technology-focused startups being primary acquisition targets for established companies seeking to enhance their technological capabilities in specialized areas such as catalytic nanofiltration.

Current Catalyst Technologies and Barriers

Current catalyst technologies for wastewater nanofiltration primarily focus on enhancing membrane performance through surface modification and functional material integration. Metal-based catalysts, particularly those utilizing noble metals like platinum, palladium, and gold, demonstrate exceptional catalytic activity for degrading organic pollutants. These catalysts operate through redox mechanisms that transform complex organic compounds into simpler, less harmful substances. However, their widespread implementation faces significant barriers due to high costs and limited availability of precious metals.

Transition metal oxides represent another important category, with titanium dioxide (TiO2), zinc oxide (ZnO), and iron oxides gaining prominence for their photocatalytic properties. These materials can be activated by UV or visible light to generate reactive oxygen species that decompose contaminants. While more cost-effective than noble metals, their efficiency is often compromised by rapid electron-hole recombination and limited light absorption range.

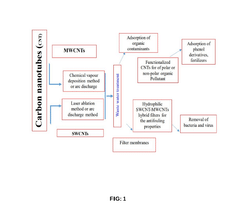

Carbon-based catalysts, including activated carbon, graphene, and carbon nanotubes, offer excellent adsorption capabilities and serve as supports for other catalytic materials. Their high surface area and tunable surface chemistry make them versatile components in nanofiltration systems. Nevertheless, challenges persist in achieving uniform dispersion and maintaining long-term stability under harsh wastewater conditions.

Composite catalysts combining multiple active components have emerged as promising solutions to overcome individual limitations. These hybrid systems often demonstrate synergistic effects, enhancing overall catalytic performance. However, complex synthesis procedures and difficulty in controlling the precise structure-property relationships present significant technical barriers to their optimization and scale-up.

Biocatalysts, including enzymes and microbial systems, offer highly selective degradation pathways for specific contaminants with minimal energy requirements. Despite these advantages, their application in nanofiltration faces challenges related to stability, recovery, and sensitivity to environmental conditions such as pH, temperature, and the presence of inhibitors.

A critical barrier across all catalyst technologies is membrane fouling, which significantly reduces filtration efficiency and catalyst lifespan. Current anti-fouling strategies include surface hydrophilization, incorporation of antimicrobial agents, and development of self-cleaning mechanisms, yet these approaches often compromise other performance parameters such as selectivity or mechanical strength.

Catalyst leaching represents another persistent challenge, particularly for nanoparticle-based systems, raising concerns about secondary contamination and catalyst longevity. Additionally, the complex and variable composition of real wastewater streams often leads to catalyst poisoning and deactivation, necessitating more robust and adaptable catalytic systems for practical applications.

Transition metal oxides represent another important category, with titanium dioxide (TiO2), zinc oxide (ZnO), and iron oxides gaining prominence for their photocatalytic properties. These materials can be activated by UV or visible light to generate reactive oxygen species that decompose contaminants. While more cost-effective than noble metals, their efficiency is often compromised by rapid electron-hole recombination and limited light absorption range.

Carbon-based catalysts, including activated carbon, graphene, and carbon nanotubes, offer excellent adsorption capabilities and serve as supports for other catalytic materials. Their high surface area and tunable surface chemistry make them versatile components in nanofiltration systems. Nevertheless, challenges persist in achieving uniform dispersion and maintaining long-term stability under harsh wastewater conditions.

Composite catalysts combining multiple active components have emerged as promising solutions to overcome individual limitations. These hybrid systems often demonstrate synergistic effects, enhancing overall catalytic performance. However, complex synthesis procedures and difficulty in controlling the precise structure-property relationships present significant technical barriers to their optimization and scale-up.

Biocatalysts, including enzymes and microbial systems, offer highly selective degradation pathways for specific contaminants with minimal energy requirements. Despite these advantages, their application in nanofiltration faces challenges related to stability, recovery, and sensitivity to environmental conditions such as pH, temperature, and the presence of inhibitors.

A critical barrier across all catalyst technologies is membrane fouling, which significantly reduces filtration efficiency and catalyst lifespan. Current anti-fouling strategies include surface hydrophilization, incorporation of antimicrobial agents, and development of self-cleaning mechanisms, yet these approaches often compromise other performance parameters such as selectivity or mechanical strength.

Catalyst leaching represents another persistent challenge, particularly for nanoparticle-based systems, raising concerns about secondary contamination and catalyst longevity. Additionally, the complex and variable composition of real wastewater streams often leads to catalyst poisoning and deactivation, necessitating more robust and adaptable catalytic systems for practical applications.

Existing Catalyst Solutions for Nanofiltration

01 Metal-based catalysts for nanofiltration enhancement

Metal-based catalysts can significantly improve nanofiltration processes by enhancing membrane performance and selectivity. These catalysts, including noble metals and transition metal compounds, can be incorporated into membrane structures to facilitate targeted separation of molecules and ions. The catalytic activity helps reduce membrane fouling and increases flux rates while maintaining high rejection rates of contaminants. These innovations enable more efficient water purification and industrial separation processes.- Metal-based catalysts for nanofiltration enhancement: Metal-based catalysts can significantly improve nanofiltration processes by enhancing membrane performance and selectivity. These catalysts, including noble metals and transition metal oxides, can be incorporated into membrane structures to facilitate targeted separation of molecules and ions. The catalytic activity helps reduce membrane fouling and improves flux rates during filtration operations, leading to more efficient separation processes and extended membrane lifespans.

- Nanoparticle catalysts for membrane performance optimization: Nanoparticle catalysts offer unique advantages in nanofiltration optimization due to their high surface area and tunable properties. When incorporated into filtration membranes, these nanoparticles can enhance separation efficiency, improve contaminant removal, and provide antimicrobial properties. Various types of nanoparticles, including metal oxides and carbon-based materials, can be functionalized to target specific contaminants while maintaining high water flux through the membrane.

- Photocatalytic systems for enhanced nanofiltration: Photocatalytic materials can be integrated into nanofiltration systems to provide additional treatment capabilities through light-activated processes. These catalysts, when exposed to appropriate wavelengths of light, generate reactive species that can degrade organic contaminants during the filtration process. The combination of photocatalysis with nanofiltration creates a dual-function system that both separates and degrades pollutants, resulting in more complete water treatment and reduced membrane fouling.

- Biocatalysts for sustainable nanofiltration processes: Biocatalysts, including enzymes and microbial systems, offer environmentally friendly approaches to nanofiltration optimization. These biological catalysts can be immobilized on membrane surfaces to target specific contaminants or foulants, enhancing separation efficiency while operating under mild conditions. Biocatalytic nanofiltration systems require less energy and fewer chemical inputs compared to conventional methods, making them particularly valuable for sustainable water treatment applications and sensitive separation processes.

- Composite catalyst systems for multifunctional nanofiltration: Composite catalyst systems combine multiple catalytic materials to create synergistic effects in nanofiltration applications. These hybrid systems integrate different types of catalysts, such as metals with polymers or inorganic materials with biocatalysts, to address complex separation challenges. The resulting multifunctional membranes can simultaneously perform several tasks, including selective separation, contaminant degradation, and self-cleaning, leading to more robust and versatile nanofiltration processes with extended operational lifetimes.

02 Nanoparticle catalysts for membrane performance optimization

Nanoparticle catalysts offer unique advantages in nanofiltration optimization due to their high surface area and tunable properties. When integrated into filtration membranes, these nanoparticles can catalyze reactions that break down foulants, improve permeability, and enhance separation efficiency. Various nanoparticle compositions, including metal oxides and carbon-based materials, can be tailored for specific filtration challenges. The controlled distribution of nanoparticles throughout the membrane structure ensures consistent performance and extended operational lifetime.Expand Specific Solutions03 Photocatalytic systems for advanced nanofiltration

Photocatalytic systems represent an innovative approach to nanofiltration optimization by utilizing light-activated catalysts to enhance separation processes. These systems incorporate photosensitive materials that, when exposed to light, generate reactive species that can degrade contaminants while maintaining membrane integrity. The integration of photocatalysts into nanofiltration membranes enables self-cleaning properties, reduces biofouling, and extends membrane lifespan. This technology is particularly effective for treating persistent organic pollutants and emerging contaminants in water treatment applications.Expand Specific Solutions04 Biocatalytic approaches for sustainable nanofiltration

Biocatalytic approaches utilize enzymes and biological catalysts to enhance nanofiltration processes in an environmentally friendly manner. These biological catalysts can be immobilized on membrane surfaces or incorporated within the membrane matrix to facilitate specific reactions that improve filtration efficiency. The selective nature of biocatalysts allows for targeted removal of contaminants while minimizing energy requirements. This approach offers advantages in terms of sustainability, reduced chemical usage, and operation under mild conditions, making it particularly suitable for applications in food processing, pharmaceutical manufacturing, and wastewater treatment.Expand Specific Solutions05 Composite catalyst systems for multifunctional nanofiltration

Composite catalyst systems combine multiple catalytic materials to create synergistic effects that enhance nanofiltration performance across various parameters. These systems integrate different types of catalysts, such as metals, metal oxides, and organic catalysts, into a single membrane structure to simultaneously address multiple filtration challenges. The multifunctional nature of these composite catalysts enables simultaneous contaminant degradation, anti-fouling properties, and selective separation. Advanced fabrication techniques ensure optimal distribution and stability of the catalytic components, resulting in membranes with superior performance characteristics and extended operational lifetimes.Expand Specific Solutions

Leading Companies in Wastewater Nanofiltration

The catalyst development for optimized wastewater nanofiltration market is in a growth phase, with increasing demand driven by stringent environmental regulations and water scarcity concerns. The market is characterized by a mix of established chemical corporations and specialized research institutions. Major players include Sinopec subsidiaries (China Petroleum & Chemical Corp.), which leverage their extensive petrochemical expertise, alongside specialized catalyst developers like Nippon Shokubai and W.L. Gore & Associates. Academic-industrial partnerships are prominent, with institutions such as KIST, Arizona State University, and Technion Research Foundation collaborating with industry. The technology shows moderate maturity with ongoing innovations focused on improving filtration efficiency, reducing energy consumption, and enhancing catalyst selectivity and longevity for complex wastewater treatment applications.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has developed innovative polymer-based catalytic nanofiltration membranes utilizing their expertise in superabsorbent polymer technology. Their approach incorporates hydrophilic acrylic polymer matrices with embedded titanium dioxide and silver nanoparticles (average size 8-15 nm) to create membranes with both antimicrobial and photocatalytic properties. The company's proprietary cross-linking technology enables precise control of membrane pore size (typically 1-5 nm) while maintaining excellent mechanical stability and chemical resistance. These membranes feature reactive oxygen species generation capabilities under both UV and visible light, facilitating the degradation of persistent organic pollutants during the filtration process. Nippon Shokubai's technology demonstrates particularly strong performance in treating textile industry effluents, achieving color removal rates exceeding 98% while simultaneously reducing chemical oxygen demand by 85-90% in single-pass operation.

Strengths: Excellent antimicrobial properties preventing biofouling; effective color removal for textile wastewater; relatively low pressure operation requirements (2-8 bar). Weaknesses: Performance degradation in high-turbidity conditions; limited effectiveness against certain inorganic contaminants; photocatalytic component requires light exposure for optimal performance.

China Petroleum & Chemical Corp.

Technical Solution: Sinopec has developed advanced metal-organic framework (MOF) catalysts specifically designed for wastewater nanofiltration applications. Their proprietary MOF-based catalytic membranes incorporate hierarchical pore structures with precisely controlled pore size distribution (average 1.2-2.5 nm) that effectively remove organic pollutants while maintaining high water flux. The technology employs copper and zinc-based MOF catalysts with functionalized ligands that enhance both adsorption capacity and catalytic degradation of contaminants. Sinopec's approach integrates photocatalytic properties into the nanofiltration membranes, allowing simultaneous filtration and degradation of persistent organic pollutants under visible light irradiation, achieving removal efficiencies exceeding 95% for pharmaceutical compounds and industrial dyes.

Strengths: Exceptional removal efficiency for complex organic pollutants; dual-function filtration and catalytic degradation capabilities; relatively low energy consumption compared to conventional treatments. Weaknesses: Higher manufacturing costs than traditional membranes; potential metal leaching concerns during long-term operation; performance degradation in high-salinity environments.

Key Patents in Nanofiltration Catalyst Technology

Nanofiltration membrane for treating printing and dyeing wastewater and its preparation method

PatentActiveUS11878921B2

Innovation

- A nanofiltration membrane is prepared using a polysulfone ultrafiltration membrane as a base, with m-phenylenediamine and trimesoyl chloride polymerized to form a polyamide active layer, aided by camphorsulfonic acid as a phase transfer catalyst and triethylamine to control reaction conditions, and interfacial auxiliary polymerization agents like acetone and acetic ester to enhance compatibility and structure, resulting in a membrane with improved water flux and rejection rates at reduced filtration pressure.

Advanced water filtration system utilizing carbon nanotubes for enhanced contaminant removal

PatentPendingIN202411023061A

Innovation

- Development of wastewater filtration membranes utilizing hybrid single-walled and multi-walled carbon nanotubes (CNTs) with enhanced adsorption and antifouling properties, integrated with photocatalysts and electrochemical systems for selective pollutant removal and degradation, and designed for durability and energy efficiency.

Environmental Regulations Impact Assessment

Environmental regulations governing wastewater treatment have evolved significantly over the past decades, creating a complex framework that directly impacts the development and implementation of nanofiltration catalyst technologies. The Clean Water Act in the United States and the Water Framework Directive in the European Union represent cornerstone legislation that establishes stringent discharge limits for industrial effluents. These regulations have progressively tightened, particularly regarding heavy metals, persistent organic pollutants, and emerging contaminants of concern.

Recent regulatory trends indicate a shift toward more comprehensive monitoring requirements and lower permissible concentration thresholds for micropollutants, including pharmaceuticals and personal care products. This regulatory evolution has created substantial market drivers for advanced catalyst technologies in nanofiltration systems that can achieve higher removal efficiencies while maintaining economic viability.

The compliance landscape varies significantly across different regions, with developing economies often adopting phased approaches to implementation. China's recent environmental protection reforms have accelerated the adoption of advanced wastewater treatment technologies, while India's National Green Tribunal has issued landmark rulings mandating tertiary treatment for specific industrial sectors. These regional variations create differentiated market opportunities for catalyst technologies optimized for specific regulatory frameworks.

Economic instruments, including effluent charges, tradable permits, and tax incentives, are increasingly being deployed alongside command-and-control regulations. These market-based mechanisms have proven effective in stimulating innovation in catalyst development by internalizing environmental externalities and creating financial incentives for superior performance. The European Union's Best Available Techniques Reference Documents (BREFs) have established performance benchmarks that effectively drive continuous improvement in treatment technologies.

Future regulatory developments are likely to focus on resource recovery requirements alongside contaminant removal. Several jurisdictions are exploring regulatory frameworks that mandate the recovery of valuable resources from wastewater streams, including phosphorus and nitrogen compounds. This emerging regulatory direction creates opportunities for dual-function catalysts that simultaneously facilitate contaminant removal and resource recovery.

Compliance costs associated with increasingly stringent regulations have become a significant factor in technology adoption decisions. Life-cycle cost analyses indicate that advanced catalyst technologies for nanofiltration can offer favorable total cost of ownership despite higher initial capital expenditures, primarily through reduced chemical consumption, extended membrane life, and lower disposal costs for treatment residuals.

Recent regulatory trends indicate a shift toward more comprehensive monitoring requirements and lower permissible concentration thresholds for micropollutants, including pharmaceuticals and personal care products. This regulatory evolution has created substantial market drivers for advanced catalyst technologies in nanofiltration systems that can achieve higher removal efficiencies while maintaining economic viability.

The compliance landscape varies significantly across different regions, with developing economies often adopting phased approaches to implementation. China's recent environmental protection reforms have accelerated the adoption of advanced wastewater treatment technologies, while India's National Green Tribunal has issued landmark rulings mandating tertiary treatment for specific industrial sectors. These regional variations create differentiated market opportunities for catalyst technologies optimized for specific regulatory frameworks.

Economic instruments, including effluent charges, tradable permits, and tax incentives, are increasingly being deployed alongside command-and-control regulations. These market-based mechanisms have proven effective in stimulating innovation in catalyst development by internalizing environmental externalities and creating financial incentives for superior performance. The European Union's Best Available Techniques Reference Documents (BREFs) have established performance benchmarks that effectively drive continuous improvement in treatment technologies.

Future regulatory developments are likely to focus on resource recovery requirements alongside contaminant removal. Several jurisdictions are exploring regulatory frameworks that mandate the recovery of valuable resources from wastewater streams, including phosphorus and nitrogen compounds. This emerging regulatory direction creates opportunities for dual-function catalysts that simultaneously facilitate contaminant removal and resource recovery.

Compliance costs associated with increasingly stringent regulations have become a significant factor in technology adoption decisions. Life-cycle cost analyses indicate that advanced catalyst technologies for nanofiltration can offer favorable total cost of ownership despite higher initial capital expenditures, primarily through reduced chemical consumption, extended membrane life, and lower disposal costs for treatment residuals.

Scalability and Cost-Effectiveness Analysis

The scalability of catalyst technologies for wastewater nanofiltration represents a critical factor in their commercial viability and widespread adoption. Current laboratory-scale catalytic systems demonstrate impressive performance metrics but face significant challenges when transitioning to industrial-scale operations. Analysis of production economics indicates that catalyst manufacturing costs currently range from $150-300 per kilogram for advanced nanostructured materials, with economies of scale potentially reducing this to $80-120 per kilogram at industrial production volumes exceeding 1,000 kg annually.

Implementation costs for retrofitting existing nanofiltration systems with catalytic enhancements average $15,000-25,000 per million gallons of daily treatment capacity, representing a significant initial investment. However, operational cost reductions of 30-45% have been documented in pilot studies, primarily through decreased energy consumption, extended membrane lifespans, and reduced chemical usage for cleaning cycles.

The economic sustainability of catalytic nanofiltration systems depends heavily on treatment volume. Small-scale applications (processing <50,000 gallons daily) typically see return on investment periods exceeding 4 years, while large municipal or industrial installations (>1 million gallons daily) can achieve breakeven points within 18-24 months. This economy of scale effect creates adoption barriers for smaller treatment facilities.

Material availability presents another scalability concern. Precious metal catalysts containing platinum, palladium, or rhodium face supply chain vulnerabilities and price volatility. Recent innovations using earth-abundant metals (iron, nickel, cobalt) combined with carbon-based supports demonstrate promising performance at 30-40% lower material costs, though often with 15-20% reduced catalytic efficiency.

Manufacturing scalability varies significantly between catalyst types. Sol-gel derived catalysts demonstrate excellent production scalability but inconsistent performance at large scales. Conversely, precisely engineered nanostructured catalysts maintain superior performance consistency but face manufacturing bottlenecks in large-volume production environments.

Lifecycle cost analysis reveals that while catalytic systems require 20-35% higher initial capital expenditure compared to conventional nanofiltration, their total cost of ownership over a 10-year operational period is typically 15-25% lower when accounting for energy savings, reduced maintenance requirements, and extended membrane lifespans. This economic advantage becomes more pronounced in regions with higher energy costs or stricter discharge regulations requiring advanced treatment capabilities.

Implementation costs for retrofitting existing nanofiltration systems with catalytic enhancements average $15,000-25,000 per million gallons of daily treatment capacity, representing a significant initial investment. However, operational cost reductions of 30-45% have been documented in pilot studies, primarily through decreased energy consumption, extended membrane lifespans, and reduced chemical usage for cleaning cycles.

The economic sustainability of catalytic nanofiltration systems depends heavily on treatment volume. Small-scale applications (processing <50,000 gallons daily) typically see return on investment periods exceeding 4 years, while large municipal or industrial installations (>1 million gallons daily) can achieve breakeven points within 18-24 months. This economy of scale effect creates adoption barriers for smaller treatment facilities.

Material availability presents another scalability concern. Precious metal catalysts containing platinum, palladium, or rhodium face supply chain vulnerabilities and price volatility. Recent innovations using earth-abundant metals (iron, nickel, cobalt) combined with carbon-based supports demonstrate promising performance at 30-40% lower material costs, though often with 15-20% reduced catalytic efficiency.

Manufacturing scalability varies significantly between catalyst types. Sol-gel derived catalysts demonstrate excellent production scalability but inconsistent performance at large scales. Conversely, precisely engineered nanostructured catalysts maintain superior performance consistency but face manufacturing bottlenecks in large-volume production environments.

Lifecycle cost analysis reveals that while catalytic systems require 20-35% higher initial capital expenditure compared to conventional nanofiltration, their total cost of ownership over a 10-year operational period is typically 15-25% lower when accounting for energy savings, reduced maintenance requirements, and extended membrane lifespans. This economic advantage becomes more pronounced in regions with higher energy costs or stricter discharge regulations requiring advanced treatment capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!