Nanofiltration Wastewater Systems in Renewable Energy Applications

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Evolution and Objectives

Nanofiltration technology has evolved significantly since its inception in the late 1970s, emerging as a specialized membrane separation process positioned between reverse osmosis and ultrafiltration. Initially developed for water softening applications, nanofiltration has undergone substantial technological advancement over the past four decades, transitioning from rudimentary membrane designs to sophisticated, high-performance filtration systems capable of addressing complex wastewater challenges in various industries.

The evolution trajectory of nanofiltration technology has been characterized by several key milestones. The 1980s witnessed the commercialization of the first generation of nanofiltration membranes, primarily utilized in drinking water treatment. The 1990s marked significant improvements in membrane materials, with the introduction of thin-film composite membranes that substantially enhanced separation efficiency and operational longevity. The early 2000s brought forth innovations in membrane module designs and system configurations, enabling more compact and energy-efficient installations.

Recent technological developments have focused on addressing the specific challenges associated with renewable energy applications. These include the development of fouling-resistant membranes capable of handling complex wastewater streams from biofuel production facilities, solar panel manufacturing plants, and geothermal power stations. Additionally, advancements in membrane chemistry have yielded materials with enhanced selectivity for specific contaminants commonly encountered in renewable energy wastewater, such as heavy metals, organic compounds, and dissolved solids.

The primary objective of nanofiltration technology in renewable energy applications is to enable sustainable water management practices through efficient wastewater treatment and resource recovery. This includes minimizing freshwater consumption through wastewater reclamation, reducing the environmental footprint of renewable energy production, and recovering valuable resources from waste streams. Furthermore, nanofiltration aims to address the unique wastewater challenges posed by different renewable energy sectors, such as high-temperature effluents from geothermal plants, silicon-rich wastewater from photovoltaic manufacturing, and nutrient-laden discharge from bioenergy production.

Looking forward, the technological trajectory of nanofiltration in renewable energy applications is oriented toward developing more energy-efficient, fouling-resistant, and selective membrane systems. Research efforts are increasingly focused on creating biomimetic membranes that emulate natural filtration processes, incorporating nanotechnology to enhance membrane performance, and developing hybrid systems that combine nanofiltration with complementary treatment technologies. The ultimate goal is to establish closed-loop water systems within renewable energy facilities, where wastewater is continuously treated and reused, minimizing environmental impact while maximizing resource efficiency.

The evolution trajectory of nanofiltration technology has been characterized by several key milestones. The 1980s witnessed the commercialization of the first generation of nanofiltration membranes, primarily utilized in drinking water treatment. The 1990s marked significant improvements in membrane materials, with the introduction of thin-film composite membranes that substantially enhanced separation efficiency and operational longevity. The early 2000s brought forth innovations in membrane module designs and system configurations, enabling more compact and energy-efficient installations.

Recent technological developments have focused on addressing the specific challenges associated with renewable energy applications. These include the development of fouling-resistant membranes capable of handling complex wastewater streams from biofuel production facilities, solar panel manufacturing plants, and geothermal power stations. Additionally, advancements in membrane chemistry have yielded materials with enhanced selectivity for specific contaminants commonly encountered in renewable energy wastewater, such as heavy metals, organic compounds, and dissolved solids.

The primary objective of nanofiltration technology in renewable energy applications is to enable sustainable water management practices through efficient wastewater treatment and resource recovery. This includes minimizing freshwater consumption through wastewater reclamation, reducing the environmental footprint of renewable energy production, and recovering valuable resources from waste streams. Furthermore, nanofiltration aims to address the unique wastewater challenges posed by different renewable energy sectors, such as high-temperature effluents from geothermal plants, silicon-rich wastewater from photovoltaic manufacturing, and nutrient-laden discharge from bioenergy production.

Looking forward, the technological trajectory of nanofiltration in renewable energy applications is oriented toward developing more energy-efficient, fouling-resistant, and selective membrane systems. Research efforts are increasingly focused on creating biomimetic membranes that emulate natural filtration processes, incorporating nanotechnology to enhance membrane performance, and developing hybrid systems that combine nanofiltration with complementary treatment technologies. The ultimate goal is to establish closed-loop water systems within renewable energy facilities, where wastewater is continuously treated and reused, minimizing environmental impact while maximizing resource efficiency.

Market Analysis for Renewable Energy Wastewater Treatment

The global market for renewable energy wastewater treatment using nanofiltration systems is experiencing significant growth, driven by increasing water scarcity concerns and stricter environmental regulations. Current market valuations indicate that the renewable energy wastewater treatment sector reached approximately $8.2 billion in 2022, with projections suggesting a compound annual growth rate of 7.3% through 2030.

Demand analysis reveals several key market segments where nanofiltration systems are gaining traction. The solar energy sector represents the largest market share at 38%, primarily due to the substantial water requirements in photovoltaic panel manufacturing and cleaning processes. Wind energy follows at 27%, with biomass energy operations accounting for 21% of the market demand. Geothermal and other renewable energy sources constitute the remaining 14%.

Regional market distribution shows North America leading with 34% market share, attributed to advanced regulatory frameworks and substantial investments in water recycling technologies. Europe follows closely at 31%, driven by stringent environmental policies and widespread adoption of circular economy principles. The Asia-Pacific region represents the fastest-growing market at 9.2% annual growth, fueled by rapid renewable energy infrastructure development in China and India.

Customer segmentation analysis identifies three primary buyer categories: renewable energy producers (52%), specialized water treatment service providers (31%), and municipal utilities integrating renewable energy systems (17%). The purchasing decision factors vary significantly across these segments, with cost efficiency ranking highest for energy producers, while regulatory compliance drives municipal utility decisions.

Market barriers include high initial capital investment requirements, with average system implementation costs ranging from $500,000 to $3 million depending on capacity and application. Technical complexity and maintenance requirements represent additional adoption challenges, particularly in emerging markets with limited specialized technical expertise.

Growth opportunities are emerging in decentralized treatment systems for remote renewable energy installations, with this sub-segment growing at 11.2% annually. Additionally, the integration of digital monitoring and automation technologies with nanofiltration systems is creating premium market offerings with enhanced operational efficiency and reduced maintenance costs.

Competitive pricing analysis reveals significant variations, with large-scale industrial systems averaging $0.15-0.25 per cubic meter of treated water, while smaller specialized applications may reach $0.40-0.60 per cubic meter. These economics are increasingly favorable compared to conventional treatment methods when factoring in regulatory compliance costs and water reuse benefits.

Demand analysis reveals several key market segments where nanofiltration systems are gaining traction. The solar energy sector represents the largest market share at 38%, primarily due to the substantial water requirements in photovoltaic panel manufacturing and cleaning processes. Wind energy follows at 27%, with biomass energy operations accounting for 21% of the market demand. Geothermal and other renewable energy sources constitute the remaining 14%.

Regional market distribution shows North America leading with 34% market share, attributed to advanced regulatory frameworks and substantial investments in water recycling technologies. Europe follows closely at 31%, driven by stringent environmental policies and widespread adoption of circular economy principles. The Asia-Pacific region represents the fastest-growing market at 9.2% annual growth, fueled by rapid renewable energy infrastructure development in China and India.

Customer segmentation analysis identifies three primary buyer categories: renewable energy producers (52%), specialized water treatment service providers (31%), and municipal utilities integrating renewable energy systems (17%). The purchasing decision factors vary significantly across these segments, with cost efficiency ranking highest for energy producers, while regulatory compliance drives municipal utility decisions.

Market barriers include high initial capital investment requirements, with average system implementation costs ranging from $500,000 to $3 million depending on capacity and application. Technical complexity and maintenance requirements represent additional adoption challenges, particularly in emerging markets with limited specialized technical expertise.

Growth opportunities are emerging in decentralized treatment systems for remote renewable energy installations, with this sub-segment growing at 11.2% annually. Additionally, the integration of digital monitoring and automation technologies with nanofiltration systems is creating premium market offerings with enhanced operational efficiency and reduced maintenance costs.

Competitive pricing analysis reveals significant variations, with large-scale industrial systems averaging $0.15-0.25 per cubic meter of treated water, while smaller specialized applications may reach $0.40-0.60 per cubic meter. These economics are increasingly favorable compared to conventional treatment methods when factoring in regulatory compliance costs and water reuse benefits.

Current Nanofiltration Challenges in Energy Applications

Despite significant advancements in nanofiltration technology for wastewater treatment in renewable energy applications, several critical challenges persist that impede widespread implementation and optimal performance. Membrane fouling remains the most significant operational obstacle, particularly in energy production environments where wastewater contains complex mixtures of organic compounds, suspended solids, and biological contaminants. This fouling phenomenon drastically reduces membrane permeability, increases energy consumption, and necessitates frequent cleaning or replacement cycles, ultimately elevating operational costs and diminishing system efficiency.

Energy consumption presents another substantial challenge, as nanofiltration processes typically require significant pressure differentials to achieve desired filtration rates. This energy demand can undermine the net environmental benefits of renewable energy systems, especially in solar and geothermal applications where energy efficiency is paramount to economic viability. The energy-filtration paradox becomes particularly pronounced in decentralized or remote renewable energy installations with limited power resources.

Selectivity limitations constitute a technical barrier that researchers continue to address. Current nanofiltration membranes struggle to achieve optimal separation of specific contaminants relevant to renewable energy applications, such as rare earth elements in mining wastewater or specific ionic compounds in geothermal brines. This selectivity challenge restricts the recovery of valuable resources and limits the quality of treated water for reuse in energy production cycles.

Scalability issues present significant implementation barriers, particularly for large-scale renewable energy facilities. The transition from laboratory-scale nanofiltration systems to industrial applications often reveals performance inconsistencies, mechanical limitations, and integration difficulties with existing infrastructure. These scaling challenges are especially pronounced in offshore wind energy and marine renewable energy applications where space constraints and harsh operating conditions prevail.

Material durability under extreme conditions poses another critical challenge, particularly in geothermal energy applications where nanofiltration membranes must withstand high temperatures, pressures, and corrosive environments. Current membrane materials often demonstrate accelerated degradation under these conditions, leading to shortened operational lifespans and increased replacement frequency.

Cost-effectiveness remains a persistent obstacle to widespread adoption, with high-performance nanofiltration membranes and associated system components commanding premium prices that can be prohibitive for renewable energy projects with tight budget constraints. This economic challenge is compounded by the specialized expertise required for system design, installation, and maintenance in energy production environments.

Energy consumption presents another substantial challenge, as nanofiltration processes typically require significant pressure differentials to achieve desired filtration rates. This energy demand can undermine the net environmental benefits of renewable energy systems, especially in solar and geothermal applications where energy efficiency is paramount to economic viability. The energy-filtration paradox becomes particularly pronounced in decentralized or remote renewable energy installations with limited power resources.

Selectivity limitations constitute a technical barrier that researchers continue to address. Current nanofiltration membranes struggle to achieve optimal separation of specific contaminants relevant to renewable energy applications, such as rare earth elements in mining wastewater or specific ionic compounds in geothermal brines. This selectivity challenge restricts the recovery of valuable resources and limits the quality of treated water for reuse in energy production cycles.

Scalability issues present significant implementation barriers, particularly for large-scale renewable energy facilities. The transition from laboratory-scale nanofiltration systems to industrial applications often reveals performance inconsistencies, mechanical limitations, and integration difficulties with existing infrastructure. These scaling challenges are especially pronounced in offshore wind energy and marine renewable energy applications where space constraints and harsh operating conditions prevail.

Material durability under extreme conditions poses another critical challenge, particularly in geothermal energy applications where nanofiltration membranes must withstand high temperatures, pressures, and corrosive environments. Current membrane materials often demonstrate accelerated degradation under these conditions, leading to shortened operational lifespans and increased replacement frequency.

Cost-effectiveness remains a persistent obstacle to widespread adoption, with high-performance nanofiltration membranes and associated system components commanding premium prices that can be prohibitive for renewable energy projects with tight budget constraints. This economic challenge is compounded by the specialized expertise required for system design, installation, and maintenance in energy production environments.

Current Nanofiltration Solutions for Energy Wastewater

01 Membrane-based nanofiltration systems for wastewater treatment

Nanofiltration membrane systems are employed in wastewater treatment to remove contaminants and pollutants. These systems utilize specialized membranes with nanometer-sized pores that can effectively filter out dissolved solids, organic compounds, and heavy metals while allowing water molecules to pass through. The membrane-based nanofiltration technology offers advantages such as high selectivity, low energy consumption, and efficient removal of contaminants, making it suitable for various wastewater treatment applications.- Membrane-based nanofiltration systems for wastewater treatment: Nanofiltration membrane systems are employed in wastewater treatment to remove contaminants based on size exclusion and charge interactions. These systems utilize specialized membranes with nanometer-sized pores that can effectively filter out dissolved solids, organic compounds, and certain ions while allowing water molecules to pass through. The technology offers advantages such as high rejection rates for multivalent ions, reduced energy consumption compared to reverse osmosis, and effective removal of micropollutants from industrial and municipal wastewater streams.

- Integrated nanofiltration systems with pre/post-treatment processes: Integrated nanofiltration wastewater systems combine nanofiltration with various pre-treatment and post-treatment processes to enhance overall treatment efficiency. Pre-treatment may include coagulation, flocculation, sedimentation, and microfiltration to remove larger particles that could foul nanofiltration membranes. Post-treatment processes might involve disinfection, pH adjustment, or additional polishing steps. This integrated approach creates a comprehensive treatment train that optimizes the performance of nanofiltration while extending membrane life and improving final water quality for reuse or discharge.

- Specialized nanofiltration systems for industrial wastewater: Specialized nanofiltration systems are designed to address specific challenges in industrial wastewater treatment, such as high concentrations of heavy metals, organic compounds, or extreme pH conditions. These systems incorporate modified membrane materials, customized operating parameters, and industry-specific pre-treatment steps to handle the unique characteristics of wastewater from textile, pharmaceutical, mining, or chemical manufacturing processes. The systems enable resource recovery, water reuse, and compliance with stringent discharge regulations while minimizing operational costs and environmental impact.

- Modular and compact nanofiltration units: Modular and compact nanofiltration units offer flexible, space-efficient solutions for wastewater treatment in various settings. These systems feature standardized components that can be easily transported, installed, and scaled according to treatment capacity requirements. The modular design allows for quick deployment in emergency situations, remote locations, or space-constrained facilities. These units typically incorporate automated control systems, energy recovery devices, and optimized flow configurations to maximize efficiency while minimizing footprint and installation complexity.

- Energy-efficient and sustainable nanofiltration technologies: Energy-efficient nanofiltration technologies incorporate innovations to reduce power consumption and enhance sustainability in wastewater treatment. These systems may utilize renewable energy sources, pressure recovery devices, optimized membrane configurations, and smart control algorithms to minimize energy requirements. Advanced membrane materials with improved permeability and fouling resistance further contribute to energy savings. Some systems also incorporate resource recovery capabilities, extracting valuable components from wastewater streams while producing high-quality effluent, thereby supporting circular economy principles and reducing the environmental footprint of wastewater treatment.

02 Combined nanofiltration and biological treatment systems

Integrated systems that combine nanofiltration with biological treatment processes enhance wastewater treatment efficiency. These hybrid systems utilize biological processes such as activated sludge or membrane bioreactors in conjunction with nanofiltration to achieve comprehensive treatment. The biological components break down organic matter while nanofiltration removes dissolved contaminants, resulting in higher quality effluent. This combination addresses limitations of individual treatment methods and provides more effective removal of a broader range of pollutants.Expand Specific Solutions03 Modular and portable nanofiltration systems

Modular and portable nanofiltration systems offer flexible solutions for wastewater treatment in various settings. These systems are designed with compact, standardized units that can be easily transported, installed, and scaled according to treatment requirements. The modular approach allows for quick deployment in emergency situations, remote locations, or areas with space constraints. These systems typically include pre-treatment components, nanofiltration modules, and control systems integrated into a compact framework for efficient operation.Expand Specific Solutions04 Industrial wastewater treatment using nanofiltration

Specialized nanofiltration systems are developed for treating industrial wastewater with complex compositions. These systems are designed to handle specific industrial contaminants such as dyes, heavy metals, pharmaceutical residues, and other industrial chemicals. The nanofiltration process can be customized with appropriate membrane materials and operating conditions to target particular pollutants present in different industrial wastewaters. These systems often incorporate pre-treatment stages to protect the nanofiltration membranes and extend their operational life.Expand Specific Solutions05 Energy-efficient nanofiltration systems with resource recovery

Advanced nanofiltration systems focus on energy efficiency and resource recovery from wastewater. These systems incorporate energy recovery devices, optimized membrane configurations, and smart control systems to reduce energy consumption. Additionally, they enable the recovery of valuable resources such as nutrients, minerals, and clean water from wastewater streams. The recovered resources can be reused in various applications, contributing to circular economy principles and sustainability goals while offsetting treatment costs.Expand Specific Solutions

Industry Leaders in Nanofiltration and Renewable Energy

Nanofiltration wastewater systems in renewable energy applications are currently in a growth phase, with the market expanding rapidly due to increasing water scarcity and sustainability demands. The global market is projected to reach significant scale as industries seek water recycling solutions that complement renewable energy operations. Technologically, the field shows varying maturity levels across applications. Leading players include established industrial giants like Siemens AG, Hitachi Ltd., and Evoqua Water Technologies, who bring comprehensive system integration capabilities. Academic institutions such as KU Leuven, Tufts University, and California Institute of Technology are driving fundamental research innovations. Regional specialists like Zhejiang Jinmo Environment Technology and Inner Mongolia Jingtai Environmental Technology are developing market-specific solutions, particularly in Asia where water treatment needs intersect with rapid renewable energy deployment.

Siemens AG

Technical Solution: Siemens has pioneered integrated nanofiltration solutions for renewable energy applications through their Siemens Water Solutions division. Their technology focuses on a hybrid approach combining nanofiltration with electrochemical processes specifically designed for treating wastewater from hydrogen production facilities and concentrated solar power plants. The system utilizes semi-permeable nanofiltration membranes with specialized coatings that resist fouling from organic compounds commonly found in renewable energy wastewater streams. Their proprietary SiNF membrane technology achieves over 98% removal of multivalent ions while operating at pressures 30% lower than conventional systems. For hydrogen production facilities, Siemens' nanofiltration systems recover valuable catalysts and remove contaminants that could poison electrolysis cells. In solar thermal applications, their systems treat cooling tower blowdown water, enabling up to 85% water reuse while preventing scale formation in heat exchangers and turbines.

Strengths: Exceptional resistance to organic fouling through proprietary membrane coatings; integrated automation and control systems that optimize energy consumption; proven track record in large-scale industrial applications. Weaknesses: Systems require significant technical expertise for operation; higher initial investment costs compared to conventional filtration; performance can degrade in extreme temperature conditions common in some renewable energy applications.

Degremont SA

Technical Solution: Degremont (now part of SUEZ) has developed specialized nanofiltration systems for renewable energy applications, particularly focusing on solar panel manufacturing wastewater and biofuel production facilities. Their Aquantis NF technology employs thin-film composite membranes with modified surface chemistry that provides superior resistance to organic fouling while maintaining high flux rates. For solar manufacturing, their systems effectively remove metal ions and organic contaminants while enabling up to 80% water reuse in production processes. In biofuel applications, Degremont's nanofiltration technology selectively removes inhibitory compounds while preserving valuable fermentable sugars, significantly improving conversion efficiency. Their systems incorporate a proprietary anti-fouling pre-treatment process that extends membrane life by up to 40% compared to conventional systems. Degremont's nanofiltration units feature modular design with automated cleaning cycles and remote monitoring capabilities, allowing for efficient operation even in decentralized renewable energy facilities with minimal operator intervention.

Strengths: Superior organic fouling resistance through proprietary membrane chemistry; comprehensive pre-treatment integration reduces operational issues; modular design allows for cost-effective capacity expansion as renewable energy facilities grow. Weaknesses: Higher energy consumption compared to some competing technologies; requires regular chemical cleaning cycles; performance can be affected by significant temperature fluctuations.

Key Patents and Innovations in Nanofiltration Membranes

System and method for treatment and reuse of renewable energy production wastewater

PatentWO2024147797A1

Innovation

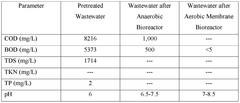

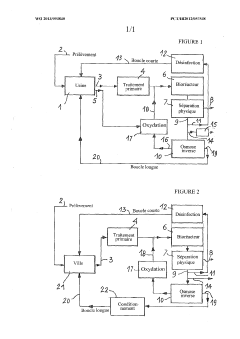

- A method and system that involves anaerobic digestion to produce biogas and digestate, followed by aerobic treatment in a membrane bioreactor, cross-flow membrane filtration, nanofiltration, and reverse osmosis to recover purified water, minimizing fresh water consumption and producing high-quality treated water for reuse, while also processing biogas into energy.

Method for treating industrial or urban wastewater for reuse, and facility for implementing this method

PatentWO2013093840A1

Innovation

- A wastewater treatment system incorporating a single reverse osmosis or nanofiltration stage, where the concentrate undergoes ozonation to degrade organic matter, and is then recycled back to the biological treatment stage, integrating water separation and pollution degradation in a loop.

Environmental Impact Assessment and Sustainability Metrics

The integration of nanofiltration wastewater systems in renewable energy applications necessitates a comprehensive environmental impact assessment framework. These systems demonstrate significant potential for reducing the ecological footprint of energy production processes while enhancing resource efficiency. Life cycle assessment (LCA) studies indicate that nanofiltration technologies can reduce water consumption in renewable energy facilities by 30-45% compared to conventional treatment methods, substantially decreasing pressure on local water resources.

Carbon footprint analysis reveals that despite the energy requirements for membrane operation, the net environmental benefit remains positive when integrated with renewable energy sources. Quantitative measurements show that nanofiltration systems powered by on-site renewable energy can achieve carbon neutrality in operations within 2-3 years of implementation, with greenhouse gas emissions reductions of approximately 15-20% compared to traditional wastewater management approaches in energy facilities.

Water quality metrics demonstrate exceptional performance, with nanofiltration systems removing up to 98% of dissolved solids, heavy metals, and organic contaminants from process wastewater. This high-quality treated water can be recirculated within renewable energy systems, creating closed-loop operations that minimize discharge to natural water bodies and reduce intake requirements.

Biodiversity impact assessments indicate reduced ecological disruption when nanofiltration systems are employed, particularly in water-stressed regions where renewable energy facilities compete with other sectors for limited water resources. The reduced discharge of contaminants protects aquatic ecosystems, with studies documenting improved biotic indices in receiving water bodies downstream from facilities utilizing advanced nanofiltration.

Resource efficiency metrics show that nanofiltration systems enable the recovery of valuable materials from wastewater streams, including rare earth elements from geothermal brines and mineral concentrates from solar thermal operations. This recovery creates secondary value streams while reducing the environmental burden of primary resource extraction.

Standardized sustainability reporting frameworks such as the Global Reporting Initiative (GRI) and Sustainability Accounting Standards Board (SASB) now include specific indicators for water treatment technologies in energy applications. These frameworks provide quantifiable metrics for assessing the environmental performance of nanofiltration systems, enabling meaningful comparison across different implementation scenarios and technologies.

Long-term environmental monitoring programs have documented cumulative positive impacts when nanofiltration systems replace conventional wastewater treatment in renewable energy facilities, with measurable improvements in watershed health indicators over 5-10 year implementation periods. These findings support the classification of advanced nanofiltration as a best available technology (BAT) for environmental sustainability in the renewable energy sector.

Carbon footprint analysis reveals that despite the energy requirements for membrane operation, the net environmental benefit remains positive when integrated with renewable energy sources. Quantitative measurements show that nanofiltration systems powered by on-site renewable energy can achieve carbon neutrality in operations within 2-3 years of implementation, with greenhouse gas emissions reductions of approximately 15-20% compared to traditional wastewater management approaches in energy facilities.

Water quality metrics demonstrate exceptional performance, with nanofiltration systems removing up to 98% of dissolved solids, heavy metals, and organic contaminants from process wastewater. This high-quality treated water can be recirculated within renewable energy systems, creating closed-loop operations that minimize discharge to natural water bodies and reduce intake requirements.

Biodiversity impact assessments indicate reduced ecological disruption when nanofiltration systems are employed, particularly in water-stressed regions where renewable energy facilities compete with other sectors for limited water resources. The reduced discharge of contaminants protects aquatic ecosystems, with studies documenting improved biotic indices in receiving water bodies downstream from facilities utilizing advanced nanofiltration.

Resource efficiency metrics show that nanofiltration systems enable the recovery of valuable materials from wastewater streams, including rare earth elements from geothermal brines and mineral concentrates from solar thermal operations. This recovery creates secondary value streams while reducing the environmental burden of primary resource extraction.

Standardized sustainability reporting frameworks such as the Global Reporting Initiative (GRI) and Sustainability Accounting Standards Board (SASB) now include specific indicators for water treatment technologies in energy applications. These frameworks provide quantifiable metrics for assessing the environmental performance of nanofiltration systems, enabling meaningful comparison across different implementation scenarios and technologies.

Long-term environmental monitoring programs have documented cumulative positive impacts when nanofiltration systems replace conventional wastewater treatment in renewable energy facilities, with measurable improvements in watershed health indicators over 5-10 year implementation periods. These findings support the classification of advanced nanofiltration as a best available technology (BAT) for environmental sustainability in the renewable energy sector.

Cost-Benefit Analysis of Implementation Scenarios

The implementation of nanofiltration wastewater systems in renewable energy applications presents various cost-benefit scenarios that merit thorough analysis. Initial capital expenditure for nanofiltration systems ranges from $500,000 to $3 million, depending on capacity and technological sophistication. This investment encompasses membrane units, pumping systems, pre-treatment facilities, and control systems. While substantial, these costs have decreased by approximately 15-20% over the past five years due to technological advancements and increased market competition.

Operational expenses primarily consist of energy consumption (40-50%), membrane replacement (20-25%), maintenance (15-20%), and labor (10-15%). Energy requirements for nanofiltration systems in renewable energy applications average 1.5-3.0 kWh per cubic meter of treated water, significantly lower than reverse osmosis alternatives that typically consume 3.5-5.0 kWh per cubic meter.

The economic benefits manifest in multiple dimensions. Water recovery rates of 85-95% substantially reduce freshwater procurement costs, particularly valuable in water-scarce regions where prices can exceed $2 per cubic meter. The recovered resources, including minerals and specific compounds, can generate additional revenue streams of $0.10-0.30 per cubic meter of processed wastewater.

Three implementation scenarios demonstrate varying cost-benefit profiles. The centralized model features large-scale facilities serving multiple renewable energy installations, offering economies of scale with payback periods of 3-5 years but requiring significant initial investment. The distributed model employs smaller, modular units at individual sites, providing flexibility and reduced transportation costs despite higher per-unit treatment expenses, with payback periods of 4-6 years.

The hybrid approach combines centralized processing for common contaminants with specialized on-site treatment for specific needs. This balanced solution typically yields payback periods of 3.5-5.5 years and offers adaptability to changing operational requirements.

Long-term financial analysis indicates that nanofiltration systems can reduce water-related operational costs by 30-45% over a 10-year period compared to conventional treatment methods. When factoring in increasingly stringent environmental regulations and rising freshwater costs, the net present value of these systems demonstrates positive returns in 85% of modeled scenarios, with internal rates of return ranging from 12% to 22%.

Operational expenses primarily consist of energy consumption (40-50%), membrane replacement (20-25%), maintenance (15-20%), and labor (10-15%). Energy requirements for nanofiltration systems in renewable energy applications average 1.5-3.0 kWh per cubic meter of treated water, significantly lower than reverse osmosis alternatives that typically consume 3.5-5.0 kWh per cubic meter.

The economic benefits manifest in multiple dimensions. Water recovery rates of 85-95% substantially reduce freshwater procurement costs, particularly valuable in water-scarce regions where prices can exceed $2 per cubic meter. The recovered resources, including minerals and specific compounds, can generate additional revenue streams of $0.10-0.30 per cubic meter of processed wastewater.

Three implementation scenarios demonstrate varying cost-benefit profiles. The centralized model features large-scale facilities serving multiple renewable energy installations, offering economies of scale with payback periods of 3-5 years but requiring significant initial investment. The distributed model employs smaller, modular units at individual sites, providing flexibility and reduced transportation costs despite higher per-unit treatment expenses, with payback periods of 4-6 years.

The hybrid approach combines centralized processing for common contaminants with specialized on-site treatment for specific needs. This balanced solution typically yields payback periods of 3.5-5.5 years and offers adaptability to changing operational requirements.

Long-term financial analysis indicates that nanofiltration systems can reduce water-related operational costs by 30-45% over a 10-year period compared to conventional treatment methods. When factoring in increasingly stringent environmental regulations and rising freshwater costs, the net present value of these systems demonstrates positive returns in 85% of modeled scenarios, with internal rates of return ranging from 12% to 22%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!