Wastewater Nanofiltration in Renewable Energy Resource Management

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Background and Objectives

Nanofiltration technology has evolved significantly over the past three decades, emerging as a critical solution at the intersection of wastewater treatment and renewable energy management. Initially developed in the 1980s as a modified form of reverse osmosis, nanofiltration has progressed from laboratory experiments to commercial applications across various industries. The technology utilizes semi-permeable membranes with pore sizes typically ranging from 1-10 nanometers, positioning it strategically between ultrafiltration and reverse osmosis in the membrane filtration spectrum.

The evolution of nanofiltration has been characterized by continuous improvements in membrane materials, from early cellulose acetate compositions to advanced thin-film composite membranes incorporating nanomaterials such as graphene oxide and carbon nanotubes. These advancements have significantly enhanced filtration efficiency, reduced energy consumption, and extended membrane lifespan, making nanofiltration increasingly viable for large-scale applications.

In the context of renewable energy resource management, nanofiltration serves multiple critical functions. Primarily, it enables the recovery and reuse of water from various waste streams, reducing the water footprint of renewable energy production processes such as biofuel manufacturing, geothermal power generation, and solar panel production. Additionally, nanofiltration facilitates the extraction of valuable resources from wastewater, including rare earth elements essential for renewable energy technologies and nutrients that can be repurposed for bioenergy feedstock production.

The technical objectives for advancing nanofiltration in renewable energy applications are multifaceted. First, there is a pressing need to develop fouling-resistant membranes that can maintain performance under challenging conditions typical in renewable energy wastewater streams, which often contain high levels of organic matter and mineral scaling agents. Second, energy efficiency improvements remain paramount, with research focused on reducing the pressure requirements and therefore the energy consumption of nanofiltration systems.

Another key objective involves enhancing selectivity for specific contaminants and valuable resources, enabling more precise separation capabilities tailored to different renewable energy applications. This includes developing membranes with controlled surface charges and pore sizes that can selectively remove harmful contaminants while allowing beneficial minerals to pass through.

The integration of nanofiltration with other treatment technologies represents another important development trajectory, with hybrid systems combining nanofiltration with biological treatment, advanced oxidation processes, or electrochemical methods showing promising results for complex wastewater streams from renewable energy facilities. These integrated approaches aim to maximize resource recovery while minimizing waste generation, aligning with circular economy principles increasingly adopted in the renewable energy sector.

The evolution of nanofiltration has been characterized by continuous improvements in membrane materials, from early cellulose acetate compositions to advanced thin-film composite membranes incorporating nanomaterials such as graphene oxide and carbon nanotubes. These advancements have significantly enhanced filtration efficiency, reduced energy consumption, and extended membrane lifespan, making nanofiltration increasingly viable for large-scale applications.

In the context of renewable energy resource management, nanofiltration serves multiple critical functions. Primarily, it enables the recovery and reuse of water from various waste streams, reducing the water footprint of renewable energy production processes such as biofuel manufacturing, geothermal power generation, and solar panel production. Additionally, nanofiltration facilitates the extraction of valuable resources from wastewater, including rare earth elements essential for renewable energy technologies and nutrients that can be repurposed for bioenergy feedstock production.

The technical objectives for advancing nanofiltration in renewable energy applications are multifaceted. First, there is a pressing need to develop fouling-resistant membranes that can maintain performance under challenging conditions typical in renewable energy wastewater streams, which often contain high levels of organic matter and mineral scaling agents. Second, energy efficiency improvements remain paramount, with research focused on reducing the pressure requirements and therefore the energy consumption of nanofiltration systems.

Another key objective involves enhancing selectivity for specific contaminants and valuable resources, enabling more precise separation capabilities tailored to different renewable energy applications. This includes developing membranes with controlled surface charges and pore sizes that can selectively remove harmful contaminants while allowing beneficial minerals to pass through.

The integration of nanofiltration with other treatment technologies represents another important development trajectory, with hybrid systems combining nanofiltration with biological treatment, advanced oxidation processes, or electrochemical methods showing promising results for complex wastewater streams from renewable energy facilities. These integrated approaches aim to maximize resource recovery while minimizing waste generation, aligning with circular economy principles increasingly adopted in the renewable energy sector.

Market Analysis for Wastewater Treatment in Renewable Energy

The global wastewater treatment market within renewable energy sectors is experiencing significant growth, driven by increasing water scarcity concerns and stricter environmental regulations. Current market valuation stands at approximately $21.8 billion in 2023, with projections indicating a compound annual growth rate of 7.2% through 2030, potentially reaching $35.6 billion by the end of the decade.

Nanofiltration technology specifically represents one of the fastest-growing segments within this market, currently accounting for about 18% of the total wastewater treatment solutions in renewable energy applications. This growth is particularly pronounced in regions facing severe water stress, including the Middle East, parts of Asia-Pacific, and the southwestern United States.

The renewable energy sector generates distinctive wastewater challenges that create specialized market opportunities. Solar panel manufacturing produces wastewater containing heavy metals and chemical compounds, while geothermal plants generate brine with high mineral content. Biofuel production facilities create organic-rich wastewater streams that require specialized treatment approaches. These diverse needs are driving demand for customized nanofiltration solutions.

Market segmentation reveals that solar energy represents the largest application segment (42%), followed by bioenergy (28%), geothermal (18%), and other renewable sectors (12%). This distribution reflects both the relative market sizes of these energy sectors and the volume and complexity of wastewater they generate.

Geographically, Asia-Pacific dominates the market with 38% share, driven by China's massive renewable energy investments and water scarcity challenges. North America follows at 27%, with Europe at 24%. The fastest growth is occurring in emerging markets, particularly India, Brazil, and parts of Southeast Asia, where renewable energy deployment is accelerating rapidly.

Customer analysis indicates three primary market segments: large utility-scale renewable energy producers seeking comprehensive wastewater management systems; medium-sized independent power producers requiring modular, scalable solutions; and specialized technology providers integrating nanofiltration into broader water recycling systems.

Key market drivers include increasingly stringent discharge regulations, rising freshwater costs, growing corporate sustainability commitments, and technological advancements reducing operational costs of nanofiltration systems. The water-energy nexus is becoming a central consideration in renewable energy project planning, with water recycling and resource recovery emerging as critical economic and environmental factors.

Market barriers include high initial capital costs, energy requirements for nanofiltration operations, membrane fouling challenges in certain applications, and competition from alternative treatment technologies. Despite these challenges, the fundamental market trajectory remains strongly positive as water conservation becomes increasingly integrated with renewable energy development strategies.

Nanofiltration technology specifically represents one of the fastest-growing segments within this market, currently accounting for about 18% of the total wastewater treatment solutions in renewable energy applications. This growth is particularly pronounced in regions facing severe water stress, including the Middle East, parts of Asia-Pacific, and the southwestern United States.

The renewable energy sector generates distinctive wastewater challenges that create specialized market opportunities. Solar panel manufacturing produces wastewater containing heavy metals and chemical compounds, while geothermal plants generate brine with high mineral content. Biofuel production facilities create organic-rich wastewater streams that require specialized treatment approaches. These diverse needs are driving demand for customized nanofiltration solutions.

Market segmentation reveals that solar energy represents the largest application segment (42%), followed by bioenergy (28%), geothermal (18%), and other renewable sectors (12%). This distribution reflects both the relative market sizes of these energy sectors and the volume and complexity of wastewater they generate.

Geographically, Asia-Pacific dominates the market with 38% share, driven by China's massive renewable energy investments and water scarcity challenges. North America follows at 27%, with Europe at 24%. The fastest growth is occurring in emerging markets, particularly India, Brazil, and parts of Southeast Asia, where renewable energy deployment is accelerating rapidly.

Customer analysis indicates three primary market segments: large utility-scale renewable energy producers seeking comprehensive wastewater management systems; medium-sized independent power producers requiring modular, scalable solutions; and specialized technology providers integrating nanofiltration into broader water recycling systems.

Key market drivers include increasingly stringent discharge regulations, rising freshwater costs, growing corporate sustainability commitments, and technological advancements reducing operational costs of nanofiltration systems. The water-energy nexus is becoming a central consideration in renewable energy project planning, with water recycling and resource recovery emerging as critical economic and environmental factors.

Market barriers include high initial capital costs, energy requirements for nanofiltration operations, membrane fouling challenges in certain applications, and competition from alternative treatment technologies. Despite these challenges, the fundamental market trajectory remains strongly positive as water conservation becomes increasingly integrated with renewable energy development strategies.

Current Challenges in Wastewater Nanofiltration Technologies

Nanofiltration (NF) technology has emerged as a promising solution for wastewater treatment in renewable energy resource management. However, despite its potential, several significant challenges currently impede its widespread implementation and optimal performance. The primary technical obstacle remains membrane fouling, which occurs when particles, colloids, and organic matter accumulate on membrane surfaces, reducing filtration efficiency and increasing operational costs. This fouling phenomenon is particularly problematic in energy-related wastewater streams that contain complex mixtures of contaminants, including oils, heavy metals, and various organic compounds.

Energy consumption represents another critical challenge for nanofiltration systems. Current NF processes require substantial pressure to force water through semi-permeable membranes, resulting in high electricity demands that can offset the environmental benefits of the technology. This energy-intensive nature contradicts the sustainability goals of renewable energy resource management, creating a paradoxical situation where wastewater treatment itself becomes an energy burden.

Membrane selectivity limitations further complicate the application of nanofiltration in renewable energy contexts. Existing membranes often struggle to achieve optimal separation of specific contaminants while maintaining high water flux rates. This selectivity challenge is particularly evident when treating wastewater from biofuel production, geothermal operations, or solar panel manufacturing, where unique contaminant profiles require specialized filtration capabilities.

The durability and lifespan of nanofiltration membranes under harsh operating conditions present ongoing concerns. Wastewater from renewable energy processes often contains extreme pH levels, oxidizing agents, or temperature variations that can degrade membrane materials prematurely. Current membrane technologies typically demonstrate limited resistance to these aggressive conditions, necessitating frequent replacement and increasing overall system costs.

Scale-up challenges persist as laboratory successes often fail to translate effectively to industrial-scale applications. The hydraulic and mechanical complexities of large-scale nanofiltration systems create performance inconsistencies that are difficult to predict from small-scale experiments. This scaling gap has slowed commercial adoption of advanced nanofiltration solutions in renewable energy facilities.

Regulatory and standardization issues compound these technical challenges. The lack of unified performance metrics and testing protocols for nanofiltration systems in energy-related applications creates market uncertainty and hampers technology comparison. Additionally, varying regulatory requirements across different regions create compliance complexities for technology developers and implementers.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current nanofiltration technologies for specialized energy-sector applications often carry prohibitive capital and operational expenses compared to conventional treatment methods, despite their superior performance in certain parameters. This economic challenge is particularly acute for smaller renewable energy operations with limited financial resources.

Energy consumption represents another critical challenge for nanofiltration systems. Current NF processes require substantial pressure to force water through semi-permeable membranes, resulting in high electricity demands that can offset the environmental benefits of the technology. This energy-intensive nature contradicts the sustainability goals of renewable energy resource management, creating a paradoxical situation where wastewater treatment itself becomes an energy burden.

Membrane selectivity limitations further complicate the application of nanofiltration in renewable energy contexts. Existing membranes often struggle to achieve optimal separation of specific contaminants while maintaining high water flux rates. This selectivity challenge is particularly evident when treating wastewater from biofuel production, geothermal operations, or solar panel manufacturing, where unique contaminant profiles require specialized filtration capabilities.

The durability and lifespan of nanofiltration membranes under harsh operating conditions present ongoing concerns. Wastewater from renewable energy processes often contains extreme pH levels, oxidizing agents, or temperature variations that can degrade membrane materials prematurely. Current membrane technologies typically demonstrate limited resistance to these aggressive conditions, necessitating frequent replacement and increasing overall system costs.

Scale-up challenges persist as laboratory successes often fail to translate effectively to industrial-scale applications. The hydraulic and mechanical complexities of large-scale nanofiltration systems create performance inconsistencies that are difficult to predict from small-scale experiments. This scaling gap has slowed commercial adoption of advanced nanofiltration solutions in renewable energy facilities.

Regulatory and standardization issues compound these technical challenges. The lack of unified performance metrics and testing protocols for nanofiltration systems in energy-related applications creates market uncertainty and hampers technology comparison. Additionally, varying regulatory requirements across different regions create compliance complexities for technology developers and implementers.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current nanofiltration technologies for specialized energy-sector applications often carry prohibitive capital and operational expenses compared to conventional treatment methods, despite their superior performance in certain parameters. This economic challenge is particularly acute for smaller renewable energy operations with limited financial resources.

Existing Nanofiltration Methods for Renewable Energy Applications

01 Nanofiltration membrane materials and structures

Various materials and structures are used in nanofiltration membranes for wastewater treatment. These include composite membranes with specialized coatings, modified polymer membranes, and novel nanomaterials that enhance filtration efficiency. The structural design of these membranes affects their performance characteristics such as flux rate, selectivity, and fouling resistance. Advanced membrane materials can significantly improve the removal of specific contaminants while maintaining high water throughput.- Nanofiltration membrane materials for wastewater treatment: Various nanofiltration membrane materials are used in wastewater treatment systems to effectively remove contaminants. These materials include polymeric membranes, ceramic membranes, and composite membranes with specific properties tailored for different types of wastewater. The membrane materials are designed to have optimal pore size, surface charge, and chemical resistance to enhance filtration efficiency while maintaining durability under harsh wastewater conditions.

- Integrated wastewater nanofiltration systems: Integrated systems combine nanofiltration with other treatment processes to achieve comprehensive wastewater purification. These systems typically include pre-treatment units (such as coagulation, flocculation, or sedimentation), nanofiltration modules, and post-treatment processes. The integration optimizes the overall treatment efficiency, reduces membrane fouling, extends membrane life, and ensures that the treated water meets required quality standards for reuse or discharge.

- Anti-fouling strategies for nanofiltration membranes: Fouling is a major challenge in nanofiltration of wastewater. Various strategies are employed to mitigate membrane fouling, including surface modifications of membranes, incorporation of antimicrobial agents, optimization of operating conditions, and development of cleaning protocols. These anti-fouling approaches help maintain filtration efficiency, extend membrane lifespan, and reduce operational costs in wastewater treatment applications.

- Industrial wastewater-specific nanofiltration applications: Nanofiltration technologies are specifically designed for treating industrial wastewaters with unique characteristics. These applications address the removal of heavy metals, organic pollutants, dyes, and other industry-specific contaminants. The nanofiltration systems are tailored to handle high concentrations of pollutants, extreme pH conditions, and variable wastewater compositions from industries such as textile, pharmaceutical, mining, and chemical manufacturing.

- Energy-efficient nanofiltration processes for wastewater: Energy efficiency is a critical consideration in wastewater nanofiltration. Innovations focus on reducing energy consumption through improved membrane designs, optimized operating pressures, energy recovery devices, and process configurations. These energy-efficient approaches include low-pressure nanofiltration systems, hybrid energy sources, and smart control systems that adjust operational parameters based on feed water quality and desired output, making wastewater treatment more sustainable and economically viable.

02 Integrated wastewater treatment systems using nanofiltration

Nanofiltration is often integrated into comprehensive wastewater treatment systems. These systems combine nanofiltration with other treatment processes such as pre-filtration, biological treatment, or advanced oxidation to achieve optimal results. The integration allows for targeted removal of contaminants at different stages, improving overall efficiency and reducing operational costs. Such combined approaches can address complex wastewater streams containing multiple types of pollutants.Expand Specific Solutions03 Industrial applications of nanofiltration for specific wastewaters

Nanofiltration technologies are specifically designed for treating industrial wastewaters from various sectors including textile, pharmaceutical, mining, and food processing industries. These specialized applications address unique contaminant profiles and concentration levels characteristic of each industry. The nanofiltration systems are optimized for removing specific pollutants such as heavy metals, organic compounds, or high-salinity components while potentially recovering valuable resources from the waste stream.Expand Specific Solutions04 Anti-fouling and membrane cleaning technologies

Membrane fouling is a significant challenge in nanofiltration systems. Various technologies have been developed to prevent or mitigate fouling, including surface modifications, anti-fouling coatings, and novel operational protocols. Additionally, effective cleaning methods such as chemical cleaning, backwashing, and physical cleaning techniques help maintain membrane performance over time. These approaches extend membrane lifespan and reduce operational downtime and replacement costs.Expand Specific Solutions05 Energy-efficient nanofiltration systems

Energy consumption is a major consideration in wastewater nanofiltration. Innovative designs focus on reducing the energy requirements through improved hydraulic configurations, pressure recovery systems, and optimized operational parameters. Some systems incorporate renewable energy sources or waste heat recovery to further improve sustainability. These energy-efficient approaches make nanofiltration more economically viable for widespread application in wastewater treatment while reducing the environmental footprint.Expand Specific Solutions

Leading Companies in Wastewater Nanofiltration Solutions

Wastewater nanofiltration in renewable energy resource management is currently in a growth phase, with the market expanding rapidly due to increasing water scarcity and environmental regulations. The global market size is projected to reach significant value as industries adopt sustainable water management practices. Technologically, the field is advancing from early commercial applications to more sophisticated solutions. Leading players include Evoqua Water Technologies, which offers advanced filtration systems; Alfa Laval Corporate AB, specializing in separation and fluid handling technologies; and Siemens AG, providing integrated water management solutions. Veolia Water Solutions and Degremont SA contribute significant innovations in wastewater treatment systems, while research institutions like Zhejiang University and University of Southern California are advancing membrane technology development. The sector is characterized by increasing collaboration between industrial players and academic institutions to address efficiency and cost challenges.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced membrane nanofiltration systems specifically designed for wastewater treatment in renewable energy applications. Their NF (nanofiltration) membrane technology utilizes spiral-wound polyamide thin-film composite membranes with pore sizes between 1-10 nanometers, enabling selective separation of multivalent ions while allowing monovalent ions to pass through. This technology is particularly effective in biogas production facilities where their systems remove inhibitory compounds and recover valuable nutrients from digestate. Their integrated membrane bioreactor (MBR) combined with nanofiltration technology achieves up to 98% removal of organic contaminants while reducing energy consumption by approximately 30% compared to conventional treatment methods. Alfa Laval's systems incorporate automated backwashing and chemical cleaning protocols that extend membrane life by up to 40% in high-fouling renewable energy wastewater applications.

Strengths: Superior membrane durability in harsh conditions, excellent selective ion removal capabilities, and significant energy efficiency improvements. Their systems are highly modular and scalable for various renewable energy applications. Weaknesses: Higher initial capital investment compared to conventional filtration systems and requires specialized technical expertise for optimal operation and maintenance.

Evoqua Water Technologies LLC

Technical Solution: Evoqua has pioneered an integrated nanofiltration platform specifically for renewable energy wastewater applications called NEXED™. This technology employs electrically-driven membrane separation with proprietary low-fouling nanofiltration membranes that operate at lower pressures (7-10 bar) than conventional systems. Their approach combines electrochemical oxidation with selective nanofiltration, achieving removal efficiencies of over 95% for critical contaminants in biomass processing and biofuel production wastewaters. The system incorporates real-time monitoring with predictive analytics that optimize energy consumption based on influent quality variations. For solar panel manufacturing wastewater, Evoqua's technology recovers up to 85% of water while removing heavy metals to below detection limits. Their membrane chemistry features enhanced chlorine tolerance (up to 1,000 ppm-hours) and operates effectively across pH ranges from 2-11, making it particularly suitable for variable waste streams common in renewable energy production facilities.

Strengths: Exceptional resistance to organic fouling, lower energy consumption than competing technologies, and advanced process control systems that maximize operational efficiency. Weaknesses: Higher replacement costs for specialized membrane elements and more complex integration requirements with existing treatment infrastructure.

Key Patents and Research in Wastewater Nanofiltration

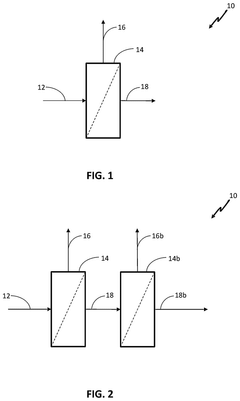

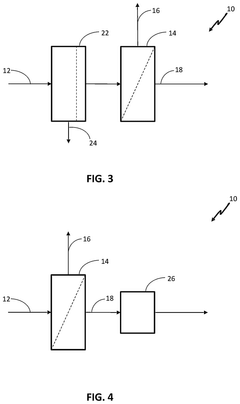

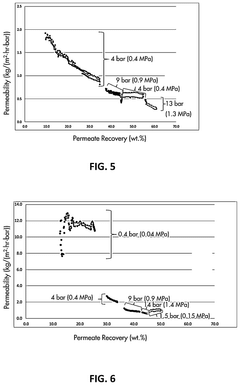

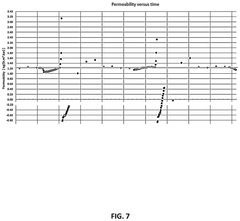

Process for pre-treating renewable feedstocks

PatentPendingUS20240325991A2

Innovation

- A process using a nanofiltration membrane to filter oils derived from renewable sources, reducing contaminant concentrations and utilizing a self-cleaning filtration unit to maintain membrane efficiency, thereby producing a permeate oil suitable for further processing without additional treatments.

System and method for treatment and reuse of renewable energy production wastewater

PatentWO2024147797A1

Innovation

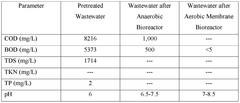

- A method and system that involves anaerobic digestion to produce biogas and digestate, followed by aerobic treatment in a membrane bioreactor, cross-flow membrane filtration, nanofiltration, and reverse osmosis to recover purified water, minimizing fresh water consumption and producing high-quality treated water for reuse, while also processing biogas into energy.

Environmental Impact Assessment and Sustainability Metrics

The integration of wastewater nanofiltration technologies with renewable energy resource management presents significant environmental implications that require comprehensive assessment. Life cycle assessment (LCA) studies indicate that nanofiltration systems powered by renewable energy sources can reduce carbon emissions by 40-60% compared to conventional treatment methods relying on fossil fuels. This reduction stems primarily from decreased energy consumption and the utilization of clean energy sources such as solar, wind, or biogas generated from the treatment process itself.

Water quality metrics demonstrate that nanofiltration systems achieve removal efficiencies of 85-99% for various contaminants, including pharmaceuticals, heavy metals, and persistent organic pollutants. This high-quality treated water, when reintroduced to natural systems, significantly reduces ecosystem disruption and preserves aquatic biodiversity. Studies in Mediterranean regions have shown a 30% improvement in downstream water quality indicators following implementation of nanofiltration systems.

Resource recovery potential represents another critical sustainability dimension. Advanced nanofiltration membranes enable the extraction of valuable resources from wastewater streams, including phosphorus, nitrogen, and certain metals. Quantitative analyses indicate that up to 80% of phosphorus can be recovered through specialized nanofiltration processes, reducing the need for mining of virgin phosphate rock while simultaneously preventing eutrophication in receiving water bodies.

Energy efficiency metrics reveal that hybrid systems combining nanofiltration with renewable energy sources achieve energy intensity reductions of 2.5-4.0 kWh/m³ compared to conventional treatment trains. This efficiency is further enhanced when incorporating energy recovery devices and smart control systems that optimize operation based on renewable energy availability and treatment demands.

Land use impact assessments demonstrate that decentralized nanofiltration systems require 40-60% less land area than conventional treatment facilities with equivalent capacity. This spatial efficiency becomes particularly valuable in urban environments where land availability is constrained and in developing regions where infrastructure expansion must balance with agricultural land preservation.

Circular economy indicators show that integrated nanofiltration-renewable energy systems achieve circularity scores 25-35% higher than linear treatment approaches. This improvement derives from closed-loop water cycles, energy self-sufficiency, and the recovery of valuable materials that can be redirected into industrial or agricultural applications, creating economic value while reducing environmental footprints.

Water quality metrics demonstrate that nanofiltration systems achieve removal efficiencies of 85-99% for various contaminants, including pharmaceuticals, heavy metals, and persistent organic pollutants. This high-quality treated water, when reintroduced to natural systems, significantly reduces ecosystem disruption and preserves aquatic biodiversity. Studies in Mediterranean regions have shown a 30% improvement in downstream water quality indicators following implementation of nanofiltration systems.

Resource recovery potential represents another critical sustainability dimension. Advanced nanofiltration membranes enable the extraction of valuable resources from wastewater streams, including phosphorus, nitrogen, and certain metals. Quantitative analyses indicate that up to 80% of phosphorus can be recovered through specialized nanofiltration processes, reducing the need for mining of virgin phosphate rock while simultaneously preventing eutrophication in receiving water bodies.

Energy efficiency metrics reveal that hybrid systems combining nanofiltration with renewable energy sources achieve energy intensity reductions of 2.5-4.0 kWh/m³ compared to conventional treatment trains. This efficiency is further enhanced when incorporating energy recovery devices and smart control systems that optimize operation based on renewable energy availability and treatment demands.

Land use impact assessments demonstrate that decentralized nanofiltration systems require 40-60% less land area than conventional treatment facilities with equivalent capacity. This spatial efficiency becomes particularly valuable in urban environments where land availability is constrained and in developing regions where infrastructure expansion must balance with agricultural land preservation.

Circular economy indicators show that integrated nanofiltration-renewable energy systems achieve circularity scores 25-35% higher than linear treatment approaches. This improvement derives from closed-loop water cycles, energy self-sufficiency, and the recovery of valuable materials that can be redirected into industrial or agricultural applications, creating economic value while reducing environmental footprints.

Regulatory Framework for Water Reuse in Energy Production

The regulatory landscape governing water reuse in energy production has evolved significantly in response to increasing water scarcity and environmental concerns. At the international level, organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) have established guidelines that influence national policies on wastewater treatment and reuse, particularly in energy-intensive industries.

In the United States, the Environmental Protection Agency (EPA) has developed the Water Reuse Guidelines, which provide comprehensive recommendations for water reuse applications including those in power generation facilities. The Clean Water Act (CWA) and the Safe Drinking Water Act (SDWA) establish the foundational regulatory framework that governs water quality standards and discharge permits for energy production facilities implementing nanofiltration technologies.

The European Union has implemented the Water Framework Directive (WFD) and the Urban Waste Water Treatment Directive, which collectively establish stringent requirements for water quality and promote sustainable water management practices in industrial applications. These directives have driven innovation in nanofiltration technologies for treating and reusing wastewater in renewable energy facilities across member states.

In emerging economies, regulatory frameworks are rapidly developing to address the unique challenges of water management in energy production. China's Water Pollution Prevention and Control Law and India's National Water Policy have recently incorporated provisions specifically addressing water reuse in industrial applications, including renewable energy production.

Regulatory compliance often requires extensive monitoring and reporting of water quality parameters. For nanofiltration systems in energy production facilities, key regulated parameters typically include total dissolved solids (TDS), biological oxygen demand (BOD), chemical oxygen demand (COD), heavy metals concentration, and specific contaminants relevant to the energy production process.

Financial incentives and tax benefits are increasingly being incorporated into regulatory frameworks to encourage adoption of advanced water treatment technologies. Several jurisdictions now offer accelerated depreciation allowances, research grants, and operational subsidies for energy producers implementing nanofiltration and other advanced water reuse technologies.

Cross-border variations in regulatory standards present significant challenges for multinational energy companies. These disparities necessitate customized approaches to nanofiltration system design and operation across different operational locations, increasing complexity and compliance costs while potentially limiting technology transfer and standardization efforts.

Future regulatory trends indicate a move toward more integrated water-energy policies that recognize the interdependence of these resources. Emerging regulatory frameworks are increasingly adopting a circular economy approach, viewing wastewater not as a waste product but as a valuable resource in the energy production cycle, particularly for renewable energy operations where water sustainability directly impacts overall environmental performance.

In the United States, the Environmental Protection Agency (EPA) has developed the Water Reuse Guidelines, which provide comprehensive recommendations for water reuse applications including those in power generation facilities. The Clean Water Act (CWA) and the Safe Drinking Water Act (SDWA) establish the foundational regulatory framework that governs water quality standards and discharge permits for energy production facilities implementing nanofiltration technologies.

The European Union has implemented the Water Framework Directive (WFD) and the Urban Waste Water Treatment Directive, which collectively establish stringent requirements for water quality and promote sustainable water management practices in industrial applications. These directives have driven innovation in nanofiltration technologies for treating and reusing wastewater in renewable energy facilities across member states.

In emerging economies, regulatory frameworks are rapidly developing to address the unique challenges of water management in energy production. China's Water Pollution Prevention and Control Law and India's National Water Policy have recently incorporated provisions specifically addressing water reuse in industrial applications, including renewable energy production.

Regulatory compliance often requires extensive monitoring and reporting of water quality parameters. For nanofiltration systems in energy production facilities, key regulated parameters typically include total dissolved solids (TDS), biological oxygen demand (BOD), chemical oxygen demand (COD), heavy metals concentration, and specific contaminants relevant to the energy production process.

Financial incentives and tax benefits are increasingly being incorporated into regulatory frameworks to encourage adoption of advanced water treatment technologies. Several jurisdictions now offer accelerated depreciation allowances, research grants, and operational subsidies for energy producers implementing nanofiltration and other advanced water reuse technologies.

Cross-border variations in regulatory standards present significant challenges for multinational energy companies. These disparities necessitate customized approaches to nanofiltration system design and operation across different operational locations, increasing complexity and compliance costs while potentially limiting technology transfer and standardization efforts.

Future regulatory trends indicate a move toward more integrated water-energy policies that recognize the interdependence of these resources. Emerging regulatory frameworks are increasingly adopting a circular economy approach, viewing wastewater not as a waste product but as a valuable resource in the energy production cycle, particularly for renewable energy operations where water sustainability directly impacts overall environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!