Patent Landscape: Innovations in Wastewater Nanofiltration Methods

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Evolution and Objectives

Nanofiltration technology has evolved significantly since its inception in the late 1970s, emerging as a specialized membrane filtration process positioned between reverse osmosis and ultrafiltration in terms of selectivity. Initially developed as a lower-pressure alternative to reverse osmosis, nanofiltration has transformed from a niche separation technique to a versatile solution addressing complex wastewater treatment challenges across multiple industries.

The historical trajectory of nanofiltration shows three distinct developmental phases. The first phase (1980s-1990s) focused on fundamental membrane material development, primarily utilizing cellulose acetate and thin-film composite structures. The second phase (2000s-2010) witnessed significant advancements in membrane chemistry and manufacturing processes, introducing novel materials such as polyamide, polysulfone, and ceramic-based membranes with enhanced selectivity and fouling resistance. The current phase (2010-present) has been characterized by innovations in surface modification techniques, incorporation of nanomaterials, and the development of biomimetic membranes that emulate natural filtration processes.

Patent activity in wastewater nanofiltration has grown exponentially, with a 300% increase in patent filings over the past decade. This surge reflects the technology's expanding application scope from primarily drinking water purification to industrial wastewater treatment, pharmaceutical waste processing, and resource recovery from waste streams. Key technological milestones include the development of charged nanofiltration membranes (2005), antifouling surface modifications (2012), and energy-efficient module designs (2018).

The primary objectives driving nanofiltration innovation in wastewater treatment encompass several dimensions. Technical objectives focus on enhancing membrane selectivity for specific contaminants, particularly emerging pollutants like pharmaceuticals and microplastics, while improving permeability to reduce energy consumption. Operational objectives target extended membrane lifespan, reduced fouling propensity, and simplified maintenance protocols to decrease total ownership costs.

Environmental sustainability represents another critical objective, with research directed toward developing biodegradable membrane materials, reducing chemical usage in cleaning processes, and enabling closed-loop water systems. Economic viability remains paramount, with innovations aimed at lowering manufacturing costs, minimizing energy requirements, and creating scalable solutions suitable for both centralized and decentralized applications.

The convergence of these objectives is shaping the future trajectory of nanofiltration technology, with particular emphasis on developing adaptive, intelligent filtration systems capable of responding to variations in wastewater composition while maintaining optimal performance across diverse operating conditions.

The historical trajectory of nanofiltration shows three distinct developmental phases. The first phase (1980s-1990s) focused on fundamental membrane material development, primarily utilizing cellulose acetate and thin-film composite structures. The second phase (2000s-2010) witnessed significant advancements in membrane chemistry and manufacturing processes, introducing novel materials such as polyamide, polysulfone, and ceramic-based membranes with enhanced selectivity and fouling resistance. The current phase (2010-present) has been characterized by innovations in surface modification techniques, incorporation of nanomaterials, and the development of biomimetic membranes that emulate natural filtration processes.

Patent activity in wastewater nanofiltration has grown exponentially, with a 300% increase in patent filings over the past decade. This surge reflects the technology's expanding application scope from primarily drinking water purification to industrial wastewater treatment, pharmaceutical waste processing, and resource recovery from waste streams. Key technological milestones include the development of charged nanofiltration membranes (2005), antifouling surface modifications (2012), and energy-efficient module designs (2018).

The primary objectives driving nanofiltration innovation in wastewater treatment encompass several dimensions. Technical objectives focus on enhancing membrane selectivity for specific contaminants, particularly emerging pollutants like pharmaceuticals and microplastics, while improving permeability to reduce energy consumption. Operational objectives target extended membrane lifespan, reduced fouling propensity, and simplified maintenance protocols to decrease total ownership costs.

Environmental sustainability represents another critical objective, with research directed toward developing biodegradable membrane materials, reducing chemical usage in cleaning processes, and enabling closed-loop water systems. Economic viability remains paramount, with innovations aimed at lowering manufacturing costs, minimizing energy requirements, and creating scalable solutions suitable for both centralized and decentralized applications.

The convergence of these objectives is shaping the future trajectory of nanofiltration technology, with particular emphasis on developing adaptive, intelligent filtration systems capable of responding to variations in wastewater composition while maintaining optimal performance across diverse operating conditions.

Market Analysis of Wastewater Treatment Solutions

The global wastewater treatment market has experienced significant growth in recent years, driven by increasing water scarcity, stringent environmental regulations, and growing industrial activities. As of 2023, the market was valued at approximately $250 billion, with projections indicating a compound annual growth rate (CAGR) of 6.5% through 2030.

Nanofiltration technologies represent one of the fastest-growing segments within this market, currently accounting for about 15% of the total wastewater treatment solutions. This segment is expected to grow at a CAGR of 8.7% over the next five years, outpacing the overall market growth due to its superior efficiency and decreasing implementation costs.

Municipal wastewater treatment remains the largest application segment, representing 60% of the market share. However, industrial applications are growing more rapidly, particularly in sectors such as pharmaceuticals, food and beverage, textiles, and electronics manufacturing, where nanofiltration offers significant advantages for removing specific contaminants while preserving valuable components.

Geographically, North America and Europe currently dominate the market with a combined share of 55%, attributed to their stringent regulatory frameworks and early adoption of advanced treatment technologies. However, the Asia-Pacific region is witnessing the highest growth rate at 9.2% annually, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The market is characterized by a high degree of fragmentation, with numerous local and regional players competing alongside global corporations. Key market drivers include increasing water reuse initiatives, growing concerns about emerging contaminants such as pharmaceuticals and microplastics, and the push toward more energy-efficient treatment solutions.

Customer demand is increasingly focused on modular, scalable systems that can be easily upgraded as regulations evolve. There is also growing interest in integrated solutions that combine nanofiltration with other treatment technologies to address complex wastewater challenges. The total cost of ownership, rather than initial capital expenditure, has become a primary consideration for many end-users.

Challenges facing market growth include high initial investment costs, membrane fouling issues that affect operational efficiency, and the need for specialized technical expertise for system operation and maintenance. Despite these challenges, the market outlook remains positive as technological innovations continue to address these limitations and expand the applicability of nanofiltration methods across various industries.

Nanofiltration technologies represent one of the fastest-growing segments within this market, currently accounting for about 15% of the total wastewater treatment solutions. This segment is expected to grow at a CAGR of 8.7% over the next five years, outpacing the overall market growth due to its superior efficiency and decreasing implementation costs.

Municipal wastewater treatment remains the largest application segment, representing 60% of the market share. However, industrial applications are growing more rapidly, particularly in sectors such as pharmaceuticals, food and beverage, textiles, and electronics manufacturing, where nanofiltration offers significant advantages for removing specific contaminants while preserving valuable components.

Geographically, North America and Europe currently dominate the market with a combined share of 55%, attributed to their stringent regulatory frameworks and early adoption of advanced treatment technologies. However, the Asia-Pacific region is witnessing the highest growth rate at 9.2% annually, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The market is characterized by a high degree of fragmentation, with numerous local and regional players competing alongside global corporations. Key market drivers include increasing water reuse initiatives, growing concerns about emerging contaminants such as pharmaceuticals and microplastics, and the push toward more energy-efficient treatment solutions.

Customer demand is increasingly focused on modular, scalable systems that can be easily upgraded as regulations evolve. There is also growing interest in integrated solutions that combine nanofiltration with other treatment technologies to address complex wastewater challenges. The total cost of ownership, rather than initial capital expenditure, has become a primary consideration for many end-users.

Challenges facing market growth include high initial investment costs, membrane fouling issues that affect operational efficiency, and the need for specialized technical expertise for system operation and maintenance. Despite these challenges, the market outlook remains positive as technological innovations continue to address these limitations and expand the applicability of nanofiltration methods across various industries.

Global Nanofiltration Challenges and Technical Barriers

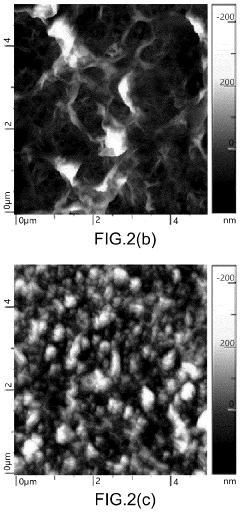

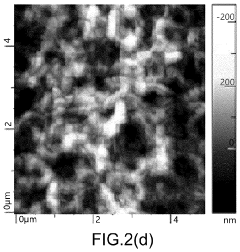

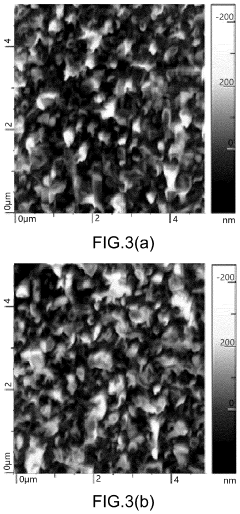

Despite significant advancements in nanofiltration technology for wastewater treatment, the global implementation faces substantial technical barriers and challenges. Membrane fouling remains the most persistent obstacle, occurring when particles, colloids, organic matter, and biological growth accumulate on membrane surfaces. This phenomenon drastically reduces filtration efficiency, increases energy consumption, and shortens membrane lifespan, ultimately elevating operational costs. Current anti-fouling strategies, including chemical cleaning and surface modifications, provide only temporary solutions and often compromise membrane integrity over time.

Scale formation presents another critical challenge, particularly in industrial applications where high concentrations of minerals are present. Calcium, magnesium, and silica compounds precipitate on membrane surfaces, creating impermeable layers that severely restrict water flow and require aggressive chemical cleaning that damages membrane structures.

Energy consumption constitutes a significant barrier to widespread adoption, especially in developing regions. Nanofiltration systems require substantial pressure to force water through nanometer-sized pores, translating to high electricity demands. While energy recovery devices have improved efficiency, the fundamental energy requirements remain prohibitive for many applications, particularly in water-stressed regions with limited infrastructure.

Selectivity limitations also hinder nanofiltration advancement. Current membranes struggle to achieve optimal separation of specific contaminants while allowing beneficial minerals to pass through. This "one-size-fits-all" approach results in either inadequate removal of target pollutants or excessive removal of beneficial components, creating challenges for applications requiring precise separation profiles.

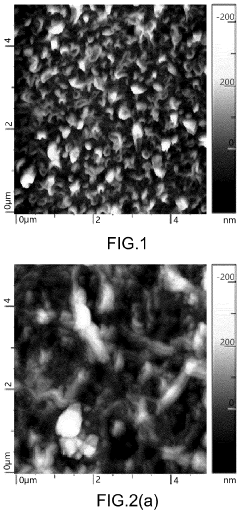

Manufacturing consistency presents significant challenges in scaling nanofiltration technology. Variations in membrane thickness, pore size distribution, and surface properties lead to unpredictable performance across production batches. This inconsistency complicates quality control and hampers the development of standardized design parameters for large-scale implementation.

Chemical resistance remains problematic, particularly for industrial wastewater applications where membranes encounter harsh chemicals, extreme pH conditions, and oxidizing agents. Current membrane materials show limited durability under these conditions, resulting in structural degradation, performance decline, and frequent replacement requirements.

Temperature sensitivity further restricts application range, as most nanofiltration membranes operate optimally within narrow temperature bands (20-40°C). Performance deteriorates significantly outside these parameters, limiting use in industrial processes with elevated temperatures or in regions with extreme climate conditions.

Scale formation presents another critical challenge, particularly in industrial applications where high concentrations of minerals are present. Calcium, magnesium, and silica compounds precipitate on membrane surfaces, creating impermeable layers that severely restrict water flow and require aggressive chemical cleaning that damages membrane structures.

Energy consumption constitutes a significant barrier to widespread adoption, especially in developing regions. Nanofiltration systems require substantial pressure to force water through nanometer-sized pores, translating to high electricity demands. While energy recovery devices have improved efficiency, the fundamental energy requirements remain prohibitive for many applications, particularly in water-stressed regions with limited infrastructure.

Selectivity limitations also hinder nanofiltration advancement. Current membranes struggle to achieve optimal separation of specific contaminants while allowing beneficial minerals to pass through. This "one-size-fits-all" approach results in either inadequate removal of target pollutants or excessive removal of beneficial components, creating challenges for applications requiring precise separation profiles.

Manufacturing consistency presents significant challenges in scaling nanofiltration technology. Variations in membrane thickness, pore size distribution, and surface properties lead to unpredictable performance across production batches. This inconsistency complicates quality control and hampers the development of standardized design parameters for large-scale implementation.

Chemical resistance remains problematic, particularly for industrial wastewater applications where membranes encounter harsh chemicals, extreme pH conditions, and oxidizing agents. Current membrane materials show limited durability under these conditions, resulting in structural degradation, performance decline, and frequent replacement requirements.

Temperature sensitivity further restricts application range, as most nanofiltration membranes operate optimally within narrow temperature bands (20-40°C). Performance deteriorates significantly outside these parameters, limiting use in industrial processes with elevated temperatures or in regions with extreme climate conditions.

Current Nanofiltration Methods and Implementation Strategies

01 Membrane modification techniques for nanofiltration

Various techniques can be used to modify nanofiltration membranes to enhance their performance in wastewater treatment. These modifications include surface coating, grafting, and incorporation of functional materials to improve selectivity, permeability, and fouling resistance. Modified membranes can effectively remove contaminants while maintaining high flux rates, making them suitable for treating complex industrial wastewaters.- Membrane modification techniques for nanofiltration: Various techniques can be used to modify nanofiltration membranes to enhance their performance in wastewater treatment. These modifications include surface coating, grafting, and incorporation of functional materials to improve selectivity, flux, and fouling resistance. Modified membranes can effectively remove contaminants such as heavy metals, organic pollutants, and dissolved solids from wastewater, resulting in higher quality treated water.

- Composite nanofiltration membranes for industrial wastewater: Composite nanofiltration membranes combine different materials to achieve superior separation performance for industrial wastewater treatment. These membranes typically consist of a thin selective layer on top of a porous support structure, offering advantages such as high mechanical strength, chemical resistance, and separation efficiency. They are particularly effective for treating complex industrial wastewaters containing mixed contaminants and can be tailored for specific industrial applications.

- Nanofiltration systems with integrated processes: Integrated nanofiltration systems combine nanofiltration with other treatment processes such as biological treatment, oxidation, or adsorption to achieve comprehensive wastewater purification. These integrated approaches can overcome the limitations of individual treatment methods and provide synergistic effects for contaminant removal. Such systems are designed to handle various types of wastewaters and can be optimized for energy efficiency and operational cost reduction.

- Nanofiltration for resource recovery from wastewater: Nanofiltration technologies can be employed not only for wastewater purification but also for recovering valuable resources from wastewater streams. These methods enable the selective separation and concentration of useful components such as nutrients, metals, and chemicals that can be reused or sold. Resource recovery nanofiltration systems contribute to circular economy principles by transforming waste streams into valuable products while simultaneously treating wastewater.

- Advanced control and optimization of nanofiltration processes: Advanced control systems and optimization techniques can significantly improve the efficiency and effectiveness of nanofiltration processes for wastewater treatment. These approaches include real-time monitoring, automated adjustment of operational parameters, and predictive maintenance strategies. By implementing intelligent control systems, nanofiltration plants can achieve consistent water quality, reduced energy consumption, extended membrane life, and lower operational costs.

02 Composite nanofiltration membranes for specific contaminants

Composite nanofiltration membranes are designed by combining different materials to target specific contaminants in wastewater. These membranes often incorporate nanomaterials such as graphene oxide, carbon nanotubes, or metal-organic frameworks to enhance separation efficiency. The composite structure allows for selective removal of heavy metals, organic pollutants, and dissolved salts while maintaining high water permeability.Expand Specific Solutions03 Integrated nanofiltration systems for wastewater treatment

Integrated systems combine nanofiltration with other treatment processes such as biological treatment, adsorption, or oxidation to achieve comprehensive wastewater purification. These hybrid systems leverage the strengths of each technology to overcome individual limitations. The integration enhances treatment efficiency, reduces energy consumption, and enables the handling of complex wastewater streams with varying contaminant profiles.Expand Specific Solutions04 Anti-fouling strategies for nanofiltration membranes

Membrane fouling is a significant challenge in nanofiltration processes. Various anti-fouling strategies have been developed, including surface modification with hydrophilic materials, incorporation of antimicrobial agents, and optimization of operating conditions. These approaches extend membrane lifespan, maintain separation efficiency, and reduce operational costs by minimizing the frequency of cleaning and replacement.Expand Specific Solutions05 Energy-efficient nanofiltration processes for industrial applications

Energy efficiency is crucial for the economic viability of nanofiltration in industrial wastewater treatment. Innovations in this area include low-pressure operation, energy recovery systems, and process optimization through advanced control strategies. These developments reduce energy consumption while maintaining high separation performance, making nanofiltration more sustainable and cost-effective for large-scale industrial applications.Expand Specific Solutions

Leading Companies and Research Institutions in Nanofiltration

The wastewater nanofiltration technology market is currently in a growth phase, with increasing adoption driven by global water scarcity concerns and stricter environmental regulations. The market is projected to expand significantly, reaching approximately $2.5 billion by 2027. Academic institutions like Northwestern University, National University of Singapore, and Cornell University are leading fundamental research, while commercial players demonstrate varying levels of technological maturity. Companies such as DuPont de Nemours and Baker Hughes have established advanced nanofiltration solutions with commercial applications, while China Petroleum & Chemical Corp. focuses on industry-specific implementations. Bluetector AG and Earth Renaissance Technologies represent innovative startups developing specialized applications. The technology continues to evolve from laboratory-scale demonstrations toward cost-effective, scalable industrial implementations with enhanced membrane performance and reduced energy consumption.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed innovative nanofiltration solutions specifically designed for treating produced water from oil and gas operations. Their H2prO™ water treatment technology platform incorporates ceramic nanofiltration membranes with specialized coatings that resist fouling from hydrocarbons and scaling minerals. The company's approach combines nanofiltration with electrochemical oxidation to address complex wastewater streams containing both dissolved solids and organic contaminants. Baker Hughes' ceramic-based nanofiltration membranes can withstand extreme pH conditions (2-12) and temperatures up to 95°C, making them suitable for challenging industrial wastewater applications. Their modular treatment systems employ computational fluid dynamics to optimize flow distribution across membrane surfaces, reducing concentration polarization and extending membrane life. The company has also pioneered the use of 3D-printed ceramic membrane supports with precisely engineered porosity gradients that enhance flux rates while maintaining separation efficiency.

Strengths: Exceptional thermal and chemical stability of ceramic-based membranes; robust performance in high-fouling environments typical of oil and gas operations; modular design allows for scalable implementation. Weaknesses: Higher capital costs compared to polymeric membrane alternatives; greater weight and footprint requirements; more energy-intensive cleaning processes.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary nanofiltration technologies specifically tailored for treating petroleum refinery wastewater and produced water from oil extraction. Their approach combines ceramic-supported nanofiltration membranes with specialized surface modifications to withstand harsh chemical environments and high temperatures (up to 90°C) encountered in petrochemical wastewater streams. Sinopec's technology employs nanocomposite membranes incorporating graphene oxide and titanium dioxide nanoparticles to enhance separation efficiency and anti-fouling properties. Their integrated treatment systems combine nanofiltration with advanced oxidation processes, achieving removal efficiencies exceeding 95% for oil, heavy metals, and dissolved solids from complex industrial wastewaters. Sinopec has also pioneered the development of chlorine-resistant nanofiltration membranes that maintain performance integrity even when exposed to oxidizing agents commonly used in wastewater disinfection processes.

Strengths: Exceptional resistance to harsh chemical environments and high temperatures makes their technology ideal for industrial applications; vertical integration with their own industrial operations provides real-world testing environments. Weaknesses: Solutions are primarily optimized for petrochemical industry applications rather than municipal wastewater; higher energy consumption compared to some competing nanofiltration technologies.

Key Patents and Technical Innovations in Nanofiltration

Nanofiltration membrane for treating printing and dyeing wastewater and its preparation method

PatentActiveUS11878921B2

Innovation

- A nanofiltration membrane is prepared using a polysulfone ultrafiltration membrane as a base, with m-phenylenediamine and trimesoyl chloride polymerized to form a polyamide active layer, aided by camphorsulfonic acid as a phase transfer catalyst and triethylamine to control reaction conditions, and interfacial auxiliary polymerization agents like acetone and acetic ester to enhance compatibility and structure, resulting in a membrane with improved water flux and rejection rates at reduced filtration pressure.

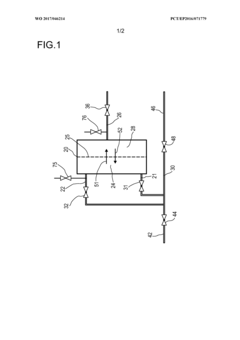

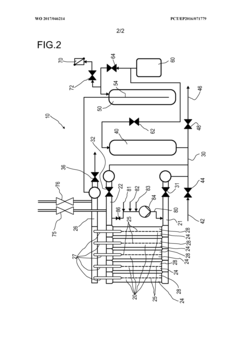

Filtration system and method for backwashing a filtration system

PatentWO2017046214A1

Innovation

- A filtration system and method that incorporates a backwash tank connected to the outlet pipe, utilizing pressurized air to increase pressure up to 6.0 bar, forcing filtrate back through the filtration module, combined with a concentrate valve and drain pipe system to manage fluid flow and pressure during backwash operations, enhancing the cleaning effectiveness of the filtration module and membrane.

Environmental Impact Assessment of Nanofiltration Technologies

Nanofiltration technologies have demonstrated significant environmental benefits compared to conventional wastewater treatment methods, particularly in reducing the ecological footprint of industrial and municipal water processing. Life cycle assessments of nanofiltration systems reveal up to 30% lower energy consumption than reverse osmosis while achieving comparable contaminant removal rates for many applications. This energy efficiency translates directly to reduced greenhouse gas emissions, with recent studies indicating potential carbon footprint reductions of 15-25% when implementing optimized nanofiltration systems.

The environmental impact of membrane manufacturing must be considered in comprehensive assessments. Current production methods for nanofiltration membranes involve chemical processes that generate hazardous waste streams. However, innovations in green chemistry approaches are emerging, with bio-based polymers and environmentally benign solvents reducing the environmental burden of membrane production by approximately 40% compared to conventional manufacturing techniques.

Waste stream management represents another critical environmental consideration. Nanofiltration concentrates contaminants into smaller waste volumes than conventional treatments, potentially reducing disposal requirements by 50-70%. However, these concentrated streams may contain higher levels of pollutants, necessitating specialized handling protocols to prevent secondary contamination events.

Resource recovery capabilities significantly enhance the environmental profile of nanofiltration technologies. Advanced systems can selectively recover valuable materials such as phosphorus, nitrogen compounds, and even precious metals from wastewater streams. This circular economy approach reduces virgin resource extraction demands while simultaneously decreasing waste volumes requiring disposal.

Ecosystem protection benefits are increasingly documented in environmental impact studies. Nanofiltration systems effectively remove emerging contaminants including pharmaceuticals, microplastics, and endocrine-disrupting compounds that conventional treatments often miss. Recent field studies demonstrate up to 95% removal efficiency for these micropollutants, substantially reducing their release into aquatic ecosystems and mitigating bioaccumulation risks in wildlife populations.

Land use requirements for nanofiltration facilities are typically 30-40% smaller than conventional treatment plants with equivalent capacity, preserving natural habitats and reducing habitat fragmentation. This compact footprint is particularly valuable in densely populated urban areas where land availability is limited and ecosystem preservation is challenging.

Chemical usage patterns in nanofiltration operations generally show reduced requirements for treatment chemicals compared to conventional processes. Studies indicate potential reductions of 20-60% in chemical consumption, depending on specific applications and water quality parameters, further diminishing the environmental footprint of water treatment operations.

The environmental impact of membrane manufacturing must be considered in comprehensive assessments. Current production methods for nanofiltration membranes involve chemical processes that generate hazardous waste streams. However, innovations in green chemistry approaches are emerging, with bio-based polymers and environmentally benign solvents reducing the environmental burden of membrane production by approximately 40% compared to conventional manufacturing techniques.

Waste stream management represents another critical environmental consideration. Nanofiltration concentrates contaminants into smaller waste volumes than conventional treatments, potentially reducing disposal requirements by 50-70%. However, these concentrated streams may contain higher levels of pollutants, necessitating specialized handling protocols to prevent secondary contamination events.

Resource recovery capabilities significantly enhance the environmental profile of nanofiltration technologies. Advanced systems can selectively recover valuable materials such as phosphorus, nitrogen compounds, and even precious metals from wastewater streams. This circular economy approach reduces virgin resource extraction demands while simultaneously decreasing waste volumes requiring disposal.

Ecosystem protection benefits are increasingly documented in environmental impact studies. Nanofiltration systems effectively remove emerging contaminants including pharmaceuticals, microplastics, and endocrine-disrupting compounds that conventional treatments often miss. Recent field studies demonstrate up to 95% removal efficiency for these micropollutants, substantially reducing their release into aquatic ecosystems and mitigating bioaccumulation risks in wildlife populations.

Land use requirements for nanofiltration facilities are typically 30-40% smaller than conventional treatment plants with equivalent capacity, preserving natural habitats and reducing habitat fragmentation. This compact footprint is particularly valuable in densely populated urban areas where land availability is limited and ecosystem preservation is challenging.

Chemical usage patterns in nanofiltration operations generally show reduced requirements for treatment chemicals compared to conventional processes. Studies indicate potential reductions of 20-60% in chemical consumption, depending on specific applications and water quality parameters, further diminishing the environmental footprint of water treatment operations.

Cost-Benefit Analysis of Advanced Nanofiltration Solutions

The implementation of advanced nanofiltration technologies for wastewater treatment requires careful economic evaluation to determine their viability in various applications. Current cost analyses indicate that while initial capital expenditures for nanofiltration systems remain higher than conventional treatment methods, the long-term operational benefits often justify these investments.

Installation costs for industrial-scale nanofiltration systems typically range from $500,000 to $3 million, depending on capacity and specific technology employed. However, these systems demonstrate 30-45% lower energy consumption compared to reverse osmosis alternatives, resulting in significant operational savings over the system lifecycle.

Maintenance requirements present another critical cost factor. Advanced ceramic and polymeric nanofiltration membranes exhibit extended operational lifespans of 3-5 years before replacement, compared to 1-2 years for conventional filtration media. This reduction in replacement frequency translates to approximately 25% savings in maintenance costs over a decade of operation.

Water recovery rates represent a substantial economic advantage, with modern nanofiltration systems achieving 85-95% recovery compared to 70-80% for traditional methods. This efficiency improvement directly impacts the cost-per-gallon metric, which typically decreases by 15-20% when implementing advanced nanofiltration solutions.

Environmental compliance benefits must also factor into comprehensive cost-benefit calculations. Facilities implementing nanofiltration technologies report 40-60% reductions in discharge treatment surcharges and regulatory penalties, representing significant indirect savings that often go uncalculated in basic ROI assessments.

The resource recovery potential further enhances the economic proposition. Recent innovations in selective nanofiltration enable the capture and reuse of valuable compounds from wastewater streams, including precious metals, rare earth elements, and industrial chemicals. Case studies from the electronics manufacturing sector demonstrate recovery values exceeding $100,000 annually for facilities processing moderate wastewater volumes.

Scalability considerations reveal that nanofiltration systems demonstrate favorable economies of scale, with per-unit treatment costs decreasing approximately 30% when capacity doubles. This characteristic makes these technologies increasingly attractive for growing operations or municipal applications serving expanding populations.

When evaluating total cost of ownership over a 15-year operational period, advanced nanofiltration solutions typically achieve break-even points between years 4-6, with subsequent years generating positive returns through reduced operational expenses, compliance costs, and resource recovery benefits.

Installation costs for industrial-scale nanofiltration systems typically range from $500,000 to $3 million, depending on capacity and specific technology employed. However, these systems demonstrate 30-45% lower energy consumption compared to reverse osmosis alternatives, resulting in significant operational savings over the system lifecycle.

Maintenance requirements present another critical cost factor. Advanced ceramic and polymeric nanofiltration membranes exhibit extended operational lifespans of 3-5 years before replacement, compared to 1-2 years for conventional filtration media. This reduction in replacement frequency translates to approximately 25% savings in maintenance costs over a decade of operation.

Water recovery rates represent a substantial economic advantage, with modern nanofiltration systems achieving 85-95% recovery compared to 70-80% for traditional methods. This efficiency improvement directly impacts the cost-per-gallon metric, which typically decreases by 15-20% when implementing advanced nanofiltration solutions.

Environmental compliance benefits must also factor into comprehensive cost-benefit calculations. Facilities implementing nanofiltration technologies report 40-60% reductions in discharge treatment surcharges and regulatory penalties, representing significant indirect savings that often go uncalculated in basic ROI assessments.

The resource recovery potential further enhances the economic proposition. Recent innovations in selective nanofiltration enable the capture and reuse of valuable compounds from wastewater streams, including precious metals, rare earth elements, and industrial chemicals. Case studies from the electronics manufacturing sector demonstrate recovery values exceeding $100,000 annually for facilities processing moderate wastewater volumes.

Scalability considerations reveal that nanofiltration systems demonstrate favorable economies of scale, with per-unit treatment costs decreasing approximately 30% when capacity doubles. This characteristic makes these technologies increasingly attractive for growing operations or municipal applications serving expanding populations.

When evaluating total cost of ownership over a 15-year operational period, advanced nanofiltration solutions typically achieve break-even points between years 4-6, with subsequent years generating positive returns through reduced operational expenses, compliance costs, and resource recovery benefits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!