Catalytic Agents in Nanofiltration for Enhanced Wastewater Treatment

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Catalysis Background and Objectives

Nanofiltration technology has evolved significantly over the past three decades, transforming from a niche separation process to a cornerstone technology in advanced wastewater treatment systems. Initially developed in the 1980s as a pressure-driven membrane process positioned between reverse osmosis and ultrafiltration, nanofiltration has gained prominence due to its unique ability to selectively remove multivalent ions, organic compounds, and micropollutants while operating at lower pressures than reverse osmosis.

The integration of catalytic agents into nanofiltration represents a revolutionary advancement in this field. Traditional nanofiltration membranes primarily rely on size exclusion, charge effects, and solution-diffusion mechanisms for separation. However, these conventional approaches face limitations in removing persistent contaminants and suffer from membrane fouling, which reduces operational efficiency and membrane lifespan.

Recent technological trends indicate a paradigm shift toward multifunctional membrane systems that combine physical separation with chemical transformation capabilities. This convergence has given rise to catalytic nanofiltration, where strategically incorporated catalytic agents can degrade contaminants during the filtration process, rather than merely separating them from the water stream.

The evolution of catalytic materials has been instrumental in this development. From early metal-based catalysts to advanced nanomaterials including metal-organic frameworks (MOFs), graphene-based composites, and enzyme-mimetic structures, the field has witnessed remarkable innovation in catalyst design and integration methodologies.

The primary objective of catalytic nanofiltration research is to develop high-performance, fouling-resistant membrane systems capable of simultaneously removing and degrading recalcitrant pollutants in wastewater. Specific technical goals include enhancing catalytic activity while maintaining membrane permeability, improving catalyst stability and longevity under operational conditions, and developing scalable fabrication methods for commercial viability.

Additionally, research aims to expand the application spectrum of catalytic nanofiltration beyond traditional wastewater treatment to emerging challenges such as pharmaceutical residue removal, microplastic degradation, and selective resource recovery from industrial effluents. The technology seeks to address the growing global water crisis by providing more efficient, sustainable treatment solutions with reduced energy consumption and chemical usage.

The ultimate technological objective is to create next-generation water treatment systems that combine the selective separation capabilities of nanofiltration with the transformative power of catalysis, resulting in a process that not only purifies water but also detoxifies contaminants in a single, energy-efficient step. This convergence represents a promising frontier in environmental remediation technology with significant implications for water security and sustainability.

The integration of catalytic agents into nanofiltration represents a revolutionary advancement in this field. Traditional nanofiltration membranes primarily rely on size exclusion, charge effects, and solution-diffusion mechanisms for separation. However, these conventional approaches face limitations in removing persistent contaminants and suffer from membrane fouling, which reduces operational efficiency and membrane lifespan.

Recent technological trends indicate a paradigm shift toward multifunctional membrane systems that combine physical separation with chemical transformation capabilities. This convergence has given rise to catalytic nanofiltration, where strategically incorporated catalytic agents can degrade contaminants during the filtration process, rather than merely separating them from the water stream.

The evolution of catalytic materials has been instrumental in this development. From early metal-based catalysts to advanced nanomaterials including metal-organic frameworks (MOFs), graphene-based composites, and enzyme-mimetic structures, the field has witnessed remarkable innovation in catalyst design and integration methodologies.

The primary objective of catalytic nanofiltration research is to develop high-performance, fouling-resistant membrane systems capable of simultaneously removing and degrading recalcitrant pollutants in wastewater. Specific technical goals include enhancing catalytic activity while maintaining membrane permeability, improving catalyst stability and longevity under operational conditions, and developing scalable fabrication methods for commercial viability.

Additionally, research aims to expand the application spectrum of catalytic nanofiltration beyond traditional wastewater treatment to emerging challenges such as pharmaceutical residue removal, microplastic degradation, and selective resource recovery from industrial effluents. The technology seeks to address the growing global water crisis by providing more efficient, sustainable treatment solutions with reduced energy consumption and chemical usage.

The ultimate technological objective is to create next-generation water treatment systems that combine the selective separation capabilities of nanofiltration with the transformative power of catalysis, resulting in a process that not only purifies water but also detoxifies contaminants in a single, energy-efficient step. This convergence represents a promising frontier in environmental remediation technology with significant implications for water security and sustainability.

Market Analysis for Advanced Wastewater Treatment Solutions

The global wastewater treatment market is experiencing significant growth, driven by increasing water scarcity, stringent environmental regulations, and growing industrial activities. The market for advanced wastewater treatment solutions was valued at approximately $242 billion in 2022 and is projected to reach $376 billion by 2029, growing at a CAGR of 6.5% during the forecast period.

Nanofiltration technologies, particularly those incorporating catalytic agents, represent one of the fastest-growing segments within this market. This growth is attributed to their superior efficiency in removing contaminants while maintaining lower operational costs compared to traditional methods. The nanofiltration membrane market specifically is expected to grow at a CAGR of 8.2% through 2030, outpacing the broader wastewater treatment sector.

Regional analysis reveals that North America and Europe currently dominate the advanced wastewater treatment market, accounting for approximately 60% of global market share. However, the Asia-Pacific region is witnessing the highest growth rate, with China and India leading investments in wastewater infrastructure development. These emerging markets are increasingly adopting catalytic nanofiltration technologies to address severe water pollution challenges.

Industry-specific demand patterns show that municipal wastewater treatment accounts for the largest market share (42%), followed by industrial applications (38%) and commercial uses (20%). Within industrial applications, pharmaceutical, textile, and chemical manufacturing sectors demonstrate the highest adoption rates for catalytic nanofiltration solutions due to their complex wastewater profiles requiring advanced treatment methods.

Customer segmentation analysis indicates three primary buyer categories: municipal utilities seeking cost-effective solutions for large-scale operations, industrial entities requiring specialized treatment for compliance with discharge regulations, and engineering firms that integrate these technologies into comprehensive water management systems. Each segment prioritizes different value propositions, with municipalities focusing on operational costs, industries on treatment effectiveness, and engineering firms on integration capabilities.

Market barriers include high initial capital investment requirements, technological complexity requiring specialized expertise, and competition from established treatment methods. However, decreasing production costs of nanofiltration membranes and catalytic materials, coupled with increasing regulatory pressure for higher quality treated water, are gradually overcoming these barriers.

The competitive landscape features both established water treatment corporations and innovative startups. Major players include Veolia, Suez, Evoqua Water Technologies, and Pentair, who are increasingly incorporating catalytic nanofiltration technologies into their product portfolios through acquisitions and R&D investments. Meanwhile, specialized technology providers like NanoMembranes Ltd. and CatalySys Water Solutions are gaining market share through focused innovation in catalytic agent development.

Nanofiltration technologies, particularly those incorporating catalytic agents, represent one of the fastest-growing segments within this market. This growth is attributed to their superior efficiency in removing contaminants while maintaining lower operational costs compared to traditional methods. The nanofiltration membrane market specifically is expected to grow at a CAGR of 8.2% through 2030, outpacing the broader wastewater treatment sector.

Regional analysis reveals that North America and Europe currently dominate the advanced wastewater treatment market, accounting for approximately 60% of global market share. However, the Asia-Pacific region is witnessing the highest growth rate, with China and India leading investments in wastewater infrastructure development. These emerging markets are increasingly adopting catalytic nanofiltration technologies to address severe water pollution challenges.

Industry-specific demand patterns show that municipal wastewater treatment accounts for the largest market share (42%), followed by industrial applications (38%) and commercial uses (20%). Within industrial applications, pharmaceutical, textile, and chemical manufacturing sectors demonstrate the highest adoption rates for catalytic nanofiltration solutions due to their complex wastewater profiles requiring advanced treatment methods.

Customer segmentation analysis indicates three primary buyer categories: municipal utilities seeking cost-effective solutions for large-scale operations, industrial entities requiring specialized treatment for compliance with discharge regulations, and engineering firms that integrate these technologies into comprehensive water management systems. Each segment prioritizes different value propositions, with municipalities focusing on operational costs, industries on treatment effectiveness, and engineering firms on integration capabilities.

Market barriers include high initial capital investment requirements, technological complexity requiring specialized expertise, and competition from established treatment methods. However, decreasing production costs of nanofiltration membranes and catalytic materials, coupled with increasing regulatory pressure for higher quality treated water, are gradually overcoming these barriers.

The competitive landscape features both established water treatment corporations and innovative startups. Major players include Veolia, Suez, Evoqua Water Technologies, and Pentair, who are increasingly incorporating catalytic nanofiltration technologies into their product portfolios through acquisitions and R&D investments. Meanwhile, specialized technology providers like NanoMembranes Ltd. and CatalySys Water Solutions are gaining market share through focused innovation in catalytic agent development.

Current Challenges in Catalytic Nanofiltration Technology

Despite significant advancements in catalytic nanofiltration technology for wastewater treatment, several critical challenges continue to impede its widespread industrial implementation. The integration of catalytic agents with nanofiltration membranes faces persistent issues related to catalyst stability and longevity. Current catalytic nanoparticles often experience leaching during operation, resulting in decreased efficiency over time and potential secondary contamination of treated water. This degradation typically manifests after 200-300 operational hours, significantly below the 1000+ hours required for commercial viability.

Membrane fouling remains another substantial obstacle, particularly in complex wastewater streams containing organic pollutants, oils, and biological materials. The presence of catalytic agents can sometimes exacerbate fouling by creating additional nucleation sites for contaminant aggregation. Studies indicate that fouling can reduce filtration efficiency by 30-50% within the first 72 hours of operation, necessitating frequent cleaning cycles that interrupt continuous processing.

The selectivity-permeability trade-off continues to challenge researchers, as enhancing catalytic activity often comes at the expense of membrane permeability. Current technologies struggle to maintain high water flux rates while simultaneously achieving effective catalytic degradation of contaminants. Most systems demonstrate either excellent filtration with moderate catalytic activity or strong catalytic performance with compromised filtration rates.

Energy consumption presents another significant hurdle, with catalytic nanofiltration systems typically requiring 1.5-2.5 kWh per cubic meter of treated water. This energy demand makes the technology less economically viable compared to conventional treatment methods, which generally consume 0.5-1.0 kWh per cubic meter. The additional energy requirements primarily stem from pressure needs to overcome membrane resistance enhanced by catalytic agents.

Scalability issues further complicate industrial adoption, as laboratory-scale successes have proven difficult to translate to commercial-scale operations. The uniform distribution of catalytic agents across large membrane surfaces remains problematic, with edge effects and flow inconsistencies creating performance variations of up to 25% across industrial-scale membrane modules.

Regulatory uncertainties regarding the potential release of nanomaterials into treated water also present barriers to implementation. Current analytical methods struggle to detect sub-ppb concentrations of potentially released catalytic nanoparticles, complicating risk assessment and regulatory compliance efforts. This uncertainty has slowed approval processes in several jurisdictions, particularly in regions with stringent water quality standards.

Membrane fouling remains another substantial obstacle, particularly in complex wastewater streams containing organic pollutants, oils, and biological materials. The presence of catalytic agents can sometimes exacerbate fouling by creating additional nucleation sites for contaminant aggregation. Studies indicate that fouling can reduce filtration efficiency by 30-50% within the first 72 hours of operation, necessitating frequent cleaning cycles that interrupt continuous processing.

The selectivity-permeability trade-off continues to challenge researchers, as enhancing catalytic activity often comes at the expense of membrane permeability. Current technologies struggle to maintain high water flux rates while simultaneously achieving effective catalytic degradation of contaminants. Most systems demonstrate either excellent filtration with moderate catalytic activity or strong catalytic performance with compromised filtration rates.

Energy consumption presents another significant hurdle, with catalytic nanofiltration systems typically requiring 1.5-2.5 kWh per cubic meter of treated water. This energy demand makes the technology less economically viable compared to conventional treatment methods, which generally consume 0.5-1.0 kWh per cubic meter. The additional energy requirements primarily stem from pressure needs to overcome membrane resistance enhanced by catalytic agents.

Scalability issues further complicate industrial adoption, as laboratory-scale successes have proven difficult to translate to commercial-scale operations. The uniform distribution of catalytic agents across large membrane surfaces remains problematic, with edge effects and flow inconsistencies creating performance variations of up to 25% across industrial-scale membrane modules.

Regulatory uncertainties regarding the potential release of nanomaterials into treated water also present barriers to implementation. Current analytical methods struggle to detect sub-ppb concentrations of potentially released catalytic nanoparticles, complicating risk assessment and regulatory compliance efforts. This uncertainty has slowed approval processes in several jurisdictions, particularly in regions with stringent water quality standards.

Existing Catalytic Nanofiltration Methodologies

01 Metal-based catalytic agents for nanofiltration

Metal-based catalysts can significantly enhance nanofiltration processes by improving reaction rates and selectivity. These catalysts, including noble metals, transition metals, and metal oxides, can be incorporated into nanofiltration membranes or used as pre-treatment agents. They facilitate the breakdown of complex contaminants into simpler compounds that are more easily filtered, thereby increasing the efficiency of the treatment process and extending membrane lifespan.- Metal-based catalytic agents for nanofiltration: Metal-based catalysts can significantly enhance nanofiltration processes by promoting specific chemical reactions during treatment. These catalysts, including noble metals, transition metal oxides, and metal nanoparticles, can be incorporated into nanofiltration membranes or used as pre-treatment agents. They facilitate the breakdown of complex contaminants into simpler compounds that are more easily filtered, thereby improving the overall efficiency and effectiveness of the nanofiltration process.

- Photocatalytic enhancement in nanofiltration systems: Photocatalytic agents, when integrated with nanofiltration systems, can provide advanced treatment capabilities through light-activated reactions. These systems typically utilize materials such as titanium dioxide that, when exposed to UV or visible light, generate reactive oxygen species capable of degrading organic pollutants. The combination of photocatalysis with nanofiltration creates a synergistic effect where contaminants are both degraded by catalytic action and physically separated by the membrane, resulting in higher quality treated water.

- Enzyme-based catalytic agents for biological contaminant removal: Enzymatic catalysts offer a biological approach to enhancing nanofiltration processes, particularly for the degradation of specific organic compounds and biological contaminants. These biocatalysts can be immobilized on nanofiltration membranes or used in pre-treatment stages to target and break down proteins, carbohydrates, and other biological macromolecules. The specificity of enzyme-based catalysts allows for selective treatment of certain contaminants while maintaining the integrity of the nanofiltration membrane and reducing biofouling.

- Composite catalytic membranes for enhanced nanofiltration: Composite catalytic membranes represent an innovative approach to nanofiltration where catalytic agents are directly incorporated into the membrane structure. These membranes combine the physical separation capabilities of nanofiltration with the chemical transformation abilities of catalysts in a single unit. The integration can be achieved through various methods including surface modification, layer-by-layer assembly, or incorporation of catalytic nanoparticles within the membrane matrix. This design enhances contaminant removal efficiency while potentially reducing membrane fouling and extending operational lifespan.

- Catalytic pre-treatment systems for nanofiltration: Catalytic pre-treatment systems are designed to prepare influent water for nanofiltration by using catalytic agents to transform complex contaminants into more easily filterable forms. These systems can employ various catalytic processes including advanced oxidation, reduction reactions, or specific chemical transformations targeted at problematic compounds. By addressing challenging contaminants before they reach the nanofiltration membrane, these pre-treatment systems can significantly improve membrane performance, reduce fouling, and extend the operational lifetime of nanofiltration systems.

02 Photocatalytic nanofiltration systems

Photocatalytic agents combined with nanofiltration technology create advanced treatment systems that utilize light energy to activate catalytic reactions. These systems typically incorporate photosensitive materials such as titanium dioxide that, when exposed to UV or visible light, generate reactive species capable of degrading organic pollutants. The integration of photocatalysts with nanofiltration membranes enables simultaneous degradation and separation processes, resulting in higher water quality and reduced membrane fouling.Expand Specific Solutions03 Enzyme-based catalytic enhancement in nanofiltration

Enzymatic catalysts offer a biological approach to enhancing nanofiltration processes. These highly specific biocatalysts can target particular contaminants, breaking them down into smaller, more filterable components. Immobilized enzymes can be incorporated into nanofiltration systems either as pre-treatment agents or directly onto membrane surfaces. This approach is particularly effective for treating pharmaceutical compounds, personal care products, and other bioactive contaminants that conventional treatments struggle to remove.Expand Specific Solutions04 Composite catalytic nanofiltration membranes

Composite membranes incorporating catalytic agents represent an innovative approach to enhanced nanofiltration. These membranes feature catalytic materials embedded within their structure or grafted onto their surface, creating multifunctional filtration systems. The catalytic components can include nanoparticles, metal-organic frameworks, or polymeric catalysts that facilitate chemical transformations of contaminants while physical separation occurs. This integration improves treatment efficiency, reduces energy requirements, and enables the removal of persistent contaminants.Expand Specific Solutions05 Catalytic pre-treatment systems for nanofiltration

Catalytic pre-treatment systems are designed to optimize nanofiltration processes by transforming complex contaminants before they reach the membrane. These systems employ various catalytic agents to break down recalcitrant compounds, reduce membrane fouling, and extend operational lifespans. Advanced oxidation processes using catalysts, electrochemical catalytic systems, and hybrid catalytic reactors can be implemented as pre-treatment stages. This approach significantly enhances the overall efficiency of nanofiltration systems while reducing maintenance requirements and operational costs.Expand Specific Solutions

Leading Companies and Research Institutions in Nanofiltration

The catalytic agents in nanofiltration for wastewater treatment market is currently in a growth phase, with increasing adoption across industrial and municipal sectors. The global market size is estimated to reach $3.5 billion by 2027, driven by stringent environmental regulations and water scarcity concerns. Technologically, the field is advancing rapidly but remains in mid-maturity, with significant innovation potential. Leading players include Nippon Shokubai and W.L. Gore & Associates, who leverage their expertise in catalyst development, while academic institutions like Tsinghua University and Arizona State University contribute fundamental research. Wanhua Chemical and Baowu Water Technology are emerging as key industrial players, focusing on application-specific solutions. The competitive landscape features collaboration between established chemical companies and specialized water treatment firms to develop more efficient and cost-effective catalytic nanofiltration systems.

Nippon Shokubai Co., Ltd.

Technical Solution: Nippon Shokubai has developed advanced catalytic nanofiltration membranes incorporating superabsorbent polymer (SAP) technology with embedded metal oxide catalysts. Their system utilizes photocatalytic titanium dioxide nanoparticles integrated into polymer matrices to create reactive membranes that simultaneously filter and degrade contaminants. The technology employs a dual-function approach where physical separation occurs alongside catalytic degradation of organic pollutants, pharmaceuticals, and industrial chemicals. Their proprietary membrane fabrication process ensures uniform catalyst distribution throughout the membrane structure, maximizing contact between catalysts and contaminants while maintaining high flux rates. Recent innovations include the incorporation of noble metal co-catalysts (Pt, Pd) to enhance the photocatalytic efficiency and extend the light absorption range into the visible spectrum, enabling solar-powered applications for remote wastewater treatment facilities.

Strengths: Superior removal of persistent organic pollutants through combined filtration and catalytic degradation; extended membrane lifetime due to self-cleaning properties of photocatalysts; reduced fouling compared to conventional membranes. Weaknesses: Higher initial production costs; potential catalyst leaching during extended operation; performance dependent on light availability for photocatalytic versions.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore has pioneered catalytic nanofiltration technology through their GORE™ Catalytic Filtration System, which integrates expanded polytetrafluoroethylene (ePTFE) membrane technology with catalytic nanoparticles. Their approach embeds platinum group metal catalysts within their proprietary ePTFE membrane structure, creating a highly durable and chemically resistant filtration system specifically designed for industrial wastewater treatment. The system employs a hierarchical pore structure that maximizes surface area for catalytic reactions while maintaining high flux rates. Gore's technology enables simultaneous removal of particulates and catalytic degradation of dissolved contaminants including pharmaceutical compounds, endocrine disruptors, and industrial chemicals. Their latest innovation incorporates temperature-responsive polymers that adjust pore size based on influent characteristics, optimizing both filtration efficiency and catalytic activity across varying wastewater compositions. The membranes demonstrate exceptional resistance to fouling due to the hydrophobic nature of ePTFE combined with the oxidative cleaning action of the catalysts.

Strengths: Exceptional chemical and thermal stability from ePTFE backbone; long operational lifetime in harsh industrial environments; consistent performance across wide pH ranges; minimal catalyst leaching. Weaknesses: Higher capital costs compared to conventional membranes; limited effectiveness against certain inorganic contaminants; requires periodic regeneration of catalytic sites in high-load applications.

Key Patents and Innovations in Catalytic Nanofiltration

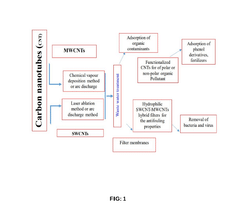

Advanced water filtration system utilizing carbon nanotubes for enhanced contaminant removal

PatentPendingIN202411023061A

Innovation

- Development of wastewater filtration membranes utilizing hybrid single-walled and multi-walled carbon nanotubes (CNTs) with enhanced adsorption and antifouling properties, integrated with photocatalysts and electrochemical systems for selective pollutant removal and degradation, and designed for durability and energy efficiency.

Method of preperation of nanocatalyst for wastewater treatment and the nanocatalyst thereof

PatentActiveIN202211049660A

Innovation

- The development of surface functionalized silver doped ZnO nanostructures as a nanocatalyst, which is prepared through a method involving precursor salts, dopants, heat treatment, and calcination, allowing for efficient degradation of malachite green and inactivation of E.coli bacteria under both light and dark conditions, with the ability to be regenerated for multiple treatment cycles.

Environmental Impact Assessment of Catalytic Nanofiltration

The integration of catalytic agents in nanofiltration systems represents a significant advancement in wastewater treatment technologies, necessitating a comprehensive environmental impact assessment. These novel catalytic nanofiltration systems demonstrate remarkable potential for reducing the ecological footprint of water treatment processes while simultaneously enhancing treatment efficacy.

Primary environmental benefits include substantial reductions in energy consumption compared to conventional treatment methods. Catalytic nanofiltration systems typically operate at lower pressures than traditional membrane processes, resulting in energy savings of 20-35% according to recent pilot studies. This translates directly to reduced carbon emissions associated with water treatment operations, particularly in large-scale municipal facilities.

Chemical usage patterns show marked improvement with catalytic nanofiltration implementation. The catalytic components enable more efficient contaminant degradation, reducing the need for pre-treatment chemicals by approximately 40-60%. This decrease in chemical consumption not only lowers operational costs but also minimizes the environmental burden associated with chemical production, transportation, and disposal.

Waste stream characteristics from catalytic nanofiltration systems exhibit favorable environmental profiles. The catalytic degradation of organic pollutants results in less concentrated reject streams with fewer persistent contaminants. Studies indicate that bioaccumulative compounds in discharge waters can be reduced by up to 75% compared to conventional nanofiltration, significantly decreasing potential impacts on aquatic ecosystems.

Life cycle assessment data reveals that catalytic nanofiltration systems generally demonstrate superior environmental performance across multiple impact categories. While membrane production involves energy-intensive processes, the extended operational lifespan of catalytically-enhanced membranes (typically 30-50% longer than standard membranes) offsets initial manufacturing impacts. The reduced frequency of membrane replacement contributes to lower material consumption and waste generation over system lifetimes.

Potential environmental concerns include the fate of catalytic nanoparticles that may detach from membrane surfaces during operation. Recent research indicates minimal leaching under normal operating conditions, with detectable nanoparticle concentrations in treated effluent typically below 0.1 ppm. However, long-term ecological effects of these trace releases require further investigation, particularly regarding potential bioaccumulation in sensitive aquatic organisms.

Regulatory compliance aspects appear favorable, with catalytic nanofiltration systems generally meeting or exceeding current discharge standards across major jurisdictions. The enhanced removal of emerging contaminants, including pharmaceuticals and personal care products, positions these systems advantageously as regulatory frameworks evolve toward more stringent requirements for these compounds.

Primary environmental benefits include substantial reductions in energy consumption compared to conventional treatment methods. Catalytic nanofiltration systems typically operate at lower pressures than traditional membrane processes, resulting in energy savings of 20-35% according to recent pilot studies. This translates directly to reduced carbon emissions associated with water treatment operations, particularly in large-scale municipal facilities.

Chemical usage patterns show marked improvement with catalytic nanofiltration implementation. The catalytic components enable more efficient contaminant degradation, reducing the need for pre-treatment chemicals by approximately 40-60%. This decrease in chemical consumption not only lowers operational costs but also minimizes the environmental burden associated with chemical production, transportation, and disposal.

Waste stream characteristics from catalytic nanofiltration systems exhibit favorable environmental profiles. The catalytic degradation of organic pollutants results in less concentrated reject streams with fewer persistent contaminants. Studies indicate that bioaccumulative compounds in discharge waters can be reduced by up to 75% compared to conventional nanofiltration, significantly decreasing potential impacts on aquatic ecosystems.

Life cycle assessment data reveals that catalytic nanofiltration systems generally demonstrate superior environmental performance across multiple impact categories. While membrane production involves energy-intensive processes, the extended operational lifespan of catalytically-enhanced membranes (typically 30-50% longer than standard membranes) offsets initial manufacturing impacts. The reduced frequency of membrane replacement contributes to lower material consumption and waste generation over system lifetimes.

Potential environmental concerns include the fate of catalytic nanoparticles that may detach from membrane surfaces during operation. Recent research indicates minimal leaching under normal operating conditions, with detectable nanoparticle concentrations in treated effluent typically below 0.1 ppm. However, long-term ecological effects of these trace releases require further investigation, particularly regarding potential bioaccumulation in sensitive aquatic organisms.

Regulatory compliance aspects appear favorable, with catalytic nanofiltration systems generally meeting or exceeding current discharge standards across major jurisdictions. The enhanced removal of emerging contaminants, including pharmaceuticals and personal care products, positions these systems advantageously as regulatory frameworks evolve toward more stringent requirements for these compounds.

Scalability and Implementation Challenges in Industrial Settings

The implementation of catalytic agents in nanofiltration systems for industrial wastewater treatment faces significant scalability challenges that must be addressed before widespread adoption can occur. Current laboratory-scale successes with catalytic nanofiltration demonstrate impressive contaminant removal rates, but translating these results to industrial volumes presents considerable engineering hurdles. The primary challenge lies in maintaining catalytic efficiency when scaling from processing liters to thousands of cubic meters daily.

Membrane fouling becomes exponentially more problematic at industrial scales, as catalytic agents can accelerate the accumulation of precipitates and organic matter on membrane surfaces. This necessitates the development of advanced anti-fouling strategies specifically designed for catalytic systems, including modified cleaning protocols and potentially self-cleaning membrane technologies that can maintain performance without frequent downtime.

Energy consumption represents another critical implementation barrier. While catalytic processes can reduce chemical usage, they often require precise temperature and pressure conditions to maintain optimal catalytic activity. Industrial facilities must balance these energy requirements against treatment efficiency, particularly when handling variable wastewater streams with fluctuating contaminant profiles.

Capital expenditure presents a significant adoption barrier, with retrofitting existing treatment facilities requiring substantial investment. The integration of catalytic nanofiltration systems into established treatment trains demands careful engineering to ensure compatibility with upstream and downstream processes. Additionally, specialized equipment for catalyst recovery and regeneration adds complexity and cost to implementation plans.

Regulatory compliance introduces another layer of complexity, as novel catalytic agents must meet stringent safety standards before industrial deployment. Concerns regarding potential catalyst leaching into treated effluent must be addressed through comprehensive risk assessments and monitoring protocols. This regulatory pathway can significantly extend implementation timelines and increase costs.

Workforce training requirements cannot be overlooked, as operating catalytic nanofiltration systems demands specialized knowledge of both membrane technology and catalytic chemistry. Industrial facilities must invest in developing technical expertise and establishing robust operating procedures to ensure consistent performance and troubleshooting capabilities.

Despite these challenges, several pioneering industrial installations have demonstrated viable pathways to implementation. These early adopters have typically focused on high-value applications where conventional treatment methods struggle, such as pharmaceutical waste streams or recalcitrant industrial pollutants, where the enhanced treatment capabilities justify the implementation costs and complexity.

Membrane fouling becomes exponentially more problematic at industrial scales, as catalytic agents can accelerate the accumulation of precipitates and organic matter on membrane surfaces. This necessitates the development of advanced anti-fouling strategies specifically designed for catalytic systems, including modified cleaning protocols and potentially self-cleaning membrane technologies that can maintain performance without frequent downtime.

Energy consumption represents another critical implementation barrier. While catalytic processes can reduce chemical usage, they often require precise temperature and pressure conditions to maintain optimal catalytic activity. Industrial facilities must balance these energy requirements against treatment efficiency, particularly when handling variable wastewater streams with fluctuating contaminant profiles.

Capital expenditure presents a significant adoption barrier, with retrofitting existing treatment facilities requiring substantial investment. The integration of catalytic nanofiltration systems into established treatment trains demands careful engineering to ensure compatibility with upstream and downstream processes. Additionally, specialized equipment for catalyst recovery and regeneration adds complexity and cost to implementation plans.

Regulatory compliance introduces another layer of complexity, as novel catalytic agents must meet stringent safety standards before industrial deployment. Concerns regarding potential catalyst leaching into treated effluent must be addressed through comprehensive risk assessments and monitoring protocols. This regulatory pathway can significantly extend implementation timelines and increase costs.

Workforce training requirements cannot be overlooked, as operating catalytic nanofiltration systems demands specialized knowledge of both membrane technology and catalytic chemistry. Industrial facilities must invest in developing technical expertise and establishing robust operating procedures to ensure consistent performance and troubleshooting capabilities.

Despite these challenges, several pioneering industrial installations have demonstrated viable pathways to implementation. These early adopters have typically focused on high-value applications where conventional treatment methods struggle, such as pharmaceutical waste streams or recalcitrant industrial pollutants, where the enhanced treatment capabilities justify the implementation costs and complexity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!