Innovations in Wastewater Nanofiltration for Industrial Efficiency

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Background and Objectives

Nanofiltration technology emerged in the late 1980s as a specialized membrane separation process positioned between reverse osmosis and ultrafiltration in terms of selectivity and operating pressure. The evolution of this technology has been marked by significant advancements in membrane materials, from early cellulose acetate compositions to contemporary thin-film composite structures that offer enhanced selectivity, durability, and energy efficiency.

The industrial wastewater treatment landscape has undergone a paradigm shift over the past three decades, transitioning from conventional physical-chemical processes to more sophisticated membrane-based solutions. This shift has been driven by increasingly stringent environmental regulations, escalating water scarcity concerns, and the growing recognition of wastewater as a potential resource rather than merely a waste stream.

Nanofiltration represents a critical innovation in this context, offering a unique combination of benefits including selective ion rejection, lower operating pressures compared to reverse osmosis, and higher flux rates. These characteristics position nanofiltration as an ideal technology for applications requiring the removal of divalent ions, organic compounds, and certain micropollutants while allowing beneficial monovalent ions to pass through.

The primary technical objectives in nanofiltration development currently focus on addressing several key challenges. First, enhancing membrane fouling resistance remains paramount, as fouling continues to be the most significant operational limitation in industrial applications. Second, improving energy efficiency through novel membrane architectures and module designs is essential for reducing operational costs and environmental footprint.

Third, developing specialized membranes for specific industrial waste streams represents a frontier of innovation, particularly for challenging sectors such as textile, pharmaceutical, and petrochemical industries. Fourth, advancing process integration capabilities to create hybrid treatment systems that maximize efficiency and resource recovery potential is increasingly important in circular economy frameworks.

Recent technological trajectories indicate a convergence of nanofiltration with complementary technologies such as advanced oxidation processes, biological treatments, and resource recovery systems. This integration trend reflects the evolving objective of not merely treating wastewater but extracting value from it through the recovery of water, energy, and valuable compounds.

The anticipated technological evolution path suggests that next-generation nanofiltration systems will likely incorporate smart monitoring capabilities, self-cleaning mechanisms, and modular designs that can be rapidly adapted to changing waste stream characteristics. These advancements align with the broader industrial trend toward more flexible, resilient, and sustainable water management infrastructure.

The industrial wastewater treatment landscape has undergone a paradigm shift over the past three decades, transitioning from conventional physical-chemical processes to more sophisticated membrane-based solutions. This shift has been driven by increasingly stringent environmental regulations, escalating water scarcity concerns, and the growing recognition of wastewater as a potential resource rather than merely a waste stream.

Nanofiltration represents a critical innovation in this context, offering a unique combination of benefits including selective ion rejection, lower operating pressures compared to reverse osmosis, and higher flux rates. These characteristics position nanofiltration as an ideal technology for applications requiring the removal of divalent ions, organic compounds, and certain micropollutants while allowing beneficial monovalent ions to pass through.

The primary technical objectives in nanofiltration development currently focus on addressing several key challenges. First, enhancing membrane fouling resistance remains paramount, as fouling continues to be the most significant operational limitation in industrial applications. Second, improving energy efficiency through novel membrane architectures and module designs is essential for reducing operational costs and environmental footprint.

Third, developing specialized membranes for specific industrial waste streams represents a frontier of innovation, particularly for challenging sectors such as textile, pharmaceutical, and petrochemical industries. Fourth, advancing process integration capabilities to create hybrid treatment systems that maximize efficiency and resource recovery potential is increasingly important in circular economy frameworks.

Recent technological trajectories indicate a convergence of nanofiltration with complementary technologies such as advanced oxidation processes, biological treatments, and resource recovery systems. This integration trend reflects the evolving objective of not merely treating wastewater but extracting value from it through the recovery of water, energy, and valuable compounds.

The anticipated technological evolution path suggests that next-generation nanofiltration systems will likely incorporate smart monitoring capabilities, self-cleaning mechanisms, and modular designs that can be rapidly adapted to changing waste stream characteristics. These advancements align with the broader industrial trend toward more flexible, resilient, and sustainable water management infrastructure.

Industrial Wastewater Treatment Market Analysis

The global industrial wastewater treatment market is experiencing significant growth, driven by increasing environmental regulations, water scarcity concerns, and industrial expansion. As of 2023, the market was valued at approximately $38 billion, with projections indicating a compound annual growth rate (CAGR) of 5.8% through 2030, potentially reaching $56 billion by the end of the forecast period.

Manufacturing sectors, particularly chemical processing, pharmaceuticals, food and beverage, and electronics, represent the largest market segments for advanced wastewater treatment technologies. These industries generate complex effluent streams containing contaminants that conventional treatment methods struggle to remove efficiently, creating substantial demand for nanofiltration solutions.

Regionally, Asia-Pacific dominates the industrial wastewater treatment market, accounting for nearly 40% of global market share. This dominance stems from rapid industrialization in countries like China and India, coupled with increasingly stringent environmental regulations. North America and Europe follow with mature markets characterized by technology innovation and replacement demand rather than new installations.

The market structure reveals a competitive landscape with several tiers of players. Global water technology corporations like Veolia, Suez, Evoqua Water Technologies, and Pentair control approximately 35% of the market share with comprehensive solution portfolios. Mid-sized specialized filtration companies occupy another 40%, while regional players and technology startups comprise the remaining 25%.

Customer demand patterns indicate a growing preference for modular, scalable systems that can be integrated into existing treatment trains with minimal disruption. Return on investment (ROI) considerations are increasingly driving purchasing decisions, with industries seeking solutions that demonstrate water reuse capabilities and reduced operational costs within 2-3 years.

Market barriers include high initial capital expenditure requirements for nanofiltration systems, which can be 30-50% higher than conventional filtration technologies. Additionally, technical expertise requirements for operation and maintenance present adoption challenges for smaller industrial operations.

Emerging trends reveal increasing interest in service-based business models, with "Water-as-a-Service" offerings gaining traction. This approach allows industries to access advanced treatment technologies without significant upfront investment, potentially accelerating market penetration of nanofiltration solutions in previously underserved industrial segments.

The regulatory landscape continues to evolve, with global tightening of discharge standards creating market opportunities. Particularly, regulations targeting micropollutants, pharmaceutical residues, and PFAS compounds are driving innovation in selective nanofiltration membrane technologies designed for specific contaminant removal.

Manufacturing sectors, particularly chemical processing, pharmaceuticals, food and beverage, and electronics, represent the largest market segments for advanced wastewater treatment technologies. These industries generate complex effluent streams containing contaminants that conventional treatment methods struggle to remove efficiently, creating substantial demand for nanofiltration solutions.

Regionally, Asia-Pacific dominates the industrial wastewater treatment market, accounting for nearly 40% of global market share. This dominance stems from rapid industrialization in countries like China and India, coupled with increasingly stringent environmental regulations. North America and Europe follow with mature markets characterized by technology innovation and replacement demand rather than new installations.

The market structure reveals a competitive landscape with several tiers of players. Global water technology corporations like Veolia, Suez, Evoqua Water Technologies, and Pentair control approximately 35% of the market share with comprehensive solution portfolios. Mid-sized specialized filtration companies occupy another 40%, while regional players and technology startups comprise the remaining 25%.

Customer demand patterns indicate a growing preference for modular, scalable systems that can be integrated into existing treatment trains with minimal disruption. Return on investment (ROI) considerations are increasingly driving purchasing decisions, with industries seeking solutions that demonstrate water reuse capabilities and reduced operational costs within 2-3 years.

Market barriers include high initial capital expenditure requirements for nanofiltration systems, which can be 30-50% higher than conventional filtration technologies. Additionally, technical expertise requirements for operation and maintenance present adoption challenges for smaller industrial operations.

Emerging trends reveal increasing interest in service-based business models, with "Water-as-a-Service" offerings gaining traction. This approach allows industries to access advanced treatment technologies without significant upfront investment, potentially accelerating market penetration of nanofiltration solutions in previously underserved industrial segments.

The regulatory landscape continues to evolve, with global tightening of discharge standards creating market opportunities. Particularly, regulations targeting micropollutants, pharmaceutical residues, and PFAS compounds are driving innovation in selective nanofiltration membrane technologies designed for specific contaminant removal.

Global Nanofiltration Challenges and Development Status

Nanofiltration technology has experienced significant global development over the past two decades, with varying adoption rates across different regions. North America and Europe currently lead in nanofiltration implementation for industrial wastewater treatment, accounting for approximately 60% of the global market share. These regions benefit from stringent environmental regulations and substantial investment in water treatment infrastructure, driving innovation and adoption.

Asia-Pacific represents the fastest-growing market for nanofiltration technologies, with China, Japan, and South Korea making substantial investments in research and development. China, in particular, has increased its patent filings related to nanofiltration by over 200% in the last five years, focusing on cost-effective membrane production techniques and energy-efficient systems designed for industrial applications.

Despite technological advancements, several critical challenges persist globally. Membrane fouling remains the most significant operational challenge, reducing system efficiency by 20-40% and increasing maintenance costs. Current anti-fouling strategies have only partially addressed this issue, with most industrial systems requiring frequent cleaning cycles that interrupt operations and reduce membrane lifespan.

Energy consumption presents another substantial challenge, as nanofiltration systems typically require 1.5-3.0 kWh per cubic meter of treated water. This energy requirement makes the technology less accessible in developing regions where energy costs are prohibitive or supply is unreliable, creating a significant adoption barrier in areas that often face the most severe water quality challenges.

Membrane selectivity limitations also constrain broader application, particularly for complex industrial wastewaters containing multiple contaminant types. Current nanofiltration membranes struggle to simultaneously reject diverse pollutants while maintaining high flux rates, forcing compromises between treatment effectiveness and operational efficiency.

Cost factors remain prohibitive in many regions, with initial capital expenditure for industrial-scale nanofiltration systems ranging from $500,000 to several million dollars. Operational expenses add 15-25% of the initial investment annually, making economic justification difficult without regulatory pressure or water scarcity concerns.

The geographical distribution of nanofiltration expertise shows significant disparity. Approximately 75% of advanced research facilities and membrane manufacturing capabilities are concentrated in developed economies, creating technology access barriers for developing nations. International collaboration initiatives have begun addressing this imbalance, with knowledge transfer programs and joint research projects emerging between established technology leaders and developing markets seeking sustainable water treatment solutions.

Asia-Pacific represents the fastest-growing market for nanofiltration technologies, with China, Japan, and South Korea making substantial investments in research and development. China, in particular, has increased its patent filings related to nanofiltration by over 200% in the last five years, focusing on cost-effective membrane production techniques and energy-efficient systems designed for industrial applications.

Despite technological advancements, several critical challenges persist globally. Membrane fouling remains the most significant operational challenge, reducing system efficiency by 20-40% and increasing maintenance costs. Current anti-fouling strategies have only partially addressed this issue, with most industrial systems requiring frequent cleaning cycles that interrupt operations and reduce membrane lifespan.

Energy consumption presents another substantial challenge, as nanofiltration systems typically require 1.5-3.0 kWh per cubic meter of treated water. This energy requirement makes the technology less accessible in developing regions where energy costs are prohibitive or supply is unreliable, creating a significant adoption barrier in areas that often face the most severe water quality challenges.

Membrane selectivity limitations also constrain broader application, particularly for complex industrial wastewaters containing multiple contaminant types. Current nanofiltration membranes struggle to simultaneously reject diverse pollutants while maintaining high flux rates, forcing compromises between treatment effectiveness and operational efficiency.

Cost factors remain prohibitive in many regions, with initial capital expenditure for industrial-scale nanofiltration systems ranging from $500,000 to several million dollars. Operational expenses add 15-25% of the initial investment annually, making economic justification difficult without regulatory pressure or water scarcity concerns.

The geographical distribution of nanofiltration expertise shows significant disparity. Approximately 75% of advanced research facilities and membrane manufacturing capabilities are concentrated in developed economies, creating technology access barriers for developing nations. International collaboration initiatives have begun addressing this imbalance, with knowledge transfer programs and joint research projects emerging between established technology leaders and developing markets seeking sustainable water treatment solutions.

Current Nanofiltration Solutions for Industrial Wastewater

01 Membrane material innovations for nanofiltration

Advanced membrane materials are being developed to enhance nanofiltration efficiency in wastewater treatment. These innovations include composite membranes with specialized coatings, modified polymer structures, and incorporation of nanomaterials that improve selectivity, flux rates, and fouling resistance. These materials are designed to effectively remove specific contaminants while maintaining high throughput and energy efficiency in wastewater treatment applications.- Membrane material innovations for nanofiltration: Advanced membrane materials are being developed to enhance nanofiltration efficiency in wastewater treatment. These innovations include composite membranes with specialized coatings, modified polymer structures, and novel nanomaterials that improve selectivity, flux rates, and fouling resistance. These materials are designed to effectively remove specific contaminants while maintaining high throughput and energy efficiency in wastewater treatment applications.

- Multi-stage nanofiltration systems: Multi-stage nanofiltration systems incorporate sequential filtration processes to progressively treat wastewater with increasing efficiency. These systems often combine nanofiltration with other treatment methods such as ultrafiltration, reverse osmosis, or biological treatment. By arranging nanofiltration membranes in series or parallel configurations, these systems can achieve higher removal rates of contaminants while optimizing energy consumption and extending membrane life.

- Anti-fouling strategies for nanofiltration membranes: Various anti-fouling strategies have been developed to maintain nanofiltration efficiency over time. These include physical modifications to membrane surfaces, chemical treatments, hydrodynamic improvements, and cleaning protocols. By reducing membrane fouling, these approaches help maintain consistent flux rates, extend membrane lifespan, and reduce operational costs in wastewater treatment applications.

- Process optimization techniques for nanofiltration: Process optimization techniques focus on enhancing nanofiltration efficiency through operational parameter adjustments. These include optimizing transmembrane pressure, cross-flow velocity, temperature control, pH adjustment, and feed pretreatment. Advanced control systems and monitoring technologies enable real-time adjustments to maintain optimal performance under varying wastewater conditions, resulting in improved contaminant removal and energy efficiency.

- Specialized nanofiltration applications for industrial wastewater: Specialized nanofiltration systems are being developed for specific industrial wastewater streams with unique contaminant profiles. These applications include treatment of textile effluents, pharmaceutical waste, mining wastewater, and food processing wastewater. Customized membrane configurations and operating conditions are designed to target specific pollutants such as heavy metals, organic compounds, and dissolved solids, achieving higher removal efficiencies for these challenging waste streams.

02 Integrated nanofiltration systems for industrial wastewater

Integrated treatment systems combine nanofiltration with complementary technologies to enhance overall wastewater treatment efficiency. These systems incorporate pre-treatment stages, multiple filtration steps, and post-treatment processes to handle complex industrial wastewaters. The integration optimizes removal of diverse contaminants, extends membrane life, reduces energy consumption, and improves recovery rates in industrial applications where wastewater composition varies significantly.Expand Specific Solutions03 Anti-fouling strategies for nanofiltration membranes

Various anti-fouling strategies have been developed to maintain nanofiltration efficiency over extended operation periods. These include physical cleaning mechanisms, chemical treatment protocols, surface modifications of membranes, and hydrodynamic optimization techniques. By preventing or mitigating membrane fouling, these approaches maintain consistent filtration performance, reduce maintenance requirements, and extend the operational lifetime of nanofiltration systems in wastewater treatment applications.Expand Specific Solutions04 Process optimization for enhanced nanofiltration efficiency

Process optimization techniques focus on improving operational parameters to maximize nanofiltration efficiency. These include adjustments to pressure, flow rate, temperature, pH control, and cross-flow velocity. Advanced control systems, real-time monitoring, and feedback mechanisms enable dynamic optimization of these parameters based on influent characteristics and desired effluent quality, resulting in improved contaminant removal, reduced energy consumption, and optimized recovery rates.Expand Specific Solutions05 Specialized nanofiltration applications for specific contaminants

Specialized nanofiltration systems are being developed to target specific contaminants in wastewater streams. These applications include removal of heavy metals, pharmaceutical residues, dyes, pesticides, and emerging pollutants. By tailoring membrane properties, operating conditions, and system configurations to specific contaminant characteristics, these specialized systems achieve higher removal efficiencies for targeted substances while maintaining reasonable energy consumption and operational costs.Expand Specific Solutions

Leading Companies in Industrial Wastewater Nanofiltration

The wastewater nanofiltration industry is currently in a growth phase, with increasing adoption across industrial sectors seeking improved efficiency and sustainability. The market is expanding rapidly, driven by stringent environmental regulations and water scarcity concerns, with projections indicating a compound annual growth rate of 5-7% over the next five years. Technologically, the field shows varying maturity levels, with companies like Siemens AG, Ecolab, and China Petroleum & Chemical Corp leading commercial applications through established membrane technologies, while academic institutions such as National University of Singapore and University of Hong Kong are advancing next-generation solutions. Baosteel Engineering and Bayer Technology Services are developing sector-specific adaptations for heavy industry, while smaller players like Chengdu Junfeng Technology are creating niche innovations. The competitive landscape features both multinational corporations with integrated water treatment portfolios and specialized technology providers focusing on specific industrial applications.

Ecolab GmbH & Co. oHG

Technical Solution: Ecolab has developed an innovative nanofiltration solution called "NanoNet" specifically designed for industrial wastewater treatment. This technology utilizes proprietary thin-film composite membranes with precisely engineered pore sizes (1-5 nm) and surface chemistry modifications that enhance selectivity for specific contaminants. The system incorporates a multi-barrier approach with pre-filtration, nanofiltration, and optional post-treatment stages. Ecolab's solution features their patented anti-fouling membrane technology that reduces cleaning frequency by up to 60% compared to conventional membranes. The system utilizes variable frequency drives and pressure recovery devices that optimize energy consumption based on water quality parameters. Their digital monitoring platform "ECOLAB3D" provides real-time analytics and predictive maintenance capabilities, reducing downtime by approximately 30%. The technology achieves water recovery rates of 85-95% while removing over 98% of hardness minerals, heavy metals, and organic compounds. Ecolab's solution is particularly effective for food and beverage, manufacturing, and pharmaceutical industries where water reuse quality is critical.

Strengths: Exceptional anti-fouling properties, comprehensive digital monitoring capabilities, and industry-specific optimization for various manufacturing sectors. The technology offers superior operational efficiency with reduced maintenance requirements. Weaknesses: Higher initial investment costs compared to conventional filtration systems and requires specialized chemicals for optimal membrane maintenance.

Siemens AG

Technical Solution: Siemens has developed advanced nanofiltration systems for industrial wastewater treatment that combine ceramic membrane technology with intelligent automation. Their solution integrates ultrafiltration and nanofiltration in a multi-stage process, utilizing specialized nano-coated membranes with controlled pore sizes (typically 1-10 nm). The system employs cross-flow filtration techniques to minimize fouling and incorporates real-time monitoring through their SIMATIC PCS 7 control system. This allows for continuous optimization of filtration parameters based on influent quality variations. Siemens' technology can remove over 95% of dissolved solids, heavy metals, and organic compounds while reducing energy consumption by approximately 30% compared to conventional reverse osmosis systems. The modular design enables scalability from small industrial applications to large municipal facilities, with automated backwashing and cleaning cycles that extend membrane life by up to 40%.

Strengths: Superior integration with industrial automation systems, excellent energy efficiency, and comprehensive monitoring capabilities. The modular approach allows for customized solutions across various industries. Weaknesses: Higher initial capital investment compared to conventional filtration systems and requires specialized technical expertise for maintenance and optimization.

Key Patents and Innovations in Nanofiltration Membranes

Super-high-permeance thin-film composite nanofiltration membrane incorporating silk nanofiber interlayer

PatentPendingUS20240058754A1

Innovation

- Development of nanofiltration membranes incorporating a silk layer, optionally with a porous substrate and selective layer, which significantly enhances water permeance and ion removal efficiency, utilizing silk nanomaterials like fibroin fibers with specific structural and chemical properties to improve mechanical stability and selectivity.

Process for treating industrial wastewaters

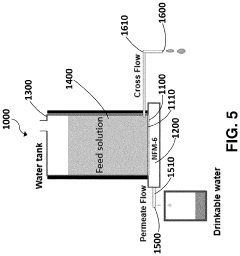

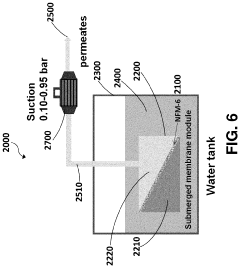

PatentInactiveUS6787037B2

Innovation

- A process combining flocculation or precipitation for heavy metal removal, followed by biological purification and nanofiltration, with recirculation of wastewater through nanofiltration to concentrate pollutants and maintain liquid rates, allowing for continuous treatment and reuse of wastewater.

Environmental Compliance and Sustainability Impacts

The implementation of advanced nanofiltration technologies in industrial wastewater treatment has significant implications for environmental compliance and sustainability. Industries are increasingly facing stringent regulatory frameworks designed to minimize environmental impacts of wastewater discharge. Nanofiltration systems enable companies to meet or exceed these regulatory requirements by effectively removing contaminants that traditional filtration methods cannot address, including heavy metals, organic compounds, and emerging pollutants of concern.

Regulatory compliance landscapes vary globally but share common trends toward more rigorous standards. The European Union's Water Framework Directive and the United States Environmental Protection Agency's Clean Water Act represent comprehensive regulatory frameworks that continue to evolve with advancing scientific understanding of pollutant impacts. Nanofiltration technologies provide industries with adaptable solutions that can be calibrated to meet these evolving standards, reducing the risk of non-compliance penalties and operational disruptions.

Beyond mere compliance, nanofiltration contributes substantially to broader sustainability goals. The technology enables significant reductions in freshwater consumption through enhanced water recycling capabilities, addressing growing concerns about water scarcity. Studies indicate that industrial facilities implementing advanced nanofiltration systems can achieve water reuse rates of 60-80%, substantially reducing their water footprint and associated environmental impacts.

Energy efficiency represents another critical sustainability dimension. While nanofiltration requires energy input, technological innovations have progressively reduced energy requirements. Contemporary nanofiltration systems consume approximately 30-50% less energy than reverse osmosis alternatives for comparable filtration outcomes. This efficiency translates to reduced carbon emissions and aligns with corporate and governmental carbon reduction targets.

The lifecycle environmental impact of nanofiltration technologies must also be considered. Recent advancements in membrane materials have extended operational lifespans and reduced chemical cleaning requirements, minimizing waste generation and chemical usage. Manufacturers are increasingly developing membranes from bio-based or recyclable materials, further enhancing sustainability credentials.

Economic sustainability intersects with environmental benefits through cost savings associated with reduced water consumption, lower discharge fees, and decreased chemical usage. The return on investment period for industrial nanofiltration systems has decreased from 5-7 years to 2-4 years in many applications, making sustainability improvements economically viable for a broader range of industries.

As circular economy principles gain traction globally, nanofiltration technologies enable the recovery of valuable resources from wastewater streams, transforming waste management from a cost center to a potential revenue source. This paradigm shift represents perhaps the most profound sustainability impact of advanced nanofiltration technologies in industrial applications.

Regulatory compliance landscapes vary globally but share common trends toward more rigorous standards. The European Union's Water Framework Directive and the United States Environmental Protection Agency's Clean Water Act represent comprehensive regulatory frameworks that continue to evolve with advancing scientific understanding of pollutant impacts. Nanofiltration technologies provide industries with adaptable solutions that can be calibrated to meet these evolving standards, reducing the risk of non-compliance penalties and operational disruptions.

Beyond mere compliance, nanofiltration contributes substantially to broader sustainability goals. The technology enables significant reductions in freshwater consumption through enhanced water recycling capabilities, addressing growing concerns about water scarcity. Studies indicate that industrial facilities implementing advanced nanofiltration systems can achieve water reuse rates of 60-80%, substantially reducing their water footprint and associated environmental impacts.

Energy efficiency represents another critical sustainability dimension. While nanofiltration requires energy input, technological innovations have progressively reduced energy requirements. Contemporary nanofiltration systems consume approximately 30-50% less energy than reverse osmosis alternatives for comparable filtration outcomes. This efficiency translates to reduced carbon emissions and aligns with corporate and governmental carbon reduction targets.

The lifecycle environmental impact of nanofiltration technologies must also be considered. Recent advancements in membrane materials have extended operational lifespans and reduced chemical cleaning requirements, minimizing waste generation and chemical usage. Manufacturers are increasingly developing membranes from bio-based or recyclable materials, further enhancing sustainability credentials.

Economic sustainability intersects with environmental benefits through cost savings associated with reduced water consumption, lower discharge fees, and decreased chemical usage. The return on investment period for industrial nanofiltration systems has decreased from 5-7 years to 2-4 years in many applications, making sustainability improvements economically viable for a broader range of industries.

As circular economy principles gain traction globally, nanofiltration technologies enable the recovery of valuable resources from wastewater streams, transforming waste management from a cost center to a potential revenue source. This paradigm shift represents perhaps the most profound sustainability impact of advanced nanofiltration technologies in industrial applications.

Cost-Benefit Analysis of Advanced Nanofiltration Systems

The implementation of advanced nanofiltration systems for industrial wastewater treatment requires substantial initial investment but offers significant long-term economic benefits. Initial capital expenditures typically range from $500,000 to $3 million depending on system capacity, membrane technology selection, and integration complexity with existing infrastructure. These costs encompass membrane modules, pressure vessels, pumping systems, pre-treatment equipment, control systems, and installation expenses.

Operational costs must be carefully evaluated against traditional treatment methods. While nanofiltration systems require ongoing membrane replacement (typically every 3-5 years at $50,000-$150,000), energy consumption (0.5-2.5 kWh per cubic meter of treated water), and maintenance expenses, they deliver substantial savings in multiple areas.

Water recycling capabilities represent the most significant economic advantage, with recovery rates of 85-95% possible in advanced systems. For industries consuming 1,000 cubic meters daily, this translates to potential savings of $300,000-$500,000 annually in water procurement costs alone. Additionally, valuable resource recovery from wastewater streams can generate secondary revenue streams, particularly in industries like mining, pharmaceuticals, and food processing.

Regulatory compliance benefits provide another critical economic advantage. Advanced nanofiltration systems consistently meet increasingly stringent discharge regulations, eliminating potential non-compliance penalties that can reach millions annually for serious violations. The reduction in discharge fees and taxes further enhances the economic proposition.

Return on investment analysis indicates most industrial nanofiltration systems achieve breakeven within 2-4 years, with subsequent years delivering substantial positive returns. Case studies from textile manufacturing demonstrate 30-40% reductions in total water management costs, while chemical processing facilities report 25-35% decreases in overall operational expenses related to water and waste management.

The total cost of ownership calculations must incorporate less quantifiable benefits including brand reputation enhancement, sustainability certification advantages, and future-proofing against anticipated regulatory tightening. When these factors are included, advanced nanofiltration systems consistently outperform conventional treatment approaches in long-term economic analysis, despite higher initial investment requirements.

Operational costs must be carefully evaluated against traditional treatment methods. While nanofiltration systems require ongoing membrane replacement (typically every 3-5 years at $50,000-$150,000), energy consumption (0.5-2.5 kWh per cubic meter of treated water), and maintenance expenses, they deliver substantial savings in multiple areas.

Water recycling capabilities represent the most significant economic advantage, with recovery rates of 85-95% possible in advanced systems. For industries consuming 1,000 cubic meters daily, this translates to potential savings of $300,000-$500,000 annually in water procurement costs alone. Additionally, valuable resource recovery from wastewater streams can generate secondary revenue streams, particularly in industries like mining, pharmaceuticals, and food processing.

Regulatory compliance benefits provide another critical economic advantage. Advanced nanofiltration systems consistently meet increasingly stringent discharge regulations, eliminating potential non-compliance penalties that can reach millions annually for serious violations. The reduction in discharge fees and taxes further enhances the economic proposition.

Return on investment analysis indicates most industrial nanofiltration systems achieve breakeven within 2-4 years, with subsequent years delivering substantial positive returns. Case studies from textile manufacturing demonstrate 30-40% reductions in total water management costs, while chemical processing facilities report 25-35% decreases in overall operational expenses related to water and waste management.

The total cost of ownership calculations must incorporate less quantifiable benefits including brand reputation enhancement, sustainability certification advantages, and future-proofing against anticipated regulatory tightening. When these factors are included, advanced nanofiltration systems consistently outperform conventional treatment approaches in long-term economic analysis, despite higher initial investment requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!