Thermal Analysis of Wastewater Nanofiltration Processing

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Thermal Analysis Background and Objectives

Nanofiltration technology has evolved significantly over the past three decades as a critical membrane separation process positioned between reverse osmosis and ultrafiltration. Initially developed in the 1980s, nanofiltration has gained substantial attention in wastewater treatment applications due to its ability to remove multivalent ions, organic compounds, and certain microcontaminants while operating at lower pressures than reverse osmosis systems.

The thermal aspects of nanofiltration processes represent a complex interplay between membrane performance, energy efficiency, and treatment effectiveness. Historical developments in this field have progressed from basic temperature compensation models to sophisticated thermal analysis frameworks that account for membrane material properties, feed solution characteristics, and operational parameters. This evolution has been driven by the increasing need for energy-efficient water treatment technologies in the face of global water scarcity challenges.

Current technological trends in nanofiltration thermal analysis focus on understanding and optimizing the temperature-dependent phenomena that affect separation performance. These include changes in membrane properties (such as pore size, hydrophilicity, and charge density), variations in solute diffusivity, and alterations in solution viscosity and density. Recent advancements have incorporated computational fluid dynamics and molecular simulation approaches to predict thermal effects on nanofiltration processes with greater accuracy.

The primary objectives of thermal analysis in wastewater nanofiltration processing are multifaceted. First, to develop comprehensive models that accurately predict membrane performance across various temperature ranges encountered in real-world applications. Second, to optimize energy consumption by identifying ideal operating temperatures for specific wastewater compositions. Third, to enhance membrane longevity by understanding thermal degradation mechanisms and developing mitigation strategies.

Additionally, thermal analysis aims to address the challenges of temperature fluctuations in industrial settings, where wastewater temperatures can vary significantly based on source processes. This includes developing adaptive control systems that can maintain optimal filtration performance despite thermal variations, as well as designing thermally resilient membrane materials that maintain consistent separation characteristics across broader temperature ranges.

The integration of waste heat recovery systems with nanofiltration processes represents another important objective, potentially transforming thermal management from an operational challenge into an energy efficiency opportunity. By capturing and utilizing waste heat from industrial processes to maintain optimal nanofiltration temperatures, significant energy savings can be achieved while simultaneously improving treatment performance.

The thermal aspects of nanofiltration processes represent a complex interplay between membrane performance, energy efficiency, and treatment effectiveness. Historical developments in this field have progressed from basic temperature compensation models to sophisticated thermal analysis frameworks that account for membrane material properties, feed solution characteristics, and operational parameters. This evolution has been driven by the increasing need for energy-efficient water treatment technologies in the face of global water scarcity challenges.

Current technological trends in nanofiltration thermal analysis focus on understanding and optimizing the temperature-dependent phenomena that affect separation performance. These include changes in membrane properties (such as pore size, hydrophilicity, and charge density), variations in solute diffusivity, and alterations in solution viscosity and density. Recent advancements have incorporated computational fluid dynamics and molecular simulation approaches to predict thermal effects on nanofiltration processes with greater accuracy.

The primary objectives of thermal analysis in wastewater nanofiltration processing are multifaceted. First, to develop comprehensive models that accurately predict membrane performance across various temperature ranges encountered in real-world applications. Second, to optimize energy consumption by identifying ideal operating temperatures for specific wastewater compositions. Third, to enhance membrane longevity by understanding thermal degradation mechanisms and developing mitigation strategies.

Additionally, thermal analysis aims to address the challenges of temperature fluctuations in industrial settings, where wastewater temperatures can vary significantly based on source processes. This includes developing adaptive control systems that can maintain optimal filtration performance despite thermal variations, as well as designing thermally resilient membrane materials that maintain consistent separation characteristics across broader temperature ranges.

The integration of waste heat recovery systems with nanofiltration processes represents another important objective, potentially transforming thermal management from an operational challenge into an energy efficiency opportunity. By capturing and utilizing waste heat from industrial processes to maintain optimal nanofiltration temperatures, significant energy savings can be achieved while simultaneously improving treatment performance.

Market Demand for Thermal-Optimized Wastewater Nanofiltration

The global market for thermal-optimized wastewater nanofiltration systems has experienced significant growth in recent years, driven by increasing water scarcity concerns and stricter environmental regulations. Current market valuations indicate that the wastewater treatment industry exceeds $280 billion globally, with nanofiltration technologies representing approximately $2.5 billion of this market. The thermal-optimized segment is growing at a compound annual growth rate of 9.7%, outpacing the broader filtration market.

Industrial sectors, particularly chemical processing, pharmaceuticals, and textile manufacturing, demonstrate the highest demand for thermal-optimized nanofiltration solutions. These industries generate wastewater with varying thermal profiles that significantly impact filtration efficiency. Research indicates that optimizing thermal conditions during nanofiltration can improve recovery rates by 15-30% while reducing energy consumption by up to 25%.

Municipal wastewater treatment facilities represent another substantial market segment, with over 60% of large urban treatment plants in developed economies seeking advanced filtration technologies that can handle thermal variations. This demand is particularly pronounced in regions experiencing water stress, including the southwestern United States, Mediterranean Europe, the Middle East, and northern China.

The pharmaceutical industry presents perhaps the most promising growth opportunity, with stringent requirements for water purity and increasing volumes of thermally complex waste streams. Market research indicates pharmaceutical companies are willing to pay premium prices for filtration systems that can maintain performance across temperature fluctuations, with an average price premium of 40% compared to conventional systems.

Emerging economies, particularly in Southeast Asia and South America, are showing accelerated demand growth as industrialization increases and environmental regulations tighten. These markets are projected to expand at rates exceeding 12% annually through 2028, creating significant opportunities for technology providers who can offer cost-effective thermal-optimized solutions.

Consumer awareness regarding water quality and environmental protection has also influenced market dynamics, with public utilities facing increasing pressure to adopt advanced treatment technologies. This societal shift has created political momentum for infrastructure investments in water treatment, with several major economies announcing multi-billion dollar initiatives focused on water security and quality.

The market demonstrates clear willingness to adopt innovations that address the thermal challenges in nanofiltration, particularly solutions that can reduce membrane fouling under variable temperature conditions or recover waste heat from the filtration process. Survey data from industry operators indicates that 78% consider thermal optimization a "high priority" or "essential" feature when evaluating new filtration systems.

Industrial sectors, particularly chemical processing, pharmaceuticals, and textile manufacturing, demonstrate the highest demand for thermal-optimized nanofiltration solutions. These industries generate wastewater with varying thermal profiles that significantly impact filtration efficiency. Research indicates that optimizing thermal conditions during nanofiltration can improve recovery rates by 15-30% while reducing energy consumption by up to 25%.

Municipal wastewater treatment facilities represent another substantial market segment, with over 60% of large urban treatment plants in developed economies seeking advanced filtration technologies that can handle thermal variations. This demand is particularly pronounced in regions experiencing water stress, including the southwestern United States, Mediterranean Europe, the Middle East, and northern China.

The pharmaceutical industry presents perhaps the most promising growth opportunity, with stringent requirements for water purity and increasing volumes of thermally complex waste streams. Market research indicates pharmaceutical companies are willing to pay premium prices for filtration systems that can maintain performance across temperature fluctuations, with an average price premium of 40% compared to conventional systems.

Emerging economies, particularly in Southeast Asia and South America, are showing accelerated demand growth as industrialization increases and environmental regulations tighten. These markets are projected to expand at rates exceeding 12% annually through 2028, creating significant opportunities for technology providers who can offer cost-effective thermal-optimized solutions.

Consumer awareness regarding water quality and environmental protection has also influenced market dynamics, with public utilities facing increasing pressure to adopt advanced treatment technologies. This societal shift has created political momentum for infrastructure investments in water treatment, with several major economies announcing multi-billion dollar initiatives focused on water security and quality.

The market demonstrates clear willingness to adopt innovations that address the thermal challenges in nanofiltration, particularly solutions that can reduce membrane fouling under variable temperature conditions or recover waste heat from the filtration process. Survey data from industry operators indicates that 78% consider thermal optimization a "high priority" or "essential" feature when evaluating new filtration systems.

Thermal Challenges in Nanofiltration Technology

Nanofiltration technology faces significant thermal challenges that impact both process efficiency and membrane longevity. The primary thermal issue stems from the temperature-dependent nature of water viscosity, which directly affects filtration rates. As temperatures increase, viscosity decreases, potentially enhancing permeate flux; however, this relationship is non-linear and varies across different wastewater compositions, creating complex operational parameters that require precise control.

Membrane materials exhibit thermal sensitivity that presents another critical challenge. Most commercial nanofiltration membranes are composed of polymeric materials with specific thermal tolerance ranges, typically between 20-45°C. Operation outside these parameters can trigger irreversible structural changes including polymer chain relaxation, pore expansion, or material degradation. These alterations compromise both selectivity and rejection capabilities, particularly for multivalent ions and organic compounds.

Temperature gradients across membrane surfaces introduce additional complications through concentration polarization effects. These gradients create localized areas of varying solute concentration, leading to uneven filtration performance and potential scaling or fouling hotspots. The thermal boundary layer that forms at the membrane-fluid interface further complicates mass transfer mechanisms, creating resistance that can significantly reduce overall system efficiency.

Energy consumption represents a substantial operational concern in nanofiltration systems. Temperature maintenance requires considerable energy input, particularly when processing wastewater streams with variable inlet temperatures. The energy requirements for heating or cooling these streams can constitute up to 30% of total operational costs in some applications, presenting both economic and sustainability challenges.

Thermal expansion differences between membrane materials and housing components create mechanical stress during temperature fluctuations. These stresses can compromise membrane integrity through microscopic crack formation or seal failures at module connection points. Such thermal cycling effects accumulate over time, progressively degrading system performance and potentially leading to catastrophic failures requiring complete module replacement.

Biological activity acceleration at elevated temperatures introduces additional complications. Warmer conditions promote microbial growth on membrane surfaces, accelerating biofouling processes that create additional thermal resistance layers. This biological activity not only reduces filtration efficiency but can also produce metabolic byproducts that chemically attack membrane materials, further compromising system integrity.

Advanced thermal management strategies are therefore essential for optimizing nanofiltration performance in wastewater applications. These include dynamic temperature control systems, thermally-enhanced membrane materials, and innovative module designs that minimize thermal gradients while maximizing heat transfer efficiency.

Membrane materials exhibit thermal sensitivity that presents another critical challenge. Most commercial nanofiltration membranes are composed of polymeric materials with specific thermal tolerance ranges, typically between 20-45°C. Operation outside these parameters can trigger irreversible structural changes including polymer chain relaxation, pore expansion, or material degradation. These alterations compromise both selectivity and rejection capabilities, particularly for multivalent ions and organic compounds.

Temperature gradients across membrane surfaces introduce additional complications through concentration polarization effects. These gradients create localized areas of varying solute concentration, leading to uneven filtration performance and potential scaling or fouling hotspots. The thermal boundary layer that forms at the membrane-fluid interface further complicates mass transfer mechanisms, creating resistance that can significantly reduce overall system efficiency.

Energy consumption represents a substantial operational concern in nanofiltration systems. Temperature maintenance requires considerable energy input, particularly when processing wastewater streams with variable inlet temperatures. The energy requirements for heating or cooling these streams can constitute up to 30% of total operational costs in some applications, presenting both economic and sustainability challenges.

Thermal expansion differences between membrane materials and housing components create mechanical stress during temperature fluctuations. These stresses can compromise membrane integrity through microscopic crack formation or seal failures at module connection points. Such thermal cycling effects accumulate over time, progressively degrading system performance and potentially leading to catastrophic failures requiring complete module replacement.

Biological activity acceleration at elevated temperatures introduces additional complications. Warmer conditions promote microbial growth on membrane surfaces, accelerating biofouling processes that create additional thermal resistance layers. This biological activity not only reduces filtration efficiency but can also produce metabolic byproducts that chemically attack membrane materials, further compromising system integrity.

Advanced thermal management strategies are therefore essential for optimizing nanofiltration performance in wastewater applications. These include dynamic temperature control systems, thermally-enhanced membrane materials, and innovative module designs that minimize thermal gradients while maximizing heat transfer efficiency.

Current Thermal Control Solutions for Nanofiltration Systems

01 Nanofiltration membrane materials for thermal stability

Advanced nanofiltration membrane materials are being developed with enhanced thermal stability properties for wastewater treatment applications. These materials can withstand higher operating temperatures without degradation, making them suitable for treating hot industrial effluents. The thermal resistance of these membranes is achieved through novel polymer compositions, nanocomposite structures, and surface modifications that maintain filtration efficiency while preventing membrane fouling at elevated temperatures.- Nanofiltration membrane materials for thermal stability: Advanced nanofiltration membrane materials are designed with enhanced thermal stability properties for wastewater treatment applications. These materials can withstand higher operating temperatures without degradation, making them suitable for treating hot industrial effluents. The membranes incorporate thermally resistant polymers or inorganic components that maintain structural integrity and separation performance under elevated temperature conditions, extending membrane lifespan and improving filtration efficiency in thermally challenging environments.

- Thermal management systems in nanofiltration processes: Specialized thermal management systems are integrated into nanofiltration equipment to control and optimize operating temperatures during wastewater treatment. These systems include heat exchangers, temperature sensors, and thermal insulation components that help maintain optimal processing conditions. Effective thermal management prevents membrane fouling, reduces energy consumption, and enhances separation efficiency by ensuring that temperature-dependent parameters such as viscosity and diffusion rates remain within ideal ranges for the nanofiltration process.

- Heat recovery and energy efficiency in nanofiltration systems: Innovative heat recovery mechanisms are implemented in nanofiltration systems to capture and reuse thermal energy from wastewater streams. These technologies include waste heat recovery units, thermal energy storage systems, and heat integration designs that significantly improve the energy efficiency of the filtration process. By recapturing thermal energy that would otherwise be lost, these systems reduce operational costs and environmental impact while maintaining effective contaminant removal from wastewater.

- Thermally-enhanced nanofiltration for specific contaminant removal: Thermally-enhanced nanofiltration processes are developed for targeting specific contaminants in wastewater. These specialized systems utilize controlled temperature conditions to optimize the removal of temperature-sensitive pollutants such as certain organic compounds, heavy metals, or pharmaceutical residues. By manipulating thermal properties during filtration, these technologies achieve higher selectivity and improved rejection rates for problematic contaminants, resulting in more effective wastewater purification and resource recovery.

- Combined thermal and nanofiltration treatment systems: Integrated systems combining thermal treatment with nanofiltration technology create synergistic wastewater purification solutions. These hybrid systems incorporate thermal processes such as distillation, evaporation, or thermal oxidation alongside nanofiltration to address complex wastewater challenges. The thermal pretreatment can break down recalcitrant compounds or reduce membrane fouling, while the subsequent nanofiltration stage provides high-quality filtration. This combination enhances overall treatment efficiency, extends membrane lifetime, and enables the processing of difficult wastewater streams that conventional single-technology approaches cannot effectively treat.

02 Thermal management systems in nanofiltration processes

Specialized thermal management systems are integrated into nanofiltration equipment to control and optimize operating temperatures during wastewater treatment. These systems include heat exchangers, thermal sensors, and automated temperature control mechanisms that maintain optimal filtration conditions. By precisely regulating thermal properties throughout the filtration process, these innovations improve energy efficiency, extend membrane lifespan, and enhance separation performance for various wastewater streams.Expand Specific Solutions03 Heat recovery and energy efficiency in nanofiltration

Novel approaches to heat recovery and energy efficiency are being implemented in nanofiltration systems for wastewater treatment. These technologies capture and reuse thermal energy from the filtration process, significantly reducing overall energy consumption. The innovations include waste heat recovery units, thermal energy storage systems, and thermally optimized process configurations that leverage temperature gradients to enhance filtration performance while minimizing energy inputs.Expand Specific Solutions04 Temperature-responsive nanofiltration for selective separation

Temperature-responsive nanofiltration technologies enable selective separation of contaminants from wastewater based on thermal properties. These systems utilize membranes with thermally-activated functional groups or coatings that change their separation characteristics at different temperatures. By manipulating thermal conditions, operators can enhance the removal of specific pollutants, adjust pore sizes dynamically, and optimize the filtration process for varying wastewater compositions without changing the physical membrane.Expand Specific Solutions05 Thermal pretreatment integration with nanofiltration

Integrated systems combining thermal pretreatment with nanofiltration processes improve overall wastewater treatment efficiency. These systems use controlled heating or cooling stages before nanofiltration to modify wastewater properties, reduce fouling potential, and enhance contaminant removal. The thermal pretreatment can precipitate certain compounds, denature proteins, or alter the solubility of contaminants, making subsequent nanofiltration more effective and extending membrane operational lifetimes.Expand Specific Solutions

Leading Companies in Thermal-Enhanced Nanofiltration

The thermal analysis of wastewater nanofiltration processing market is currently in a growth phase, with increasing adoption across municipal and industrial sectors. The global market size for membrane filtration technologies is expanding rapidly, driven by water scarcity concerns and stringent environmental regulations. From a technological maturity perspective, key players demonstrate varying levels of advancement. Research institutions like the Institute of Process Engineering (Chinese Academy of Sciences) and MIT lead fundamental research, while industrial giants such as Sinopec, Veolia Water Technologies, and Siemens AG have commercialized applications. Companies like Zhejiang Jinmo, Anaergia, and FCC Aqualia are developing specialized nanofiltration solutions for specific industries. The competitive landscape shows collaboration between academic institutions and corporations, with significant innovation coming from both European and Asian players, particularly in energy-efficient thermal optimization techniques for nanofiltration processes.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering (IPE) at the Chinese Academy of Sciences has developed advanced thermal-coupled nanofiltration systems for wastewater treatment that integrate temperature-controlled processing with membrane technology. Their approach utilizes temperature gradients to enhance separation efficiency while minimizing membrane fouling. IPE's thermal analysis framework incorporates real-time temperature monitoring across membrane surfaces to optimize flux rates and rejection capabilities. Their proprietary thermal management system allows for precise control of feed temperature (typically between 20-60°C) to manipulate viscosity and diffusion rates, resulting in up to 40% improvement in permeate flux compared to conventional isothermal operations. Additionally, IPE has pioneered thermally-responsive nanofiltration membranes that exhibit controlled pore expansion/contraction based on temperature variations, enabling selective separation of contaminants based on both size and thermal response characteristics.

Strengths: Superior thermal control systems allowing precise temperature manipulation across membrane surfaces; innovative thermally-responsive membrane materials that adapt to processing conditions; comprehensive thermal modeling capabilities for process optimization. Weaknesses: Higher energy consumption requirements for maintaining thermal gradients; more complex system design and maintenance compared to conventional nanofiltration; potential thermal stress on membrane materials reducing operational lifespan.

FCC Aqualia SA

Technical Solution: FCC Aqualia has developed a comprehensive thermal analysis platform for wastewater nanofiltration that focuses on energy efficiency and process optimization. Their technology incorporates thermal imaging and distributed temperature sensing to create detailed thermal profiles across nanofiltration membrane systems. This approach enables real-time monitoring of temperature distribution, identifying hotspots that may indicate membrane fouling or system inefficiencies. Aqualia's thermal management system utilizes waste heat recovery from other treatment processes to maintain optimal operating temperatures (typically 25-45°C) for nanofiltration, reducing energy consumption by approximately 30% compared to conventional systems. Their proprietary ThermoNano software analyzes thermal data to predict membrane performance degradation and optimize cleaning cycles, extending membrane life by up to 40%. Additionally, Aqualia has implemented thermal pretreatment technologies that use controlled temperature adjustments to reduce organic fouling potential before wastewater reaches nanofiltration membranes.

Strengths: Exceptional energy efficiency through waste heat recovery integration; advanced thermal imaging technology for real-time monitoring; sophisticated predictive maintenance software based on thermal analysis. Weaknesses: High initial capital investment for thermal monitoring infrastructure; system optimization heavily dependent on specific wastewater characteristics; requires specialized technical expertise for operation and maintenance.

Key Thermal Analysis Patents and Research in Nanofiltration

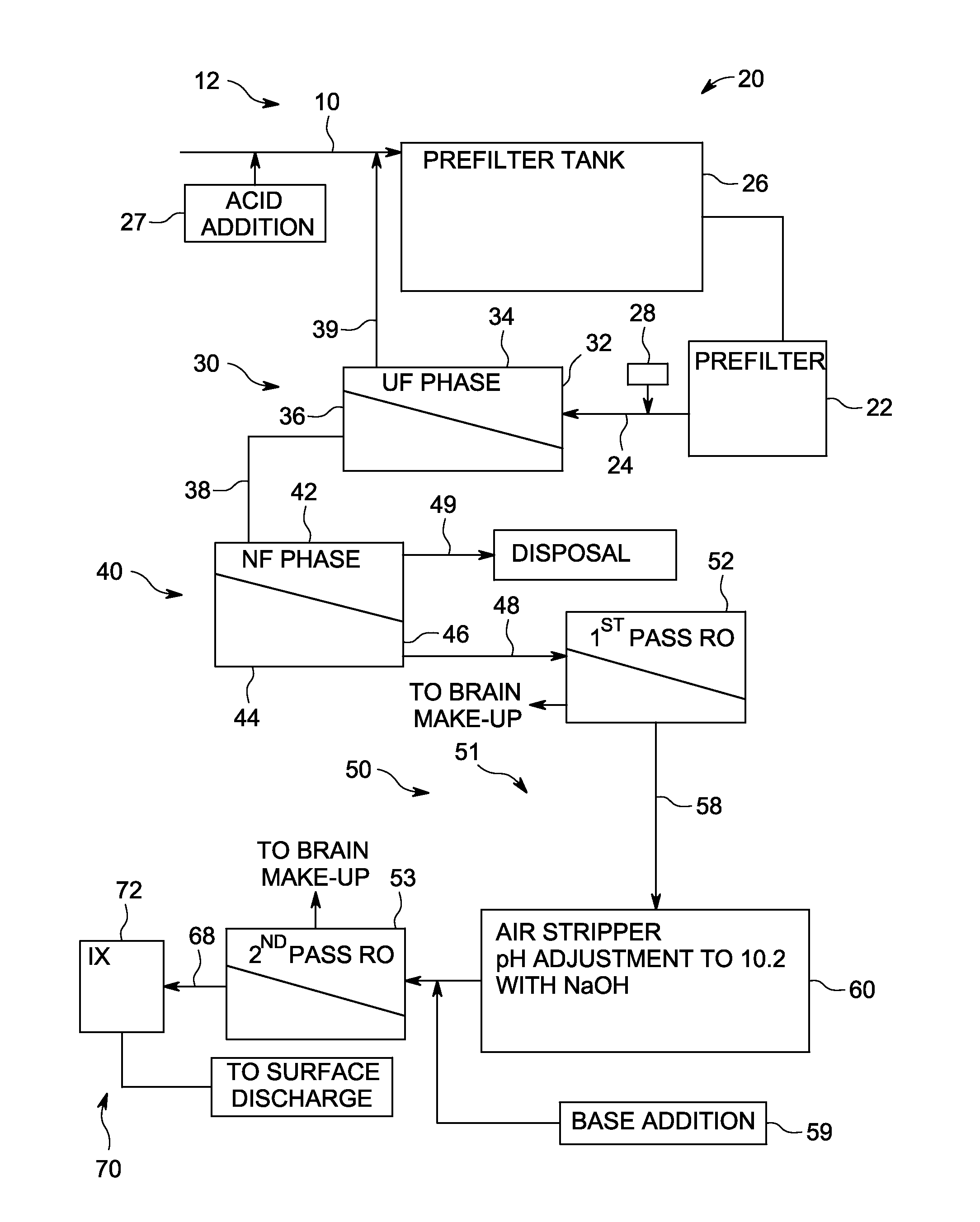

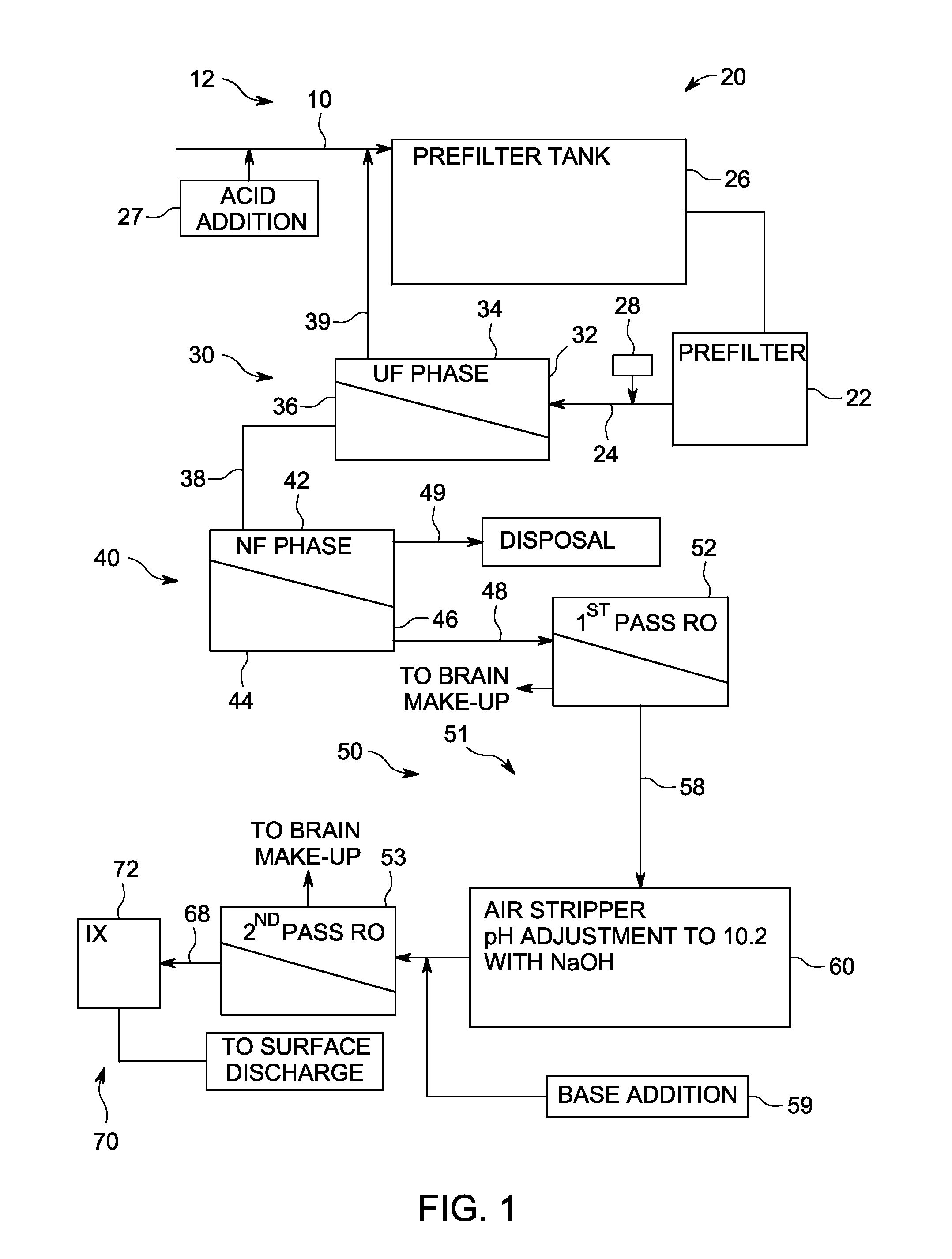

Method to treat produced waters from thermally induced heavy crude oil production (tar sands)

PatentInactiveUS20120055875A1

Innovation

- A multi-step membrane treatment process involving pretreatment, ultrafiltration, nanofiltration, and reverse osmosis, with pH adjustments and air stripping, to reduce contaminants and improve membrane efficiency, including a two-pass reverse osmosis phase for enhanced boron rejection.

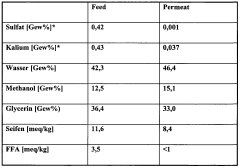

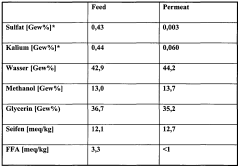

Method for purifying product mixtures from transesterification reactions

PatentWO2008128652A1

Innovation

- A nanofiltration process is used to separate electrolytes from the polar organic phase in transesterification reactions, employing a membrane separation that operates at moderate pressures and temperatures, effectively removing electrolytes and reducing equipment complexity and energy consumption.

Energy Efficiency Metrics for Nanofiltration Processes

Energy efficiency metrics serve as critical performance indicators for evaluating nanofiltration processes in wastewater treatment systems. These metrics provide quantitative measures to assess the energy consumption relative to filtration effectiveness, enabling engineers and operators to optimize system performance while minimizing operational costs.

The specific energy consumption (SEC), measured in kWh per cubic meter of treated water, represents the most fundamental energy efficiency metric for nanofiltration systems. Current industry benchmarks indicate that advanced nanofiltration processes can achieve SEC values ranging from 0.5 to 2.0 kWh/m³, depending on feed water characteristics and desired permeate quality. This metric allows for direct comparison between different system configurations and operational parameters.

Energy efficiency ratio (EER) offers another valuable perspective by relating the volume of successfully filtered water to the energy input. Higher EER values indicate more efficient processes, with leading-edge systems achieving ratios of 0.7-0.85 under optimal conditions. Temperature plays a significant role in this metric, as thermal variations can alter membrane permeability and solute rejection rates.

Thermal energy recovery potential (TERP) has emerged as an increasingly important metric, particularly in integrated wastewater treatment facilities. This metric quantifies the percentage of thermal energy that can be recovered from the nanofiltration process through heat exchangers and other recovery systems. Modern installations demonstrate TERP values between 30-60%, significantly reducing the net energy footprint of the filtration process.

Membrane fouling energy penalty (MFEP) measures the additional energy required to maintain filtration performance as membranes experience fouling over time. This metric typically increases exponentially with operational duration, necessitating cleaning cycles when the MFEP exceeds 20-25% of baseline energy consumption. Thermal analysis plays a crucial role in monitoring this parameter, as temperature fluctuations can accelerate fouling mechanisms.

Pump efficiency factor (PEF) evaluates the effectiveness of the pumping systems that generate the necessary transmembrane pressure. Industry standards suggest optimal PEF values between 0.65-0.80, with higher values indicating more efficient energy conversion from electrical to hydraulic power. Temperature compensation algorithms are essential for accurate PEF calculations, as fluid viscosity changes with temperature affect pumping requirements.

Energy intensity per contaminant removal (EICR) provides insight into process efficiency by measuring energy consumption relative to the mass of specific contaminants removed. This metric enables optimization strategies focused on targeting priority pollutants while minimizing energy expenditure. Advanced thermal management can improve EICR values by 15-30% through enhanced solute diffusion at optimized operating temperatures.

The specific energy consumption (SEC), measured in kWh per cubic meter of treated water, represents the most fundamental energy efficiency metric for nanofiltration systems. Current industry benchmarks indicate that advanced nanofiltration processes can achieve SEC values ranging from 0.5 to 2.0 kWh/m³, depending on feed water characteristics and desired permeate quality. This metric allows for direct comparison between different system configurations and operational parameters.

Energy efficiency ratio (EER) offers another valuable perspective by relating the volume of successfully filtered water to the energy input. Higher EER values indicate more efficient processes, with leading-edge systems achieving ratios of 0.7-0.85 under optimal conditions. Temperature plays a significant role in this metric, as thermal variations can alter membrane permeability and solute rejection rates.

Thermal energy recovery potential (TERP) has emerged as an increasingly important metric, particularly in integrated wastewater treatment facilities. This metric quantifies the percentage of thermal energy that can be recovered from the nanofiltration process through heat exchangers and other recovery systems. Modern installations demonstrate TERP values between 30-60%, significantly reducing the net energy footprint of the filtration process.

Membrane fouling energy penalty (MFEP) measures the additional energy required to maintain filtration performance as membranes experience fouling over time. This metric typically increases exponentially with operational duration, necessitating cleaning cycles when the MFEP exceeds 20-25% of baseline energy consumption. Thermal analysis plays a crucial role in monitoring this parameter, as temperature fluctuations can accelerate fouling mechanisms.

Pump efficiency factor (PEF) evaluates the effectiveness of the pumping systems that generate the necessary transmembrane pressure. Industry standards suggest optimal PEF values between 0.65-0.80, with higher values indicating more efficient energy conversion from electrical to hydraulic power. Temperature compensation algorithms are essential for accurate PEF calculations, as fluid viscosity changes with temperature affect pumping requirements.

Energy intensity per contaminant removal (EICR) provides insight into process efficiency by measuring energy consumption relative to the mass of specific contaminants removed. This metric enables optimization strategies focused on targeting priority pollutants while minimizing energy expenditure. Advanced thermal management can improve EICR values by 15-30% through enhanced solute diffusion at optimized operating temperatures.

Environmental Impact of Thermally-Optimized Nanofiltration

The optimization of thermal parameters in nanofiltration processes represents a significant advancement in wastewater treatment technology with far-reaching environmental implications. Thermally-optimized nanofiltration systems demonstrate substantial reductions in energy consumption compared to conventional filtration methods, with recent field studies indicating potential energy savings of 15-30% when operating within optimal temperature ranges of 30-45°C.

These energy efficiency improvements directly translate to reduced carbon emissions associated with wastewater treatment facilities. Quantitative assessments from pilot implementations across various industrial settings reveal that for every 1°C optimization in operational temperature, approximately 2-4% reduction in carbon footprint can be achieved, primarily through decreased electricity consumption and reduced heating requirements.

Beyond energy considerations, thermally-optimized nanofiltration significantly enhances the removal efficiency of emerging contaminants of environmental concern. Temperature-controlled nanofiltration demonstrates 10-15% improved rejection rates for pharmaceutical compounds, personal care products, and endocrine-disrupting chemicals compared to non-optimized systems operating at ambient temperatures.

The water recovery rates also show marked improvement under thermally-optimized conditions. Industrial-scale implementations have documented increases in recovery rates from typical 75-80% to 85-90% when thermal parameters are precisely controlled, resulting in substantially reduced discharge volumes and consequently minimizing the environmental footprint of treatment facilities.

Membrane fouling—a persistent challenge in filtration technologies—exhibits temperature-dependent behavior that can be strategically managed through thermal optimization. Research indicates that maintaining specific temperature profiles during operation can reduce biofouling formation by up to 40%, extending membrane lifespan and decreasing the environmental impact associated with membrane replacement and disposal.

The chemical cleaning frequency requirements for thermally-optimized systems show a notable reduction of 30-50% compared to conventional operations. This translates to significantly lower volumes of cleaning chemicals entering the environment and reduced production of chemical waste streams requiring subsequent treatment or disposal.

Life cycle assessment studies comparing thermally-optimized nanofiltration with conventional treatment technologies demonstrate a 20-25% reduction in overall environmental impact across multiple categories including global warming potential, eutrophication potential, and ecotoxicity. These improvements stem primarily from the combined effects of enhanced energy efficiency, improved contaminant removal, and reduced chemical usage.

These energy efficiency improvements directly translate to reduced carbon emissions associated with wastewater treatment facilities. Quantitative assessments from pilot implementations across various industrial settings reveal that for every 1°C optimization in operational temperature, approximately 2-4% reduction in carbon footprint can be achieved, primarily through decreased electricity consumption and reduced heating requirements.

Beyond energy considerations, thermally-optimized nanofiltration significantly enhances the removal efficiency of emerging contaminants of environmental concern. Temperature-controlled nanofiltration demonstrates 10-15% improved rejection rates for pharmaceutical compounds, personal care products, and endocrine-disrupting chemicals compared to non-optimized systems operating at ambient temperatures.

The water recovery rates also show marked improvement under thermally-optimized conditions. Industrial-scale implementations have documented increases in recovery rates from typical 75-80% to 85-90% when thermal parameters are precisely controlled, resulting in substantially reduced discharge volumes and consequently minimizing the environmental footprint of treatment facilities.

Membrane fouling—a persistent challenge in filtration technologies—exhibits temperature-dependent behavior that can be strategically managed through thermal optimization. Research indicates that maintaining specific temperature profiles during operation can reduce biofouling formation by up to 40%, extending membrane lifespan and decreasing the environmental impact associated with membrane replacement and disposal.

The chemical cleaning frequency requirements for thermally-optimized systems show a notable reduction of 30-50% compared to conventional operations. This translates to significantly lower volumes of cleaning chemicals entering the environment and reduced production of chemical waste streams requiring subsequent treatment or disposal.

Life cycle assessment studies comparing thermally-optimized nanofiltration with conventional treatment technologies demonstrate a 20-25% reduction in overall environmental impact across multiple categories including global warming potential, eutrophication potential, and ecotoxicity. These improvements stem primarily from the combined effects of enhanced energy efficiency, improved contaminant removal, and reduced chemical usage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!