The Role of Wastewater Nanofiltration in Global Water Regulations

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Evolution and Objectives

Nanofiltration technology has evolved significantly since its inception in the late 1970s, emerging as a specialized membrane separation process positioned between reverse osmosis and ultrafiltration. Initially developed as a lower-pressure alternative to reverse osmosis, nanofiltration has transformed from experimental laboratory applications to widespread industrial implementation over the past four decades.

The 1980s marked the first commercial applications of nanofiltration membranes, primarily in water softening operations. During this period, the technology was characterized by limited selectivity and relatively low flux rates. The 1990s witnessed substantial improvements in membrane materials, with the introduction of thin-film composite membranes that dramatically enhanced separation efficiency and operational longevity.

By the early 2000s, nanofiltration technology expanded beyond water softening to include applications in pharmaceutical processing, food and beverage industries, and preliminary wastewater treatment. This period saw significant advancements in membrane chemistry, resulting in improved resistance to fouling and chemical degradation—critical factors for wastewater applications.

The 2010s brought revolutionary developments in nanomaterial science that transformed nanofiltration capabilities. Integration of nanomaterials such as graphene oxide, carbon nanotubes, and metal-organic frameworks into membrane structures created unprecedented improvements in selectivity, permeability, and anti-fouling properties. These innovations directly addressed the complex challenges of wastewater filtration, particularly for emerging contaminants.

Current technological objectives for nanofiltration in wastewater treatment focus on several key areas. First is the enhancement of membrane selectivity for specific contaminants of concern in global water regulations, including pharmaceuticals, personal care products, and industrial chemicals at trace concentrations. Second is the development of energy-efficient systems that reduce the operational costs associated with pressure-driven membrane processes.

Another critical objective is improving membrane fouling resistance, particularly for complex wastewater matrices with high organic content. Research is actively pursuing biomimetic membrane designs and surface modifications that minimize fouling while maintaining high flux rates. Additionally, there is significant interest in developing modular, scalable nanofiltration systems that can be deployed in diverse regulatory environments and treatment scenarios.

The integration of nanofiltration with complementary technologies represents another important objective, with particular emphasis on hybrid systems that combine nanofiltration with biological treatment, advanced oxidation, or adsorption processes to achieve comprehensive contaminant removal in accordance with increasingly stringent global water quality standards.

The 1980s marked the first commercial applications of nanofiltration membranes, primarily in water softening operations. During this period, the technology was characterized by limited selectivity and relatively low flux rates. The 1990s witnessed substantial improvements in membrane materials, with the introduction of thin-film composite membranes that dramatically enhanced separation efficiency and operational longevity.

By the early 2000s, nanofiltration technology expanded beyond water softening to include applications in pharmaceutical processing, food and beverage industries, and preliminary wastewater treatment. This period saw significant advancements in membrane chemistry, resulting in improved resistance to fouling and chemical degradation—critical factors for wastewater applications.

The 2010s brought revolutionary developments in nanomaterial science that transformed nanofiltration capabilities. Integration of nanomaterials such as graphene oxide, carbon nanotubes, and metal-organic frameworks into membrane structures created unprecedented improvements in selectivity, permeability, and anti-fouling properties. These innovations directly addressed the complex challenges of wastewater filtration, particularly for emerging contaminants.

Current technological objectives for nanofiltration in wastewater treatment focus on several key areas. First is the enhancement of membrane selectivity for specific contaminants of concern in global water regulations, including pharmaceuticals, personal care products, and industrial chemicals at trace concentrations. Second is the development of energy-efficient systems that reduce the operational costs associated with pressure-driven membrane processes.

Another critical objective is improving membrane fouling resistance, particularly for complex wastewater matrices with high organic content. Research is actively pursuing biomimetic membrane designs and surface modifications that minimize fouling while maintaining high flux rates. Additionally, there is significant interest in developing modular, scalable nanofiltration systems that can be deployed in diverse regulatory environments and treatment scenarios.

The integration of nanofiltration with complementary technologies represents another important objective, with particular emphasis on hybrid systems that combine nanofiltration with biological treatment, advanced oxidation, or adsorption processes to achieve comprehensive contaminant removal in accordance with increasingly stringent global water quality standards.

Global Water Scarcity and Purification Market Analysis

Water scarcity has emerged as one of the most pressing global challenges of the 21st century. Currently, over 2 billion people live in countries experiencing high water stress, and this number is projected to increase significantly by 2050. Climate change, population growth, urbanization, and industrial expansion are exacerbating water scarcity issues worldwide, creating an urgent need for effective water management and purification solutions.

The global water purification market has responded to this crisis with remarkable growth. Valued at approximately $29.6 billion in 2022, the market is expected to reach $44.3 billion by 2028, growing at a CAGR of 7.2%. This growth is primarily driven by increasing water pollution, stringent regulatory frameworks, and rising awareness about waterborne diseases.

Nanofiltration technology represents a significant segment within this market, with particular relevance to wastewater treatment. The global nanofiltration membrane market was valued at $792 million in 2021 and is projected to grow at a CAGR of 10.5% through 2030. This growth reflects the technology's effectiveness in removing contaminants while maintaining essential minerals, making it particularly suitable for water reuse applications.

Regional analysis reveals varying market dynamics. North America and Europe currently dominate the advanced water purification market due to strict regulatory frameworks and high technological adoption rates. However, the Asia-Pacific region is witnessing the fastest growth, driven by rapid industrialization, urbanization, and increasing government investments in water infrastructure.

The municipal sector remains the largest end-user of water purification technologies, accounting for approximately 60% of the market share. However, industrial applications are growing rapidly, particularly in sectors such as pharmaceuticals, food and beverage, and electronics manufacturing, where ultrapure water is essential.

Demand for wastewater nanofiltration is particularly strong in regions facing severe water stress. The Middle East and North Africa, with 12 of the world's 17 most water-stressed countries, are investing heavily in advanced filtration technologies. Similarly, parts of Asia, particularly India and China, are experiencing growing demand as they address their significant water quality challenges.

The economic value proposition of nanofiltration is compelling. Studies indicate that implementing advanced filtration systems can reduce water treatment costs by 20-30% compared to conventional methods when considering lifecycle costs. Additionally, the ability to recover valuable resources from wastewater streams is creating new revenue opportunities, further driving market growth.

The global water purification market has responded to this crisis with remarkable growth. Valued at approximately $29.6 billion in 2022, the market is expected to reach $44.3 billion by 2028, growing at a CAGR of 7.2%. This growth is primarily driven by increasing water pollution, stringent regulatory frameworks, and rising awareness about waterborne diseases.

Nanofiltration technology represents a significant segment within this market, with particular relevance to wastewater treatment. The global nanofiltration membrane market was valued at $792 million in 2021 and is projected to grow at a CAGR of 10.5% through 2030. This growth reflects the technology's effectiveness in removing contaminants while maintaining essential minerals, making it particularly suitable for water reuse applications.

Regional analysis reveals varying market dynamics. North America and Europe currently dominate the advanced water purification market due to strict regulatory frameworks and high technological adoption rates. However, the Asia-Pacific region is witnessing the fastest growth, driven by rapid industrialization, urbanization, and increasing government investments in water infrastructure.

The municipal sector remains the largest end-user of water purification technologies, accounting for approximately 60% of the market share. However, industrial applications are growing rapidly, particularly in sectors such as pharmaceuticals, food and beverage, and electronics manufacturing, where ultrapure water is essential.

Demand for wastewater nanofiltration is particularly strong in regions facing severe water stress. The Middle East and North Africa, with 12 of the world's 17 most water-stressed countries, are investing heavily in advanced filtration technologies. Similarly, parts of Asia, particularly India and China, are experiencing growing demand as they address their significant water quality challenges.

The economic value proposition of nanofiltration is compelling. Studies indicate that implementing advanced filtration systems can reduce water treatment costs by 20-30% compared to conventional methods when considering lifecycle costs. Additionally, the ability to recover valuable resources from wastewater streams is creating new revenue opportunities, further driving market growth.

Nanofiltration Technical Challenges and Geographical Implementation

Nanofiltration technology faces several significant technical challenges that impact its widespread implementation. The primary challenge lies in membrane fouling, where contaminants accumulate on membrane surfaces, reducing filtration efficiency and increasing operational costs. This fouling phenomenon is particularly problematic in wastewater treatment applications where high concentrations of organic matter, colloids, and microorganisms are present. Current research focuses on developing anti-fouling membrane materials and optimizing cleaning protocols to extend membrane lifespan.

Energy consumption represents another substantial challenge, as nanofiltration systems require considerable pressure to force water through nanometer-sized pores. This energy requirement directly impacts operational costs and carbon footprint, making energy efficiency improvements critical for sustainable implementation. Innovations in low-energy membrane configurations and pressure recovery systems are emerging to address this limitation.

Selectivity optimization remains technically challenging, as nanofiltration membranes must balance the removal of specific contaminants while allowing beneficial minerals to pass through. This selective permeability is particularly important in drinking water applications where complete demineralization is undesirable. Researchers are exploring novel membrane materials with precisely controlled pore sizes and surface chemistries to enhance selectivity.

The geographical implementation of nanofiltration technologies varies significantly across regions, influenced by water scarcity, regulatory frameworks, and economic development. Europe leads in nanofiltration adoption, particularly in countries like the Netherlands, Germany, and France, where stringent water quality regulations drive implementation. These regions primarily utilize nanofiltration for drinking water treatment, focusing on pesticide removal and water softening applications.

North America shows strong adoption in industrial applications, particularly in the pharmaceutical and food processing sectors. Municipal implementations are growing, especially in regions facing emerging contaminants like PFAS (per- and polyfluoroalkyl substances). The regulatory landscape in the United States is evolving to address these contaminants, potentially accelerating nanofiltration adoption.

In water-scarce regions of the Middle East and North Africa, nanofiltration serves as a critical component in comprehensive water treatment trains, often paired with reverse osmosis for seawater desalination. These implementations focus on maximizing water recovery rates while minimizing energy consumption.

Asia-Pacific represents the fastest-growing market for nanofiltration technologies, with China and India making significant investments in water treatment infrastructure. However, implementation faces challenges related to technical expertise, maintenance capabilities, and cost constraints in developing regions.

Rural and remote areas globally face unique implementation challenges, including limited technical support, inconsistent power supply, and financial constraints. Decentralized, modular nanofiltration systems are emerging as potential solutions for these contexts, though significant adaptation and simplification of the technology is required.

Energy consumption represents another substantial challenge, as nanofiltration systems require considerable pressure to force water through nanometer-sized pores. This energy requirement directly impacts operational costs and carbon footprint, making energy efficiency improvements critical for sustainable implementation. Innovations in low-energy membrane configurations and pressure recovery systems are emerging to address this limitation.

Selectivity optimization remains technically challenging, as nanofiltration membranes must balance the removal of specific contaminants while allowing beneficial minerals to pass through. This selective permeability is particularly important in drinking water applications where complete demineralization is undesirable. Researchers are exploring novel membrane materials with precisely controlled pore sizes and surface chemistries to enhance selectivity.

The geographical implementation of nanofiltration technologies varies significantly across regions, influenced by water scarcity, regulatory frameworks, and economic development. Europe leads in nanofiltration adoption, particularly in countries like the Netherlands, Germany, and France, where stringent water quality regulations drive implementation. These regions primarily utilize nanofiltration for drinking water treatment, focusing on pesticide removal and water softening applications.

North America shows strong adoption in industrial applications, particularly in the pharmaceutical and food processing sectors. Municipal implementations are growing, especially in regions facing emerging contaminants like PFAS (per- and polyfluoroalkyl substances). The regulatory landscape in the United States is evolving to address these contaminants, potentially accelerating nanofiltration adoption.

In water-scarce regions of the Middle East and North Africa, nanofiltration serves as a critical component in comprehensive water treatment trains, often paired with reverse osmosis for seawater desalination. These implementations focus on maximizing water recovery rates while minimizing energy consumption.

Asia-Pacific represents the fastest-growing market for nanofiltration technologies, with China and India making significant investments in water treatment infrastructure. However, implementation faces challenges related to technical expertise, maintenance capabilities, and cost constraints in developing regions.

Rural and remote areas globally face unique implementation challenges, including limited technical support, inconsistent power supply, and financial constraints. Decentralized, modular nanofiltration systems are emerging as potential solutions for these contexts, though significant adaptation and simplification of the technology is required.

Current Nanofiltration Membrane Solutions and Applications

01 Nanofiltration membrane materials and structures

Various materials and structures are used in nanofiltration membranes for wastewater treatment. These include composite membranes with specialized layers, modified polymeric materials, and novel nanostructured materials that enhance filtration performance. The membrane structure can be optimized for specific contaminant removal while maintaining high flux rates and minimizing fouling. Advanced manufacturing techniques allow for precise control of pore size and distribution, critical for effective nanofiltration.- Nanofiltration membrane materials and structures: Various materials and structures are used in nanofiltration membranes for wastewater treatment. These include composite membranes, modified polymeric materials, and novel nanostructured materials that enhance filtration efficiency. The membrane structure can be optimized for specific contaminant removal while maintaining high flux rates and minimizing fouling. Advanced fabrication techniques allow for precise control of pore size and surface properties.

- Integrated wastewater treatment systems with nanofiltration: Nanofiltration can be integrated into comprehensive wastewater treatment systems that combine multiple treatment processes. These integrated systems often include pre-treatment steps, nanofiltration units, and post-treatment processes to achieve optimal water quality. The integration enhances overall system efficiency, reduces energy consumption, and improves contaminant removal rates compared to standalone filtration methods.

- Industrial wastewater treatment applications: Nanofiltration technologies are specifically designed for treating industrial wastewaters containing complex contaminants. These applications address challenges in textile, pharmaceutical, mining, and chemical industries where conventional treatment methods are insufficient. The nanofiltration systems can be tailored to remove specific industrial pollutants while allowing for water reuse, thereby reducing environmental impact and operational costs.

- Enhanced nanofiltration through process optimization: Process optimization techniques improve nanofiltration performance in wastewater treatment. These include adjustments to operating parameters such as pressure, flow rate, pH, and temperature. Advanced control systems, cross-flow configurations, and cleaning protocols help maintain membrane performance over time. Optimization strategies can significantly increase contaminant removal efficiency while reducing energy consumption and extending membrane lifespan.

- Novel nanofiltration equipment designs: Innovative equipment designs enhance nanofiltration performance for wastewater treatment. These include modular systems, compact units for decentralized applications, and specialized configurations for challenging wastewater streams. The equipment incorporates features to minimize fouling, facilitate maintenance, and improve energy efficiency. Some designs integrate monitoring systems for real-time performance assessment and automated operation adjustments.

02 Integrated wastewater treatment systems using nanofiltration

Nanofiltration is often integrated into comprehensive wastewater treatment systems. These systems combine nanofiltration with other treatment processes such as pre-filtration, biological treatment, or advanced oxidation to achieve optimal results. The integration allows for targeted removal of specific contaminants while optimizing energy consumption and operational efficiency. Such systems can be designed for various scales, from industrial applications to municipal wastewater treatment facilities.Expand Specific Solutions03 Specialized nanofiltration for industrial wastewater

Industrial wastewater presents unique challenges that require specialized nanofiltration solutions. These applications focus on removing specific industrial contaminants such as heavy metals, organic compounds, or process chemicals. The nanofiltration systems are designed to handle high contaminant loads, variable pH conditions, and potentially corrosive environments. Customized membrane materials and system configurations enable effective treatment of complex industrial effluents while recovering valuable resources.Expand Specific Solutions04 Fouling prevention and membrane cleaning techniques

Membrane fouling is a significant challenge in nanofiltration systems. Various techniques have been developed to prevent fouling and extend membrane life, including surface modifications, anti-fouling coatings, and optimized operational parameters. When fouling does occur, specialized cleaning protocols using chemical, physical, or combined approaches can restore membrane performance. Advanced monitoring systems can detect early signs of fouling, allowing for preventive maintenance and optimized cleaning schedules.Expand Specific Solutions05 Energy-efficient nanofiltration systems

Energy efficiency is a critical consideration in wastewater nanofiltration. Innovations in this area include low-pressure operation membranes, energy recovery devices, and optimized system designs that minimize energy consumption. Some systems incorporate renewable energy sources or waste heat recovery to further reduce environmental impact. Smart control systems can dynamically adjust operational parameters based on feed water quality and treatment requirements, maximizing efficiency while maintaining treatment effectiveness.Expand Specific Solutions

Leading Companies and Research Institutions in Nanofiltration

The wastewater nanofiltration market is in a growth phase, driven by increasingly stringent global water regulations and growing water scarcity concerns. The market is expected to expand significantly as nanofiltration technology matures from experimental to commercial applications. Academic institutions like King Fahd University of Petroleum & Minerals, Columbia University, and University of Hong Kong are leading fundamental research, while companies such as Siemens AG, Cambrian Innovation, and GreenTech Environmental are commercializing solutions. The technology maturity varies across applications, with industrial wastewater treatment being more advanced than municipal applications. Collaboration between research institutions and industry players like BP Exploration and Environmental Management Corp. is accelerating innovation in membrane technology and system integration for regulatory compliance.

Siemens AG

Technical Solution: Siemens has developed advanced nanofiltration membrane systems specifically designed for wastewater treatment that comply with global water regulations. Their technology utilizes cross-flow filtration with specialized polymer-based membranes featuring controlled pore sizes between 1-10 nanometers. These systems effectively remove multivalent ions, organic compounds, and micropollutants while allowing beneficial minerals to pass through. Siemens' nanofiltration solutions incorporate anti-fouling technology and energy recovery systems that reduce operational costs by up to 30% compared to conventional systems. Their modular design allows for scalability from municipal to industrial applications, with automated monitoring systems that ensure continuous compliance with varying international water quality standards. Siemens has implemented these systems in over 400 installations worldwide, demonstrating consistent performance in meeting the increasingly stringent global water regulations.

Strengths: Siemens' nanofiltration technology offers superior energy efficiency with 30-40% lower energy consumption than reverse osmosis while maintaining high removal rates for targeted contaminants. Their global presence enables rapid adaptation to changing regional regulations. Weaknesses: Higher initial capital investment compared to conventional filtration systems and requires specialized maintenance expertise.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies has developed proprietary nanofiltration systems for industrial wastewater treatment that address global automotive manufacturing regulations. Their technology employs composite thin-film nanofiltration membranes with specialized surface modifications that target the removal of heavy metals, oils, and process chemicals specific to automotive manufacturing. The system integrates real-time monitoring with predictive analytics to optimize filtration performance and ensure compliance with varying international discharge standards. Ford's approach includes a multi-stage filtration process that pre-treats wastewater before nanofiltration, extending membrane life by up to 40% compared to single-stage systems. Their technology enables water recycling rates of up to 85% in manufacturing facilities, significantly reducing freshwater consumption while meeting or exceeding regulatory requirements across different global markets where Ford operates.

Strengths: Ford's system is specifically optimized for automotive manufacturing wastewater, providing excellent removal of industry-specific contaminants while enabling high water recycling rates. Their technology integrates seamlessly with existing manufacturing processes. Weaknesses: Limited application outside automotive and similar industrial settings, and requires significant customization for different manufacturing processes.

Key Patents and Innovations in Wastewater Nanofiltration

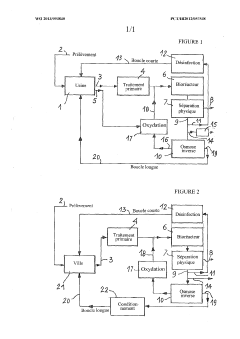

Method for treating industrial or urban wastewater for reuse, and facility for implementing this method

PatentWO2013093840A1

Innovation

- A wastewater treatment system incorporating a single reverse osmosis or nanofiltration stage, where the concentrate undergoes ozonation to degrade organic matter, and is then recycled back to the biological treatment stage, integrating water separation and pollution degradation in a loop.

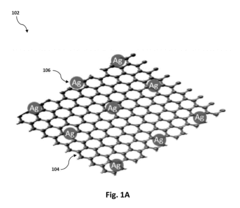

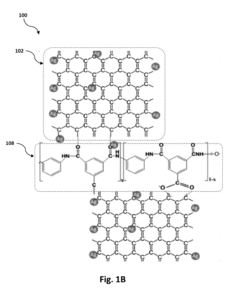

Nanocomposite material for adsorption of dissolved metals

PatentInactiveUS20190070581A1

Innovation

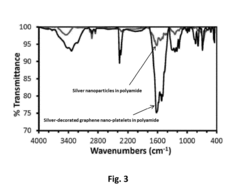

- A metal adsorbent comprising silver-decorated graphene nano-platelets dispersed in a polyamide matrix, with a specific surface area of 200 to 300 m2/g and average pore size of 50 to 100 Å, which effectively adsorbs heavy metals and cations, including mercury, chromium, cadmium, lead, nickel, and copper, through a method involving the mixing of silver-decorated graphene nano-platelets with an aromatic amine and acyl halide in a polymerization process.

Regulatory Frameworks Governing Water Reuse Technologies

The global landscape of water reuse regulations has evolved significantly in response to increasing water scarcity and the advancement of treatment technologies like nanofiltration. Currently, regulatory frameworks governing water reuse technologies vary considerably across different regions, reflecting diverse approaches to water management, environmental protection, and public health concerns.

In the European Union, the Water Framework Directive (2000/60/EC) provides the overarching structure for water management, while the more recent EU Regulation 2020/741 specifically addresses minimum requirements for water reuse in agricultural irrigation. These regulations increasingly recognize nanofiltration as a viable technology for achieving required water quality standards, particularly for removing micropollutants and pharmaceutical residues.

The United States employs a decentralized regulatory approach, with the EPA providing guidelines through the National Water Reuse Action Plan, while individual states establish their own specific regulations. California's Title 22 regulations and Florida's comprehensive water reuse program represent some of the most advanced frameworks that explicitly incorporate membrane filtration technologies, including nanofiltration, as approved treatment methods for various reuse applications.

In Asia, Singapore's NEWater initiative stands as a global benchmark, with its "Four National Taps" strategy incorporating advanced membrane technologies under strict regulatory oversight. China has recently strengthened its regulatory framework through the Water Pollution Prevention and Control Law, which now includes provisions for advanced treatment technologies in water reclamation projects.

International organizations such as the World Health Organization and ISO have developed guidelines and standards that serve as reference points for countries developing their own regulatory frameworks. The WHO's Guidelines for the Safe Use of Wastewater, Excreta and Greywater provides risk-based approaches that increasingly acknowledge the role of advanced filtration technologies.

A notable trend in regulatory evolution is the shift from technology-based to performance-based standards, allowing greater flexibility in technology selection while maintaining strict output quality requirements. This approach has facilitated the adoption of nanofiltration in various applications, as regulations focus on contaminant removal efficiency rather than prescribing specific technologies.

Emerging regulatory considerations include the management of concentrate streams from nanofiltration processes, energy efficiency requirements, and the establishment of monitoring protocols specific to membrane integrity and performance. These aspects are gradually being incorporated into updated regulatory frameworks, reflecting the growing importance of sustainability in water reuse applications.

In the European Union, the Water Framework Directive (2000/60/EC) provides the overarching structure for water management, while the more recent EU Regulation 2020/741 specifically addresses minimum requirements for water reuse in agricultural irrigation. These regulations increasingly recognize nanofiltration as a viable technology for achieving required water quality standards, particularly for removing micropollutants and pharmaceutical residues.

The United States employs a decentralized regulatory approach, with the EPA providing guidelines through the National Water Reuse Action Plan, while individual states establish their own specific regulations. California's Title 22 regulations and Florida's comprehensive water reuse program represent some of the most advanced frameworks that explicitly incorporate membrane filtration technologies, including nanofiltration, as approved treatment methods for various reuse applications.

In Asia, Singapore's NEWater initiative stands as a global benchmark, with its "Four National Taps" strategy incorporating advanced membrane technologies under strict regulatory oversight. China has recently strengthened its regulatory framework through the Water Pollution Prevention and Control Law, which now includes provisions for advanced treatment technologies in water reclamation projects.

International organizations such as the World Health Organization and ISO have developed guidelines and standards that serve as reference points for countries developing their own regulatory frameworks. The WHO's Guidelines for the Safe Use of Wastewater, Excreta and Greywater provides risk-based approaches that increasingly acknowledge the role of advanced filtration technologies.

A notable trend in regulatory evolution is the shift from technology-based to performance-based standards, allowing greater flexibility in technology selection while maintaining strict output quality requirements. This approach has facilitated the adoption of nanofiltration in various applications, as regulations focus on contaminant removal efficiency rather than prescribing specific technologies.

Emerging regulatory considerations include the management of concentrate streams from nanofiltration processes, energy efficiency requirements, and the establishment of monitoring protocols specific to membrane integrity and performance. These aspects are gradually being incorporated into updated regulatory frameworks, reflecting the growing importance of sustainability in water reuse applications.

Environmental Impact Assessment of Nanofiltration Systems

The environmental impact assessment of nanofiltration systems reveals both significant benefits and potential concerns related to their implementation in wastewater treatment processes. Nanofiltration technology demonstrates remarkable efficiency in removing contaminants while consuming less energy compared to reverse osmosis systems, positioning it as an environmentally favorable option within the global water regulatory framework.

The primary environmental advantage of nanofiltration lies in its ability to substantially reduce the discharge of harmful pollutants into natural water bodies. By effectively filtering out pharmaceuticals, personal care products, microplastics, and industrial chemicals, these systems help maintain aquatic ecosystem health and biodiversity. Studies indicate that properly implemented nanofiltration can remove up to 95% of emerging contaminants that conventional treatment methods fail to address.

Energy consumption represents another critical environmental consideration. Nanofiltration typically requires 20-30% less energy than reverse osmosis while still providing excellent filtration capabilities for most applications. This reduced energy footprint translates to lower greenhouse gas emissions associated with water treatment operations, aligning with global carbon reduction initiatives embedded in water regulations across developed nations.

The membrane manufacturing process and disposal present notable environmental challenges. Current production methods for nanofiltration membranes involve energy-intensive processes and potentially hazardous chemicals. The limited lifespan of these membranes (typically 3-7 years) creates a waste management issue that regulators increasingly address through extended producer responsibility requirements in regions like the European Union and parts of Asia.

Concentrate management remains perhaps the most significant environmental concern. The concentrated waste stream produced during nanofiltration contains elevated levels of the very contaminants the system removes. Regulatory frameworks in Australia, Singapore, and Israel have pioneered stringent requirements for concentrate handling, often mandating additional treatment before discharge or encouraging beneficial reuse applications.

Life cycle assessment studies comparing nanofiltration to alternative treatment technologies demonstrate its favorable environmental profile when properly implemented. However, these assessments highlight the importance of context-specific evaluation, as local energy sources, water quality parameters, and discharge regulations significantly influence the overall environmental impact. This has led regulatory bodies in North America and Europe to adopt more nuanced, performance-based approaches rather than prescriptive technology mandates.

The primary environmental advantage of nanofiltration lies in its ability to substantially reduce the discharge of harmful pollutants into natural water bodies. By effectively filtering out pharmaceuticals, personal care products, microplastics, and industrial chemicals, these systems help maintain aquatic ecosystem health and biodiversity. Studies indicate that properly implemented nanofiltration can remove up to 95% of emerging contaminants that conventional treatment methods fail to address.

Energy consumption represents another critical environmental consideration. Nanofiltration typically requires 20-30% less energy than reverse osmosis while still providing excellent filtration capabilities for most applications. This reduced energy footprint translates to lower greenhouse gas emissions associated with water treatment operations, aligning with global carbon reduction initiatives embedded in water regulations across developed nations.

The membrane manufacturing process and disposal present notable environmental challenges. Current production methods for nanofiltration membranes involve energy-intensive processes and potentially hazardous chemicals. The limited lifespan of these membranes (typically 3-7 years) creates a waste management issue that regulators increasingly address through extended producer responsibility requirements in regions like the European Union and parts of Asia.

Concentrate management remains perhaps the most significant environmental concern. The concentrated waste stream produced during nanofiltration contains elevated levels of the very contaminants the system removes. Regulatory frameworks in Australia, Singapore, and Israel have pioneered stringent requirements for concentrate handling, often mandating additional treatment before discharge or encouraging beneficial reuse applications.

Life cycle assessment studies comparing nanofiltration to alternative treatment technologies demonstrate its favorable environmental profile when properly implemented. However, these assessments highlight the importance of context-specific evaluation, as local energy sources, water quality parameters, and discharge regulations significantly influence the overall environmental impact. This has led regulatory bodies in North America and Europe to adopt more nuanced, performance-based approaches rather than prescriptive technology mandates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!