Analysis of Wastewater Nanofiltration Systems for Quality Control

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Evolution and Objectives

Nanofiltration technology has evolved significantly since its inception in the late 1970s, emerging as a specialized membrane separation process positioned between reverse osmosis and ultrafiltration in terms of selectivity. The initial development focused primarily on water softening applications, with early commercial nanofiltration membranes designed specifically for hardness removal. Throughout the 1980s, researchers concentrated on understanding the fundamental mechanisms of nanofiltration, particularly the interplay between size exclusion and charge effects that give this technology its unique separation characteristics.

The 1990s marked a period of rapid advancement in membrane materials science, with the introduction of thin-film composite membranes that dramatically improved flux rates and selectivity. These innovations expanded nanofiltration's potential applications beyond simple softening to include the removal of specific contaminants such as pesticides, pharmaceuticals, and industrial chemicals from water sources. By the early 2000s, nanofiltration had established itself as a viable technology for drinking water treatment in municipal systems.

The evolution of wastewater nanofiltration systems specifically for quality control represents a more recent development trajectory. Initially, nanofiltration was considered too costly and prone to fouling for widespread wastewater applications. However, advances in anti-fouling membrane materials, module designs, and operational protocols have gradually overcome these limitations. The period from 2010 to 2020 saw particularly significant innovations in membrane chemistry and surface modifications that enhanced resistance to organic fouling, a critical factor in wastewater applications.

Current technological objectives for nanofiltration in wastewater quality control focus on several key areas. First, improving energy efficiency remains paramount, as energy consumption continues to be a significant operational cost. Research aims to develop membranes that maintain high flux rates at lower operating pressures. Second, enhancing selectivity for emerging contaminants of concern, particularly pharmaceutical residues and microplastics, represents a critical objective as regulatory standards become increasingly stringent.

Another important goal is the development of "smart" nanofiltration systems with real-time monitoring capabilities and automated adjustment of operational parameters. These systems aim to optimize performance based on influent water quality variations, maximizing treatment efficiency while minimizing energy consumption and membrane fouling. Additionally, research is directed toward creating more sustainable nanofiltration technologies, including membranes manufactured from bio-based materials and systems designed for minimal chemical cleaning requirements.

The ultimate technological objective is to position nanofiltration as a core component in circular water economy approaches, where treated wastewater becomes a valuable resource rather than a waste stream. This requires nanofiltration systems capable of producing effluent quality tailored to specific reuse applications, from industrial process water to agricultural irrigation, with consistent reliability and economic viability.

The 1990s marked a period of rapid advancement in membrane materials science, with the introduction of thin-film composite membranes that dramatically improved flux rates and selectivity. These innovations expanded nanofiltration's potential applications beyond simple softening to include the removal of specific contaminants such as pesticides, pharmaceuticals, and industrial chemicals from water sources. By the early 2000s, nanofiltration had established itself as a viable technology for drinking water treatment in municipal systems.

The evolution of wastewater nanofiltration systems specifically for quality control represents a more recent development trajectory. Initially, nanofiltration was considered too costly and prone to fouling for widespread wastewater applications. However, advances in anti-fouling membrane materials, module designs, and operational protocols have gradually overcome these limitations. The period from 2010 to 2020 saw particularly significant innovations in membrane chemistry and surface modifications that enhanced resistance to organic fouling, a critical factor in wastewater applications.

Current technological objectives for nanofiltration in wastewater quality control focus on several key areas. First, improving energy efficiency remains paramount, as energy consumption continues to be a significant operational cost. Research aims to develop membranes that maintain high flux rates at lower operating pressures. Second, enhancing selectivity for emerging contaminants of concern, particularly pharmaceutical residues and microplastics, represents a critical objective as regulatory standards become increasingly stringent.

Another important goal is the development of "smart" nanofiltration systems with real-time monitoring capabilities and automated adjustment of operational parameters. These systems aim to optimize performance based on influent water quality variations, maximizing treatment efficiency while minimizing energy consumption and membrane fouling. Additionally, research is directed toward creating more sustainable nanofiltration technologies, including membranes manufactured from bio-based materials and systems designed for minimal chemical cleaning requirements.

The ultimate technological objective is to position nanofiltration as a core component in circular water economy approaches, where treated wastewater becomes a valuable resource rather than a waste stream. This requires nanofiltration systems capable of producing effluent quality tailored to specific reuse applications, from industrial process water to agricultural irrigation, with consistent reliability and economic viability.

Market Analysis for Wastewater Treatment Solutions

The global wastewater treatment solutions market has experienced significant growth in recent years, driven by increasing water scarcity concerns, stringent environmental regulations, and growing industrial activities. As of 2023, the market was valued at approximately 125 billion USD, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2030, potentially reaching 197 billion USD by the end of the forecast period.

Nanofiltration systems represent one of the fastest-growing segments within this market, currently accounting for about 18% of the total wastewater treatment solutions market. This segment is expected to grow at a CAGR of 9.2% through 2030, outpacing the overall market growth due to its superior efficiency in removing specific contaminants while maintaining essential minerals.

Regional analysis reveals that North America and Europe currently dominate the wastewater nanofiltration market, collectively holding approximately 58% market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to rapid industrialization, urbanization, and increasingly stringent environmental regulations. The Middle East region also shows promising growth potential due to severe water scarcity issues and substantial investments in water reuse technologies.

By application segment, industrial wastewater treatment currently represents the largest market share (42%), followed by municipal wastewater treatment (38%) and commercial applications (20%). Within industrial applications, the pharmaceutical, food and beverage, and textile industries are the primary adopters of nanofiltration technology for quality control purposes.

Customer demand analysis indicates a growing preference for integrated wastewater treatment solutions that combine nanofiltration with other technologies to achieve comprehensive water quality management. End-users increasingly prioritize systems that offer reduced energy consumption, minimal chemical usage, and lower operational costs, alongside reliable performance and compliance with regulatory standards.

Market challenges include the relatively high initial capital investment required for nanofiltration systems, which creates adoption barriers particularly for small and medium-sized enterprises. Additionally, membrane fouling issues and the need for specialized maintenance expertise represent ongoing operational challenges that influence purchasing decisions.

Emerging market opportunities include the development of specialized nanofiltration solutions for emerging contaminants of concern, such as pharmaceutical residues, microplastics, and PFAS (per- and polyfluoroalkyl substances). The growing focus on water reuse and circular economy principles is also creating new market segments for advanced nanofiltration systems capable of producing high-quality recycled water for various applications.

Nanofiltration systems represent one of the fastest-growing segments within this market, currently accounting for about 18% of the total wastewater treatment solutions market. This segment is expected to grow at a CAGR of 9.2% through 2030, outpacing the overall market growth due to its superior efficiency in removing specific contaminants while maintaining essential minerals.

Regional analysis reveals that North America and Europe currently dominate the wastewater nanofiltration market, collectively holding approximately 58% market share. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India leading the expansion due to rapid industrialization, urbanization, and increasingly stringent environmental regulations. The Middle East region also shows promising growth potential due to severe water scarcity issues and substantial investments in water reuse technologies.

By application segment, industrial wastewater treatment currently represents the largest market share (42%), followed by municipal wastewater treatment (38%) and commercial applications (20%). Within industrial applications, the pharmaceutical, food and beverage, and textile industries are the primary adopters of nanofiltration technology for quality control purposes.

Customer demand analysis indicates a growing preference for integrated wastewater treatment solutions that combine nanofiltration with other technologies to achieve comprehensive water quality management. End-users increasingly prioritize systems that offer reduced energy consumption, minimal chemical usage, and lower operational costs, alongside reliable performance and compliance with regulatory standards.

Market challenges include the relatively high initial capital investment required for nanofiltration systems, which creates adoption barriers particularly for small and medium-sized enterprises. Additionally, membrane fouling issues and the need for specialized maintenance expertise represent ongoing operational challenges that influence purchasing decisions.

Emerging market opportunities include the development of specialized nanofiltration solutions for emerging contaminants of concern, such as pharmaceutical residues, microplastics, and PFAS (per- and polyfluoroalkyl substances). The growing focus on water reuse and circular economy principles is also creating new market segments for advanced nanofiltration systems capable of producing high-quality recycled water for various applications.

Current Nanofiltration Systems and Technical Barriers

Nanofiltration (NF) technology has emerged as a critical component in advanced wastewater treatment systems, positioned between reverse osmosis and ultrafiltration in terms of selectivity and operating pressure. Current commercial nanofiltration systems typically employ thin-film composite membranes with pore sizes ranging from 1-10 nanometers, capable of rejecting multivalent ions, organic molecules, and certain microcontaminants while allowing monovalent ions to pass through.

The predominant configuration in industrial applications is spiral-wound modules, which offer high packing density and moderate fouling resistance. Hollow fiber and tubular configurations are also utilized in specific applications where higher fouling resistance is required, albeit at lower packing densities. Most systems operate at pressures between 5-20 bar, significantly lower than reverse osmosis systems, resulting in reduced energy consumption.

Despite technological advancements, nanofiltration systems face several persistent technical barriers. Membrane fouling remains the most significant challenge, manifesting as organic fouling, biofouling, scaling, and colloidal fouling. These phenomena reduce flux, increase energy consumption, and necessitate frequent chemical cleaning, which in turn shortens membrane lifespan and increases operational costs.

Concentration polarization presents another substantial barrier, occurring when rejected solutes accumulate at the membrane surface, creating a concentration gradient that reduces effective driving force and separation efficiency. This phenomenon is particularly problematic in wastewater applications with high organic content or variable influent composition.

Membrane stability under harsh chemical environments poses additional challenges. Current nanofiltration membranes exhibit limited tolerance to extreme pH conditions, oxidizing agents, and certain organic solvents commonly found in industrial wastewaters. This restricts their application in treating complex industrial effluents without extensive pre-treatment.

Selectivity limitations constitute another significant barrier. While nanofiltration excels at removing multivalent ions and larger organic molecules, its performance in rejecting certain micropollutants, pharmaceuticals, and personal care products remains inconsistent. This is particularly problematic as regulatory standards for these contaminants become increasingly stringent.

Energy efficiency remains a concern despite improvements over reverse osmosis. The trade-off between permeability and selectivity continues to challenge membrane designers, with highly selective membranes typically requiring higher operating pressures and energy inputs.

Scale-up and system integration issues persist in transitioning from laboratory to industrial scale. Maintaining uniform flow distribution, minimizing concentration polarization, and ensuring consistent performance across large membrane areas present significant engineering challenges that impact overall system reliability and efficiency.

The predominant configuration in industrial applications is spiral-wound modules, which offer high packing density and moderate fouling resistance. Hollow fiber and tubular configurations are also utilized in specific applications where higher fouling resistance is required, albeit at lower packing densities. Most systems operate at pressures between 5-20 bar, significantly lower than reverse osmosis systems, resulting in reduced energy consumption.

Despite technological advancements, nanofiltration systems face several persistent technical barriers. Membrane fouling remains the most significant challenge, manifesting as organic fouling, biofouling, scaling, and colloidal fouling. These phenomena reduce flux, increase energy consumption, and necessitate frequent chemical cleaning, which in turn shortens membrane lifespan and increases operational costs.

Concentration polarization presents another substantial barrier, occurring when rejected solutes accumulate at the membrane surface, creating a concentration gradient that reduces effective driving force and separation efficiency. This phenomenon is particularly problematic in wastewater applications with high organic content or variable influent composition.

Membrane stability under harsh chemical environments poses additional challenges. Current nanofiltration membranes exhibit limited tolerance to extreme pH conditions, oxidizing agents, and certain organic solvents commonly found in industrial wastewaters. This restricts their application in treating complex industrial effluents without extensive pre-treatment.

Selectivity limitations constitute another significant barrier. While nanofiltration excels at removing multivalent ions and larger organic molecules, its performance in rejecting certain micropollutants, pharmaceuticals, and personal care products remains inconsistent. This is particularly problematic as regulatory standards for these contaminants become increasingly stringent.

Energy efficiency remains a concern despite improvements over reverse osmosis. The trade-off between permeability and selectivity continues to challenge membrane designers, with highly selective membranes typically requiring higher operating pressures and energy inputs.

Scale-up and system integration issues persist in transitioning from laboratory to industrial scale. Maintaining uniform flow distribution, minimizing concentration polarization, and ensuring consistent performance across large membrane areas present significant engineering challenges that impact overall system reliability and efficiency.

Existing Nanofiltration Quality Control Methodologies

01 Membrane integrity monitoring systems

Quality control in nanofiltration systems requires continuous monitoring of membrane integrity to ensure optimal filtration performance. These monitoring systems employ sensors and detection methods to identify membrane damage, fouling, or performance degradation in real-time. Advanced monitoring technologies can detect microscopic defects before they compromise the entire filtration process, allowing for timely maintenance interventions and ensuring consistent water quality output.- Membrane integrity monitoring systems: Quality control in nanofiltration systems requires continuous monitoring of membrane integrity to ensure optimal filtration performance. These monitoring systems use sensors and real-time data analysis to detect membrane damage, fouling, or performance degradation. Advanced monitoring technologies can measure parameters such as pressure differentials, flow rates, and rejection rates to identify potential issues before they affect water quality. This proactive approach helps maintain consistent filtration efficiency and extends membrane lifespan.

- Automated cleaning and maintenance processes: Automated cleaning and maintenance processes are essential for quality control in wastewater nanofiltration systems. These processes include chemical cleaning sequences, backwashing mechanisms, and scheduled maintenance protocols that prevent membrane fouling and scaling. By implementing automated cleaning cycles based on operational parameters, the systems can maintain consistent filtration performance and reduce manual intervention. These processes often incorporate smart scheduling algorithms that optimize cleaning frequency based on water quality and membrane condition.

- Water quality parameter analysis and control: Comprehensive water quality parameter analysis is crucial for nanofiltration system quality control. This involves continuous monitoring of influent and effluent characteristics including pH, turbidity, conductivity, and specific contaminant levels. Advanced analytical instruments and sensors provide real-time data that enables automatic adjustments to system operations. By maintaining tight control over these parameters, nanofiltration systems can consistently produce high-quality treated water that meets regulatory standards and process requirements.

- Modular and scalable system designs: Modular and scalable nanofiltration system designs enhance quality control by allowing for flexible operation and easier maintenance. These systems feature standardized components that can be individually monitored, replaced, or upgraded without disrupting the entire filtration process. The modular approach enables targeted quality control measures for specific filtration stages and facilitates system expansion or reconfiguration as treatment requirements change. This design philosophy improves overall system reliability and simplifies troubleshooting when quality issues arise.

- Integration of digital monitoring and control platforms: Digital monitoring and control platforms integrate various quality control aspects of wastewater nanofiltration systems into unified management systems. These platforms utilize IoT sensors, cloud computing, and artificial intelligence to collect, analyze, and respond to operational data. Advanced algorithms can predict potential quality issues before they occur and automatically adjust system parameters to maintain optimal performance. Remote monitoring capabilities allow operators to oversee multiple systems simultaneously and implement quality control measures promptly when deviations are detected.

02 Automated control and feedback mechanisms

Automated control systems integrate sensors, controllers, and feedback loops to maintain optimal operating conditions in nanofiltration processes. These systems continuously adjust parameters such as pressure, flow rate, and chemical dosing based on real-time water quality measurements. By implementing predictive algorithms and machine learning techniques, these control mechanisms can anticipate system failures, optimize energy consumption, and ensure consistent filtration performance while minimizing human intervention.Expand Specific Solutions03 Multi-parameter water quality testing

Comprehensive quality control in nanofiltration systems involves simultaneous monitoring of multiple water quality parameters. These testing systems analyze physical, chemical, and biological characteristics of both influent and effluent water streams. Parameters monitored include turbidity, conductivity, pH, total dissolved solids, specific contaminant concentrations, and microbial presence. Integrated testing platforms enable rapid detection of quality deviations and provide data for process optimization and regulatory compliance.Expand Specific Solutions04 Modular and scalable quality control infrastructure

Modular quality control systems for nanofiltration allow for flexible implementation across different scales of operation. These systems feature standardized components that can be easily integrated, upgraded, or replaced as needed. The modular approach enables customization based on specific wastewater characteristics and treatment requirements while maintaining consistent quality control protocols. This infrastructure supports scalability from pilot projects to industrial-scale applications while ensuring reliable performance monitoring throughout system expansion.Expand Specific Solutions05 Advanced fouling prevention and cleaning validation

Quality control systems for nanofiltration incorporate specialized methods to prevent membrane fouling and validate cleaning procedures. These systems employ preventive measures such as pretreatment optimization, anti-scaling agents, and controlled hydrodynamic conditions. For cleaning validation, they utilize techniques to measure cleaning effectiveness through parameters like flux recovery, pressure differential normalization, and surface analysis. Real-time fouling detection combined with automated cleaning protocols ensures consistent filtration efficiency and extends membrane lifespan.Expand Specific Solutions

Leading Companies in Nanofiltration Industry

The nanofiltration wastewater treatment market is currently in a growth phase, with increasing adoption across industrial and municipal sectors. Market size is expanding rapidly due to stringent water quality regulations and growing water scarcity concerns, estimated to reach several billion dollars globally by 2025. Technologically, the field shows varying maturity levels, with companies like Kurita Water Industries, Veolia Water Technologies, and Hitachi demonstrating advanced commercial solutions, while newer entrants such as WOTA Corp and Fluid Technology Solutions (FTS) focus on innovative approaches. Academic institutions including Nanyang Technological University and University of Hong Kong are driving fundamental research advancements. Regional leaders have emerged, with Midea Group and its subsidiary Foshan Midea Qinghu dominating in Asia, while European players like Siemens and Wehrle-Werk maintain strong positions in industrial applications.

Wehrle-Werk AG

Technical Solution: Wehrle-Werk has developed the BIOMEMBRAT® NF system, an integrated membrane bioreactor and nanofiltration technology specifically designed for high-quality wastewater treatment. Their system combines biological treatment with advanced nanofiltration using proprietary composite membranes featuring precisely controlled pore sizes between 1-5 nanometers. This configuration achieves exceptional removal rates: >99.9% for suspended solids, >95% for organic compounds, and >90% for multivalent ions and micropollutants. The system employs their patented VARI-FLUX™ technology that dynamically adjusts transmembrane pressure and cross-flow velocity based on real-time fouling indicators, maintaining optimal flux rates (20-30 LMH) while minimizing energy consumption. Wehrle's nanofiltration membranes incorporate specialized surface modifications that reduce organic and biological fouling, extending operational periods between cleaning cycles by up to 50% compared to conventional membranes. Their quality control system features comprehensive monitoring with multiple sensor arrays tracking over 15 water quality parameters in real-time, with automated adjustment of operational parameters to maintain consistent permeate quality. The system includes their proprietary SCADA platform with advanced analytics that provides predictive maintenance alerts and performance optimization recommendations based on historical operational data and current conditions. Wehrle's technology is particularly effective for industrial wastewaters with complex compositions, achieving consistent quality control even with highly variable influent characteristics.

Strengths: Exceptional removal of diverse contaminants including micropollutants; integrated biological and membrane filtration approach; advanced fouling prevention and management; sophisticated monitoring and control systems; proven effectiveness with challenging industrial wastewaters. Weaknesses: Higher capital and operational costs compared to conventional systems; complex technology requiring specialized expertise for operation and maintenance; significant energy requirements for high-throughput applications; challenges with wastewaters containing certain membrane-damaging compounds.

Fluid Technology Solutions (FTS), Inc.

Technical Solution: Fluid Technology Solutions has developed advanced Forward Osmosis (FO) nanofiltration systems for wastewater treatment that utilize proprietary Cellulose Triacetate (CTA) and Thin Film Composite (TFC) membranes. Their technology employs a semi-permeable membrane with pore sizes of approximately 1-10 nanometers to effectively remove contaminants while allowing water molecules to pass through. The system operates at significantly lower hydraulic pressures (5-10 bar) compared to conventional reverse osmosis systems (15-25 bar), resulting in energy savings of up to 30%. FTS's nanofiltration technology incorporates specialized spiral-wound membrane modules with optimized spacer designs that minimize fouling and concentration polarization, extending membrane life by up to 40% compared to standard configurations. Their systems include automated backwashing and chemical cleaning protocols that maintain consistent flux rates over extended operational periods. The company has implemented real-time monitoring systems that analyze permeate quality through multiple parameters including conductivity, pH, and specific contaminant concentrations to ensure consistent water quality control.

Strengths: Lower energy consumption compared to conventional filtration systems; excellent removal of multivalent ions and organic compounds; modular design allows for scalability; proprietary membrane technology with enhanced fouling resistance. Weaknesses: Higher initial capital investment; requires specialized maintenance expertise; potential for membrane degradation when treating certain industrial wastewaters with extreme pH or oxidizing agents.

Key Patents and Research in Nanofiltration Systems

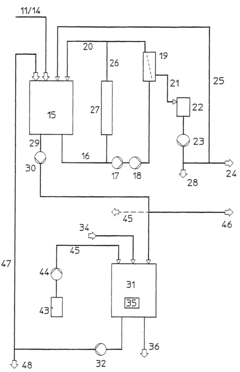

Process and device for purifying waste water

PatentInactiveEP0806399A1

Innovation

- The method involves recycling treated concentrate from physical and/or chemical treatment back into the filter circuit, utilizing membrane filter devices, particularly nanofilters, to concentrate harmful constituents, allowing for efficient conversion and separation independent of biological pre-treatment, using adsorbents, oxidizing agents, and ion exchange agents to convert substances into separable forms.

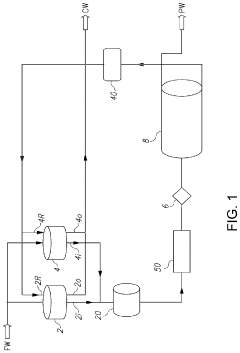

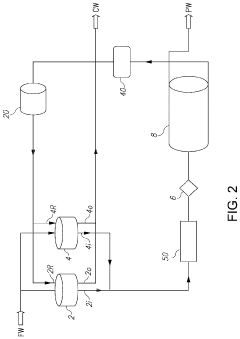

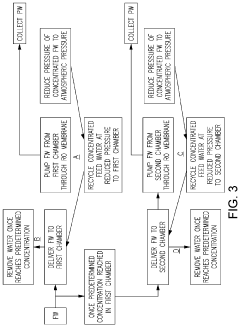

Improved reverse osmosis or nanofiltration process for cleaning water

PatentPendingUS20240181392A1

Innovation

- The system employs multiple feed chambers with a switching mechanism that detects efficiency reductions, allowing the concentrated feed stream to be recycled and pressure-reduced, then switched between chambers for continuous cleaning and desalination, using desaturation units to remove contaminants, and pre-treatment to maintain efficiency.

Environmental Regulations Impact on Wastewater Treatment

Environmental regulations have become increasingly stringent worldwide, significantly impacting wastewater treatment processes and technologies. The implementation of nanofiltration systems for wastewater quality control is directly influenced by these evolving regulatory frameworks. In the United States, the Clean Water Act establishes the foundation for regulating discharges of pollutants into water bodies, with the Environmental Protection Agency (EPA) continuously updating effluent guidelines that specify treatment requirements for different industries.

The European Union's Water Framework Directive represents one of the most comprehensive regulatory approaches globally, mandating member states to achieve "good ecological status" for all water bodies. This directive has accelerated the adoption of advanced treatment technologies like nanofiltration systems, particularly for removing emerging contaminants such as pharmaceuticals and microplastics that traditional treatment methods cannot effectively address.

In Asia, countries like China and India have recently strengthened their environmental regulations in response to severe water pollution challenges. China's Water Pollution Prevention and Control Action Plan, implemented in 2015, has led to substantial investments in advanced wastewater treatment technologies, creating a rapidly growing market for nanofiltration systems. Similarly, India's National Green Tribunal has issued increasingly strict discharge standards, particularly for industrial wastewater.

Regulatory compliance costs have become a significant factor in the economic evaluation of wastewater treatment technologies. The capital expenditure for implementing nanofiltration systems must be balanced against potential non-compliance penalties, which have increased substantially in many jurisdictions. This cost-benefit analysis often favors investment in advanced treatment technologies despite higher initial costs.

The regulatory landscape also influences research and development priorities in nanofiltration technology. Anticipation of future regulatory requirements drives innovation in membrane materials and system designs that can achieve higher removal efficiencies for contaminants likely to be regulated in the future. This regulatory-driven innovation cycle has accelerated the development of more selective, energy-efficient, and fouling-resistant nanofiltration membranes.

International trade agreements increasingly include environmental standards that affect wastewater treatment requirements. Companies operating globally must navigate complex and sometimes contradictory regulatory frameworks, often adopting the most stringent standards across their operations to ensure compliance in all markets. This regulatory harmonization trend benefits advanced treatment technologies like nanofiltration systems that can meet diverse quality requirements.

Climate change policies are also beginning to influence wastewater treatment regulations, with growing emphasis on energy efficiency and carbon footprint reduction. Nanofiltration systems, while energy-intensive compared to conventional treatments, offer advantages in water reuse applications that can contribute to overall sustainability goals and climate resilience strategies mandated by emerging regulations.

The European Union's Water Framework Directive represents one of the most comprehensive regulatory approaches globally, mandating member states to achieve "good ecological status" for all water bodies. This directive has accelerated the adoption of advanced treatment technologies like nanofiltration systems, particularly for removing emerging contaminants such as pharmaceuticals and microplastics that traditional treatment methods cannot effectively address.

In Asia, countries like China and India have recently strengthened their environmental regulations in response to severe water pollution challenges. China's Water Pollution Prevention and Control Action Plan, implemented in 2015, has led to substantial investments in advanced wastewater treatment technologies, creating a rapidly growing market for nanofiltration systems. Similarly, India's National Green Tribunal has issued increasingly strict discharge standards, particularly for industrial wastewater.

Regulatory compliance costs have become a significant factor in the economic evaluation of wastewater treatment technologies. The capital expenditure for implementing nanofiltration systems must be balanced against potential non-compliance penalties, which have increased substantially in many jurisdictions. This cost-benefit analysis often favors investment in advanced treatment technologies despite higher initial costs.

The regulatory landscape also influences research and development priorities in nanofiltration technology. Anticipation of future regulatory requirements drives innovation in membrane materials and system designs that can achieve higher removal efficiencies for contaminants likely to be regulated in the future. This regulatory-driven innovation cycle has accelerated the development of more selective, energy-efficient, and fouling-resistant nanofiltration membranes.

International trade agreements increasingly include environmental standards that affect wastewater treatment requirements. Companies operating globally must navigate complex and sometimes contradictory regulatory frameworks, often adopting the most stringent standards across their operations to ensure compliance in all markets. This regulatory harmonization trend benefits advanced treatment technologies like nanofiltration systems that can meet diverse quality requirements.

Climate change policies are also beginning to influence wastewater treatment regulations, with growing emphasis on energy efficiency and carbon footprint reduction. Nanofiltration systems, while energy-intensive compared to conventional treatments, offer advantages in water reuse applications that can contribute to overall sustainability goals and climate resilience strategies mandated by emerging regulations.

Energy Efficiency in Nanofiltration Systems

Energy efficiency has emerged as a critical factor in the design and operation of wastewater nanofiltration systems. Current nanofiltration technologies typically consume between 1.5-3.0 kWh per cubic meter of treated water, representing a significant operational cost for treatment facilities. This energy consumption is primarily attributed to the high pressure requirements needed to force water through nanometer-sized membrane pores, which typically operate at 5-15 bar pressure ranges.

Recent advancements in membrane materials have shown promising results in reducing energy demands. Thin-film composite membranes with optimized surface chemistry have demonstrated up to 25% reduction in energy consumption compared to conventional membranes. These improvements stem from enhanced water permeability while maintaining selectivity for contaminant rejection.

Process optimization strategies have also contributed significantly to energy efficiency gains. Implementation of variable frequency drives (VFDs) on high-pressure pumps allows for dynamic adjustment of system pressure based on feed water quality and desired output specifications. Studies indicate that VFD implementation can reduce energy consumption by 15-30% in nanofiltration systems without compromising filtration performance.

Pressure recovery devices represent another technological advancement with substantial energy-saving potential. Energy recovery systems such as pressure exchangers and turbochargers can recapture up to 60% of the hydraulic energy from the concentrate stream, which would otherwise be wasted. The integration of these devices has been shown to reduce overall energy requirements by 25-40% in large-scale installations.

Membrane fouling remains a significant challenge to energy efficiency in nanofiltration systems. As membranes become fouled with organic matter, colloids, or scale deposits, higher operating pressures are required to maintain desired flux rates, resulting in increased energy consumption. Advanced pretreatment methods, including ultrafiltration and specialized chemical treatments, have demonstrated effectiveness in reducing fouling rates and associated energy penalties.

Emerging technologies such as forward osmosis-nanofiltration hybrid systems show promise for further energy efficiency improvements. These systems utilize natural osmotic pressure gradients to drive initial separation processes, reducing the energy required for subsequent nanofiltration stages. Laboratory-scale studies indicate potential energy savings of 30-50% compared to conventional nanofiltration, though commercial viability remains under investigation.

Temperature management strategies also impact energy efficiency, as water viscosity decreases at higher temperatures, reducing pressure requirements. However, this must be balanced against potential membrane degradation at elevated temperatures and the energy costs associated with heating feed water.

Recent advancements in membrane materials have shown promising results in reducing energy demands. Thin-film composite membranes with optimized surface chemistry have demonstrated up to 25% reduction in energy consumption compared to conventional membranes. These improvements stem from enhanced water permeability while maintaining selectivity for contaminant rejection.

Process optimization strategies have also contributed significantly to energy efficiency gains. Implementation of variable frequency drives (VFDs) on high-pressure pumps allows for dynamic adjustment of system pressure based on feed water quality and desired output specifications. Studies indicate that VFD implementation can reduce energy consumption by 15-30% in nanofiltration systems without compromising filtration performance.

Pressure recovery devices represent another technological advancement with substantial energy-saving potential. Energy recovery systems such as pressure exchangers and turbochargers can recapture up to 60% of the hydraulic energy from the concentrate stream, which would otherwise be wasted. The integration of these devices has been shown to reduce overall energy requirements by 25-40% in large-scale installations.

Membrane fouling remains a significant challenge to energy efficiency in nanofiltration systems. As membranes become fouled with organic matter, colloids, or scale deposits, higher operating pressures are required to maintain desired flux rates, resulting in increased energy consumption. Advanced pretreatment methods, including ultrafiltration and specialized chemical treatments, have demonstrated effectiveness in reducing fouling rates and associated energy penalties.

Emerging technologies such as forward osmosis-nanofiltration hybrid systems show promise for further energy efficiency improvements. These systems utilize natural osmotic pressure gradients to drive initial separation processes, reducing the energy required for subsequent nanofiltration stages. Laboratory-scale studies indicate potential energy savings of 30-50% compared to conventional nanofiltration, though commercial viability remains under investigation.

Temperature management strategies also impact energy efficiency, as water viscosity decreases at higher temperatures, reducing pressure requirements. However, this must be balanced against potential membrane degradation at elevated temperatures and the energy costs associated with heating feed water.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!