Wastewater Nanofiltration: Comparative Material Studies

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Background and Objectives

Nanofiltration (NF) technology has emerged as a critical advancement in wastewater treatment systems over the past three decades. Positioned between reverse osmosis and ultrafiltration in terms of selectivity, nanofiltration offers a unique combination of size exclusion and charge-based separation mechanisms. The technology originated in the late 1980s as a modification of reverse osmosis membranes, with significant commercial development occurring throughout the 1990s as environmental regulations became more stringent worldwide.

The evolution of nanofiltration has been characterized by continuous improvements in membrane materials, from early cellulose acetate compositions to modern thin-film composite structures. This progression has enabled enhanced separation efficiency while reducing energy consumption requirements, making nanofiltration increasingly economically viable for various applications. Recent technological trends indicate a shift toward biomimetic and mixed matrix membranes that incorporate nanomaterials to achieve superior performance characteristics.

In wastewater treatment specifically, nanofiltration has demonstrated remarkable versatility in addressing complex contamination challenges. The technology excels at removing divalent ions, organic micropollutants, and color compounds while allowing beneficial monovalent ions to pass through. This selective filtration capability represents a significant advantage over conventional treatment methods, particularly for industrial effluents containing mixed contaminants.

The primary objective of comparative material studies in wastewater nanofiltration is to systematically evaluate and optimize membrane performance across diverse operational conditions and contaminant profiles. This includes assessing various polymeric, ceramic, and composite materials for their filtration efficiency, fouling resistance, mechanical stability, and economic feasibility. Such comparative analyses are essential for developing application-specific solutions that balance treatment effectiveness with operational costs.

Current research aims to address persistent challenges in nanofiltration technology, particularly membrane fouling and concentration polarization phenomena that reduce operational efficiency over time. Material innovation focuses on developing anti-fouling surfaces through hydrophilicity modification, incorporation of antimicrobial agents, and optimization of surface morphology. Additionally, researchers are exploring sustainable manufacturing approaches to reduce the environmental footprint of membrane production processes.

The technological trajectory suggests increasing integration of nanofiltration with complementary treatment processes in hybrid systems, allowing for more comprehensive wastewater remediation. Emerging objectives include the development of responsive or "smart" membranes capable of adapting to changing influent characteristics, as well as membranes specifically engineered for resource recovery applications, aligning with circular economy principles in water management.

The evolution of nanofiltration has been characterized by continuous improvements in membrane materials, from early cellulose acetate compositions to modern thin-film composite structures. This progression has enabled enhanced separation efficiency while reducing energy consumption requirements, making nanofiltration increasingly economically viable for various applications. Recent technological trends indicate a shift toward biomimetic and mixed matrix membranes that incorporate nanomaterials to achieve superior performance characteristics.

In wastewater treatment specifically, nanofiltration has demonstrated remarkable versatility in addressing complex contamination challenges. The technology excels at removing divalent ions, organic micropollutants, and color compounds while allowing beneficial monovalent ions to pass through. This selective filtration capability represents a significant advantage over conventional treatment methods, particularly for industrial effluents containing mixed contaminants.

The primary objective of comparative material studies in wastewater nanofiltration is to systematically evaluate and optimize membrane performance across diverse operational conditions and contaminant profiles. This includes assessing various polymeric, ceramic, and composite materials for their filtration efficiency, fouling resistance, mechanical stability, and economic feasibility. Such comparative analyses are essential for developing application-specific solutions that balance treatment effectiveness with operational costs.

Current research aims to address persistent challenges in nanofiltration technology, particularly membrane fouling and concentration polarization phenomena that reduce operational efficiency over time. Material innovation focuses on developing anti-fouling surfaces through hydrophilicity modification, incorporation of antimicrobial agents, and optimization of surface morphology. Additionally, researchers are exploring sustainable manufacturing approaches to reduce the environmental footprint of membrane production processes.

The technological trajectory suggests increasing integration of nanofiltration with complementary treatment processes in hybrid systems, allowing for more comprehensive wastewater remediation. Emerging objectives include the development of responsive or "smart" membranes capable of adapting to changing influent characteristics, as well as membranes specifically engineered for resource recovery applications, aligning with circular economy principles in water management.

Market Analysis for Wastewater Treatment Solutions

The global wastewater treatment solutions market is experiencing robust growth, driven by increasing water scarcity concerns, stringent environmental regulations, and growing industrial activities. Currently valued at approximately 250 billion USD, the market is projected to reach 376 billion USD by 2027, representing a compound annual growth rate of 7.1% during the forecast period.

Nanofiltration technology, particularly for wastewater treatment, represents one of the fastest-growing segments within this market. The nanofiltration membrane market specifically is expanding at nearly 8.5% annually, outpacing conventional filtration technologies due to its superior performance characteristics and decreasing implementation costs.

Demand for advanced wastewater treatment solutions is particularly strong in regions facing severe water stress. Asia-Pacific leads market growth with China and India investing heavily in water infrastructure. North America and Europe maintain significant market shares driven by replacement of aging infrastructure and increasingly stringent regulatory frameworks regarding effluent quality and micropollutant removal.

Industrial applications constitute the largest market segment for nanofiltration technologies, accounting for approximately 45% of the total market. Manufacturing, chemical processing, and pharmaceutical industries are primary adopters, seeking to meet discharge regulations while exploring water reuse opportunities. Municipal applications follow at 35%, with the remainder distributed across commercial and specialized applications.

Material innovation in nanofiltration membranes represents a critical competitive differentiator. Polymeric membranes currently dominate with 78% market share, while ceramic and hybrid materials are gaining traction in specialized applications requiring extreme chemical or thermal resistance. Thin-film composite membranes based on polyamide chemistry lead commercial implementations, though novel materials incorporating graphene, metal-organic frameworks, and biomimetic approaches are showing promising performance improvements in laboratory settings.

Customer priorities are evolving beyond traditional metrics of filtration efficiency and cost. Energy consumption, membrane fouling resistance, operational lifespan, and sustainability credentials are increasingly important decision factors. Solutions offering comprehensive performance across these parameters command premium pricing, with customers demonstrating willingness to pay 15-20% more for technologies that reduce total operational costs over system lifetime.

Market fragmentation remains high with over 200 companies offering nanofiltration solutions globally. However, consolidation is accelerating through strategic acquisitions as larger water technology conglomerates seek to expand their technological portfolios. This trend is expected to continue as the technology matures and economies of scale become increasingly important for commercial competitiveness.

Nanofiltration technology, particularly for wastewater treatment, represents one of the fastest-growing segments within this market. The nanofiltration membrane market specifically is expanding at nearly 8.5% annually, outpacing conventional filtration technologies due to its superior performance characteristics and decreasing implementation costs.

Demand for advanced wastewater treatment solutions is particularly strong in regions facing severe water stress. Asia-Pacific leads market growth with China and India investing heavily in water infrastructure. North America and Europe maintain significant market shares driven by replacement of aging infrastructure and increasingly stringent regulatory frameworks regarding effluent quality and micropollutant removal.

Industrial applications constitute the largest market segment for nanofiltration technologies, accounting for approximately 45% of the total market. Manufacturing, chemical processing, and pharmaceutical industries are primary adopters, seeking to meet discharge regulations while exploring water reuse opportunities. Municipal applications follow at 35%, with the remainder distributed across commercial and specialized applications.

Material innovation in nanofiltration membranes represents a critical competitive differentiator. Polymeric membranes currently dominate with 78% market share, while ceramic and hybrid materials are gaining traction in specialized applications requiring extreme chemical or thermal resistance. Thin-film composite membranes based on polyamide chemistry lead commercial implementations, though novel materials incorporating graphene, metal-organic frameworks, and biomimetic approaches are showing promising performance improvements in laboratory settings.

Customer priorities are evolving beyond traditional metrics of filtration efficiency and cost. Energy consumption, membrane fouling resistance, operational lifespan, and sustainability credentials are increasingly important decision factors. Solutions offering comprehensive performance across these parameters command premium pricing, with customers demonstrating willingness to pay 15-20% more for technologies that reduce total operational costs over system lifetime.

Market fragmentation remains high with over 200 companies offering nanofiltration solutions globally. However, consolidation is accelerating through strategic acquisitions as larger water technology conglomerates seek to expand their technological portfolios. This trend is expected to continue as the technology matures and economies of scale become increasingly important for commercial competitiveness.

Current Nanofiltration Materials and Technical Challenges

Nanofiltration (NF) technology has emerged as a promising solution for wastewater treatment, positioned between ultrafiltration and reverse osmosis in terms of selectivity and operating pressure. Current nanofiltration materials can be broadly categorized into polymeric, inorganic, and hybrid materials, each with distinct properties and applications in wastewater treatment scenarios.

Polymeric membranes dominate the commercial nanofiltration market, with polyamide thin-film composite (TFC) membranes being the most widely utilized. These membranes typically consist of a thin polyamide selective layer (0.1-1 μm) on top of a porous support. Other common polymeric materials include polysulfone, polyethersulfone, and cellulose acetate. While these materials offer excellent separation performance and relatively low production costs, they face significant challenges related to chlorine sensitivity, fouling propensity, and limited thermal and chemical stability.

Inorganic membranes, primarily composed of ceramic materials such as alumina, zirconia, titania, and silica, represent an alternative with superior thermal and chemical stability. These membranes can withstand harsh operating conditions, including high temperatures (up to 800°C) and extreme pH environments. However, their widespread implementation is hindered by high manufacturing costs, brittleness, and challenges in achieving precise pore size control at the nanoscale.

Hybrid or mixed-matrix membranes (MMMs) have been developed to combine the advantages of both polymeric and inorganic materials. These typically incorporate nanomaterials such as metal-organic frameworks (MOFs), graphene oxide, carbon nanotubes, or metal oxide nanoparticles into polymer matrices. While showing promising performance improvements in lab settings, these materials face significant challenges in scaling up production and maintaining long-term stability under real operating conditions.

A critical technical challenge across all nanofiltration materials is the trade-off between permeability and selectivity. Membranes with higher water flux typically demonstrate lower rejection rates for contaminants, while highly selective membranes often suffer from low permeability, requiring higher operating pressures and energy consumption.

Membrane fouling remains perhaps the most persistent challenge in nanofiltration applications. Organic fouling, biofouling, scaling, and colloidal fouling significantly reduce membrane performance and lifespan. Current anti-fouling strategies include surface modification with hydrophilic polymers, zwitterionic materials, or antimicrobial agents, but these approaches often compromise other membrane properties or add significant cost.

Chlorine resistance presents another major challenge, particularly for polyamide-based membranes that degrade upon exposure to chlorine-based disinfectants. This necessitates additional pre-treatment steps to remove chlorine before nanofiltration, increasing system complexity and operational costs.

Environmental sustainability concerns are also emerging as significant challenges, including the high energy consumption of nanofiltration processes and the end-of-life disposal of membrane materials, many of which are not biodegradable or easily recyclable.

Polymeric membranes dominate the commercial nanofiltration market, with polyamide thin-film composite (TFC) membranes being the most widely utilized. These membranes typically consist of a thin polyamide selective layer (0.1-1 μm) on top of a porous support. Other common polymeric materials include polysulfone, polyethersulfone, and cellulose acetate. While these materials offer excellent separation performance and relatively low production costs, they face significant challenges related to chlorine sensitivity, fouling propensity, and limited thermal and chemical stability.

Inorganic membranes, primarily composed of ceramic materials such as alumina, zirconia, titania, and silica, represent an alternative with superior thermal and chemical stability. These membranes can withstand harsh operating conditions, including high temperatures (up to 800°C) and extreme pH environments. However, their widespread implementation is hindered by high manufacturing costs, brittleness, and challenges in achieving precise pore size control at the nanoscale.

Hybrid or mixed-matrix membranes (MMMs) have been developed to combine the advantages of both polymeric and inorganic materials. These typically incorporate nanomaterials such as metal-organic frameworks (MOFs), graphene oxide, carbon nanotubes, or metal oxide nanoparticles into polymer matrices. While showing promising performance improvements in lab settings, these materials face significant challenges in scaling up production and maintaining long-term stability under real operating conditions.

A critical technical challenge across all nanofiltration materials is the trade-off between permeability and selectivity. Membranes with higher water flux typically demonstrate lower rejection rates for contaminants, while highly selective membranes often suffer from low permeability, requiring higher operating pressures and energy consumption.

Membrane fouling remains perhaps the most persistent challenge in nanofiltration applications. Organic fouling, biofouling, scaling, and colloidal fouling significantly reduce membrane performance and lifespan. Current anti-fouling strategies include surface modification with hydrophilic polymers, zwitterionic materials, or antimicrobial agents, but these approaches often compromise other membrane properties or add significant cost.

Chlorine resistance presents another major challenge, particularly for polyamide-based membranes that degrade upon exposure to chlorine-based disinfectants. This necessitates additional pre-treatment steps to remove chlorine before nanofiltration, increasing system complexity and operational costs.

Environmental sustainability concerns are also emerging as significant challenges, including the high energy consumption of nanofiltration processes and the end-of-life disposal of membrane materials, many of which are not biodegradable or easily recyclable.

Comparative Analysis of Current Nanofiltration Materials

01 Nanofiltration membrane materials

Various materials are used in nanofiltration membranes to achieve high filtration efficiency. These materials include polymeric membranes, composite membranes, and modified membranes with specific functional groups. The selection of membrane materials significantly impacts the separation performance, with factors such as pore size, surface charge, and chemical stability being critical for effective filtration of specific contaminants.- Nanofiltration membrane materials: Various materials are used in nanofiltration membranes to enhance filtration efficiency. These include polymeric materials, composite structures, and modified surfaces that provide selective permeability while maintaining structural integrity. The membrane composition directly affects pore size, charge characteristics, and fouling resistance, which are critical factors in determining filtration performance for different applications.

- Carbon-based nanofiltration materials: Carbon-based materials such as graphene, carbon nanotubes, and activated carbon are increasingly used in nanofiltration applications. These materials offer exceptional mechanical strength, chemical stability, and controllable pore structures. Their high surface area and ability to be functionalized make them particularly effective for removing specific contaminants while maintaining high flow rates, significantly improving filtration efficiency.

- Membrane surface modification techniques: Surface modification of nanofiltration membranes can significantly enhance filtration efficiency. Techniques include chemical functionalization, plasma treatment, and coating with hydrophilic or antimicrobial agents. These modifications can reduce membrane fouling, improve selectivity, and extend operational lifetime by altering surface charge, hydrophilicity, and roughness properties, leading to more efficient separation processes.

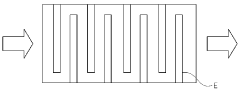

- Nanofiltration system design and optimization: The design and configuration of nanofiltration systems significantly impact filtration efficiency. Factors such as module design, flow patterns, pressure distribution, and membrane arrangement can be optimized to enhance performance. Advanced system designs incorporate features like turbulence promoters, improved hydrodynamics, and optimized operating parameters to maximize filtration efficiency while minimizing energy consumption.

- Performance evaluation and efficiency metrics: Various methods and metrics are used to evaluate nanofiltration efficiency. These include rejection rates for specific contaminants, flux measurements, pressure drop analysis, and long-term performance stability. Advanced characterization techniques help quantify membrane properties and correlate them with filtration performance, enabling the development of more efficient nanofiltration materials and systems for specific applications.

02 Carbon-based nanofiltration materials

Carbon-based materials such as carbon nanotubes, graphene oxide, and activated carbon are increasingly used in nanofiltration applications. These materials offer advantages including high surface area, excellent mechanical strength, and tunable surface properties. Carbon-based nanofiltration materials demonstrate superior filtration efficiency for various contaminants including heavy metals, organic pollutants, and microplastics.Expand Specific Solutions03 Ceramic and inorganic nanofiltration materials

Ceramic and inorganic materials provide thermal stability and chemical resistance for nanofiltration applications. These materials, including metal oxides, zeolites, and silica-based membranes, can withstand harsh operating conditions while maintaining high filtration efficiency. The controlled pore structure of ceramic nanofiltration materials allows for precise separation of molecules based on size and charge.Expand Specific Solutions04 Surface modification techniques for improved filtration efficiency

Surface modification of nanofiltration materials can significantly enhance filtration efficiency. Techniques include chemical functionalization, plasma treatment, and coating with functional polymers or nanoparticles. These modifications can alter surface charge, hydrophilicity, and anti-fouling properties, leading to improved separation performance and extended membrane lifetime in various applications.Expand Specific Solutions05 Nanofiltration system design for optimized efficiency

The overall design of nanofiltration systems plays a crucial role in achieving optimal filtration efficiency. Factors such as module configuration, flow patterns, pressure distribution, and pre-treatment processes significantly impact performance. Advanced system designs incorporate features like cross-flow filtration, backwashing capabilities, and optimized hydrodynamics to minimize fouling and maximize the effective utilization of nanofiltration materials.Expand Specific Solutions

Leading Companies in Nanofiltration Material Development

Wastewater nanofiltration technology is currently in a growth phase, with the market expected to expand significantly due to increasing water scarcity and stricter environmental regulations. The global nanofiltration membrane market is projected to reach several billion dollars by 2025, driven by industrial and municipal applications. Technical maturity varies across materials and applications, with academic institutions like Nanyang Technological University, California Institute of Technology, and National University of Singapore leading fundamental research, while companies such as LANXESS, Evonik Membrane Extraction Technology, and Ecolab are commercializing advanced membrane technologies. Research collaboration between universities (Yale, Harvard, KU Leuven) and industry partners is accelerating innovation in membrane materials, particularly focusing on fouling resistance, selectivity, and energy efficiency for sustainable wastewater treatment solutions.

Nanyang Technological University

Technical Solution: Nanyang Technological University (NTU) has developed advanced nanocomposite membranes for wastewater nanofiltration through their Singapore Membrane Technology Centre. Their innovative approach incorporates metal-organic frameworks (MOFs) into thin-film nanocomposite membranes, creating precisely controlled nanochannels that enhance both selectivity and permeability. These membranes feature a hierarchical structure with a thin selective layer (approximately 100 nm) containing UiO-66-NH₂ MOF nanoparticles that provide additional adsorption sites for organic contaminants and heavy metals. NTU researchers have optimized the interfacial polymerization process to achieve uniform MOF distribution, resulting in membranes with water permeability exceeding 15 L/m²h·bar while maintaining >95% rejection of divalent ions. Their membranes also incorporate surface-grafted zwitterionic polymers that create a hydration layer, significantly reducing fouling propensity in complex wastewater streams containing organic matter and biological contaminants.

Strengths: Enhanced removal of emerging contaminants through combined filtration and adsorption mechanisms; superior antifouling properties; maintained performance under varying feed conditions; excellent heavy metal removal. Weaknesses: Higher production complexity and cost compared to conventional membranes; potential for MOF leaching during extended operation; requires specialized expertise for manufacture and implementation.

National University of Singapore

Technical Solution: The National University of Singapore (NUS) has developed innovative biomimetic nanofiltration membranes for wastewater treatment through their Environmental Research Institute. Their approach utilizes aquaporin-incorporated biomimetic membranes that mimic natural water transport mechanisms in cell membranes. These membranes feature a vesicle-based design where aquaporin proteins are embedded in a polymer matrix, creating water-selective channels with exceptional permeability (>250 L/m²h·bar) while maintaining high rejection rates for contaminants. NUS researchers have further enhanced membrane performance through the incorporation of zwitterionic materials that significantly reduce biofouling by creating a hydration layer that repels bacterial adhesion. Their latest generation membranes also incorporate graphene oxide nanosheets that provide mechanical reinforcement and additional contaminant adsorption sites, improving both durability and filtration efficiency for complex wastewater streams.

Strengths: Exceptionally high water permeability (2-3x higher than conventional membranes); superior biofouling resistance; excellent removal of emerging contaminants including pharmaceuticals and microplastics; lower energy consumption. Weaknesses: Complex manufacturing process increases production costs; limited large-scale production capability; relatively new technology with limited long-term operational data.

Key Patents and Research in Nanofiltration Membrane Materials

A process and system for treating wastewater to reduce nano materials in wastewater

PatentInactiveKR1020150083700A

Innovation

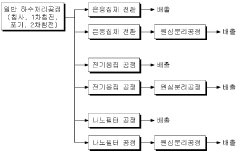

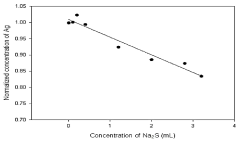

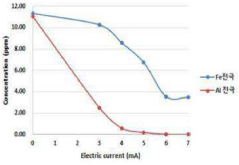

- A sewage treatment process incorporating a primary precipitation process, aeration process, secondary sedimentation process, and a nanomaterial reduction process, including methods such as silver agglomerate (Ag2S) conversion, electrocoagulation, nanofiltration, and centrifugation, to effectively reduce nanomaterials, particularly silver nanoparticles.

Environmental Impact and Sustainability Assessment

Nanofiltration technology for wastewater treatment represents a significant advancement in environmental protection efforts, with its environmental impact and sustainability profile deserving thorough assessment. The implementation of nanofiltration systems demonstrates considerable environmental benefits compared to conventional treatment methods, primarily through reduced chemical usage and energy consumption. Studies indicate that nanofiltration can decrease chemical requirements by 30-50% while achieving comparable or superior filtration results, significantly reducing the environmental footprint associated with chemical production and disposal.

Energy efficiency represents another critical environmental advantage of nanofiltration systems. Operating at lower pressures than reverse osmosis while maintaining high rejection rates for multivalent ions and organic compounds, nanofiltration typically requires 15-30% less energy than comparable treatment technologies. This translates to reduced greenhouse gas emissions and overall carbon footprint throughout the system's operational lifecycle.

The environmental impact assessment of various nanofiltration membrane materials reveals significant differences in sustainability profiles. Polymeric membranes, while cost-effective and widely deployed, present end-of-life disposal challenges with potential microplastic generation. In contrast, ceramic and biomimetic membranes offer extended operational lifespans—often 3-5 times longer than conventional polymeric alternatives—substantially reducing waste generation and replacement frequency.

Life cycle assessment (LCA) studies of nanofiltration systems demonstrate favorable environmental performance metrics when considering the entire technology lifecycle. The environmental payback period for implementing nanofiltration typically ranges from 1.5 to 3 years, depending on application scale and specific wastewater characteristics. The reduced sludge production—approximately 20-40% less than conventional treatments—further enhances environmental benefits through decreased landfill requirements and associated transportation emissions.

Water resource conservation represents perhaps the most significant sustainability contribution of nanofiltration technology. By enabling effective water reclamation and reuse, nanofiltration systems can reduce freshwater withdrawal requirements by 40-60% in industrial applications. This circular approach to water management alleviates pressure on natural water resources while simultaneously reducing wastewater discharge volumes and associated environmental impacts on receiving water bodies.

The sustainability assessment must also consider membrane manufacturing processes and material sourcing. Recent innovations in green chemistry approaches have yielded promising developments in bio-based nanofiltration materials with reduced environmental impact during production. These advanced materials demonstrate comparable performance characteristics while reducing dependence on petroleum-derived polymers and energy-intensive manufacturing processes, potentially decreasing the embodied carbon footprint by 25-35% compared to conventional membrane materials.

Energy efficiency represents another critical environmental advantage of nanofiltration systems. Operating at lower pressures than reverse osmosis while maintaining high rejection rates for multivalent ions and organic compounds, nanofiltration typically requires 15-30% less energy than comparable treatment technologies. This translates to reduced greenhouse gas emissions and overall carbon footprint throughout the system's operational lifecycle.

The environmental impact assessment of various nanofiltration membrane materials reveals significant differences in sustainability profiles. Polymeric membranes, while cost-effective and widely deployed, present end-of-life disposal challenges with potential microplastic generation. In contrast, ceramic and biomimetic membranes offer extended operational lifespans—often 3-5 times longer than conventional polymeric alternatives—substantially reducing waste generation and replacement frequency.

Life cycle assessment (LCA) studies of nanofiltration systems demonstrate favorable environmental performance metrics when considering the entire technology lifecycle. The environmental payback period for implementing nanofiltration typically ranges from 1.5 to 3 years, depending on application scale and specific wastewater characteristics. The reduced sludge production—approximately 20-40% less than conventional treatments—further enhances environmental benefits through decreased landfill requirements and associated transportation emissions.

Water resource conservation represents perhaps the most significant sustainability contribution of nanofiltration technology. By enabling effective water reclamation and reuse, nanofiltration systems can reduce freshwater withdrawal requirements by 40-60% in industrial applications. This circular approach to water management alleviates pressure on natural water resources while simultaneously reducing wastewater discharge volumes and associated environmental impacts on receiving water bodies.

The sustainability assessment must also consider membrane manufacturing processes and material sourcing. Recent innovations in green chemistry approaches have yielded promising developments in bio-based nanofiltration materials with reduced environmental impact during production. These advanced materials demonstrate comparable performance characteristics while reducing dependence on petroleum-derived polymers and energy-intensive manufacturing processes, potentially decreasing the embodied carbon footprint by 25-35% compared to conventional membrane materials.

Regulatory Framework for Water Treatment Technologies

The regulatory landscape for wastewater treatment technologies, particularly nanofiltration systems, operates within a complex framework of international, national, and local standards. The European Union's Water Framework Directive (2000/60/EC) establishes comprehensive guidelines for water quality assessment and treatment requirements, with specific provisions for membrane filtration technologies in the Urban Waste Water Treatment Directive (91/271/EEC). These regulations mandate removal efficiencies for various contaminants and set performance benchmarks for nanofiltration materials.

In the United States, the Environmental Protection Agency (EPA) regulates water treatment technologies through the Clean Water Act and Safe Drinking Water Act. The National Pollutant Discharge Elimination System (NPDES) permit program specifically addresses nanofiltration applications in industrial wastewater treatment, requiring regular performance validation and compliance monitoring. Material standards for nanofiltration membranes fall under NSF/ANSI 61 certification, which evaluates health effects of water treatment components.

Asian regulatory frameworks vary significantly by country, with Japan's Ministry of Health, Labour and Welfare implementing some of the most stringent standards for membrane filtration materials through their Water Supply Act. China's recent Five-Year Plan has introduced enhanced regulations for industrial wastewater treatment technologies, specifically addressing nanofiltration material requirements and performance metrics.

International standards organizations play a crucial role in harmonizing regulatory approaches. ISO 16075 provides guidelines for treated wastewater use in irrigation projects, while ISO 20468 establishes performance evaluation guidelines for water reuse systems utilizing membrane technologies. The World Health Organization's Guidelines for Drinking-water Quality influence regulatory frameworks globally, particularly in developing regions implementing advanced filtration technologies.

Regulatory compliance for nanofiltration materials involves rigorous testing protocols. ASTM D6908 standardizes procedures for integrity testing of membrane filtration systems, while ASTM F838 addresses bacterial retention capabilities of membrane materials. These standards directly impact material selection and development priorities in comparative nanofiltration studies.

Emerging regulatory trends indicate increasing focus on micropollutants and pharmaceutical residues removal, with the EU Watch List mechanism under Directive 2013/39/EU driving new performance requirements for nanofiltration materials. Additionally, circular economy regulations are beginning to address end-of-life management for nanofiltration membranes, with the EU's Circular Economy Action Plan potentially establishing extended producer responsibility frameworks for membrane manufacturers.

In the United States, the Environmental Protection Agency (EPA) regulates water treatment technologies through the Clean Water Act and Safe Drinking Water Act. The National Pollutant Discharge Elimination System (NPDES) permit program specifically addresses nanofiltration applications in industrial wastewater treatment, requiring regular performance validation and compliance monitoring. Material standards for nanofiltration membranes fall under NSF/ANSI 61 certification, which evaluates health effects of water treatment components.

Asian regulatory frameworks vary significantly by country, with Japan's Ministry of Health, Labour and Welfare implementing some of the most stringent standards for membrane filtration materials through their Water Supply Act. China's recent Five-Year Plan has introduced enhanced regulations for industrial wastewater treatment technologies, specifically addressing nanofiltration material requirements and performance metrics.

International standards organizations play a crucial role in harmonizing regulatory approaches. ISO 16075 provides guidelines for treated wastewater use in irrigation projects, while ISO 20468 establishes performance evaluation guidelines for water reuse systems utilizing membrane technologies. The World Health Organization's Guidelines for Drinking-water Quality influence regulatory frameworks globally, particularly in developing regions implementing advanced filtration technologies.

Regulatory compliance for nanofiltration materials involves rigorous testing protocols. ASTM D6908 standardizes procedures for integrity testing of membrane filtration systems, while ASTM F838 addresses bacterial retention capabilities of membrane materials. These standards directly impact material selection and development priorities in comparative nanofiltration studies.

Emerging regulatory trends indicate increasing focus on micropollutants and pharmaceutical residues removal, with the EU Watch List mechanism under Directive 2013/39/EU driving new performance requirements for nanofiltration materials. Additionally, circular economy regulations are beginning to address end-of-life management for nanofiltration membranes, with the EU's Circular Economy Action Plan potentially establishing extended producer responsibility frameworks for membrane manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!