The Technical Mechanisms of Wastewater Nanofiltration Processes

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Background and Objectives

Nanofiltration technology emerged in the late 1980s as an intermediate membrane filtration process between reverse osmosis and ultrafiltration. This technology has evolved significantly over the past three decades, driven by increasing global water scarcity and stricter environmental regulations regarding wastewater discharge. Initially developed as a water softening technique, nanofiltration has expanded its application scope to include wastewater treatment, particularly for industrial effluents containing complex pollutants.

The evolution of nanofiltration membranes represents a critical advancement in this field. Early membranes suffered from limited selectivity and durability, whereas contemporary nanofiltration membranes feature sophisticated thin-film composite structures with precisely engineered pore sizes typically ranging from 1 to 10 nanometers. This evolution has enabled more efficient separation of multivalent ions, organic molecules, and certain monovalent ions from wastewater streams.

Recent technological trends indicate a shift toward developing anti-fouling membranes through surface modification techniques, including grafting of hydrophilic polymers and incorporation of nanoparticles. These innovations address one of the most persistent challenges in nanofiltration: membrane fouling during wastewater treatment. Additionally, there is growing interest in developing chlorine-resistant membranes to enhance operational longevity in industrial applications.

The integration of nanofiltration with other treatment technologies represents another significant trend. Hybrid systems combining nanofiltration with biological treatment, advanced oxidation processes, or adsorption technologies have demonstrated superior performance in treating complex wastewater matrices. These integrated approaches leverage the strengths of multiple technologies while mitigating their individual limitations.

The primary technical objectives for nanofiltration in wastewater treatment include enhancing membrane selectivity for specific contaminants, improving energy efficiency to reduce operational costs, and extending membrane lifespan under challenging wastewater conditions. Researchers are particularly focused on developing membranes capable of selective removal of emerging contaminants such as pharmaceuticals, personal care products, and microplastics from wastewater streams.

Another critical objective involves optimizing operational parameters to minimize concentration polarization and scaling, which significantly impact system performance. This includes developing advanced computational fluid dynamics models to predict flow patterns and concentration gradients within membrane modules, enabling more efficient system design and operation.

Looking forward, the field aims to develop sustainable nanofiltration technologies with reduced environmental footprints. This includes creating bio-based membrane materials, implementing energy recovery systems, and designing membranes that require minimal chemical cleaning. These advancements align with global sustainability goals while addressing the growing need for efficient wastewater treatment solutions across various industries.

The evolution of nanofiltration membranes represents a critical advancement in this field. Early membranes suffered from limited selectivity and durability, whereas contemporary nanofiltration membranes feature sophisticated thin-film composite structures with precisely engineered pore sizes typically ranging from 1 to 10 nanometers. This evolution has enabled more efficient separation of multivalent ions, organic molecules, and certain monovalent ions from wastewater streams.

Recent technological trends indicate a shift toward developing anti-fouling membranes through surface modification techniques, including grafting of hydrophilic polymers and incorporation of nanoparticles. These innovations address one of the most persistent challenges in nanofiltration: membrane fouling during wastewater treatment. Additionally, there is growing interest in developing chlorine-resistant membranes to enhance operational longevity in industrial applications.

The integration of nanofiltration with other treatment technologies represents another significant trend. Hybrid systems combining nanofiltration with biological treatment, advanced oxidation processes, or adsorption technologies have demonstrated superior performance in treating complex wastewater matrices. These integrated approaches leverage the strengths of multiple technologies while mitigating their individual limitations.

The primary technical objectives for nanofiltration in wastewater treatment include enhancing membrane selectivity for specific contaminants, improving energy efficiency to reduce operational costs, and extending membrane lifespan under challenging wastewater conditions. Researchers are particularly focused on developing membranes capable of selective removal of emerging contaminants such as pharmaceuticals, personal care products, and microplastics from wastewater streams.

Another critical objective involves optimizing operational parameters to minimize concentration polarization and scaling, which significantly impact system performance. This includes developing advanced computational fluid dynamics models to predict flow patterns and concentration gradients within membrane modules, enabling more efficient system design and operation.

Looking forward, the field aims to develop sustainable nanofiltration technologies with reduced environmental footprints. This includes creating bio-based membrane materials, implementing energy recovery systems, and designing membranes that require minimal chemical cleaning. These advancements align with global sustainability goals while addressing the growing need for efficient wastewater treatment solutions across various industries.

Wastewater Treatment Market Demand Analysis

The global wastewater treatment market is experiencing significant growth, driven by increasing water scarcity, stringent environmental regulations, and growing industrialization. The market was valued at approximately $250 billion in 2022 and is projected to reach $376 billion by 2030, growing at a CAGR of 5.8% during the forecast period.

Nanofiltration technology specifically represents one of the fastest-growing segments within this market, with an estimated growth rate of 7.2% annually. This accelerated adoption is primarily attributed to nanofiltration's superior performance in removing specific contaminants while maintaining lower energy consumption compared to reverse osmosis systems.

Industrial sectors contribute significantly to market demand, with chemical manufacturing, pharmaceuticals, and food processing industries collectively accounting for over 40% of the nanofiltration applications. These industries generate complex wastewater streams containing micropollutants, heavy metals, and organic compounds that conventional treatment methods struggle to remove effectively.

Municipal wastewater treatment represents another substantial market segment, particularly in developed regions where upgrading aging infrastructure has become a priority. In North America and Europe, approximately 65% of wastewater treatment facilities are considering advanced filtration technologies, including nanofiltration, for their next upgrade cycle.

Emerging economies, particularly in Asia-Pacific and Latin America, are showing the highest growth potential for nanofiltration technologies. China and India are investing heavily in wastewater treatment infrastructure, with China allocating $82 billion for water pollution control under its latest five-year plan, a significant portion directed toward advanced treatment technologies.

Water reuse applications are creating a specialized market niche for nanofiltration processes. Industries seeking to implement closed-loop water systems to reduce freshwater consumption are increasingly turning to nanofiltration as a cost-effective solution. This trend is particularly evident in water-stressed regions where the economic value of reclaimed water continues to rise.

The COVID-19 pandemic has further accelerated market demand, as heightened awareness of public health concerns has led to increased focus on water quality and safety. This has translated into greater investment in advanced water treatment technologies, with nanofiltration benefiting from its ability to remove viruses and pharmaceutical residues from wastewater.

Consumer awareness and regulatory pressures regarding emerging contaminants such as PFAS (per- and polyfluoroalkyl substances) and microplastics are creating new market opportunities for nanofiltration technologies, which have demonstrated effectiveness in removing these challenging pollutants.

Nanofiltration technology specifically represents one of the fastest-growing segments within this market, with an estimated growth rate of 7.2% annually. This accelerated adoption is primarily attributed to nanofiltration's superior performance in removing specific contaminants while maintaining lower energy consumption compared to reverse osmosis systems.

Industrial sectors contribute significantly to market demand, with chemical manufacturing, pharmaceuticals, and food processing industries collectively accounting for over 40% of the nanofiltration applications. These industries generate complex wastewater streams containing micropollutants, heavy metals, and organic compounds that conventional treatment methods struggle to remove effectively.

Municipal wastewater treatment represents another substantial market segment, particularly in developed regions where upgrading aging infrastructure has become a priority. In North America and Europe, approximately 65% of wastewater treatment facilities are considering advanced filtration technologies, including nanofiltration, for their next upgrade cycle.

Emerging economies, particularly in Asia-Pacific and Latin America, are showing the highest growth potential for nanofiltration technologies. China and India are investing heavily in wastewater treatment infrastructure, with China allocating $82 billion for water pollution control under its latest five-year plan, a significant portion directed toward advanced treatment technologies.

Water reuse applications are creating a specialized market niche for nanofiltration processes. Industries seeking to implement closed-loop water systems to reduce freshwater consumption are increasingly turning to nanofiltration as a cost-effective solution. This trend is particularly evident in water-stressed regions where the economic value of reclaimed water continues to rise.

The COVID-19 pandemic has further accelerated market demand, as heightened awareness of public health concerns has led to increased focus on water quality and safety. This has translated into greater investment in advanced water treatment technologies, with nanofiltration benefiting from its ability to remove viruses and pharmaceutical residues from wastewater.

Consumer awareness and regulatory pressures regarding emerging contaminants such as PFAS (per- and polyfluoroalkyl substances) and microplastics are creating new market opportunities for nanofiltration technologies, which have demonstrated effectiveness in removing these challenging pollutants.

Current Nanofiltration Challenges and Global Status

Nanofiltration technology has emerged as a critical solution for wastewater treatment, positioned between ultrafiltration and reverse osmosis in terms of selectivity and operating pressure. Despite its growing adoption, the field faces significant technical challenges that impede widespread implementation. Membrane fouling remains the most persistent issue, characterized by the accumulation of rejected solutes, colloids, and biological materials on membrane surfaces, leading to reduced flux and increased energy consumption. This phenomenon is particularly problematic in industrial wastewater applications where complex chemical compositions accelerate fouling rates.

Concentration polarization presents another substantial challenge, occurring when rejected solutes accumulate near the membrane surface, creating a concentration gradient that reduces separation efficiency and increases osmotic pressure. This effect is especially pronounced in high-recovery operations and when treating wastewaters with high dissolved solids content.

Membrane stability under varying pH conditions and chemical exposure constitutes a significant limitation. Many nanofiltration membranes exhibit performance degradation when exposed to extreme pH environments or oxidizing agents commonly used in wastewater treatment processes. This chemical vulnerability necessitates careful pretreatment and operational controls, adding complexity to system design and maintenance protocols.

Energy consumption remains a critical concern, with nanofiltration typically requiring 5-10 bar operating pressures, significantly higher than conventional filtration methods. While lower than reverse osmosis, these energy requirements still present economic challenges for large-scale implementations, particularly in regions with high energy costs or limited infrastructure.

Globally, nanofiltration technology adoption shows distinct regional patterns. North America and Western Europe lead in research and implementation, with established regulatory frameworks driving adoption in municipal and industrial sectors. The United States, Germany, and the Netherlands host the majority of large-scale installations, focusing primarily on drinking water treatment and industrial process water recovery.

Asia-Pacific represents the fastest-growing market, with China and India making substantial investments in nanofiltration research and manufacturing capacity. These regions are increasingly deploying nanofiltration for industrial wastewater treatment, particularly in textile, pharmaceutical, and electronics manufacturing sectors where water reuse offers significant economic benefits.

Middle Eastern countries have embraced nanofiltration as a complementary technology to their established desalination infrastructure, using it for specific applications where its lower energy consumption provides advantages over traditional reverse osmosis systems. Israel and Saudi Arabia have emerged as regional innovation hubs, developing specialized nanofiltration membranes optimized for their unique water quality challenges.

Developing regions in Africa and parts of Asia face implementation barriers including limited technical expertise, inadequate infrastructure, and financial constraints, despite potentially benefiting significantly from the technology's ability to treat contaminated water sources.

Concentration polarization presents another substantial challenge, occurring when rejected solutes accumulate near the membrane surface, creating a concentration gradient that reduces separation efficiency and increases osmotic pressure. This effect is especially pronounced in high-recovery operations and when treating wastewaters with high dissolved solids content.

Membrane stability under varying pH conditions and chemical exposure constitutes a significant limitation. Many nanofiltration membranes exhibit performance degradation when exposed to extreme pH environments or oxidizing agents commonly used in wastewater treatment processes. This chemical vulnerability necessitates careful pretreatment and operational controls, adding complexity to system design and maintenance protocols.

Energy consumption remains a critical concern, with nanofiltration typically requiring 5-10 bar operating pressures, significantly higher than conventional filtration methods. While lower than reverse osmosis, these energy requirements still present economic challenges for large-scale implementations, particularly in regions with high energy costs or limited infrastructure.

Globally, nanofiltration technology adoption shows distinct regional patterns. North America and Western Europe lead in research and implementation, with established regulatory frameworks driving adoption in municipal and industrial sectors. The United States, Germany, and the Netherlands host the majority of large-scale installations, focusing primarily on drinking water treatment and industrial process water recovery.

Asia-Pacific represents the fastest-growing market, with China and India making substantial investments in nanofiltration research and manufacturing capacity. These regions are increasingly deploying nanofiltration for industrial wastewater treatment, particularly in textile, pharmaceutical, and electronics manufacturing sectors where water reuse offers significant economic benefits.

Middle Eastern countries have embraced nanofiltration as a complementary technology to their established desalination infrastructure, using it for specific applications where its lower energy consumption provides advantages over traditional reverse osmosis systems. Israel and Saudi Arabia have emerged as regional innovation hubs, developing specialized nanofiltration membranes optimized for their unique water quality challenges.

Developing regions in Africa and parts of Asia face implementation barriers including limited technical expertise, inadequate infrastructure, and financial constraints, despite potentially benefiting significantly from the technology's ability to treat contaminated water sources.

Current Nanofiltration Membrane Solutions

01 Size exclusion and charge-based separation mechanisms

Nanofiltration operates through size exclusion where particles larger than the membrane pores are physically blocked, and charge-based separation where charged membranes repel similarly charged ions while attracting oppositely charged ones. This dual mechanism allows nanofiltration to effectively separate multivalent ions from monovalent ions and remove organic compounds based on their molecular size and charge characteristics.- Size exclusion and charge-based separation: Nanofiltration mechanisms rely on size exclusion and charge-based separation principles. The nanofiltration membranes have pore sizes typically ranging from 1-10 nanometers, allowing them to reject larger molecules while permitting smaller ones to pass through. Additionally, the surface charge of the membrane interacts with charged particles in the solution, enhancing separation efficiency through electrostatic interactions. This dual mechanism makes nanofiltration particularly effective for removing multivalent ions, organic compounds, and certain contaminants from water and other solutions.

- Membrane structure and material composition: The filtration mechanism in nanofiltration is significantly influenced by the membrane structure and material composition. Nanofiltration membranes are typically composed of polymeric materials, ceramic materials, or composite structures that determine their selectivity and permeability. The membrane's surface properties, including hydrophilicity/hydrophobicity, roughness, and functional groups, affect the interaction with solutes and consequently the filtration performance. Advanced membrane materials incorporate specific functional groups to enhance selectivity for target compounds or improve fouling resistance.

- Concentration polarization and fouling mechanisms: Nanofiltration performance is affected by concentration polarization and membrane fouling mechanisms. Concentration polarization occurs when rejected solutes accumulate near the membrane surface, creating a concentration gradient that reduces filtration efficiency. Fouling involves the deposition of particles, colloids, organic matter, or scale on the membrane surface or within pores, further decreasing permeate flux and separation efficiency. Understanding these mechanisms is crucial for designing effective cleaning protocols and developing fouling-resistant membrane materials to maintain long-term filtration performance.

- Pressure-driven and osmotic pressure effects: Nanofiltration operates primarily as a pressure-driven process where transmembrane pressure serves as the driving force for separation. The applied pressure overcomes osmotic pressure differences across the membrane, enabling the transport of solvent molecules while rejecting solutes. The relationship between operating pressure, osmotic pressure, and separation efficiency is critical for optimizing nanofiltration performance. Higher pressures generally increase permeate flux but may also intensify concentration polarization and fouling issues, requiring careful balance in system design and operation.

- Hybrid and enhanced nanofiltration systems: Advanced nanofiltration mechanisms incorporate hybrid approaches and enhancement techniques to improve filtration efficiency. These include combining nanofiltration with other separation processes such as ultrafiltration, reverse osmosis, or adsorption in integrated systems. Enhanced nanofiltration may utilize electric fields (electro-nanofiltration), temperature gradients (thermo-nanofiltration), or catalytic materials to improve separation performance. Additionally, pre-treatment processes and membrane surface modifications can be employed to address specific separation challenges and extend membrane lifespan while maintaining high filtration efficiency.

02 Membrane surface modification for enhanced selectivity

Surface modification of nanofiltration membranes can significantly enhance their selectivity and performance. Techniques include coating with functional polymers, grafting of charged groups, and incorporation of nanomaterials. These modifications alter the membrane surface properties, improving rejection of specific contaminants, reducing fouling, and increasing membrane lifespan while maintaining high flux rates.Expand Specific Solutions03 Concentration polarization and fouling control

Concentration polarization and membrane fouling are critical challenges in nanofiltration processes. These phenomena occur when rejected solutes accumulate near the membrane surface, forming a boundary layer that reduces filtration efficiency. Advanced designs incorporate flow patterns, turbulence promoters, and cleaning mechanisms to mitigate these effects, maintaining consistent filtration performance over extended operation periods.Expand Specific Solutions04 Hybrid nanofiltration systems

Hybrid nanofiltration systems combine nanofiltration with other separation technologies such as ultrafiltration, reverse osmosis, or adsorption processes. These integrated approaches leverage the strengths of each technology to overcome individual limitations, resulting in more efficient removal of diverse contaminants, reduced energy consumption, and improved overall system performance for complex water treatment applications.Expand Specific Solutions05 Pressure-driven transport and solution-diffusion mechanisms

Nanofiltration relies on pressure-driven transport where hydraulic pressure forces water through semi-permeable membranes while retaining solutes. The solution-diffusion mechanism also plays a role, where components dissolve into the membrane material and diffuse through it at different rates based on their solubility and diffusivity. The combination of these mechanisms enables nanofiltration to achieve selective separation of dissolved substances.Expand Specific Solutions

Key Industry Players in Nanofiltration Membrane Technology

Wastewater nanofiltration technology is currently in a growth phase, with the market expanding rapidly due to increasing water scarcity and stricter environmental regulations. The global nanofiltration market is projected to reach significant scale as industrial applications diversify. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Academic institutions like Tongji University and Nanjing University are advancing fundamental research, while industrial players show distinct focus areas: Zhejiang Jinmo and Hangzhou Lanran lead in membrane technology development; SINOPEC and Veolia Water Technologies excel in industrial applications; and Alfa Laval and Siemens demonstrate strength in system integration and automation. The ecosystem reflects a balance between established corporations and specialized technology providers driving innovation.

Ecolab GmbH & Co. oHG

Technical Solution: Ecolab's nanofiltration technology centers around their NALCO Water membrane systems featuring proprietary thin-film nanocomposite membranes with engineered surface properties. Their membranes incorporate hydrophilic nanoparticles within the selective layer, creating controlled water channels while maintaining excellent rejection characteristics. The system operates using their patented PermaCare™ process control, which dynamically adjusts crossflow velocity, recovery rate, and cleaning cycles based on real-time performance metrics. Ecolab's nanofiltration membranes achieve flux rates of 20-35 L/m²/h while operating at moderate pressures (6-15 bar)[9]. Their integrated pretreatment system utilizes proprietary antiscalant chemistry specifically formulated for nanofiltration applications, extending membrane life by preventing inorganic scaling. The company's membrane modules feature optimized feed channel spacers that create controlled turbulence patterns, reducing concentration polarization while minimizing pressure drop across the system. Their automated CIP (Clean-In-Place) system utilizes specialized cleaning formulations and sequences tailored to specific foulant profiles[10].

Strengths: Comprehensive integration of membrane technology with specialized chemical programs; excellent scaling resistance through proprietary antiscalants; advanced process control optimizes performance and reduces operational costs. Weaknesses: Reliance on proprietary chemicals increases operational dependency; moderate flux rates compared to newer technologies; requires regular technical service support for optimal performance.

Siemens AG

Technical Solution: Siemens' nanofiltration technology utilizes their proprietary MemPulse™ membrane system featuring thin-film composite membranes with precisely engineered surface chemistry. Their membranes incorporate negatively charged functional groups that enhance rejection of multivalent ions while allowing controlled passage of monovalent ions. The system operates using a unique low-pressure (3-10 bar) pulsed-flow regime that creates turbulence at the membrane surface, significantly reducing concentration polarization and fouling tendencies[5]. Their integrated MemGuard™ pretreatment system combines multimedia filtration with advanced coagulation processes tailored to specific feed water characteristics. Siemens' nanofiltration modules achieve flux rates of 25-40 L/m²/h with rejection rates of 95-99% for divalent ions and organic compounds above 200 Da. The system incorporates real-time membrane integrity monitoring using pressure decay testing and automated performance optimization algorithms that adjust operating parameters based on feed water quality fluctuations[6].

Strengths: Lower energy consumption due to pulsed-flow operation; excellent removal of hardness and organic compounds; advanced automation reduces operator intervention requirements. Weaknesses: Complex control systems require specialized maintenance; higher initial capital cost compared to conventional filtration; membrane replacement requires specialized technical support.

Core Nanofiltration Mechanisms and Patents

Process for treatment of biological wastewaters

PatentInactiveCA3028760A1

Innovation

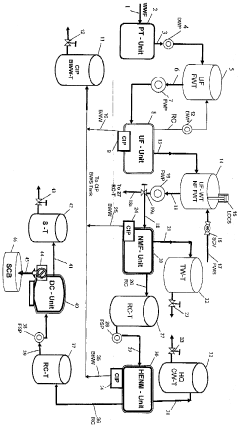

- A multi-stage process incorporating Pretreatment, Ultra Filtration, High Efficient Nano Membrane, and Disc Centrifuge Technologies, with a Liquie Consistency Control System, to handle up to 20% concentration wastewaters, producing clean water for reuse and separating solids for disposal, optimizing water quality and reducing membrane fouling.

Method for the processing of water by nanofiltration, comprises directly subjecting interior area of polymers or ceramic nanofiltration hollow fibers from raw water in a nanofiltration unit

PatentInactiveDE102008037118A1

Innovation

- A novel nanofiltration unit design utilizing hollow fibers with an inner diameter of 0.5 to 5 mm, combined with controlled stream management, allows for direct filtration of impurities and dissolved organic hydrocarbons without pre-cleaning, using forward and backflash techniques.

Environmental Regulations and Compliance Standards

Nanofiltration processes for wastewater treatment operate within a complex regulatory framework that varies significantly across regions and jurisdictions. The United States Environmental Protection Agency (EPA) establishes comprehensive guidelines under the Clean Water Act, specifically focusing on effluent limitations and water quality standards that directly impact nanofiltration implementation. These regulations typically specify maximum contaminant levels for various pollutants, including heavy metals, organic compounds, and emerging contaminants that nanofiltration systems are designed to remove.

In the European Union, the Water Framework Directive provides an overarching regulatory structure, complemented by the Urban Waste Water Treatment Directive which establishes specific treatment requirements. European standards generally adopt a more precautionary approach, often implementing stricter limits for certain contaminants compared to other regions. This regulatory environment has accelerated the adoption of advanced nanofiltration technologies in municipal and industrial applications throughout Europe.

Asian countries demonstrate varying regulatory maturity, with Japan and Singapore implementing some of the world's most stringent water quality standards, particularly for water reuse applications where nanofiltration plays a critical role. China has recently strengthened its environmental regulations through the Water Pollution Prevention and Control Law, creating significant market opportunities for nanofiltration technology deployment in industrial sectors.

Compliance with these regulations requires sophisticated monitoring protocols. Real-time monitoring systems are increasingly mandated for nanofiltration installations, particularly for critical parameters such as turbidity, conductivity, and specific contaminant concentrations. The regulatory trend toward continuous monitoring has driven innovation in sensor technologies that integrate with nanofiltration systems.

Industry-specific regulations present additional compliance considerations. Pharmaceutical manufacturing facilities face particularly stringent requirements regarding active pharmaceutical ingredients in wastewater, while food and beverage producers must address organic loading and nutrient content. These sector-specific regulations often necessitate customized nanofiltration solutions with enhanced selectivity for targeted compounds.

The regulatory landscape continues to evolve in response to emerging contaminants of concern. Per- and polyfluoroalkyl substances (PFAS) regulations are developing rapidly across jurisdictions, with nanofiltration increasingly recognized as an effective treatment technology. Similarly, microplastics and endocrine-disrupting compounds are subject to growing regulatory attention, potentially expanding nanofiltration applications as compliance solutions.

International standards organizations, particularly ISO and ASTM, have developed testing protocols and performance standards specific to membrane filtration technologies. These standards provide critical benchmarks for nanofiltration system certification and validation, facilitating regulatory compliance across multiple jurisdictions while establishing minimum performance requirements for manufacturers and system integrators.

In the European Union, the Water Framework Directive provides an overarching regulatory structure, complemented by the Urban Waste Water Treatment Directive which establishes specific treatment requirements. European standards generally adopt a more precautionary approach, often implementing stricter limits for certain contaminants compared to other regions. This regulatory environment has accelerated the adoption of advanced nanofiltration technologies in municipal and industrial applications throughout Europe.

Asian countries demonstrate varying regulatory maturity, with Japan and Singapore implementing some of the world's most stringent water quality standards, particularly for water reuse applications where nanofiltration plays a critical role. China has recently strengthened its environmental regulations through the Water Pollution Prevention and Control Law, creating significant market opportunities for nanofiltration technology deployment in industrial sectors.

Compliance with these regulations requires sophisticated monitoring protocols. Real-time monitoring systems are increasingly mandated for nanofiltration installations, particularly for critical parameters such as turbidity, conductivity, and specific contaminant concentrations. The regulatory trend toward continuous monitoring has driven innovation in sensor technologies that integrate with nanofiltration systems.

Industry-specific regulations present additional compliance considerations. Pharmaceutical manufacturing facilities face particularly stringent requirements regarding active pharmaceutical ingredients in wastewater, while food and beverage producers must address organic loading and nutrient content. These sector-specific regulations often necessitate customized nanofiltration solutions with enhanced selectivity for targeted compounds.

The regulatory landscape continues to evolve in response to emerging contaminants of concern. Per- and polyfluoroalkyl substances (PFAS) regulations are developing rapidly across jurisdictions, with nanofiltration increasingly recognized as an effective treatment technology. Similarly, microplastics and endocrine-disrupting compounds are subject to growing regulatory attention, potentially expanding nanofiltration applications as compliance solutions.

International standards organizations, particularly ISO and ASTM, have developed testing protocols and performance standards specific to membrane filtration technologies. These standards provide critical benchmarks for nanofiltration system certification and validation, facilitating regulatory compliance across multiple jurisdictions while establishing minimum performance requirements for manufacturers and system integrators.

Energy Efficiency and Operational Cost Analysis

Energy efficiency represents a critical factor in the economic viability and environmental sustainability of wastewater nanofiltration processes. Current nanofiltration systems typically consume between 1.0-2.5 kWh per cubic meter of treated water, positioning them as more energy-efficient than reverse osmosis but less so than conventional filtration methods. This energy consumption primarily stems from the pumping requirements needed to overcome membrane resistance and maintain adequate cross-flow velocities.

Operational cost analysis reveals that energy expenses constitute approximately 30-40% of total operational expenditures in nanofiltration facilities. A comprehensive breakdown shows that membrane replacement (15-25%), chemical cleaning (10-15%), labor (10-20%), and maintenance (5-10%) comprise the remaining operational costs. These proportions vary significantly based on facility scale, with larger installations benefiting from economies of scale that reduce per-unit treatment costs.

Recent technological innovations have yielded substantial improvements in energy efficiency. Advanced membrane materials incorporating nanomaterials such as graphene oxide and carbon nanotubes have demonstrated potential energy reductions of 15-30% compared to conventional polymeric membranes. Additionally, optimized module designs featuring improved hydrodynamics and reduced pressure drop have contributed to energy savings of 10-20% in pilot-scale implementations.

Process optimization strategies further enhance cost-effectiveness. Variable frequency drives for pumping systems can reduce energy consumption by 20-25% through dynamic adjustment to flow conditions. Hybrid systems combining nanofiltration with complementary technologies like electrocoagulation or advanced oxidation processes have demonstrated operational cost reductions of 15-30% in specific applications while maintaining or improving treatment efficacy.

Life cycle cost analysis indicates that despite higher initial capital investment compared to conventional treatment methods, nanofiltration systems often achieve lower long-term costs when accounting for operational expenses over a 15-20 year period. The payback period typically ranges from 3-7 years depending on application specifics, energy costs, and regulatory requirements for effluent quality.

Future developments in energy recovery devices, particularly pressure exchangers and turbochargers specifically designed for nanofiltration pressure ranges, show promise for further reducing energy consumption by 10-15%. Additionally, emerging membrane materials with anti-fouling properties could extend membrane life by 30-50%, significantly reducing replacement frequency and associated costs while maintaining optimal energy performance throughout the operational lifetime.

Operational cost analysis reveals that energy expenses constitute approximately 30-40% of total operational expenditures in nanofiltration facilities. A comprehensive breakdown shows that membrane replacement (15-25%), chemical cleaning (10-15%), labor (10-20%), and maintenance (5-10%) comprise the remaining operational costs. These proportions vary significantly based on facility scale, with larger installations benefiting from economies of scale that reduce per-unit treatment costs.

Recent technological innovations have yielded substantial improvements in energy efficiency. Advanced membrane materials incorporating nanomaterials such as graphene oxide and carbon nanotubes have demonstrated potential energy reductions of 15-30% compared to conventional polymeric membranes. Additionally, optimized module designs featuring improved hydrodynamics and reduced pressure drop have contributed to energy savings of 10-20% in pilot-scale implementations.

Process optimization strategies further enhance cost-effectiveness. Variable frequency drives for pumping systems can reduce energy consumption by 20-25% through dynamic adjustment to flow conditions. Hybrid systems combining nanofiltration with complementary technologies like electrocoagulation or advanced oxidation processes have demonstrated operational cost reductions of 15-30% in specific applications while maintaining or improving treatment efficacy.

Life cycle cost analysis indicates that despite higher initial capital investment compared to conventional treatment methods, nanofiltration systems often achieve lower long-term costs when accounting for operational expenses over a 15-20 year period. The payback period typically ranges from 3-7 years depending on application specifics, energy costs, and regulatory requirements for effluent quality.

Future developments in energy recovery devices, particularly pressure exchangers and turbochargers specifically designed for nanofiltration pressure ranges, show promise for further reducing energy consumption by 10-15%. Additionally, emerging membrane materials with anti-fouling properties could extend membrane life by 30-50%, significantly reducing replacement frequency and associated costs while maintaining optimal energy performance throughout the operational lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!