Nanofiltration Contribution to Wastewater Industry Innovations

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Technology Evolution and Objectives

Nanofiltration technology emerged in the late 1980s as a specialized membrane filtration process positioned between reverse osmosis and ultrafiltration in terms of selectivity. This technology has evolved significantly over the past three decades, driven by increasing global water scarcity and stricter environmental regulations regarding wastewater discharge. Initially developed as a cost-effective alternative to reverse osmosis for water softening applications, nanofiltration has progressively expanded its application scope within the wastewater treatment industry.

The evolution of nanofiltration membranes represents a critical advancement trajectory. First-generation nanofiltration membranes were primarily thin-film composite structures with limited chemical resistance and relatively short operational lifespans. Subsequent generations have incorporated enhanced materials science innovations, including the development of ceramic nanofiltration membranes, biomimetic membranes, and more recently, graphene-based nanofiltration systems that demonstrate superior flux rates and selectivity profiles.

From a performance perspective, nanofiltration technology has witnessed remarkable improvements in rejection capabilities, particularly for multivalent ions and organic compounds with molecular weights above 200-300 Daltons. Energy efficiency has also improved substantially, with modern nanofiltration systems requiring 30-40% less energy compared to their predecessors from the early 2000s, making them increasingly economically viable for widespread wastewater treatment applications.

The primary technical objectives for nanofiltration in wastewater treatment innovations center around several key parameters. First, enhancing membrane selectivity to target emerging contaminants of concern, including pharmaceutical residues, personal care products, and industrial micropollutants that conventional treatment processes fail to remove effectively. Second, improving fouling resistance to extend membrane operational lifetimes in challenging wastewater matrices with high organic and particulate loadings.

Additional objectives include developing modular and scalable nanofiltration systems that can be deployed across diverse treatment scenarios, from decentralized small-scale applications to large municipal facilities. Cost reduction remains a critical goal, with research focused on manufacturing processes that can reduce membrane production costs while maintaining performance integrity. Integration capabilities with complementary technologies, such as advanced oxidation processes and biological treatment systems, represent another important development target.

Looking forward, the technological trajectory for nanofiltration in wastewater applications is increasingly focused on sustainability metrics. This includes developing membranes from renewable or recyclable materials, reducing the chemical intensity of membrane cleaning protocols, and optimizing energy consumption through improved module designs and operational strategies. These evolutionary pathways align with the broader industry shift toward circular economy principles in wastewater management.

The evolution of nanofiltration membranes represents a critical advancement trajectory. First-generation nanofiltration membranes were primarily thin-film composite structures with limited chemical resistance and relatively short operational lifespans. Subsequent generations have incorporated enhanced materials science innovations, including the development of ceramic nanofiltration membranes, biomimetic membranes, and more recently, graphene-based nanofiltration systems that demonstrate superior flux rates and selectivity profiles.

From a performance perspective, nanofiltration technology has witnessed remarkable improvements in rejection capabilities, particularly for multivalent ions and organic compounds with molecular weights above 200-300 Daltons. Energy efficiency has also improved substantially, with modern nanofiltration systems requiring 30-40% less energy compared to their predecessors from the early 2000s, making them increasingly economically viable for widespread wastewater treatment applications.

The primary technical objectives for nanofiltration in wastewater treatment innovations center around several key parameters. First, enhancing membrane selectivity to target emerging contaminants of concern, including pharmaceutical residues, personal care products, and industrial micropollutants that conventional treatment processes fail to remove effectively. Second, improving fouling resistance to extend membrane operational lifetimes in challenging wastewater matrices with high organic and particulate loadings.

Additional objectives include developing modular and scalable nanofiltration systems that can be deployed across diverse treatment scenarios, from decentralized small-scale applications to large municipal facilities. Cost reduction remains a critical goal, with research focused on manufacturing processes that can reduce membrane production costs while maintaining performance integrity. Integration capabilities with complementary technologies, such as advanced oxidation processes and biological treatment systems, represent another important development target.

Looking forward, the technological trajectory for nanofiltration in wastewater applications is increasingly focused on sustainability metrics. This includes developing membranes from renewable or recyclable materials, reducing the chemical intensity of membrane cleaning protocols, and optimizing energy consumption through improved module designs and operational strategies. These evolutionary pathways align with the broader industry shift toward circular economy principles in wastewater management.

Wastewater Treatment Market Demand Analysis

The global wastewater treatment market is experiencing significant growth, driven by increasing water scarcity, stringent environmental regulations, and growing industrialization. Current market valuations place the wastewater treatment sector at approximately 250 billion USD in 2023, with projections indicating a compound annual growth rate of 7.1% through 2030, highlighting substantial economic opportunities in this domain.

Nanofiltration technology has emerged as a critical innovation area within this expanding market. Industry analyses reveal that membrane-based treatment solutions, including nanofiltration, currently represent about 20% of the total wastewater treatment market, with this segment growing at nearly twice the rate of conventional treatment technologies.

Municipal wastewater treatment remains the largest application segment, accounting for roughly 65% of the total market demand. However, industrial applications are showing the fastest growth rates, particularly in sectors such as pharmaceuticals, textiles, and food processing, where nanofiltration offers specific advantages in removing micropollutants while preserving valuable minerals.

Geographically, North America and Europe currently lead in nanofiltration adoption, collectively representing approximately 60% of the global market share. However, the Asia-Pacific region, particularly China and India, is demonstrating the most rapid growth trajectory, with annual increases exceeding 10% as these nations address severe water pollution challenges while facing increasing water scarcity.

Consumer demand patterns indicate a growing preference for sustainable and energy-efficient treatment solutions. Nanofiltration addresses this trend by offering 30-40% energy savings compared to reverse osmosis while achieving comparable contaminant removal rates for many applications. This energy efficiency translates to reduced operational costs, a critical factor driving market adoption.

Regulatory frameworks worldwide are increasingly focusing on emerging contaminants such as pharmaceuticals, personal care products, and microplastics. The European Union's Water Framework Directive and similar regulations in other regions have established progressively stringent discharge limits that conventional treatment methods struggle to meet, creating market pull for advanced solutions like nanofiltration.

Market research indicates that water reuse applications represent the fastest-growing segment within the wastewater treatment industry, expanding at approximately 9% annually. Nanofiltration's selective removal capabilities make it particularly suitable for water recycling applications where complete demineralization is undesirable, positioning this technology to capture significant market share in this high-growth segment.

Nanofiltration technology has emerged as a critical innovation area within this expanding market. Industry analyses reveal that membrane-based treatment solutions, including nanofiltration, currently represent about 20% of the total wastewater treatment market, with this segment growing at nearly twice the rate of conventional treatment technologies.

Municipal wastewater treatment remains the largest application segment, accounting for roughly 65% of the total market demand. However, industrial applications are showing the fastest growth rates, particularly in sectors such as pharmaceuticals, textiles, and food processing, where nanofiltration offers specific advantages in removing micropollutants while preserving valuable minerals.

Geographically, North America and Europe currently lead in nanofiltration adoption, collectively representing approximately 60% of the global market share. However, the Asia-Pacific region, particularly China and India, is demonstrating the most rapid growth trajectory, with annual increases exceeding 10% as these nations address severe water pollution challenges while facing increasing water scarcity.

Consumer demand patterns indicate a growing preference for sustainable and energy-efficient treatment solutions. Nanofiltration addresses this trend by offering 30-40% energy savings compared to reverse osmosis while achieving comparable contaminant removal rates for many applications. This energy efficiency translates to reduced operational costs, a critical factor driving market adoption.

Regulatory frameworks worldwide are increasingly focusing on emerging contaminants such as pharmaceuticals, personal care products, and microplastics. The European Union's Water Framework Directive and similar regulations in other regions have established progressively stringent discharge limits that conventional treatment methods struggle to meet, creating market pull for advanced solutions like nanofiltration.

Market research indicates that water reuse applications represent the fastest-growing segment within the wastewater treatment industry, expanding at approximately 9% annually. Nanofiltration's selective removal capabilities make it particularly suitable for water recycling applications where complete demineralization is undesirable, positioning this technology to capture significant market share in this high-growth segment.

Current Nanofiltration Capabilities and Limitations

Nanofiltration (NF) technology has emerged as a significant advancement in wastewater treatment, occupying a critical position between reverse osmosis and ultrafiltration in terms of selectivity and operating pressure. Current nanofiltration systems demonstrate exceptional capabilities in removing divalent ions, organic compounds with molecular weights above 300 Da, and various micropollutants, achieving rejection rates of 60-98% depending on the target contaminant and membrane specifications.

The primary strength of nanofiltration lies in its selective separation ability, allowing certain monovalent ions to pass through while effectively retaining multivalent ions and larger organic molecules. This selectivity enables applications where complete demineralization is undesirable, such as in water softening processes or nutrient recovery from wastewater. Modern NF membranes operate at moderate pressures (5-20 bar), significantly lower than reverse osmosis, translating to energy consumption reductions of 20-30% compared to RO systems for similar applications.

Despite these advantages, nanofiltration faces several technical limitations that constrain its broader implementation. Membrane fouling remains the most persistent challenge, with organic, biological, and inorganic foulants progressively decreasing flux rates and separation efficiency. Current anti-fouling strategies, including surface modifications and cleaning protocols, provide only partial solutions, with most industrial installations requiring regular chemical cleaning that interrupts continuous operation.

Selectivity control presents another significant limitation. While nanofiltration's partial selectivity is advantageous in certain applications, precisely controlling the rejection of specific ions or compounds remains difficult. This unpredictability complicates process design and optimization, particularly when treating complex wastewater streams with variable compositions. The rejection mechanism depends on multiple factors including molecular size, charge interactions, and membrane surface properties, creating challenges in developing predictive models for separation performance.

Membrane durability under harsh conditions constitutes a third major limitation. Current nanofiltration membranes exhibit limited chemical resistance, particularly to oxidizing agents, extreme pH conditions, and certain organic solvents commonly found in industrial wastewaters. Most commercial membranes operate optimally within pH ranges of 2-11 and temperatures below 45°C, restricting their application in treating high-temperature or highly acidic/alkaline industrial effluents.

The economic viability of nanofiltration systems is further constrained by membrane replacement costs, which typically account for 30-50% of operational expenses. Current membranes have average lifespans of 2-5 years under optimal conditions, but this can decrease significantly when treating challenging wastewaters. Additionally, the concentrated reject stream (typically 10-30% of feed volume) requires further treatment or disposal, adding complexity and cost to the overall treatment process.

The primary strength of nanofiltration lies in its selective separation ability, allowing certain monovalent ions to pass through while effectively retaining multivalent ions and larger organic molecules. This selectivity enables applications where complete demineralization is undesirable, such as in water softening processes or nutrient recovery from wastewater. Modern NF membranes operate at moderate pressures (5-20 bar), significantly lower than reverse osmosis, translating to energy consumption reductions of 20-30% compared to RO systems for similar applications.

Despite these advantages, nanofiltration faces several technical limitations that constrain its broader implementation. Membrane fouling remains the most persistent challenge, with organic, biological, and inorganic foulants progressively decreasing flux rates and separation efficiency. Current anti-fouling strategies, including surface modifications and cleaning protocols, provide only partial solutions, with most industrial installations requiring regular chemical cleaning that interrupts continuous operation.

Selectivity control presents another significant limitation. While nanofiltration's partial selectivity is advantageous in certain applications, precisely controlling the rejection of specific ions or compounds remains difficult. This unpredictability complicates process design and optimization, particularly when treating complex wastewater streams with variable compositions. The rejection mechanism depends on multiple factors including molecular size, charge interactions, and membrane surface properties, creating challenges in developing predictive models for separation performance.

Membrane durability under harsh conditions constitutes a third major limitation. Current nanofiltration membranes exhibit limited chemical resistance, particularly to oxidizing agents, extreme pH conditions, and certain organic solvents commonly found in industrial wastewaters. Most commercial membranes operate optimally within pH ranges of 2-11 and temperatures below 45°C, restricting their application in treating high-temperature or highly acidic/alkaline industrial effluents.

The economic viability of nanofiltration systems is further constrained by membrane replacement costs, which typically account for 30-50% of operational expenses. Current membranes have average lifespans of 2-5 years under optimal conditions, but this can decrease significantly when treating challenging wastewaters. Additionally, the concentrated reject stream (typically 10-30% of feed volume) requires further treatment or disposal, adding complexity and cost to the overall treatment process.

Existing Nanofiltration Solutions for Wastewater Treatment

01 Nanofiltration membrane materials and structures

Nanofiltration membranes can be fabricated using various materials and structures to achieve specific separation properties. These membranes typically have pore sizes in the nanometer range and can be made from polymers, ceramics, or composite materials. The structure of the membrane, including its thickness, porosity, and surface characteristics, significantly affects its performance in terms of flux, selectivity, and fouling resistance.- Nanofiltration membrane materials and structures: Nanofiltration membranes can be fabricated using various materials and structures to achieve specific separation properties. These materials include polymers, ceramics, and composite structures that provide selective permeability based on molecular size, charge, and other physicochemical properties. Advanced membrane designs incorporate nanomaterials to enhance performance characteristics such as flux, selectivity, and fouling resistance. The structure of these membranes typically consists of a thin selective layer supported by a more porous substrate.

- Water purification and treatment applications: Nanofiltration technology is widely used in water purification and treatment processes to remove contaminants such as dissolved salts, organic compounds, and microorganisms. This technology operates between ultrafiltration and reverse osmosis in terms of selectivity, allowing for the removal of multivalent ions while permitting some monovalent ions to pass through. Nanofiltration systems are employed in municipal water treatment, desalination pretreatment, and wastewater reclamation to produce high-quality water while consuming less energy than reverse osmosis.

- Industrial separation and concentration processes: Nanofiltration is utilized in various industrial applications for separation, concentration, and purification of valuable components. These applications include food and beverage processing, pharmaceutical manufacturing, and chemical production. The technology enables selective separation of molecules based on size and charge, allowing for the concentration of desired compounds while removing impurities. Industrial nanofiltration systems are designed to handle specific feed streams and operating conditions to optimize performance and product quality.

- Fouling mitigation and membrane cleaning strategies: Membrane fouling is a significant challenge in nanofiltration operations that reduces efficiency and increases operational costs. Various strategies have been developed to mitigate fouling, including surface modifications, feed pretreatment, and optimized operating conditions. Cleaning protocols using chemical agents, backwashing, and physical methods are employed to restore membrane performance. Advanced anti-fouling approaches incorporate nanomaterials and surface chemistry modifications to create membranes with inherent fouling resistance properties.

- Novel nanofiltration system designs and process optimization: Innovative nanofiltration system designs focus on improving energy efficiency, reducing environmental impact, and enhancing separation performance. These designs include hybrid systems that combine nanofiltration with other separation technologies, modular configurations for scalability, and process intensification approaches. Optimization strategies involve adjusting operating parameters such as pressure, temperature, and cross-flow velocity to maximize flux and selectivity while minimizing energy consumption. Advanced control systems and modeling tools are used to predict performance and optimize operation under varying feed conditions.

02 Water purification and treatment applications

Nanofiltration is widely used in water purification and treatment processes to remove contaminants such as dissolved salts, organic compounds, and microorganisms. It operates at lower pressures than reverse osmosis while providing higher rejection rates than ultrafiltration. This technology is particularly effective for softening water, removing divalent ions, and treating wastewater for reuse in various industries.Expand Specific Solutions03 Industrial separation and concentration processes

Nanofiltration is employed in industrial separation and concentration processes to selectively separate components based on molecular size and charge. It is used in the food and beverage industry for concentration and purification of products, in the pharmaceutical industry for separation of active ingredients, and in the chemical industry for recovery of valuable compounds from process streams. The technology enables efficient separation while maintaining product quality and reducing energy consumption.Expand Specific Solutions04 Membrane fouling prevention and cleaning methods

Membrane fouling is a significant challenge in nanofiltration operations, leading to reduced performance and increased operational costs. Various strategies have been developed to prevent and mitigate fouling, including pretreatment of feed streams, modification of membrane surface properties, optimization of operating conditions, and development of effective cleaning protocols. These methods aim to extend membrane life and maintain consistent filtration performance over time.Expand Specific Solutions05 Advanced nanofiltration system designs

Advanced nanofiltration system designs incorporate innovative features to enhance performance, efficiency, and sustainability. These designs may include hybrid systems combining nanofiltration with other separation technologies, energy recovery devices, automated control systems, and modular configurations for scalability. Such advanced systems aim to optimize energy consumption, reduce waste generation, and improve overall process economics for various applications.Expand Specific Solutions

Leading Companies in Nanofiltration Technology

Nanofiltration technology in wastewater treatment is currently in a growth phase, with the market expanding rapidly due to increasing water scarcity and stricter environmental regulations. The global nanofiltration market is projected to reach significant scale as industries adopt advanced water treatment solutions. Leading academic institutions like The University of Hong Kong, National University of Singapore, and Tongji University are driving fundamental research, while companies such as Siemens AG, China Petroleum & Chemical Corp., and Baker Hughes are commercializing applications. The technology has reached moderate maturity in certain applications but continues to evolve with innovations from specialized firms like Zhejiang Jinmo Environment Technology and Bayer Technology Services, focusing on membrane development and process optimization for industrial wastewater treatment.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced nanofiltration membrane systems specifically designed for petrochemical wastewater treatment. Their technology utilizes composite nanofiltration membranes with modified surface chemistry to selectively remove organic contaminants while allowing valuable minerals to pass through. The system incorporates a multi-stage filtration process with specialized pre-treatment to handle high-oil content wastewater typical in petroleum refining. Sinopec's nanofiltration technology achieves removal rates of over 95% for most organic pollutants and reduces total dissolved solids by 60-80% while operating at lower pressures (5-15 bar) compared to reverse osmosis. The company has implemented this technology across multiple refineries, demonstrating 30-40% reduction in wastewater treatment costs and enabling water reuse rates of up to 75% in water-scarce regions.

Strengths: Specialized for high-oil content industrial wastewater with excellent organic contaminant removal while preserving valuable minerals. Lower energy consumption than reverse osmosis. Weaknesses: Higher initial capital investment compared to conventional treatments and requires specialized maintenance expertise for optimal performance.

Siemens AG

Technical Solution: Siemens AG has pioneered an integrated nanofiltration solution called "NanoNet" for industrial wastewater treatment. This system combines advanced polymer-based nanofiltration membranes with digital monitoring and control systems. The membranes feature precisely engineered pore sizes (1-10 nm) and surface charge characteristics optimized for removing specific contaminants while minimizing fouling. Siemens' approach incorporates AI-driven predictive maintenance that continuously monitors membrane performance and adjusts operating parameters in real-time. Their system achieves up to 40% energy savings compared to conventional treatment methods while extending membrane life by 30-50%. The technology has been particularly successful in textile industry applications, where it removes up to 98% of dyes and 85% of salts, enabling closed-loop water recycling. Siemens has also developed specialized anti-fouling coatings that reduce cleaning frequency by approximately 60%, significantly improving operational efficiency.

Strengths: Integration of digital monitoring with advanced membrane technology creates a highly efficient, automated system with reduced maintenance requirements and extended membrane life. Weaknesses: Higher implementation costs and complexity compared to standalone nanofiltration systems; requires significant technical expertise for installation and optimization.

Key Patents and Research in Nanofiltration Membranes

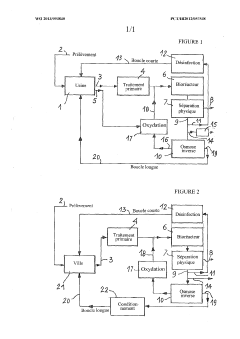

Method for treating industrial or urban wastewater for reuse, and facility for implementing this method

PatentWO2013093840A1

Innovation

- A wastewater treatment system incorporating a single reverse osmosis or nanofiltration stage, where the concentrate undergoes ozonation to degrade organic matter, and is then recycled back to the biological treatment stage, integrating water separation and pollution degradation in a loop.

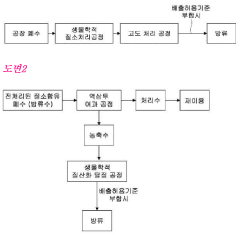

Method of treating and reusing wastewater effluent

PatentInactiveKR1020150070505A

Innovation

- A method involving reverse osmosis filtration followed by a nitrogen treatment process, including biological nitrification and denitrification, to separate treated water for reuse and concentrated water for further treatment, ensuring compliance with discharge standards.

Environmental Impact and Sustainability Assessment

Nanofiltration technology represents a significant advancement in sustainable wastewater treatment, offering substantial environmental benefits compared to conventional treatment methods. The environmental footprint of nanofiltration systems is considerably lower than traditional processes, particularly in terms of chemical usage and energy consumption. Studies indicate that nanofiltration can reduce chemical requirements by up to 40% and energy consumption by 25-30% compared to conventional treatment technologies, resulting in decreased greenhouse gas emissions and resource depletion.

The lifecycle assessment of nanofiltration membranes reveals promising sustainability metrics. Modern nanofiltration membranes typically have operational lifespans of 3-5 years, significantly longer than earlier generations, reducing waste generation and replacement frequency. Additionally, innovations in membrane materials have decreased the environmental impact of manufacturing processes, with some manufacturers implementing green chemistry principles to develop bio-based polymers for membrane production.

Water conservation represents one of nanofiltration's most significant environmental contributions. By enabling high-quality water reclamation from wastewater streams, nanofiltration facilitates water reuse in various applications, from industrial processes to agricultural irrigation. This circular approach to water management reduces pressure on freshwater resources, particularly critical in water-stressed regions where nanofiltration implementation has demonstrated up to 60% reduction in freshwater withdrawal requirements.

The technology also plays a crucial role in pollution prevention by effectively removing emerging contaminants such as pharmaceuticals, personal care products, and microplastics from wastewater. Recent studies have documented nanofiltration's ability to remove over 95% of these micropollutants, preventing their release into aquatic ecosystems and reducing bioaccumulation risks in wildlife and human food chains.

Carbon footprint analysis of wastewater treatment facilities that have integrated nanofiltration shows promising results. When compared to conventional activated sludge processes followed by tertiary treatment, nanofiltration-based systems demonstrate 15-20% lower carbon emissions across their operational lifecycle. This reduction stems primarily from decreased energy requirements for treatment and reduced chemical manufacturing and transportation needs.

From a circular economy perspective, nanofiltration enables the recovery of valuable resources from wastewater streams. Phosphorus, nitrogen, and various metals can be concentrated and extracted, transforming waste streams into potential revenue sources while simultaneously reducing environmental contamination. Some advanced nanofiltration applications have achieved recovery rates of up to 80% for certain valuable minerals, contributing to resource conservation and industrial symbiosis opportunities.

The lifecycle assessment of nanofiltration membranes reveals promising sustainability metrics. Modern nanofiltration membranes typically have operational lifespans of 3-5 years, significantly longer than earlier generations, reducing waste generation and replacement frequency. Additionally, innovations in membrane materials have decreased the environmental impact of manufacturing processes, with some manufacturers implementing green chemistry principles to develop bio-based polymers for membrane production.

Water conservation represents one of nanofiltration's most significant environmental contributions. By enabling high-quality water reclamation from wastewater streams, nanofiltration facilitates water reuse in various applications, from industrial processes to agricultural irrigation. This circular approach to water management reduces pressure on freshwater resources, particularly critical in water-stressed regions where nanofiltration implementation has demonstrated up to 60% reduction in freshwater withdrawal requirements.

The technology also plays a crucial role in pollution prevention by effectively removing emerging contaminants such as pharmaceuticals, personal care products, and microplastics from wastewater. Recent studies have documented nanofiltration's ability to remove over 95% of these micropollutants, preventing their release into aquatic ecosystems and reducing bioaccumulation risks in wildlife and human food chains.

Carbon footprint analysis of wastewater treatment facilities that have integrated nanofiltration shows promising results. When compared to conventional activated sludge processes followed by tertiary treatment, nanofiltration-based systems demonstrate 15-20% lower carbon emissions across their operational lifecycle. This reduction stems primarily from decreased energy requirements for treatment and reduced chemical manufacturing and transportation needs.

From a circular economy perspective, nanofiltration enables the recovery of valuable resources from wastewater streams. Phosphorus, nitrogen, and various metals can be concentrated and extracted, transforming waste streams into potential revenue sources while simultaneously reducing environmental contamination. Some advanced nanofiltration applications have achieved recovery rates of up to 80% for certain valuable minerals, contributing to resource conservation and industrial symbiosis opportunities.

Regulatory Framework for Advanced Wastewater Treatment

The regulatory landscape governing nanofiltration and advanced wastewater treatment technologies has evolved significantly in response to growing environmental concerns and water scarcity challenges. At the international level, frameworks such as the United Nations Sustainable Development Goals (SDG 6) have established targets for improving water quality through reducing pollution and minimizing the release of hazardous chemicals by 2030, indirectly promoting advanced treatment technologies like nanofiltration.

In developed regions, particularly the European Union, the Water Framework Directive (2000/60/EC) and Urban Waste Water Treatment Directive (91/271/EEC) have been instrumental in setting comprehensive standards for wastewater treatment. The EU has recently updated these frameworks to specifically address emerging contaminants and microplastics, areas where nanofiltration demonstrates significant advantages over conventional treatment methods.

The United States Environmental Protection Agency (EPA) regulates wastewater treatment through the Clean Water Act, with the National Pollutant Discharge Elimination System (NPDES) permitting program establishing increasingly stringent effluent limitations. Several states, including California and Florida, have implemented advanced regulations that effectively necessitate membrane filtration technologies for water reuse applications, creating market drivers for nanofiltration adoption.

Developing economies, particularly in Asia, are rapidly strengthening their regulatory frameworks. China's Water Pollution Prevention and Control Action Plan (Water Ten Plan) and India's National Green Tribunal rulings have progressively tightened industrial discharge standards, compelling industries to invest in advanced treatment technologies including nanofiltration systems.

Industry-specific regulations have emerged as significant drivers for nanofiltration implementation. Pharmaceutical manufacturing facilities face increasingly strict regulations regarding active pharmaceutical ingredients in wastewater, while textile industries confront new standards for color removal and salt reduction – both areas where nanofiltration excels technically.

Regulatory compliance costs have become a critical factor in technology selection, with nanofiltration often presenting favorable total cost of ownership compared to alternative compliance strategies. This economic reality has prompted regulatory bodies to increasingly incorporate technology-based standards that indirectly favor membrane filtration approaches.

Looking forward, regulatory trends indicate movement toward circular economy principles in wastewater management, with emerging frameworks focusing on resource recovery and water reuse. These developments are likely to further strengthen the regulatory case for nanofiltration technologies as they excel in selective separation capabilities essential for resource recovery applications.

In developed regions, particularly the European Union, the Water Framework Directive (2000/60/EC) and Urban Waste Water Treatment Directive (91/271/EEC) have been instrumental in setting comprehensive standards for wastewater treatment. The EU has recently updated these frameworks to specifically address emerging contaminants and microplastics, areas where nanofiltration demonstrates significant advantages over conventional treatment methods.

The United States Environmental Protection Agency (EPA) regulates wastewater treatment through the Clean Water Act, with the National Pollutant Discharge Elimination System (NPDES) permitting program establishing increasingly stringent effluent limitations. Several states, including California and Florida, have implemented advanced regulations that effectively necessitate membrane filtration technologies for water reuse applications, creating market drivers for nanofiltration adoption.

Developing economies, particularly in Asia, are rapidly strengthening their regulatory frameworks. China's Water Pollution Prevention and Control Action Plan (Water Ten Plan) and India's National Green Tribunal rulings have progressively tightened industrial discharge standards, compelling industries to invest in advanced treatment technologies including nanofiltration systems.

Industry-specific regulations have emerged as significant drivers for nanofiltration implementation. Pharmaceutical manufacturing facilities face increasingly strict regulations regarding active pharmaceutical ingredients in wastewater, while textile industries confront new standards for color removal and salt reduction – both areas where nanofiltration excels technically.

Regulatory compliance costs have become a critical factor in technology selection, with nanofiltration often presenting favorable total cost of ownership compared to alternative compliance strategies. This economic reality has prompted regulatory bodies to increasingly incorporate technology-based standards that indirectly favor membrane filtration approaches.

Looking forward, regulatory trends indicate movement toward circular economy principles in wastewater management, with emerging frameworks focusing on resource recovery and water reuse. These developments are likely to further strengthen the regulatory case for nanofiltration technologies as they excel in selective separation capabilities essential for resource recovery applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!