Wastewater Nanofiltration Membrane Enhancements and Market Growth

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanofiltration Membrane Technology Background and Objectives

Nanofiltration (NF) technology has evolved significantly since its inception in the late 1970s as a specialized membrane filtration process positioned between reverse osmosis and ultrafiltration. Initially developed as a water softening technique, nanofiltration has transformed into a versatile separation technology with applications spanning multiple industries, particularly in wastewater treatment. The fundamental principle relies on semi-permeable membranes with pore sizes typically ranging from 1-10 nanometers, enabling selective separation of multivalent ions, organic molecules, and contaminants from water streams.

The evolution of nanofiltration membrane technology has been marked by several key innovations, including the development of thin-film composite membranes in the 1980s, which significantly improved separation efficiency and reduced energy consumption. Subsequent advancements in material science have led to the incorporation of nanomaterials such as graphene oxide, carbon nanotubes, and metal-organic frameworks, further enhancing membrane performance characteristics.

Current global water challenges, including increasing water scarcity, stringent environmental regulations, and the growing presence of emerging contaminants, have accelerated research interest in advanced nanofiltration solutions. The United Nations estimates that by 2025, two-thirds of the world's population may face water stress conditions, underscoring the critical need for efficient water reclamation technologies. Nanofiltration presents a promising approach to address these challenges through its ability to remove specific contaminants while maintaining essential minerals.

The primary technical objectives in nanofiltration membrane research for wastewater applications include enhancing membrane selectivity, improving fouling resistance, extending operational lifespan, and reducing energy requirements. Particular emphasis is placed on developing membranes capable of effectively removing persistent organic pollutants, pharmaceutical residues, heavy metals, and other emerging contaminants that conventional treatment methods struggle to address.

Another critical objective is overcoming the trade-off between permeability and selectivity, which has traditionally limited membrane performance. Recent research directions focus on novel membrane architectures, surface modifications, and composite materials that can simultaneously achieve high water flux and excellent rejection rates for target contaminants.

The integration of nanofiltration with complementary technologies, such as advanced oxidation processes, biological treatment, and other membrane technologies, represents another important research direction. These hybrid systems aim to create more comprehensive and efficient wastewater treatment solutions that can address complex contamination scenarios while minimizing operational costs and environmental footprint.

As climate change intensifies water stress globally, nanofiltration technology is positioned to play an increasingly vital role in sustainable water management strategies, with research objectives expanding beyond performance metrics to include considerations of economic viability, scalability, and environmental impact throughout the membrane lifecycle.

The evolution of nanofiltration membrane technology has been marked by several key innovations, including the development of thin-film composite membranes in the 1980s, which significantly improved separation efficiency and reduced energy consumption. Subsequent advancements in material science have led to the incorporation of nanomaterials such as graphene oxide, carbon nanotubes, and metal-organic frameworks, further enhancing membrane performance characteristics.

Current global water challenges, including increasing water scarcity, stringent environmental regulations, and the growing presence of emerging contaminants, have accelerated research interest in advanced nanofiltration solutions. The United Nations estimates that by 2025, two-thirds of the world's population may face water stress conditions, underscoring the critical need for efficient water reclamation technologies. Nanofiltration presents a promising approach to address these challenges through its ability to remove specific contaminants while maintaining essential minerals.

The primary technical objectives in nanofiltration membrane research for wastewater applications include enhancing membrane selectivity, improving fouling resistance, extending operational lifespan, and reducing energy requirements. Particular emphasis is placed on developing membranes capable of effectively removing persistent organic pollutants, pharmaceutical residues, heavy metals, and other emerging contaminants that conventional treatment methods struggle to address.

Another critical objective is overcoming the trade-off between permeability and selectivity, which has traditionally limited membrane performance. Recent research directions focus on novel membrane architectures, surface modifications, and composite materials that can simultaneously achieve high water flux and excellent rejection rates for target contaminants.

The integration of nanofiltration with complementary technologies, such as advanced oxidation processes, biological treatment, and other membrane technologies, represents another important research direction. These hybrid systems aim to create more comprehensive and efficient wastewater treatment solutions that can address complex contamination scenarios while minimizing operational costs and environmental footprint.

As climate change intensifies water stress globally, nanofiltration technology is positioned to play an increasingly vital role in sustainable water management strategies, with research objectives expanding beyond performance metrics to include considerations of economic viability, scalability, and environmental impact throughout the membrane lifecycle.

Wastewater Treatment Market Demand Analysis

The global wastewater treatment market is experiencing significant growth driven by increasing water scarcity, stringent environmental regulations, and growing industrialization. Current market valuations place the global wastewater treatment market at approximately 250 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 7.1% through 2030, potentially reaching 400 billion USD.

Nanofiltration membrane technology represents one of the fastest-growing segments within this market, currently valued at 21 billion USD with an expected CAGR of 10.3% over the next five years. This accelerated growth is primarily attributed to nanofiltration's superior performance in removing specific contaminants while maintaining lower energy consumption compared to reverse osmosis systems.

Regional analysis reveals that Asia-Pacific dominates the market demand, accounting for 38% of global wastewater treatment expenditure. This is largely due to rapid industrialization in China and India, coupled with increasingly stringent wastewater discharge regulations. North America and Europe follow with 27% and 24% market shares respectively, where the focus is shifting toward advanced treatment technologies for emerging contaminants and water reuse applications.

Industrial wastewater treatment represents the largest application segment, constituting 61% of the total market. Manufacturing, chemical processing, and mining industries are the primary contributors, with pharmaceutical and food & beverage sectors showing the fastest growth rates in adoption of advanced filtration technologies. Municipal wastewater treatment accounts for 39% of the market but is expected to grow more rapidly in developing regions due to urbanization and infrastructure development initiatives.

Customer demand analysis indicates a clear shift toward more sustainable and cost-effective treatment solutions. End-users increasingly prioritize technologies that offer lower operational costs, reduced chemical usage, and smaller physical footprints. Energy efficiency has emerged as a critical decision factor, with 73% of industrial customers citing energy consumption as a top consideration when selecting filtration systems.

Market research shows that enhanced nanofiltration membranes with anti-fouling properties command premium pricing, with customers willing to pay 15-20% more for membranes that demonstrate extended operational lifespans. Additionally, solutions that enable water reuse capabilities are experiencing 30% higher demand growth compared to conventional treatment systems, reflecting the increasing value placed on water conservation and circular economy principles.

Regulatory drivers continue to shape market demand significantly. The implementation of more stringent discharge standards for micropollutants, pharmaceutical residues, and PFAS (per- and polyfluoroalkyl substances) is creating substantial demand for advanced filtration technologies capable of addressing these emerging contaminants.

Nanofiltration membrane technology represents one of the fastest-growing segments within this market, currently valued at 21 billion USD with an expected CAGR of 10.3% over the next five years. This accelerated growth is primarily attributed to nanofiltration's superior performance in removing specific contaminants while maintaining lower energy consumption compared to reverse osmosis systems.

Regional analysis reveals that Asia-Pacific dominates the market demand, accounting for 38% of global wastewater treatment expenditure. This is largely due to rapid industrialization in China and India, coupled with increasingly stringent wastewater discharge regulations. North America and Europe follow with 27% and 24% market shares respectively, where the focus is shifting toward advanced treatment technologies for emerging contaminants and water reuse applications.

Industrial wastewater treatment represents the largest application segment, constituting 61% of the total market. Manufacturing, chemical processing, and mining industries are the primary contributors, with pharmaceutical and food & beverage sectors showing the fastest growth rates in adoption of advanced filtration technologies. Municipal wastewater treatment accounts for 39% of the market but is expected to grow more rapidly in developing regions due to urbanization and infrastructure development initiatives.

Customer demand analysis indicates a clear shift toward more sustainable and cost-effective treatment solutions. End-users increasingly prioritize technologies that offer lower operational costs, reduced chemical usage, and smaller physical footprints. Energy efficiency has emerged as a critical decision factor, with 73% of industrial customers citing energy consumption as a top consideration when selecting filtration systems.

Market research shows that enhanced nanofiltration membranes with anti-fouling properties command premium pricing, with customers willing to pay 15-20% more for membranes that demonstrate extended operational lifespans. Additionally, solutions that enable water reuse capabilities are experiencing 30% higher demand growth compared to conventional treatment systems, reflecting the increasing value placed on water conservation and circular economy principles.

Regulatory drivers continue to shape market demand significantly. The implementation of more stringent discharge standards for micropollutants, pharmaceutical residues, and PFAS (per- and polyfluoroalkyl substances) is creating substantial demand for advanced filtration technologies capable of addressing these emerging contaminants.

Global Nanofiltration Technology Status and Challenges

Nanofiltration technology has evolved significantly over the past two decades, establishing itself as a critical solution for wastewater treatment globally. Currently, the technology has reached commercial maturity in developed regions such as North America, Europe, and parts of Asia, while still emerging in developing economies. The global nanofiltration membrane market is experiencing robust growth, with a compound annual growth rate exceeding 8% between 2020-2025, driven primarily by increasing water scarcity and stricter environmental regulations.

Despite its widespread adoption, nanofiltration faces several persistent technical challenges. Membrane fouling remains the most significant obstacle, reducing operational efficiency and increasing maintenance costs. Organic, inorganic, and biological fouling mechanisms continue to limit membrane lifespan and performance, particularly in complex wastewater streams with high organic content or variable composition. Current anti-fouling strategies show limited long-term effectiveness in real-world applications.

Energy consumption presents another major challenge, as nanofiltration systems typically require substantial pressure differentials to maintain desired flux rates. This energy intensity makes the technology less economically viable for certain applications, especially in regions with high energy costs or limited infrastructure. Research indicates that energy requirements account for 30-40% of operational costs in typical nanofiltration installations.

Membrane selectivity limitations constitute a third significant challenge. While nanofiltration excels at removing divalent ions and larger molecules, its performance with monovalent ions and certain micropollutants remains inconsistent. This selectivity gap has restricted its application in scenarios requiring comprehensive contaminant removal, such as pharmaceutical waste treatment or certain industrial processes.

Geographically, nanofiltration technology development shows distinct patterns. North America and Europe lead in research and innovation, with approximately 65% of nanofiltration patents originating from these regions. However, China has emerged as the fastest-growing market and innovation hub, with research output increasing by over 200% in the past decade. Japan and South Korea maintain specialized expertise in high-performance membrane materials.

The cost-effectiveness barrier continues to limit widespread adoption in developing regions. Initial capital expenditure for nanofiltration systems remains 30-50% higher than conventional treatment technologies, creating adoption barriers despite lower long-term operational costs. This economic challenge is particularly pronounced in water-stressed regions with limited financial resources, creating a paradoxical situation where the technology is most needed but least affordable.

Despite its widespread adoption, nanofiltration faces several persistent technical challenges. Membrane fouling remains the most significant obstacle, reducing operational efficiency and increasing maintenance costs. Organic, inorganic, and biological fouling mechanisms continue to limit membrane lifespan and performance, particularly in complex wastewater streams with high organic content or variable composition. Current anti-fouling strategies show limited long-term effectiveness in real-world applications.

Energy consumption presents another major challenge, as nanofiltration systems typically require substantial pressure differentials to maintain desired flux rates. This energy intensity makes the technology less economically viable for certain applications, especially in regions with high energy costs or limited infrastructure. Research indicates that energy requirements account for 30-40% of operational costs in typical nanofiltration installations.

Membrane selectivity limitations constitute a third significant challenge. While nanofiltration excels at removing divalent ions and larger molecules, its performance with monovalent ions and certain micropollutants remains inconsistent. This selectivity gap has restricted its application in scenarios requiring comprehensive contaminant removal, such as pharmaceutical waste treatment or certain industrial processes.

Geographically, nanofiltration technology development shows distinct patterns. North America and Europe lead in research and innovation, with approximately 65% of nanofiltration patents originating from these regions. However, China has emerged as the fastest-growing market and innovation hub, with research output increasing by over 200% in the past decade. Japan and South Korea maintain specialized expertise in high-performance membrane materials.

The cost-effectiveness barrier continues to limit widespread adoption in developing regions. Initial capital expenditure for nanofiltration systems remains 30-50% higher than conventional treatment technologies, creating adoption barriers despite lower long-term operational costs. This economic challenge is particularly pronounced in water-stressed regions with limited financial resources, creating a paradoxical situation where the technology is most needed but least affordable.

Current Nanofiltration Enhancement Solutions

01 Surface modification techniques for nanofiltration membranes

Various surface modification techniques can be applied to nanofiltration membranes to enhance their performance. These techniques include coating with functional polymers, grafting of hydrophilic groups, and layer-by-layer assembly of polyelectrolytes. Surface modifications can improve membrane selectivity, reduce fouling, and increase flux rates by altering the membrane's surface chemistry and charge properties.- Surface modification techniques for nanofiltration membranes: Various surface modification techniques can be applied to enhance nanofiltration membrane performance. These include coating with functional polymers, grafting of hydrophilic groups, and surface treatment with nanomaterials. Such modifications can improve membrane selectivity, reduce fouling, and enhance flux rates by altering the membrane's surface properties without compromising its structural integrity.

- Incorporation of nanomaterials in membrane matrix: Nanomaterials such as graphene oxide, carbon nanotubes, metal-organic frameworks, and nanoparticles can be incorporated into the polymer matrix during membrane fabrication. These nanocomposite membranes exhibit enhanced mechanical strength, thermal stability, antimicrobial properties, and improved separation performance due to the unique properties of the nanomaterials and their interaction with the polymer chains.

- Novel polymer blends for nanofiltration membranes: Developing novel polymer blends and copolymers can significantly enhance nanofiltration membrane properties. By combining different polymers with complementary characteristics, membranes with optimized hydrophilicity, porosity, chemical resistance, and mechanical stability can be created. These blended polymer membranes often demonstrate superior separation performance and longer operational lifetimes compared to single-polymer membranes.

- Anti-fouling strategies for nanofiltration membranes: Anti-fouling strategies are crucial for maintaining membrane performance over time. These include incorporating zwitterionic materials, hydrophilic polymers, or antimicrobial agents into the membrane structure. Other approaches involve creating micro-patterned surfaces or applying dynamic coatings that can be regenerated. These techniques reduce protein adsorption, biofilm formation, and organic fouling, thereby extending membrane lifespan and reducing operational costs.

- Advanced fabrication methods for nanofiltration membranes: Advanced fabrication methods such as electrospinning, interfacial polymerization, phase inversion, and 3D printing are being developed to create nanofiltration membranes with precisely controlled structures. These techniques allow for the creation of membranes with optimized pore size distribution, thickness, and surface morphology. The resulting membranes demonstrate enhanced selectivity, permeability, and mechanical durability under various operating conditions.

02 Incorporation of nanomaterials in membrane structure

Nanomaterials such as carbon nanotubes, graphene oxide, and metal-organic frameworks can be incorporated into nanofiltration membrane matrices to enhance their properties. These nanomaterials can create preferential water pathways, improve mechanical strength, and provide antimicrobial properties. The resulting nanocomposite membranes often demonstrate superior separation performance and longer operational lifetimes compared to conventional membranes.Expand Specific Solutions03 Antifouling strategies for nanofiltration membranes

Fouling is a major challenge in nanofiltration processes that reduces membrane efficiency and lifespan. Advanced antifouling strategies include the incorporation of zwitterionic materials, hydrophilic polymers, and photocatalytic nanoparticles into membrane structures. These modifications create surfaces that resist protein adsorption, bacterial attachment, and organic fouling, thereby maintaining filtration performance over extended periods of operation.Expand Specific Solutions04 Novel fabrication methods for nanofiltration membranes

Innovative fabrication techniques are being developed to create nanofiltration membranes with enhanced properties. These include electrospinning, interfacial polymerization, phase inversion, and 3D printing approaches. These methods allow for precise control over membrane morphology, pore size distribution, and thickness, resulting in membranes with improved selectivity, permeability, and mechanical stability for specific separation applications.Expand Specific Solutions05 Stimuli-responsive nanofiltration membranes

Stimuli-responsive nanofiltration membranes can change their properties in response to external stimuli such as pH, temperature, light, or electric fields. These smart membranes incorporate responsive polymers or functional groups that undergo conformational changes when exposed to specific triggers. This dynamic behavior allows for tunable separation performance, self-cleaning capabilities, and controlled permeability, offering advantages in various applications including wastewater treatment and pharmaceutical separations.Expand Specific Solutions

Leading Companies in Nanofiltration Membrane Industry

The nanofiltration membrane market is experiencing robust growth in the wastewater treatment sector, currently transitioning from early maturity to expansion phase. Market size is projected to increase significantly due to growing water scarcity concerns and stricter environmental regulations worldwide. Technologically, companies like Vontron Technology, Zhejiang Jinmo Environment Technology, and Siemens AG are leading innovation in membrane performance enhancement, while academic institutions including Tianjin University, Tongji University, and National University of Singapore are advancing fundamental research in membrane materials and processes. The competitive landscape features both specialized membrane manufacturers and diversified industrial conglomerates like Henkel and China Petroleum & Chemical Corp, indicating the technology's strategic importance across multiple sectors.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary nanofiltration membrane technology specifically designed for petrochemical wastewater treatment. Their approach combines ceramic-supported polymeric membranes with specialized surface modifications that resist fouling from oil, grease, and chemical contaminants common in refinery effluents. The company's dual-layer composite membranes incorporate graphene oxide nanosheets that enhance both permeability and selectivity, achieving removal efficiencies exceeding 99% for most organic pollutants while maintaining flux rates 40% higher than conventional membranes. Sinopec has implemented these membranes in closed-loop water recycling systems at multiple refineries, reducing freshwater consumption by up to 60%. Their latest innovation includes thermally-responsive nanofiltration membranes that can self-clean when exposed to moderate temperature changes, significantly extending membrane lifetime in challenging petrochemical environments.

Strengths: Exceptional chemical and thermal stability specifically engineered for petrochemical applications, with documented resistance to common industry solvents and pH extremes. Proprietary anti-fouling technology particularly effective against oily wastewater. Weaknesses: Higher manufacturing costs compared to standard membranes, and limited application range outside of petrochemical and heavy industrial wastewater treatment.

Tianjin University

Technical Solution: Tianjin University has developed several innovative approaches to nanofiltration membrane enhancement for wastewater treatment applications. Their research team has pioneered the development of electrospun nanofiber-supported thin film composite membranes that demonstrate significantly improved mechanical strength and chlorine resistance compared to conventional membranes. These membranes incorporate a unique three-dimensional nanofiber scaffold that increases effective filtration area while reducing internal concentration polarization. Another significant innovation from Tianjin University is their work on graphene oxide-modified nanofiltration membranes with precisely controlled interlayer spacing, allowing for exceptional selectivity in removing organic micropollutants while maintaining high water flux. Their researchers have also developed novel surface modification techniques using zwitterionic polymers that dramatically reduce membrane fouling in complex wastewater streams. Recent work has focused on incorporating photocatalytic nanoparticles into membrane structures, creating self-cleaning membranes that can degrade organic foulants under visible light irradiation.

Strengths: Exceptional mechanical durability and chemical resistance compared to conventional membranes, with documented chlorine tolerance 5-10 times higher than commercial alternatives. Innovative approaches to self-cleaning membrane surfaces that address the critical issue of fouling in wastewater applications. Weaknesses: Some technologies remain at laboratory scale with challenges in manufacturing scalability. Higher production costs compared to conventional membranes may limit adoption in cost-sensitive markets.

Key Patents and Innovations in Membrane Technology

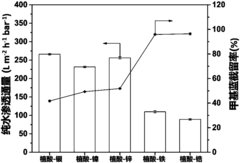

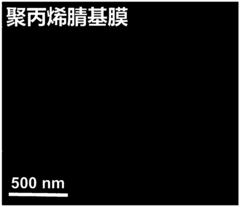

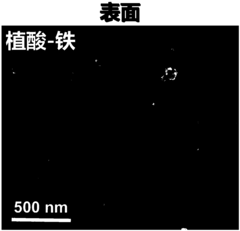

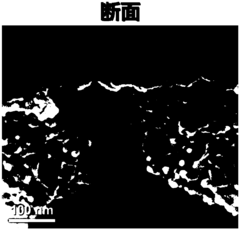

Preparation method of ultra-thin anti-contamination composite nanofiltration membrane assembled from phytic acid

PatentActiveCN109012183A

Innovation

- The phase inversion method is used to use phytic acid as the functional molecular unit in aqueous solution, and transition metal ions are used for one-step assembly to prepare a super-hydrophilic composite nanofiltration membrane with a thickness of about 8 nanometers, which simplifies the preparation process and avoids the use of organic solvents.

Environmental Impact and Sustainability Considerations

The environmental implications of nanofiltration membrane technology in wastewater treatment extend far beyond operational efficiency. As global water scarcity intensifies, these advanced filtration systems significantly reduce the environmental footprint of water treatment processes while promoting sustainable resource management.

Nanofiltration membranes demonstrate remarkable energy efficiency compared to conventional treatment methods, consuming approximately 30-50% less energy than reverse osmosis systems while achieving comparable contaminant removal rates. This energy reduction directly translates to lower greenhouse gas emissions associated with wastewater treatment operations, supporting climate change mitigation efforts across industrial and municipal sectors.

The technology's ability to selectively remove contaminants while preserving beneficial minerals represents a critical advancement in sustainable water management. By enabling the recovery of valuable resources from wastewater streams, including phosphorus, nitrogen compounds, and certain metals, nanofiltration systems support circular economy principles and reduce dependency on virgin material extraction, which often involves environmentally destructive mining practices.

Life cycle assessments of nanofiltration membrane systems reveal significant environmental advantages when evaluated against traditional treatment technologies. Studies indicate that despite the energy and materials required for membrane production, the operational benefits over the technology's lifespan result in net positive environmental outcomes, particularly when membranes incorporate bio-based or recycled materials in their construction.

Water reuse facilitated by nanofiltration technology directly addresses water scarcity challenges by reducing freshwater withdrawal requirements. Industrial facilities implementing these systems report freshwater consumption reductions of up to 70%, substantially decreasing pressure on local watersheds and aquatic ecosystems. This preservation of natural water systems maintains biodiversity and ecosystem services essential for environmental resilience.

The chemical footprint reduction achieved through nanofiltration implementation presents another significant environmental benefit. By minimizing or eliminating the need for chemical additives commonly used in conventional treatment processes, these systems reduce the discharge of potentially harmful substances into receiving water bodies, protecting aquatic life and downstream water quality.

Recent advancements in membrane manufacturing techniques have focused on incorporating sustainable materials and production processes. Bio-inspired membranes utilizing naturally derived polymers and antimicrobial compounds demonstrate promising performance while reducing reliance on petroleum-based materials, further enhancing the technology's sustainability profile and aligning with global efforts toward reduced petrochemical dependency.

Nanofiltration membranes demonstrate remarkable energy efficiency compared to conventional treatment methods, consuming approximately 30-50% less energy than reverse osmosis systems while achieving comparable contaminant removal rates. This energy reduction directly translates to lower greenhouse gas emissions associated with wastewater treatment operations, supporting climate change mitigation efforts across industrial and municipal sectors.

The technology's ability to selectively remove contaminants while preserving beneficial minerals represents a critical advancement in sustainable water management. By enabling the recovery of valuable resources from wastewater streams, including phosphorus, nitrogen compounds, and certain metals, nanofiltration systems support circular economy principles and reduce dependency on virgin material extraction, which often involves environmentally destructive mining practices.

Life cycle assessments of nanofiltration membrane systems reveal significant environmental advantages when evaluated against traditional treatment technologies. Studies indicate that despite the energy and materials required for membrane production, the operational benefits over the technology's lifespan result in net positive environmental outcomes, particularly when membranes incorporate bio-based or recycled materials in their construction.

Water reuse facilitated by nanofiltration technology directly addresses water scarcity challenges by reducing freshwater withdrawal requirements. Industrial facilities implementing these systems report freshwater consumption reductions of up to 70%, substantially decreasing pressure on local watersheds and aquatic ecosystems. This preservation of natural water systems maintains biodiversity and ecosystem services essential for environmental resilience.

The chemical footprint reduction achieved through nanofiltration implementation presents another significant environmental benefit. By minimizing or eliminating the need for chemical additives commonly used in conventional treatment processes, these systems reduce the discharge of potentially harmful substances into receiving water bodies, protecting aquatic life and downstream water quality.

Recent advancements in membrane manufacturing techniques have focused on incorporating sustainable materials and production processes. Bio-inspired membranes utilizing naturally derived polymers and antimicrobial compounds demonstrate promising performance while reducing reliance on petroleum-based materials, further enhancing the technology's sustainability profile and aligning with global efforts toward reduced petrochemical dependency.

Regulatory Framework for Water Treatment Technologies

The regulatory landscape for water treatment technologies, particularly nanofiltration membranes, has evolved significantly in response to growing water scarcity and pollution concerns worldwide. At the international level, organizations such as the World Health Organization (WHO) and the United Nations Environment Programme (UNEP) have established guidelines that influence national regulatory frameworks for water quality standards and treatment technologies.

In the United States, the Environmental Protection Agency (EPA) regulates water treatment technologies under the Safe Drinking Water Act and Clean Water Act. The EPA's National Primary Drinking Water Regulations set legally enforceable standards that apply to public water systems, while the National Pollutant Discharge Elimination System (NPDES) regulates point source discharges. These frameworks increasingly recognize nanofiltration as a Best Available Technology (BAT) for removing specific contaminants.

The European Union implements the Water Framework Directive and Drinking Water Directive, which establish comprehensive water quality objectives and monitoring requirements. The EU has also developed specific regulations for innovative water treatment technologies through its REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) program, which impacts the materials used in nanofiltration membrane manufacturing.

In Asia, China has implemented the Water Pollution Prevention and Control Law and established the "Water Ten Plan" with stringent discharge standards that drive adoption of advanced filtration technologies. Japan's regulatory framework emphasizes water reuse technologies, while Singapore's PUB (National Water Agency) has pioneered regulatory approaches that actively encourage innovation in membrane technologies.

Emerging regulatory trends include the development of specific standards for membrane performance certification, such as NSF/ANSI standards in the United States and similar frameworks in other regions. Additionally, regulations increasingly focus on the entire lifecycle of membrane technologies, including disposal and environmental impact of spent membranes.

The regulatory landscape also shows a shift toward incentive-based approaches, with many countries offering tax benefits, grants, and expedited permitting for facilities implementing advanced water treatment technologies. These incentives have become significant market drivers for nanofiltration membrane adoption in industrial and municipal applications.

Compliance costs represent a substantial factor in technology adoption decisions, with regulatory requirements often determining the economic viability of nanofiltration implementations. As regulations become more stringent regarding micropollutants, pharmaceutical residues, and emerging contaminants, the market for enhanced nanofiltration membranes is expected to expand significantly in the coming decade.

In the United States, the Environmental Protection Agency (EPA) regulates water treatment technologies under the Safe Drinking Water Act and Clean Water Act. The EPA's National Primary Drinking Water Regulations set legally enforceable standards that apply to public water systems, while the National Pollutant Discharge Elimination System (NPDES) regulates point source discharges. These frameworks increasingly recognize nanofiltration as a Best Available Technology (BAT) for removing specific contaminants.

The European Union implements the Water Framework Directive and Drinking Water Directive, which establish comprehensive water quality objectives and monitoring requirements. The EU has also developed specific regulations for innovative water treatment technologies through its REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) program, which impacts the materials used in nanofiltration membrane manufacturing.

In Asia, China has implemented the Water Pollution Prevention and Control Law and established the "Water Ten Plan" with stringent discharge standards that drive adoption of advanced filtration technologies. Japan's regulatory framework emphasizes water reuse technologies, while Singapore's PUB (National Water Agency) has pioneered regulatory approaches that actively encourage innovation in membrane technologies.

Emerging regulatory trends include the development of specific standards for membrane performance certification, such as NSF/ANSI standards in the United States and similar frameworks in other regions. Additionally, regulations increasingly focus on the entire lifecycle of membrane technologies, including disposal and environmental impact of spent membranes.

The regulatory landscape also shows a shift toward incentive-based approaches, with many countries offering tax benefits, grants, and expedited permitting for facilities implementing advanced water treatment technologies. These incentives have become significant market drivers for nanofiltration membrane adoption in industrial and municipal applications.

Compliance costs represent a substantial factor in technology adoption decisions, with regulatory requirements often determining the economic viability of nanofiltration implementations. As regulations become more stringent regarding micropollutants, pharmaceutical residues, and emerging contaminants, the market for enhanced nanofiltration membranes is expected to expand significantly in the coming decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!