Analysis of Cryogenic Electronics for Energy Storage Solutions

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Background and Objectives

Cryogenic electronics represents a frontier technology domain that operates electronic systems at extremely low temperatures, typically below -150°C (123K). The field emerged in the mid-20th century alongside advancements in superconductivity research but has gained significant momentum in recent decades due to its potential applications in quantum computing, space exploration, and energy systems. The fundamental principle driving cryogenic electronics is the dramatic improvement in electrical conductivity and reduction in thermal noise that materials exhibit at ultra-low temperatures, enabling unprecedented performance characteristics.

The evolution of cryogenic electronics has been marked by several key milestones, including the development of Josephson junctions in the 1960s, superconducting quantum interference devices (SQUIDs) in the 1970s, and more recently, superconducting qubits for quantum computing. These advancements have progressively expanded the application landscape from primarily scientific instruments to practical engineering solutions across multiple industries.

In the context of energy storage solutions, cryogenic electronics presents transformative potential by enabling more efficient energy conversion, reduced transmission losses, and novel storage mechanisms. The integration of superconducting materials and cryogenic semiconductor devices could potentially revolutionize how energy is managed in grid-scale applications, offering solutions to critical challenges in renewable energy integration and demand response systems.

The primary technical objectives for cryogenic electronics in energy storage applications include developing reliable semiconductor devices that can operate efficiently at cryogenic temperatures, creating interface systems between cryogenic and room-temperature environments, and designing energy-efficient cooling systems that don't offset the efficiency gains of cryogenic operation. Additionally, there is a pressing need to develop standardized testing methodologies and performance metrics specifically for cryogenic electronic components in energy applications.

Current research trajectories are focused on materials science innovations, particularly in the realm of high-temperature superconductors that could operate at more economically viable temperatures (above 77K). Parallel efforts are directed toward cryogenic CMOS technology that maintains functionality at extremely low temperatures while offering compatibility with conventional electronics manufacturing processes.

The convergence of advances in superconducting materials, cryogenic semiconductor physics, and practical cooling technologies is expected to determine the feasibility timeline for widespread implementation of cryogenic electronics in energy storage systems. The field stands at a critical juncture where theoretical advantages must be translated into practical, scalable, and economically viable solutions to address growing global energy challenges.

The evolution of cryogenic electronics has been marked by several key milestones, including the development of Josephson junctions in the 1960s, superconducting quantum interference devices (SQUIDs) in the 1970s, and more recently, superconducting qubits for quantum computing. These advancements have progressively expanded the application landscape from primarily scientific instruments to practical engineering solutions across multiple industries.

In the context of energy storage solutions, cryogenic electronics presents transformative potential by enabling more efficient energy conversion, reduced transmission losses, and novel storage mechanisms. The integration of superconducting materials and cryogenic semiconductor devices could potentially revolutionize how energy is managed in grid-scale applications, offering solutions to critical challenges in renewable energy integration and demand response systems.

The primary technical objectives for cryogenic electronics in energy storage applications include developing reliable semiconductor devices that can operate efficiently at cryogenic temperatures, creating interface systems between cryogenic and room-temperature environments, and designing energy-efficient cooling systems that don't offset the efficiency gains of cryogenic operation. Additionally, there is a pressing need to develop standardized testing methodologies and performance metrics specifically for cryogenic electronic components in energy applications.

Current research trajectories are focused on materials science innovations, particularly in the realm of high-temperature superconductors that could operate at more economically viable temperatures (above 77K). Parallel efforts are directed toward cryogenic CMOS technology that maintains functionality at extremely low temperatures while offering compatibility with conventional electronics manufacturing processes.

The convergence of advances in superconducting materials, cryogenic semiconductor physics, and practical cooling technologies is expected to determine the feasibility timeline for widespread implementation of cryogenic electronics in energy storage systems. The field stands at a critical juncture where theoretical advantages must be translated into practical, scalable, and economically viable solutions to address growing global energy challenges.

Market Analysis for Cryogenic Energy Storage Systems

The global market for cryogenic energy storage systems is experiencing significant growth, driven by increasing demand for efficient and sustainable energy storage solutions. Current market valuations indicate that the cryogenic energy storage sector is projected to reach substantial market size by 2030, with a compound annual growth rate exceeding traditional energy storage technologies. This growth is primarily fueled by the rising need for grid-scale energy storage to support renewable energy integration and grid stability.

Regionally, Europe leads the market adoption of cryogenic energy storage technologies, with the UK and Germany at the forefront of commercial implementations. North America follows closely, with significant research investments and pilot projects, particularly in California and New York. The Asia-Pacific region, especially China and Japan, is rapidly expanding its market share through government-backed initiatives and industrial partnerships focused on cryogenic storage technologies.

Market segmentation reveals distinct application sectors for cryogenic energy storage systems. The utility-scale segment currently dominates market share, where large-scale installations provide grid balancing and peak shaving capabilities. The industrial sector represents the second-largest market segment, utilizing cryogenic systems for process cooling integration and waste heat recovery. Commercial applications are emerging as a high-growth segment, particularly in data centers and healthcare facilities requiring both energy storage and cooling capabilities.

Consumer demand patterns indicate strong interest in long-duration energy storage solutions that can provide power for 8+ hours, where cryogenic systems offer competitive advantages over lithium-ion batteries. Market research shows that end-users increasingly value the dual-functionality of cryogenic systems that provide both electricity storage and cooling capabilities, creating unique value propositions in specific industries.

Key market drivers include the declining costs of liquefaction technologies, improved round-trip efficiencies of cryogenic systems, and increasing carbon pricing mechanisms that favor low-carbon storage solutions. Regulatory frameworks supporting clean energy transitions, particularly in Europe and parts of North America, are creating favorable market conditions for cryogenic storage deployment.

Market barriers remain significant, including high initial capital costs compared to conventional storage technologies, limited awareness among potential end-users, and technical challenges related to system integration. The competitive landscape includes established energy storage providers expanding into cryogenic technologies, specialized cryogenic engineering firms, and new market entrants focusing on innovative system designs and materials.

Regionally, Europe leads the market adoption of cryogenic energy storage technologies, with the UK and Germany at the forefront of commercial implementations. North America follows closely, with significant research investments and pilot projects, particularly in California and New York. The Asia-Pacific region, especially China and Japan, is rapidly expanding its market share through government-backed initiatives and industrial partnerships focused on cryogenic storage technologies.

Market segmentation reveals distinct application sectors for cryogenic energy storage systems. The utility-scale segment currently dominates market share, where large-scale installations provide grid balancing and peak shaving capabilities. The industrial sector represents the second-largest market segment, utilizing cryogenic systems for process cooling integration and waste heat recovery. Commercial applications are emerging as a high-growth segment, particularly in data centers and healthcare facilities requiring both energy storage and cooling capabilities.

Consumer demand patterns indicate strong interest in long-duration energy storage solutions that can provide power for 8+ hours, where cryogenic systems offer competitive advantages over lithium-ion batteries. Market research shows that end-users increasingly value the dual-functionality of cryogenic systems that provide both electricity storage and cooling capabilities, creating unique value propositions in specific industries.

Key market drivers include the declining costs of liquefaction technologies, improved round-trip efficiencies of cryogenic systems, and increasing carbon pricing mechanisms that favor low-carbon storage solutions. Regulatory frameworks supporting clean energy transitions, particularly in Europe and parts of North America, are creating favorable market conditions for cryogenic storage deployment.

Market barriers remain significant, including high initial capital costs compared to conventional storage technologies, limited awareness among potential end-users, and technical challenges related to system integration. The competitive landscape includes established energy storage providers expanding into cryogenic technologies, specialized cryogenic engineering firms, and new market entrants focusing on innovative system designs and materials.

Technical Challenges in Low-Temperature Electronics

Cryogenic electronics face significant technical barriers when operating at extremely low temperatures, particularly in energy storage applications. The fundamental challenge stems from the behavior of semiconductor materials, which exhibit carrier freeze-out at temperatures below 50K. This phenomenon causes increased resistance and altered electrical properties, rendering conventional semiconductor designs ineffective. Silicon-based devices, which dominate room-temperature electronics, experience severe performance degradation with reduced carrier mobility and increased threshold voltage shifts.

Material selection presents another critical challenge, as thermal expansion coefficient mismatches between different components can lead to mechanical stress, cracking, and connection failures during thermal cycling. Traditional solder materials become brittle at cryogenic temperatures, while standard PCB materials may not maintain their structural integrity, necessitating specialized alternatives like polyimide-based substrates or ceramic materials.

Power management in cryogenic environments introduces unique difficulties, as conventional voltage regulators and power converters exhibit significantly altered characteristics. The efficiency of power conversion circuits decreases dramatically, while parasitic effects become more pronounced. Additionally, the thermal management paradigm inverts at cryogenic temperatures – rather than removing heat, systems must often prevent excessive cooling or manage heat distribution to maintain operational temperature windows.

Signal integrity deteriorates at low temperatures due to changes in dielectric constants and increased impedance mismatches. Transmission line effects become more pronounced, requiring redesigned signal routing strategies. Conventional passive components like capacitors and resistors experience value shifts of up to 80% when cooled to liquid nitrogen temperatures, necessitating compensation circuits or specialized component selection.

Reliability testing presents methodological challenges, as accelerated life testing becomes problematic when thermal acceleration factors no longer follow Arrhenius relationships at extremely low temperatures. The lack of standardized testing protocols for cryogenic electronics further complicates qualification processes. Thermal cycling between ambient and cryogenic temperatures introduces unique failure modes not seen in conventional electronics, including microfractures in packaging materials and delamination at material interfaces.

Packaging solutions must address both electrical performance and thermal management concerns. Hermetic sealing becomes crucial to prevent moisture condensation during temperature transitions, while thermal isolation strategies must be implemented to minimize heat leakage paths. Conventional encapsulation materials become brittle and may crack during thermal cycling, requiring specialized formulations with matched thermal expansion properties.

Material selection presents another critical challenge, as thermal expansion coefficient mismatches between different components can lead to mechanical stress, cracking, and connection failures during thermal cycling. Traditional solder materials become brittle at cryogenic temperatures, while standard PCB materials may not maintain their structural integrity, necessitating specialized alternatives like polyimide-based substrates or ceramic materials.

Power management in cryogenic environments introduces unique difficulties, as conventional voltage regulators and power converters exhibit significantly altered characteristics. The efficiency of power conversion circuits decreases dramatically, while parasitic effects become more pronounced. Additionally, the thermal management paradigm inverts at cryogenic temperatures – rather than removing heat, systems must often prevent excessive cooling or manage heat distribution to maintain operational temperature windows.

Signal integrity deteriorates at low temperatures due to changes in dielectric constants and increased impedance mismatches. Transmission line effects become more pronounced, requiring redesigned signal routing strategies. Conventional passive components like capacitors and resistors experience value shifts of up to 80% when cooled to liquid nitrogen temperatures, necessitating compensation circuits or specialized component selection.

Reliability testing presents methodological challenges, as accelerated life testing becomes problematic when thermal acceleration factors no longer follow Arrhenius relationships at extremely low temperatures. The lack of standardized testing protocols for cryogenic electronics further complicates qualification processes. Thermal cycling between ambient and cryogenic temperatures introduces unique failure modes not seen in conventional electronics, including microfractures in packaging materials and delamination at material interfaces.

Packaging solutions must address both electrical performance and thermal management concerns. Hermetic sealing becomes crucial to prevent moisture condensation during temperature transitions, while thermal isolation strategies must be implemented to minimize heat leakage paths. Conventional encapsulation materials become brittle and may crack during thermal cycling, requiring specialized formulations with matched thermal expansion properties.

Current Cryogenic Circuit Solutions for Energy Storage

01 Superconducting electronic devices

Cryogenic electronics leverages superconducting materials that exhibit zero electrical resistance at extremely low temperatures. These devices include superconducting quantum interference devices (SQUIDs), superconducting qubits, and other quantum computing components that operate at temperatures near absolute zero. The superconducting state enables high-speed signal processing, ultra-sensitive magnetic field detection, and quantum information processing with minimal energy loss.- Superconducting electronic devices: Cryogenic electronics leverages superconducting materials that exhibit zero electrical resistance at extremely low temperatures. These superconducting electronic devices offer advantages such as ultra-high speed operation, minimal power consumption, and quantum coherence. Applications include quantum computing, high-precision sensing, and advanced communication systems that require minimal signal loss and noise.

- Cryogenic cooling systems for electronics: Specialized cooling systems are essential for maintaining electronic components at cryogenic temperatures. These systems employ various refrigeration techniques including liquid helium/nitrogen circulation, pulse tube coolers, and Stirling cycle refrigerators. Advanced thermal management solutions ensure stable operating temperatures while addressing challenges such as thermal cycling, condensation prevention, and efficient heat transfer from electronic components.

- Cryogenic electronic packaging and interconnects: Electronic packaging for cryogenic environments requires specialized materials and designs to accommodate thermal contraction, maintain signal integrity, and ensure reliable operation at extreme temperature differentials. These solutions include custom interconnect technologies, thermal isolation strategies, and materials with matched coefficients of thermal expansion to prevent mechanical stress and failure during cooling cycles.

- Quantum computing hardware: Cryogenic electronics form the foundation of quantum computing systems, where qubits must operate at near-absolute zero temperatures to maintain quantum coherence. These systems integrate specialized control electronics, readout circuits, and signal processing capabilities that can function reliably at cryogenic temperatures while minimizing heat load and electromagnetic interference that could disrupt delicate quantum states.

- Cryogenic sensors and detectors: Ultra-sensitive sensors and detectors operating at cryogenic temperatures offer unprecedented measurement capabilities across various applications. These include superconducting quantum interference devices (SQUIDs), transition edge sensors, and bolometers that can detect extremely weak magnetic fields, radiation, or minute temperature changes. The enhanced sensitivity results from reduced thermal noise and quantum effects that emerge at very low temperatures.

02 Cryogenic cooling systems for electronics

Specialized cooling systems are essential for maintaining electronic components at cryogenic temperatures. These systems employ various refrigeration techniques including liquid helium/nitrogen circulation, pulse tube coolers, Stirling coolers, and adiabatic demagnetization refrigerators. Advanced thermal management solutions ensure stable operating temperatures while minimizing vibration that could disrupt sensitive electronic operations. These cooling technologies enable practical implementation of superconducting and quantum electronic devices.Expand Specific Solutions03 Cryogenic electronic packaging and interconnects

Specialized packaging solutions are required for electronics operating at cryogenic temperatures. These include thermal isolation techniques, specialized materials with matched thermal expansion coefficients, and vacuum-sealed enclosures. Interconnect technologies must maintain electrical performance across extreme temperature gradients while minimizing heat leakage into the cold environment. Advanced packaging approaches incorporate multi-layer structures with thermal barriers and specialized bonding techniques to ensure reliable operation under extreme conditions.Expand Specific Solutions04 Quantum computing hardware

Cryogenic electronics form the foundation of quantum computing systems. These include control electronics for manipulating and reading quantum states, quantum processors with multiple qubits, and specialized interface circuits that bridge the quantum and classical computing domains. Operating at millikelvin temperatures, these systems require precise timing control, ultra-low noise performance, and specialized signal processing to maintain quantum coherence while enabling complex quantum algorithms.Expand Specific Solutions05 Cryogenic sensors and detectors

Ultra-sensitive sensors and detectors that operate at cryogenic temperatures offer unprecedented measurement capabilities. These include bolometers for detecting infrared and microwave radiation, single-photon detectors for quantum communications, and specialized magnetic field sensors. The extreme sensitivity is achieved through reduced thermal noise and quantum effects that emerge at low temperatures. Applications span from astronomical observations to quantum key distribution systems and medical imaging technologies.Expand Specific Solutions

Leading Companies in Cryogenic Electronics Industry

The cryogenic electronics market for energy storage solutions is in its growth phase, characterized by increasing investments and technological advancements. The market is expanding rapidly with an estimated value of several billion dollars, driven by the global push for renewable energy integration and grid stability solutions. Companies like Highview Enterprises and Huawei Digital Power are pioneering commercial-scale cryogenic energy storage systems, while established industrial gas specialists such as Air Liquide and Messer SE are providing critical infrastructure components. Research institutions including Fraunhofer-Gesellschaft, Naval Research Laboratory, and ShanghaiTech University are advancing fundamental technologies. The ecosystem shows varying degrees of technological maturity, with some players focused on commercialization while others are still in research and development phases, indicating a dynamic competitive landscape with significant growth potential.

Highview Enterprises Ltd.

Technical Solution: Highview Enterprises has developed a proprietary Liquid Air Energy Storage (LAES) system that utilizes cryogenic principles for grid-scale energy storage. Their CRYOBattery technology liquefies air by cooling it to -196°C, storing it in insulated tanks, and later expanding it through a turbine to generate electricity when needed. The system incorporates specialized cryogenic electronics that can operate efficiently at extremely low temperatures, including temperature sensors, pressure monitors, and control systems designed to withstand cryogenic conditions. Highview's approach integrates waste heat/cold utilization from nearby industrial processes to improve round-trip efficiency, which has reached approximately 60-70% in their commercial installations. Their modular design allows for scalability from 10MW to multiple GW systems with discharge durations ranging from 4 to over 24 hours, making it particularly suitable for long-duration energy storage applications.

Strengths: Long-duration storage capability (hours to days); uses established industrial components; no geographical constraints unlike pumped hydro; zero emissions during operation; and can provide multiple grid services simultaneously. Weaknesses: Lower round-trip efficiency compared to batteries; requires significant initial capital investment; complex thermal management systems; and relatively new technology with limited long-term operational data.

Air Liquide SA

Technical Solution: Air Liquide has developed advanced cryogenic electronics systems specifically designed for energy storage applications that leverage their expertise in industrial gas management. Their technology focuses on superconducting magnetic energy storage (SMES) systems that operate at cryogenic temperatures, typically using liquid helium or nitrogen as coolants. These systems store energy in magnetic fields created by direct current flowing through superconducting coils. Air Liquide's innovation lies in their specialized cryogenic electronic control systems that manage the cooling infrastructure, ensuring optimal temperature maintenance for superconducting materials while minimizing energy losses. Their proprietary cryostats incorporate advanced thermal insulation technologies that reduce heat leakage by up to 85% compared to conventional systems. Additionally, Air Liquide has developed specialized power electronics that can operate efficiently at extremely low temperatures, including cryogenic-compatible sensors, switches, and control circuits that maintain functionality at temperatures approaching absolute zero.

Strengths: Extremely rapid response times (milliseconds); nearly unlimited charge-discharge cycles; very high power density; and minimal degradation over time due to static energy storage mechanism. Weaknesses: Limited energy storage duration (typically minutes rather than hours); high capital costs for cooling infrastructure; continuous energy consumption for cryogenic cooling systems; and complexity of maintaining superconducting conditions consistently.

Key Patents in Superconducting Electronic Components

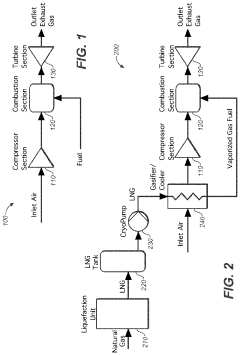

A method of storing energy and a cryogenic energy storage system

PatentWO2007096656A1

Innovation

- A cryogenic energy storage system using a cryogenic working fluid, such as liquid air, that stores energy by pumping, heating, and expanding the cryogen to drive a turbine for electricity generation or propulsion, leveraging waste heat and ambient temperature for enhanced efficiency.

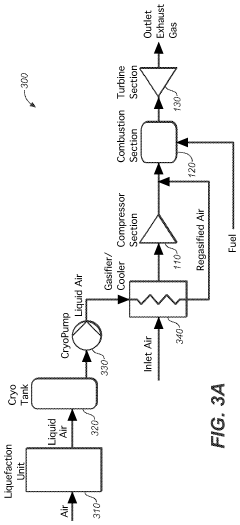

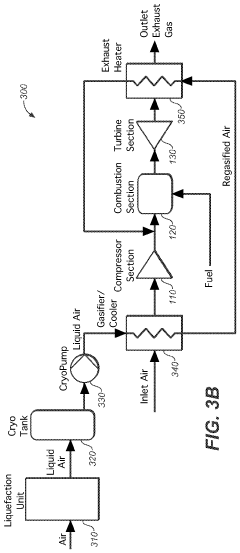

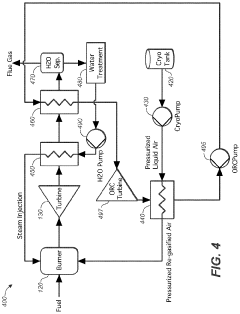

Cryogenic liquid energy storage

PatentActiveUS11686527B2

Innovation

- The method involves using cryogenic liquids like liquefied natural gas (LNG) and liquefied air to store thermal energy, which is then regasified and used to enhance the efficiency and power output of combustion turbine generators by cooling inlet air and providing a fuel source, thereby addressing both over-generation and under-generation issues.

Materials Science Advancements for Low-Temperature Applications

Recent advancements in materials science have revolutionized the field of cryogenic electronics for energy storage solutions. The development of novel materials capable of maintaining their electrical and mechanical properties at extremely low temperatures has been crucial for improving the efficiency and reliability of cryogenic energy storage systems.

Superconducting materials represent one of the most significant breakthroughs in this domain. High-temperature superconductors (HTS) such as YBCO (Yttrium Barium Copper Oxide) and BSCCO (Bismuth Strontium Calcium Copper Oxide) have demonstrated remarkable performance at liquid nitrogen temperatures (77K), significantly reducing cooling costs compared to traditional low-temperature superconductors that require liquid helium cooling.

Composite materials incorporating carbon nanotubes and graphene have shown exceptional thermal conductivity and mechanical stability at cryogenic temperatures. These materials facilitate efficient heat dissipation, a critical factor in preventing thermal runaway in cryogenic electronic systems. Research indicates that graphene-enhanced polymers can maintain flexibility even at temperatures approaching absolute zero, addressing the brittleness issue that plagues conventional materials.

Ceramic substrate materials with tailored thermal expansion coefficients have emerged as essential components for cryogenic electronic packaging. These specialized ceramics minimize thermal stress during cooling cycles, reducing the risk of microcracks and delamination that typically occur at material interfaces when subjected to extreme temperature gradients.

Metamaterials designed specifically for cryogenic environments offer unprecedented control over electromagnetic properties. These engineered structures can enhance signal integrity in cryogenic circuits while minimizing losses, a crucial advantage for quantum computing applications that often operate alongside cryogenic energy storage systems.

Insulation materials have also undergone significant innovation, with aerogels and vacuum-based multi-layer insulation (MLI) systems achieving thermal conductivity values approaching theoretical limits. These advanced insulation solutions dramatically reduce parasitic heat loads, extending the operational lifetime of cryogenic energy storage systems and improving overall energy efficiency.

Cryogenic-compatible adhesives and bonding materials have been developed to maintain structural integrity at low temperatures. These specialized formulations prevent the delamination and cracking issues that conventional adhesives experience when subjected to cryogenic cycling, ensuring long-term reliability of electronic assemblies in energy storage applications.

The integration of these material advances has enabled the miniaturization of cryogenic electronic components while simultaneously improving their performance and reliability. This trend continues to accelerate as interdisciplinary collaboration between materials scientists, electrical engineers, and cryogenic specialists drives innovation in this critical field.

Superconducting materials represent one of the most significant breakthroughs in this domain. High-temperature superconductors (HTS) such as YBCO (Yttrium Barium Copper Oxide) and BSCCO (Bismuth Strontium Calcium Copper Oxide) have demonstrated remarkable performance at liquid nitrogen temperatures (77K), significantly reducing cooling costs compared to traditional low-temperature superconductors that require liquid helium cooling.

Composite materials incorporating carbon nanotubes and graphene have shown exceptional thermal conductivity and mechanical stability at cryogenic temperatures. These materials facilitate efficient heat dissipation, a critical factor in preventing thermal runaway in cryogenic electronic systems. Research indicates that graphene-enhanced polymers can maintain flexibility even at temperatures approaching absolute zero, addressing the brittleness issue that plagues conventional materials.

Ceramic substrate materials with tailored thermal expansion coefficients have emerged as essential components for cryogenic electronic packaging. These specialized ceramics minimize thermal stress during cooling cycles, reducing the risk of microcracks and delamination that typically occur at material interfaces when subjected to extreme temperature gradients.

Metamaterials designed specifically for cryogenic environments offer unprecedented control over electromagnetic properties. These engineered structures can enhance signal integrity in cryogenic circuits while minimizing losses, a crucial advantage for quantum computing applications that often operate alongside cryogenic energy storage systems.

Insulation materials have also undergone significant innovation, with aerogels and vacuum-based multi-layer insulation (MLI) systems achieving thermal conductivity values approaching theoretical limits. These advanced insulation solutions dramatically reduce parasitic heat loads, extending the operational lifetime of cryogenic energy storage systems and improving overall energy efficiency.

Cryogenic-compatible adhesives and bonding materials have been developed to maintain structural integrity at low temperatures. These specialized formulations prevent the delamination and cracking issues that conventional adhesives experience when subjected to cryogenic cycling, ensuring long-term reliability of electronic assemblies in energy storage applications.

The integration of these material advances has enabled the miniaturization of cryogenic electronic components while simultaneously improving their performance and reliability. This trend continues to accelerate as interdisciplinary collaboration between materials scientists, electrical engineers, and cryogenic specialists drives innovation in this critical field.

Efficiency Metrics and Performance Benchmarks

Establishing standardized efficiency metrics for cryogenic electronics in energy storage applications is essential for meaningful performance evaluation and comparison. The primary efficiency metric for these systems is the coefficient of performance (COP), which measures the ratio of useful energy output to the energy input required for cooling and operation. In cryogenic environments, this metric becomes particularly critical as maintaining ultra-low temperatures consumes significant energy.

Current benchmarks indicate that state-of-the-art cryogenic electronic systems for energy storage achieve COPs ranging from 0.15 to 0.35 at operating temperatures below 77K. These values represent substantial improvements over previous generations but remain significantly lower than room-temperature electronics, which typically operate with COPs above 0.8.

Power density metrics provide another crucial performance indicator, measuring energy storage capacity per unit volume under cryogenic conditions. Leading superconducting magnetic energy storage (SMES) systems demonstrate power densities of 10-15 kW/L, while cryogenic capacitor technologies reach 5-8 kW/L. These figures represent a 30-40% improvement over conventional room-temperature alternatives but come with the added complexity of cooling requirements.

Energy efficiency loss during temperature cycling presents a significant challenge, with current systems experiencing 8-12% efficiency degradation during cool-down and warm-up cycles. This metric is particularly relevant for applications requiring intermittent operation or maintenance cycles. The industry benchmark aims to reduce this cycling loss to below 5% by 2025.

Response time metrics are equally important for energy storage applications. Current cryogenic electronic systems demonstrate response times of 5-15 milliseconds, compared to 20-50 milliseconds for conventional systems. This performance advantage becomes critical in grid stabilization applications where rapid energy discharge or absorption is essential.

Lifecycle performance benchmarks indicate that cryogenic electronic components maintain 85-90% of their initial performance characteristics after 10,000 operational cycles, outperforming conventional electronics which typically retain only 70-75% of initial performance over similar cycle counts. However, this advantage must be weighed against the higher initial costs and operational complexity.

Thermal management efficiency, measured as the ratio of cooling power to electrical power consumption, currently ranges from 25-35% for leading cryogenic electronic systems. Industry leaders are targeting 40-45% efficiency by 2026 through innovations in insulation materials and cooling cycle optimizations.

AI-based performance prediction models are increasingly being employed to establish dynamic benchmarks that account for varying operational conditions, enabling more accurate efficiency comparisons across different technological approaches and use cases.

Current benchmarks indicate that state-of-the-art cryogenic electronic systems for energy storage achieve COPs ranging from 0.15 to 0.35 at operating temperatures below 77K. These values represent substantial improvements over previous generations but remain significantly lower than room-temperature electronics, which typically operate with COPs above 0.8.

Power density metrics provide another crucial performance indicator, measuring energy storage capacity per unit volume under cryogenic conditions. Leading superconducting magnetic energy storage (SMES) systems demonstrate power densities of 10-15 kW/L, while cryogenic capacitor technologies reach 5-8 kW/L. These figures represent a 30-40% improvement over conventional room-temperature alternatives but come with the added complexity of cooling requirements.

Energy efficiency loss during temperature cycling presents a significant challenge, with current systems experiencing 8-12% efficiency degradation during cool-down and warm-up cycles. This metric is particularly relevant for applications requiring intermittent operation or maintenance cycles. The industry benchmark aims to reduce this cycling loss to below 5% by 2025.

Response time metrics are equally important for energy storage applications. Current cryogenic electronic systems demonstrate response times of 5-15 milliseconds, compared to 20-50 milliseconds for conventional systems. This performance advantage becomes critical in grid stabilization applications where rapid energy discharge or absorption is essential.

Lifecycle performance benchmarks indicate that cryogenic electronic components maintain 85-90% of their initial performance characteristics after 10,000 operational cycles, outperforming conventional electronics which typically retain only 70-75% of initial performance over similar cycle counts. However, this advantage must be weighed against the higher initial costs and operational complexity.

Thermal management efficiency, measured as the ratio of cooling power to electrical power consumption, currently ranges from 25-35% for leading cryogenic electronic systems. Industry leaders are targeting 40-45% efficiency by 2026 through innovations in insulation materials and cooling cycle optimizations.

AI-based performance prediction models are increasingly being employed to establish dynamic benchmarks that account for varying operational conditions, enabling more accurate efficiency comparisons across different technological approaches and use cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!