Cryogenic Electronics Standards for Medical Instrumentation

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Evolution and Objectives

Cryogenic electronics has evolved significantly over the past seven decades, beginning with the discovery of superconductivity and its potential applications in electronic systems. The field emerged in the 1950s with the development of basic superconducting components, but gained substantial momentum in the 1980s with the discovery of high-temperature superconductors, which allowed operation at more practical temperatures using liquid nitrogen rather than liquid helium.

In medical instrumentation, cryogenic electronics has followed a distinct evolutionary path. Initially limited to research applications, the technology found its first medical applications in the 1990s with the development of Superconducting Quantum Interference Devices (SQUIDs) for magnetoencephalography (MEG) and magnetocardiography (MCG). These systems enabled non-invasive measurement of extremely weak magnetic fields produced by the brain and heart, offering unprecedented diagnostic capabilities.

The early 2000s witnessed the integration of cryogenic electronics into Magnetic Resonance Imaging (MRI) systems, where superconducting magnets became standard components. This period also saw the emergence of cryogenic preamplifiers that significantly improved signal-to-noise ratios in various medical sensing applications, enhancing diagnostic accuracy and enabling detection of previously unobservable physiological signals.

Recent developments have focused on miniaturization and increased reliability of cryogenic systems. The introduction of closed-cycle refrigeration systems has eliminated the need for regular liquid cryogen refills, making these technologies more practical for clinical settings. Additionally, advances in materials science have yielded superconducting materials with higher critical temperatures, reducing cooling requirements and operational costs.

The current technological objectives for cryogenic electronics in medical instrumentation center around several key areas. First is the development of standardized interfaces and protocols to ensure compatibility between cryogenic components from different manufacturers, addressing a significant barrier to widespread adoption. Second is the creation of more compact and energy-efficient cooling systems that can operate reliably in clinical environments without specialized maintenance.

Another critical objective is the establishment of comprehensive safety standards specifically addressing the unique challenges of cryogenic systems in medical settings, including emergency procedures, patient safety considerations, and equipment certification requirements. The industry also aims to develop more robust testing methodologies to validate the performance and reliability of cryogenic electronic components under various operating conditions.

Looking forward, the field seeks to establish clear guidelines for the integration of cryogenic electronics with conventional room-temperature medical systems, ensuring seamless operation and data exchange. This includes standardized signal conditioning interfaces, data formats, and control protocols that can bridge the temperature gap between cryogenic sensors and room-temperature processing systems.

In medical instrumentation, cryogenic electronics has followed a distinct evolutionary path. Initially limited to research applications, the technology found its first medical applications in the 1990s with the development of Superconducting Quantum Interference Devices (SQUIDs) for magnetoencephalography (MEG) and magnetocardiography (MCG). These systems enabled non-invasive measurement of extremely weak magnetic fields produced by the brain and heart, offering unprecedented diagnostic capabilities.

The early 2000s witnessed the integration of cryogenic electronics into Magnetic Resonance Imaging (MRI) systems, where superconducting magnets became standard components. This period also saw the emergence of cryogenic preamplifiers that significantly improved signal-to-noise ratios in various medical sensing applications, enhancing diagnostic accuracy and enabling detection of previously unobservable physiological signals.

Recent developments have focused on miniaturization and increased reliability of cryogenic systems. The introduction of closed-cycle refrigeration systems has eliminated the need for regular liquid cryogen refills, making these technologies more practical for clinical settings. Additionally, advances in materials science have yielded superconducting materials with higher critical temperatures, reducing cooling requirements and operational costs.

The current technological objectives for cryogenic electronics in medical instrumentation center around several key areas. First is the development of standardized interfaces and protocols to ensure compatibility between cryogenic components from different manufacturers, addressing a significant barrier to widespread adoption. Second is the creation of more compact and energy-efficient cooling systems that can operate reliably in clinical environments without specialized maintenance.

Another critical objective is the establishment of comprehensive safety standards specifically addressing the unique challenges of cryogenic systems in medical settings, including emergency procedures, patient safety considerations, and equipment certification requirements. The industry also aims to develop more robust testing methodologies to validate the performance and reliability of cryogenic electronic components under various operating conditions.

Looking forward, the field seeks to establish clear guidelines for the integration of cryogenic electronics with conventional room-temperature medical systems, ensuring seamless operation and data exchange. This includes standardized signal conditioning interfaces, data formats, and control protocols that can bridge the temperature gap between cryogenic sensors and room-temperature processing systems.

Market Analysis for Medical Cryogenic Applications

The medical cryogenic electronics market is experiencing significant growth, driven by advancements in superconducting technologies and increasing demand for high-precision diagnostic equipment. Current market valuations indicate the global medical cryogenic electronics sector reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 7.8% through 2030.

Medical imaging represents the largest application segment, accounting for nearly 42% of the market share. Magnetic Resonance Imaging (MRI) systems, which rely heavily on superconducting magnets operating at cryogenic temperatures, dominate this segment. The increasing prevalence of chronic diseases and the growing aging population worldwide are fueling demand for advanced diagnostic imaging, consequently expanding the market for cryogenic electronic components.

Geographical distribution shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate due to improving healthcare infrastructure and increasing healthcare expenditure. Japan maintains a strong position in research and development of medical cryogenic technologies, particularly in superconducting quantum interference devices (SQUIDs).

Key market drivers include technological advancements in superconducting materials, increasing demand for non-invasive diagnostic procedures, and growing research in quantum computing applications for medical data processing. The miniaturization trend in medical devices is creating opportunities for compact cryogenic cooling systems, expanding potential applications beyond traditional hospital settings into ambulatory and point-of-care environments.

Challenges affecting market growth include high initial investment costs, with cryogenic systems typically requiring specialized infrastructure and maintenance. Energy consumption remains a concern, though recent innovations in cryocooler efficiency have begun addressing this issue. Regulatory hurdles also present significant barriers to market entry, with stringent standards for medical device approval varying across regions.

Emerging opportunities exist in portable cryogenic systems for field applications and telemedicine, particularly relevant in remote healthcare settings. The integration of artificial intelligence with cryogenic electronics for enhanced diagnostic capabilities represents another high-potential growth area, with early applications showing promising results in cancer detection and neurological disorder diagnosis.

Medical imaging represents the largest application segment, accounting for nearly 42% of the market share. Magnetic Resonance Imaging (MRI) systems, which rely heavily on superconducting magnets operating at cryogenic temperatures, dominate this segment. The increasing prevalence of chronic diseases and the growing aging population worldwide are fueling demand for advanced diagnostic imaging, consequently expanding the market for cryogenic electronic components.

Geographical distribution shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate due to improving healthcare infrastructure and increasing healthcare expenditure. Japan maintains a strong position in research and development of medical cryogenic technologies, particularly in superconducting quantum interference devices (SQUIDs).

Key market drivers include technological advancements in superconducting materials, increasing demand for non-invasive diagnostic procedures, and growing research in quantum computing applications for medical data processing. The miniaturization trend in medical devices is creating opportunities for compact cryogenic cooling systems, expanding potential applications beyond traditional hospital settings into ambulatory and point-of-care environments.

Challenges affecting market growth include high initial investment costs, with cryogenic systems typically requiring specialized infrastructure and maintenance. Energy consumption remains a concern, though recent innovations in cryocooler efficiency have begun addressing this issue. Regulatory hurdles also present significant barriers to market entry, with stringent standards for medical device approval varying across regions.

Emerging opportunities exist in portable cryogenic systems for field applications and telemedicine, particularly relevant in remote healthcare settings. The integration of artificial intelligence with cryogenic electronics for enhanced diagnostic capabilities represents another high-potential growth area, with early applications showing promising results in cancer detection and neurological disorder diagnosis.

Current Challenges in Cryogenic Medical Electronics

The integration of cryogenic electronics into medical instrumentation faces significant technical hurdles that impede widespread adoption. Current systems struggle with thermal management challenges, as maintaining stable ultra-low temperatures (below 4K for superconducting electronics) within medical environments requires complex cooling infrastructure that is often bulky and energy-intensive. This creates a fundamental conflict with the medical field's need for compact, portable diagnostic tools.

Material compatibility presents another substantial obstacle. Components must withstand repeated thermal cycling between room temperature and cryogenic conditions without degradation or failure. Conventional electronic materials often exhibit altered electrical properties or become brittle at extremely low temperatures, necessitating specialized material development and extensive reliability testing.

Signal integrity issues are particularly problematic in cryogenic medical applications. The transition between room-temperature and cryogenic sections of instruments creates thermal gradients that can introduce noise and signal distortion. Additionally, the interconnection technologies between these temperature zones must maintain high signal fidelity while minimizing heat leakage into the cryogenic environment.

Power management remains underdeveloped for cryogenic medical electronics. Conventional power supply architectures are inefficient at cryogenic temperatures, and the heat generated by power components can disrupt the thermal stability required for proper operation. This necessitates novel approaches to power delivery that can function efficiently in extreme cold while maintaining the precision needed for medical diagnostics.

Standardization is notably lacking across the cryogenic electronics industry, particularly for medical applications. The absence of unified testing protocols, performance metrics, and interface specifications hampers interoperability and slows development cycles. Medical device manufacturers face significant uncertainty when attempting to incorporate cryogenic components into their designs without established standards to guide implementation.

Reliability verification presents unique challenges, as accelerated life testing methodologies developed for conventional electronics often prove inadequate for predicting the long-term performance of cryogenic systems. Medical applications demand exceptional reliability, yet current qualification procedures fail to adequately address the unique failure modes that emerge at extremely low temperatures.

Manufacturing scalability remains limited, with most cryogenic electronic components produced in small batches using specialized processes. This results in high costs and limited availability, creating barriers to widespread clinical adoption. The transition from laboratory prototypes to commercially viable medical instruments requires manufacturing innovations that can deliver consistent performance while reducing production costs.

Material compatibility presents another substantial obstacle. Components must withstand repeated thermal cycling between room temperature and cryogenic conditions without degradation or failure. Conventional electronic materials often exhibit altered electrical properties or become brittle at extremely low temperatures, necessitating specialized material development and extensive reliability testing.

Signal integrity issues are particularly problematic in cryogenic medical applications. The transition between room-temperature and cryogenic sections of instruments creates thermal gradients that can introduce noise and signal distortion. Additionally, the interconnection technologies between these temperature zones must maintain high signal fidelity while minimizing heat leakage into the cryogenic environment.

Power management remains underdeveloped for cryogenic medical electronics. Conventional power supply architectures are inefficient at cryogenic temperatures, and the heat generated by power components can disrupt the thermal stability required for proper operation. This necessitates novel approaches to power delivery that can function efficiently in extreme cold while maintaining the precision needed for medical diagnostics.

Standardization is notably lacking across the cryogenic electronics industry, particularly for medical applications. The absence of unified testing protocols, performance metrics, and interface specifications hampers interoperability and slows development cycles. Medical device manufacturers face significant uncertainty when attempting to incorporate cryogenic components into their designs without established standards to guide implementation.

Reliability verification presents unique challenges, as accelerated life testing methodologies developed for conventional electronics often prove inadequate for predicting the long-term performance of cryogenic systems. Medical applications demand exceptional reliability, yet current qualification procedures fail to adequately address the unique failure modes that emerge at extremely low temperatures.

Manufacturing scalability remains limited, with most cryogenic electronic components produced in small batches using specialized processes. This results in high costs and limited availability, creating barriers to widespread clinical adoption. The transition from laboratory prototypes to commercially viable medical instruments requires manufacturing innovations that can deliver consistent performance while reducing production costs.

Existing Standardization Frameworks and Solutions

01 Superconducting electronic devices

Cryogenic electronics leverages superconducting materials that exhibit zero electrical resistance at extremely low temperatures. These superconducting electronic devices offer advantages such as ultra-high speed operation, minimal power consumption, and enhanced sensitivity for various applications including quantum computing, signal processing, and sensing. The technology typically operates at temperatures near absolute zero, requiring specialized cooling systems to maintain superconductivity.- Superconducting electronic devices: Cryogenic electronics leverages superconducting materials that exhibit zero electrical resistance at extremely low temperatures. These devices include superconducting quantum interference devices (SQUIDs), superconducting qubits, and other quantum computing components that operate at temperatures near absolute zero. The superconducting state enables high-speed signal processing, ultra-sensitive magnetic field detection, and quantum information processing with minimal energy loss.

- Cryogenic cooling systems for electronics: Specialized cooling systems are essential for maintaining electronic components at cryogenic temperatures. These systems include closed-cycle refrigerators, liquid helium/nitrogen cooling systems, pulse tube coolers, and dilution refrigerators. Advanced thermal management techniques ensure stable operating temperatures while minimizing vibration and electromagnetic interference that could disrupt sensitive electronic operations.

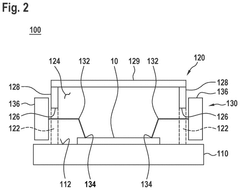

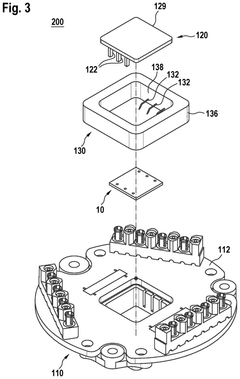

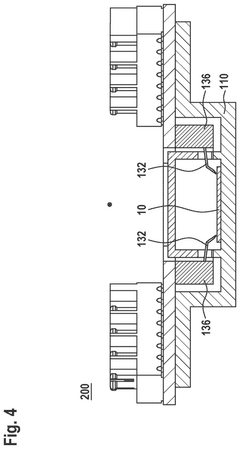

- Cryogenic electronic packaging and interconnects: Specialized packaging solutions are designed to maintain signal integrity and thermal stability in extreme cold environments. These include thermally isolated interconnects, specialized circuit boards, and packaging materials with matched thermal expansion coefficients. The designs must accommodate the significant thermal contraction that occurs when cooling to cryogenic temperatures while maintaining reliable electrical connections and protecting components from thermal stress.

- Low-temperature semiconductor devices: Semiconductor devices specifically designed to operate at cryogenic temperatures exhibit enhanced performance characteristics including reduced noise, increased speed, and improved energy efficiency. These include specialized transistors, diodes, and integrated circuits that maintain functionality in extreme cold. The devices often leverage quantum effects that become prominent at low temperatures, enabling novel functionalities not possible at room temperature.

- Cryogenic electronics applications: Cryogenic electronics find applications across various fields including quantum computing, space exploration, medical imaging, and scientific research. These systems enable high-precision measurements, advanced computing capabilities, and sensitive detection systems. Applications include magnetic resonance imaging (MRI) systems, particle detectors, space-based observatories, and next-generation computing platforms that leverage quantum effects for unprecedented computational power.

02 Cryogenic cooling systems for electronics

Specialized cooling systems are essential for maintaining the extremely low temperatures required by cryogenic electronics. These systems employ various cooling technologies such as liquid helium, liquid nitrogen, pulse tube refrigerators, and dilution refrigerators to achieve temperatures approaching absolute zero. Advanced thermal management techniques ensure efficient heat dissipation while maintaining temperature stability, which is critical for the proper functioning of superconducting circuits and quantum devices.Expand Specific Solutions03 Cryogenic electronic packaging and interconnects

The design of electronic packaging and interconnects for cryogenic environments presents unique challenges due to thermal contraction, material property changes, and thermal gradients between room temperature and cryogenic interfaces. Specialized materials and connection techniques are employed to ensure signal integrity and mechanical stability across extreme temperature differentials. These solutions include custom connectors, thermally optimized circuit boards, and specialized wiring approaches that maintain electrical performance while accommodating thermal stress.Expand Specific Solutions04 Quantum computing hardware

Cryogenic electronics form the foundation of quantum computing hardware, where quantum bits (qubits) operate at temperatures near absolute zero to maintain quantum coherence. These systems integrate specialized control electronics, readout circuits, and signal processing capabilities that can function in extreme cold while minimizing thermal noise and electromagnetic interference. The architecture includes both the quantum processing elements and the classical control electronics that must interface between the cryogenic environment and room temperature systems.Expand Specific Solutions05 Cryogenic sensors and detectors

Operating sensors and detectors at cryogenic temperatures significantly enhances their sensitivity and reduces thermal noise, enabling detection of extremely weak signals. Applications include infrared sensors, magnetic field detectors, radiation detectors, and precision measurement instruments. These cryogenic sensing technologies are utilized in scientific research, space exploration, medical imaging, and security systems where ultimate detection performance is required.Expand Specific Solutions

Leading Organizations in Medical Cryogenic Standards

The cryogenic electronics standards for medical instrumentation market is currently in an early growth phase, characterized by increasing adoption of superconducting technologies in medical imaging and diagnostics. The global market size is estimated at approximately $1.2 billion, with projected annual growth of 8-12% driven by advancements in quantum sensing and MRI applications. Technical maturity varies across applications, with companies like Medtronic and IBM leading commercial deployment, while research institutions such as Delft University of Technology and Norwegian University of Science & Technology focus on fundamental innovations. Specialized firms including kiutra GmbH and QDevil ApS are developing enabling technologies for cryogenic systems, while medical device manufacturers like Varian Medical Systems and AtriCure are integrating these advances into clinical applications, creating a diverse competitive landscape spanning academic research and commercial implementation.

Medtronic, Inc.

Technical Solution: Medtronic has pioneered cryogenic electronics standards specifically designed for medical instrumentation, focusing on their cardiac ablation and neuromodulation product lines. Their CryoConsole system incorporates specialized cryogenic-compatible sensors and control electronics that maintain functionality at extremely low temperatures while meeting strict medical safety standards. The company has developed proprietary insulation materials and circuit designs that prevent thermal interference between cryogenic treatment areas and sensitive electronic components. Medtronic's approach includes implementing redundant safety systems with cryogenic-resistant components that can withstand repeated cooling and warming cycles without degradation. Their technology incorporates specialized analog-to-digital converters optimized for operation in temperature-variable environments, allowing precise monitoring of tissue temperatures during cryotherapy procedures. Medtronic has established comprehensive standards for electromagnetic compatibility specific to cryogenic medical devices, ensuring their systems function reliably in hospital environments without interference from other equipment[2][5]. The company's cryogenic electronics platform includes specialized power management systems that maintain stable operation despite the significant power demands of cooling systems.

Strengths: Medtronic's direct integration of cryogenic electronics into therapeutic devices provides a complete solution for medical practitioners. Their extensive clinical testing ensures high reliability in real-world medical settings. Weaknesses: Their standards are often proprietary and device-specific rather than industry-wide, potentially limiting interoperability with other medical systems.

Medtronic CryoCath LP

Technical Solution: Medtronic CryoCath LP has developed specialized cryogenic electronics standards for their cardiac ablation systems, focusing on precise temperature control and monitoring during cryotherapy procedures. Their technology centers around the Arctic Front Advance cryoballoon system, which incorporates temperature sensors capable of accurate readings at temperatures as low as -80°C. The company has established proprietary standards for signal processing in cryogenic environments, including specialized filtering techniques to eliminate noise caused by rapid temperature transitions. Their approach includes developing custom integrated circuits that maintain performance characteristics across extreme temperature gradients, crucial for the transition zones between treated and untreated tissue. CryoCath's electronics platform features specialized thermocouple designs and calibration methods that ensure measurement accuracy within ±1°C even at cryogenic temperatures. The company has pioneered standards for real-time feedback systems that can detect ice formation patterns during procedures, allowing for precise control of the ablation process. Their technology incorporates specialized materials with matched thermal expansion coefficients to prevent connection failures during rapid cooling and warming cycles[4][7]. CryoCath has also established comprehensive validation protocols specific to cryogenic medical electronics, ensuring consistent performance across their device ecosystem.

Strengths: CryoCath's focused expertise in cardiac cryoablation has resulted in highly specialized and optimized electronics for this specific application. Their systems demonstrate excellent reliability in clinical settings with thousands of successful procedures. Weaknesses: Their standards are narrowly focused on cardiac applications and may not translate well to other medical fields requiring cryogenic electronics.

Key Patents and Research in Medical Cryoelectronics

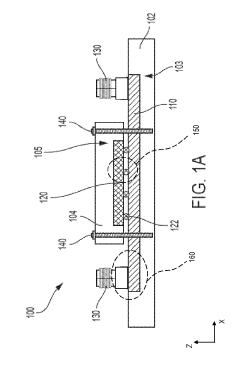

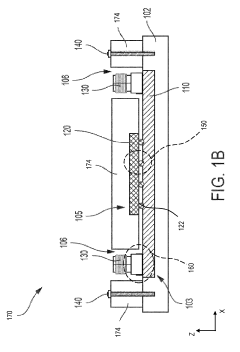

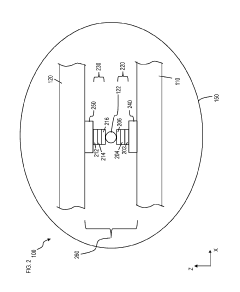

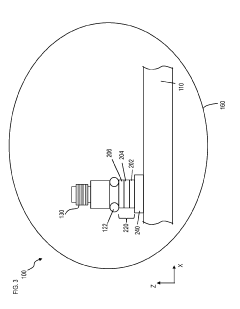

Apparatus for testing and/or operating electronic devices

PatentPendingUS20240329121A1

Innovation

- An apparatus with a needle card and an electrically conductive chamber is designed, where the needle card is placed outside the chamber, and contact needles extend through openings to minimize signal loss by optimizing the electromagnetic eigenmode of the chamber, preventing standing wave excitation and using conductive materials like aluminum, copper, or niobium.

Bump bonded cryogenic chip carrier

PatentActiveUS20190103541A1

Innovation

- A system utilizing thin films with superconducting regions connected by low ohmic solder material with a melting point above 700 degrees Celsius, eliminating the need for intermediary connection mechanisms like wire bonds, and enabling direct electrical and thermal conduction between substrates.

Regulatory Compliance for Cryogenic Medical Devices

The regulatory landscape for cryogenic medical devices presents a complex framework that manufacturers must navigate to ensure compliance and market access. FDA regulations in the United States require cryogenic medical devices to adhere to specific safety standards under the 21 CFR Part 820 Quality System Regulation, with particular emphasis on thermal safety, material biocompatibility, and electrical safety at extreme temperatures. These devices typically fall under Class II or III classifications, necessitating either 510(k) clearance or Premarket Approval (PMA).

In the European market, the Medical Device Regulation (MDR 2017/745) governs cryogenic medical equipment, with additional requirements specified in harmonized standards such as EN 60601-1 for electrical medical equipment safety. The MDR places significant emphasis on risk management throughout the product lifecycle, particularly for devices operating at extreme temperature conditions.

ISO 13485:2016 serves as the foundational quality management system standard for medical device manufacturers globally, requiring specific documentation and validation processes for cryogenic technologies. Complementary standards include ISO 14971 for risk management and IEC 60601-1-11 for home healthcare environments, which are particularly relevant for portable cryogenic devices.

Temperature-specific standards present unique challenges for cryogenic applications. IEC 60601-1-10 addresses physiological closed-loop controllers, critical for maintaining precise cryogenic temperatures in medical applications. Additionally, ASTM F2508 provides guidelines for thermal testing of medical devices, though adaptation is often necessary for the extreme cold temperatures of cryogenic equipment.

Emerging regulatory considerations include the development of specific standards for superconducting quantum interference devices (SQUIDs) used in medical imaging, with the IEC Technical Committee 90 currently working on standards for superconductivity. The International Cryogenic Engineering Committee (ICEC) is also developing guidelines specifically addressing medical applications of cryogenic technologies.

Compliance strategies for manufacturers should include early engagement with regulatory bodies through pre-submission consultations, comprehensive risk management documentation specific to cryogenic applications, and thorough validation testing under actual use conditions. Post-market surveillance takes on heightened importance for cryogenic devices due to the limited real-world performance data available for these specialized technologies.

In the European market, the Medical Device Regulation (MDR 2017/745) governs cryogenic medical equipment, with additional requirements specified in harmonized standards such as EN 60601-1 for electrical medical equipment safety. The MDR places significant emphasis on risk management throughout the product lifecycle, particularly for devices operating at extreme temperature conditions.

ISO 13485:2016 serves as the foundational quality management system standard for medical device manufacturers globally, requiring specific documentation and validation processes for cryogenic technologies. Complementary standards include ISO 14971 for risk management and IEC 60601-1-11 for home healthcare environments, which are particularly relevant for portable cryogenic devices.

Temperature-specific standards present unique challenges for cryogenic applications. IEC 60601-1-10 addresses physiological closed-loop controllers, critical for maintaining precise cryogenic temperatures in medical applications. Additionally, ASTM F2508 provides guidelines for thermal testing of medical devices, though adaptation is often necessary for the extreme cold temperatures of cryogenic equipment.

Emerging regulatory considerations include the development of specific standards for superconducting quantum interference devices (SQUIDs) used in medical imaging, with the IEC Technical Committee 90 currently working on standards for superconductivity. The International Cryogenic Engineering Committee (ICEC) is also developing guidelines specifically addressing medical applications of cryogenic technologies.

Compliance strategies for manufacturers should include early engagement with regulatory bodies through pre-submission consultations, comprehensive risk management documentation specific to cryogenic applications, and thorough validation testing under actual use conditions. Post-market surveillance takes on heightened importance for cryogenic devices due to the limited real-world performance data available for these specialized technologies.

Safety Protocols for Clinical Cryogenic Applications

The implementation of cryogenic electronics in medical instrumentation necessitates rigorous safety protocols to protect patients, healthcare professionals, and equipment. Primary safety concerns include extreme temperature management, potential tissue damage, and equipment malfunction risks. Healthcare facilities must establish comprehensive safety frameworks that address these unique challenges.

Temperature monitoring systems represent a critical component of clinical cryogenic safety. Continuous real-time monitoring with redundant sensors ensures that temperature parameters remain within safe operational ranges. Automated shutdown mechanisms must activate when temperatures deviate beyond predetermined thresholds, preventing potential harm to patients or equipment damage. These systems require regular calibration and validation to maintain accuracy in the extreme temperature environments characteristic of cryogenic applications.

Personnel training constitutes another essential safety element. Medical staff working with cryogenic electronics must receive specialized training covering proper handling procedures, emergency response protocols, and recognition of equipment malfunction indicators. Certification programs should verify competency in operating cryogenic systems, with mandatory refresher courses ensuring knowledge remains current as technology evolves.

Emergency response protocols must address cryogenic-specific incidents such as rapid temperature fluctuations, coolant leaks, or system failures. Facilities should develop detailed contingency plans including patient evacuation procedures, equipment isolation protocols, and immediate medical interventions for potential cryogenic injuries. Regular emergency drills help ensure staff readiness for rapid response to critical situations.

Equipment maintenance schedules must be more stringent than conventional medical electronics. Regular inspections should focus on insulation integrity, connection points vulnerable to thermal stress, and cooling system components. Preventive maintenance protocols must include specialized testing for materials subjected to extreme temperature cycling, as standard testing methodologies often prove inadequate for cryogenic applications.

Patient safety considerations extend beyond equipment reliability to include physiological monitoring during procedures involving cryogenic electronics. Vital sign monitoring systems must function reliably despite electromagnetic interference from cryogenic equipment. Patient screening protocols should identify contraindications for exposure to strong magnetic fields or extreme temperatures associated with certain cryogenic systems.

Regulatory compliance frameworks must evolve to address the unique challenges of cryogenic medical applications. Current standards from organizations like the International Electrotechnical Commission (IEC) and the Association for the Advancement of Medical Instrumentation (AAMI) require adaptation to encompass cryogenic-specific safety parameters. Healthcare facilities should participate in developing these emerging standards while implementing best practices based on available research and industry experience.

Temperature monitoring systems represent a critical component of clinical cryogenic safety. Continuous real-time monitoring with redundant sensors ensures that temperature parameters remain within safe operational ranges. Automated shutdown mechanisms must activate when temperatures deviate beyond predetermined thresholds, preventing potential harm to patients or equipment damage. These systems require regular calibration and validation to maintain accuracy in the extreme temperature environments characteristic of cryogenic applications.

Personnel training constitutes another essential safety element. Medical staff working with cryogenic electronics must receive specialized training covering proper handling procedures, emergency response protocols, and recognition of equipment malfunction indicators. Certification programs should verify competency in operating cryogenic systems, with mandatory refresher courses ensuring knowledge remains current as technology evolves.

Emergency response protocols must address cryogenic-specific incidents such as rapid temperature fluctuations, coolant leaks, or system failures. Facilities should develop detailed contingency plans including patient evacuation procedures, equipment isolation protocols, and immediate medical interventions for potential cryogenic injuries. Regular emergency drills help ensure staff readiness for rapid response to critical situations.

Equipment maintenance schedules must be more stringent than conventional medical electronics. Regular inspections should focus on insulation integrity, connection points vulnerable to thermal stress, and cooling system components. Preventive maintenance protocols must include specialized testing for materials subjected to extreme temperature cycling, as standard testing methodologies often prove inadequate for cryogenic applications.

Patient safety considerations extend beyond equipment reliability to include physiological monitoring during procedures involving cryogenic electronics. Vital sign monitoring systems must function reliably despite electromagnetic interference from cryogenic equipment. Patient screening protocols should identify contraindications for exposure to strong magnetic fields or extreme temperatures associated with certain cryogenic systems.

Regulatory compliance frameworks must evolve to address the unique challenges of cryogenic medical applications. Current standards from organizations like the International Electrotechnical Commission (IEC) and the Association for the Advancement of Medical Instrumentation (AAMI) require adaptation to encompass cryogenic-specific safety parameters. Healthcare facilities should participate in developing these emerging standards while implementing best practices based on available research and industry experience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!