Cryogenic Electronics and Regulation Compliance for Aerospace Engineering

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Evolution and Objectives

Cryogenic electronics represents a specialized field that has evolved significantly over the past decades, driven by the unique demands of aerospace applications where electronic systems must operate reliably at extremely low temperatures. The development trajectory began in the 1950s with rudimentary semiconductor devices capable of functioning at moderately low temperatures, primarily for military and space exploration purposes. By the 1970s, advancements in material science enabled the creation of specialized components designed specifically for cryogenic environments, marking a significant milestone in the field's evolution.

The 1990s witnessed a paradigm shift with the introduction of superconducting electronics, leveraging quantum effects that emerge at temperatures approaching absolute zero. This breakthrough expanded the potential applications dramatically, particularly for sensitive instrumentation in aerospace systems. The early 2000s brought further refinement with the development of integrated cryogenic circuits that combined multiple functions while maintaining operational integrity in extreme cold.

Current technological objectives in cryogenic electronics focus on several critical areas. Primary among these is the enhancement of energy efficiency, as power generation and thermal management present significant challenges in aerospace applications. Miniaturization remains another key goal, with efforts directed toward reducing the size and weight of cryogenic systems without compromising performance or reliability.

Radiation hardening represents a parallel objective, particularly crucial for electronics deployed in space environments where cosmic radiation can compromise system integrity. The development of materials and circuit designs capable of withstanding both extreme cold and radiation exposure continues to drive innovation in the field.

Compatibility with existing aerospace systems constitutes another important objective, as new cryogenic technologies must integrate seamlessly with established platforms and protocols. This includes ensuring compliance with increasingly stringent regulatory frameworks governing aerospace engineering, which demand rigorous testing and certification processes.

Looking forward, the field aims to achieve greater temperature stability across wider operating ranges, allowing electronics to function reliably during the transition between ambient and cryogenic conditions. Additionally, there is growing emphasis on developing self-diagnostic capabilities that enable systems to monitor their own performance and predict potential failures before they occur, a critical feature for remote aerospace applications where manual intervention is impossible.

The ultimate objective remains the creation of fully autonomous cryogenic electronic systems capable of adapting to changing environmental conditions while maintaining optimal performance throughout extended missions in the extreme conditions of space.

The 1990s witnessed a paradigm shift with the introduction of superconducting electronics, leveraging quantum effects that emerge at temperatures approaching absolute zero. This breakthrough expanded the potential applications dramatically, particularly for sensitive instrumentation in aerospace systems. The early 2000s brought further refinement with the development of integrated cryogenic circuits that combined multiple functions while maintaining operational integrity in extreme cold.

Current technological objectives in cryogenic electronics focus on several critical areas. Primary among these is the enhancement of energy efficiency, as power generation and thermal management present significant challenges in aerospace applications. Miniaturization remains another key goal, with efforts directed toward reducing the size and weight of cryogenic systems without compromising performance or reliability.

Radiation hardening represents a parallel objective, particularly crucial for electronics deployed in space environments where cosmic radiation can compromise system integrity. The development of materials and circuit designs capable of withstanding both extreme cold and radiation exposure continues to drive innovation in the field.

Compatibility with existing aerospace systems constitutes another important objective, as new cryogenic technologies must integrate seamlessly with established platforms and protocols. This includes ensuring compliance with increasingly stringent regulatory frameworks governing aerospace engineering, which demand rigorous testing and certification processes.

Looking forward, the field aims to achieve greater temperature stability across wider operating ranges, allowing electronics to function reliably during the transition between ambient and cryogenic conditions. Additionally, there is growing emphasis on developing self-diagnostic capabilities that enable systems to monitor their own performance and predict potential failures before they occur, a critical feature for remote aerospace applications where manual intervention is impossible.

The ultimate objective remains the creation of fully autonomous cryogenic electronic systems capable of adapting to changing environmental conditions while maintaining optimal performance throughout extended missions in the extreme conditions of space.

Aerospace Market Demand for Cryogenic Solutions

The aerospace industry has witnessed a significant surge in demand for cryogenic solutions, particularly in satellite systems, space exploration vehicles, and advanced aircraft. Market analysis indicates that the global aerospace cryogenic technology market is projected to grow at a compound annual growth rate of 5.8% through 2030, driven primarily by increasing satellite deployments and deep space missions requiring sophisticated thermal management systems.

The demand for cryogenic electronics stems from their superior performance characteristics at extremely low temperatures. Superconducting quantum interference devices (SQUIDs) and other cryogenic sensors offer unparalleled sensitivity for space-based observatories and Earth monitoring systems. Space agencies worldwide are investing heavily in these technologies, with NASA allocating substantial portions of its instrumentation budget to cryogenic systems for upcoming missions to Jupiter's moons and beyond.

Commercial satellite operators represent another significant market segment, with over 17,000 new satellites expected to be launched by 2030. These constellations require reliable, long-lasting electronic components that can withstand the harsh temperature variations of space. Cryogenic cooling systems extend operational lifespans and improve signal processing capabilities, making them increasingly essential for telecommunications and Earth observation platforms.

Defense aerospace applications constitute a robust market for cryogenic electronics, particularly in reconnaissance satellites and missile defense systems. These applications demand ultra-sensitive infrared detectors and signal processors that operate optimally at cryogenic temperatures. Military specifications increasingly call for components tested and rated for extreme temperature environments, creating specialized market niches for cryogenic-capable manufacturers.

The emerging commercial space tourism sector presents novel opportunities for cryogenic technologies. As companies develop vehicles for suborbital and orbital tourism, the need for reliable life support systems and propulsion components that can operate in extreme temperature conditions grows proportionally. Market forecasts suggest this segment could generate demand for specialized cryogenic solutions worth billions within the decade.

Regional analysis reveals that North America currently dominates the aerospace cryogenic market with approximately 42% share, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging space programs in India, China, and the United Arab Emirates, where substantial investments in space infrastructure are creating new demand centers for advanced cryogenic technologies.

The market increasingly values integrated solutions that combine cryogenic cooling systems with specialized electronics designed specifically for low-temperature operation, rather than adapted conventional components. This trend is reshaping supplier relationships throughout the aerospace supply chain, with system integrators preferring partners capable of delivering complete cryogenic subsystems rather than individual components.

The demand for cryogenic electronics stems from their superior performance characteristics at extremely low temperatures. Superconducting quantum interference devices (SQUIDs) and other cryogenic sensors offer unparalleled sensitivity for space-based observatories and Earth monitoring systems. Space agencies worldwide are investing heavily in these technologies, with NASA allocating substantial portions of its instrumentation budget to cryogenic systems for upcoming missions to Jupiter's moons and beyond.

Commercial satellite operators represent another significant market segment, with over 17,000 new satellites expected to be launched by 2030. These constellations require reliable, long-lasting electronic components that can withstand the harsh temperature variations of space. Cryogenic cooling systems extend operational lifespans and improve signal processing capabilities, making them increasingly essential for telecommunications and Earth observation platforms.

Defense aerospace applications constitute a robust market for cryogenic electronics, particularly in reconnaissance satellites and missile defense systems. These applications demand ultra-sensitive infrared detectors and signal processors that operate optimally at cryogenic temperatures. Military specifications increasingly call for components tested and rated for extreme temperature environments, creating specialized market niches for cryogenic-capable manufacturers.

The emerging commercial space tourism sector presents novel opportunities for cryogenic technologies. As companies develop vehicles for suborbital and orbital tourism, the need for reliable life support systems and propulsion components that can operate in extreme temperature conditions grows proportionally. Market forecasts suggest this segment could generate demand for specialized cryogenic solutions worth billions within the decade.

Regional analysis reveals that North America currently dominates the aerospace cryogenic market with approximately 42% share, followed by Europe and Asia-Pacific. However, the fastest growth is occurring in emerging space programs in India, China, and the United Arab Emirates, where substantial investments in space infrastructure are creating new demand centers for advanced cryogenic technologies.

The market increasingly values integrated solutions that combine cryogenic cooling systems with specialized electronics designed specifically for low-temperature operation, rather than adapted conventional components. This trend is reshaping supplier relationships throughout the aerospace supply chain, with system integrators preferring partners capable of delivering complete cryogenic subsystems rather than individual components.

Cryogenic Electronics Challenges in Extreme Environments

Cryogenic electronics systems face unprecedented challenges when operating in extreme environments, particularly in aerospace applications where temperatures can plummet to near absolute zero. These harsh conditions fundamentally alter the behavior of electronic components, creating a complex set of engineering obstacles that must be overcome to ensure reliable operation.

The primary challenge stems from the basic physics of semiconductor materials. At cryogenic temperatures (typically below 120K), carrier mobility changes dramatically, threshold voltages shift, and leakage currents exhibit unpredictable behaviors. Silicon-based devices, which form the backbone of conventional electronics, experience significant performance degradation, with some transistors ceasing to function entirely below certain temperature thresholds.

Material integrity presents another critical concern. The severe thermal cycling between ambient and cryogenic temperatures induces mechanical stress that can lead to microfractures in solder joints, component packages, and circuit boards. These structural failures often manifest as intermittent faults that are notoriously difficult to diagnose and repair, particularly in deployed aerospace systems where maintenance access is limited or impossible.

Power management becomes exceptionally challenging in cryogenic environments. Battery performance deteriorates substantially at extremely low temperatures, with most chemical batteries losing capacity or failing completely. Additionally, thermal management strategies must be completely reconceptualized, as traditional cooling approaches become irrelevant while heating elements must be precisely controlled to prevent localized thermal gradients that could damage sensitive components.

Radiation effects compound these challenges in aerospace applications. The reduced atmospheric shielding at high altitudes or in space exposes electronics to increased levels of cosmic radiation and charged particles. At cryogenic temperatures, semiconductor devices often exhibit altered responses to radiation events, with some becoming more susceptible to single-event upsets or cumulative damage effects.

Testing and qualification methodologies represent a significant hurdle. Standard electronic testing procedures are typically designed for room temperature operation, requiring extensive modification for cryogenic validation. The specialized equipment needed for accurate cryogenic testing is costly and technically complex, creating barriers to comprehensive verification.

Signal integrity issues emerge as particularly problematic in cryogenic systems. Transmission line characteristics change at extremely low temperatures, altering impedance matching requirements and potentially introducing signal reflections and timing errors in high-speed digital circuits. These effects can compromise data integrity in critical aerospace systems where communication reliability is paramount.

The limited availability of commercial off-the-shelf (COTS) components rated for cryogenic operation forces engineers to either extensively qualify standard parts through custom testing or develop specialized components at significantly increased cost and development time. This constraint substantially impacts system design flexibility and project timelines for aerospace applications requiring cryogenic electronics.

The primary challenge stems from the basic physics of semiconductor materials. At cryogenic temperatures (typically below 120K), carrier mobility changes dramatically, threshold voltages shift, and leakage currents exhibit unpredictable behaviors. Silicon-based devices, which form the backbone of conventional electronics, experience significant performance degradation, with some transistors ceasing to function entirely below certain temperature thresholds.

Material integrity presents another critical concern. The severe thermal cycling between ambient and cryogenic temperatures induces mechanical stress that can lead to microfractures in solder joints, component packages, and circuit boards. These structural failures often manifest as intermittent faults that are notoriously difficult to diagnose and repair, particularly in deployed aerospace systems where maintenance access is limited or impossible.

Power management becomes exceptionally challenging in cryogenic environments. Battery performance deteriorates substantially at extremely low temperatures, with most chemical batteries losing capacity or failing completely. Additionally, thermal management strategies must be completely reconceptualized, as traditional cooling approaches become irrelevant while heating elements must be precisely controlled to prevent localized thermal gradients that could damage sensitive components.

Radiation effects compound these challenges in aerospace applications. The reduced atmospheric shielding at high altitudes or in space exposes electronics to increased levels of cosmic radiation and charged particles. At cryogenic temperatures, semiconductor devices often exhibit altered responses to radiation events, with some becoming more susceptible to single-event upsets or cumulative damage effects.

Testing and qualification methodologies represent a significant hurdle. Standard electronic testing procedures are typically designed for room temperature operation, requiring extensive modification for cryogenic validation. The specialized equipment needed for accurate cryogenic testing is costly and technically complex, creating barriers to comprehensive verification.

Signal integrity issues emerge as particularly problematic in cryogenic systems. Transmission line characteristics change at extremely low temperatures, altering impedance matching requirements and potentially introducing signal reflections and timing errors in high-speed digital circuits. These effects can compromise data integrity in critical aerospace systems where communication reliability is paramount.

The limited availability of commercial off-the-shelf (COTS) components rated for cryogenic operation forces engineers to either extensively qualify standard parts through custom testing or develop specialized components at significantly increased cost and development time. This constraint substantially impacts system design flexibility and project timelines for aerospace applications requiring cryogenic electronics.

Current Cryogenic Electronics Implementation Approaches

01 Cryogenic cooling systems for electronic components

Specialized cooling systems designed to maintain electronic components at cryogenic temperatures for optimal performance. These systems utilize various refrigeration techniques to achieve extremely low temperatures necessary for certain electronic applications. The cooling mechanisms are engineered to provide stable thermal environments while addressing challenges related to thermal expansion, condensation, and heat transfer in cryogenic conditions.- Superconducting electronic devices: Cryogenic electronics leverages superconducting materials that exhibit zero electrical resistance at extremely low temperatures. These devices include superconducting quantum interference devices (SQUIDs), Josephson junctions, and superconducting circuits that operate with minimal power dissipation and high sensitivity. Applications include quantum computing, ultra-sensitive magnetic field detection, and high-speed digital logic with significantly reduced power consumption compared to conventional semiconductor electronics.

- Cryogenic cooling systems for electronics: Specialized cooling systems are essential for maintaining electronic components at cryogenic temperatures. These systems include closed-cycle refrigerators, liquid helium/nitrogen cooling systems, pulse tube cryocoolers, and dilution refrigerators. Advanced thermal management techniques ensure stable operating temperatures while minimizing vibration that could disrupt sensitive electronic operations. These cooling solutions address challenges of heat dissipation and thermal isolation in extreme low-temperature environments.

- Cryogenic electronic packaging and interconnects: Specialized packaging solutions are designed to maintain functionality at extremely low temperatures while managing thermal contraction/expansion issues. These include materials with matched thermal expansion coefficients, specialized solder compositions that remain reliable at cryogenic temperatures, and thermal isolation techniques. Advanced interconnect technologies ensure signal integrity across temperature boundaries between cryogenic and room-temperature environments, addressing challenges of thermal cycling and differential contraction.

- Quantum computing hardware: Cryogenic electronics form the foundation of quantum computing systems, particularly for superconducting qubit architectures. These systems require specialized control and readout electronics that can function at millikelvin temperatures or interface between room temperature and cryogenic environments. The hardware includes low-noise amplifiers, high-fidelity signal generators, and specialized quantum processors that leverage quantum mechanical effects that only emerge at extremely low temperatures.

- Cryogenic sensors and detectors: Ultra-sensitive sensors and detectors that operate at cryogenic temperatures offer unprecedented performance for scientific and industrial applications. These include bolometers for radiation detection, cryogenic particle detectors, infrared sensors, and magnetic field sensors with exceptional sensitivity. The extreme low-temperature operation reduces thermal noise and enables detection of extremely weak signals that would be impossible to measure at higher temperatures, making them valuable for astronomy, particle physics, and medical imaging.

02 Superconducting electronic devices

Electronic devices that leverage superconductivity properties at cryogenic temperatures to achieve superior performance characteristics. These devices exhibit zero electrical resistance when cooled below critical temperatures, enabling applications in quantum computing, sensitive detection systems, and high-speed signal processing. The designs incorporate specialized materials and structures that maintain superconducting states while interfacing with conventional electronics.Expand Specific Solutions03 Thermal management for cryogenic electronic systems

Advanced thermal management solutions specifically designed for electronic systems operating at cryogenic temperatures. These solutions address the unique challenges of heat dissipation, thermal interfaces, and temperature stability in extremely cold environments. The technologies include specialized thermal interface materials, heat spreaders, and thermal isolation techniques that maintain optimal operating conditions for sensitive cryogenic electronics.Expand Specific Solutions04 Cryogenic electronic packaging and interconnects

Specialized packaging and interconnection technologies developed for electronic systems operating at cryogenic temperatures. These designs address the challenges of thermal contraction, material compatibility, and signal integrity at extremely low temperatures. The packaging solutions incorporate materials and structures that maintain reliable electrical connections while accommodating the mechanical stresses associated with cryogenic cooling cycles.Expand Specific Solutions05 Quantum computing hardware with cryogenic electronics

Hardware systems for quantum computing that integrate cryogenic electronic components for control, readout, and signal processing. These systems combine quantum bits (qubits) operating at near-absolute zero temperatures with specialized cryogenic control electronics that minimize thermal noise and decoherence. The architectures include cryogenic amplifiers, multiplexers, and digital-to-analog converters designed to function reliably at extremely low temperatures while maintaining quantum coherence.Expand Specific Solutions

Leading Aerospace Cryogenic Technology Providers

The cryogenic electronics market for aerospace engineering is in a growth phase, characterized by increasing demand for advanced cooling systems in quantum computing, satellite technology, and aircraft systems. The market is expanding due to rising aerospace applications requiring ultra-low temperature electronics, with projections showing significant growth potential. Technologically, the field demonstrates varying maturity levels across applications. Leading players include established aerospace giants like Pratt & Whitney Canada, Rolls-Royce, and Northrop Grumman Systems providing traditional aerospace solutions, while specialized cryogenic technology comes from Montana Instruments Corporation and kiutra GmbH. Emerging players like D-Wave Systems and IBM are advancing quantum computing applications, while government-backed entities such as China Academy of Space Technology and Commercial Aircraft Corp. of China are rapidly developing capabilities to meet regulatory compliance requirements.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced cryogenic electronics systems specifically designed for aerospace applications, featuring their proprietary CryoCore™ technology that operates reliably at temperatures as low as -200°C. Their solution incorporates radiation-hardened semiconductor materials and specialized packaging techniques to ensure functionality in extreme space environments. Honeywell's cryogenic control systems include fault-tolerant architectures with triple modular redundancy for critical aerospace applications, ensuring compliance with DO-254 and DO-178C standards. Their integrated approach combines sensors, processors, and power management systems specifically engineered to maintain performance stability across extreme temperature gradients encountered during aerospace missions. Honeywell has also pioneered compliance frameworks that address both FAA and international regulatory requirements for cryogenic systems in commercial and military aircraft.

Strengths: Industry-leading radiation hardening techniques; extensive aerospace certification experience; comprehensive integration with existing aircraft systems. Weaknesses: Higher cost compared to conventional electronics; relatively larger form factor due to thermal management requirements; longer development cycles for custom solutions.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has developed the CryoSat platform, a comprehensive suite of cryogenic electronic systems designed specifically for satellite and deep space applications. Their technology utilizes superconducting circuits operating at temperatures below 10K, achieving significant power efficiency improvements while maintaining radiation tolerance required for space environments. The company's approach integrates specialized material science with advanced manufacturing techniques to create electronics that maintain functionality in extreme cold and vacuum conditions. Their compliance framework addresses both NASA and ESA requirements, with particular emphasis on reliability verification through accelerated life testing protocols. Northrop Grumman's cryogenic systems incorporate autonomous fault detection and recovery mechanisms that enable extended mission durations without human intervention, critical for deep space applications where maintenance is impossible.

Strengths: Exceptional reliability in extreme environments; proven heritage in multiple space missions; advanced fault tolerance capabilities. Weaknesses: Extremely high development and qualification costs; specialized manufacturing requirements limit production scaling; significant power requirements for cooling systems.

Critical Patents in Aerospace Cryogenic Electronics

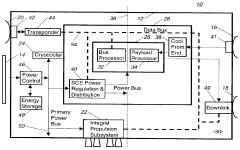

Spacecraft with all-cryogenic electronics

PatentInactiveUS6027077A

Innovation

- The spacecraft employs a cryogenic cooler to maintain electronics and power modules at low temperature levels, utilizing low-temperature superconducting processors for processing and high-temperature superconducting electronics for power regulation, with additional modules at room temperature, centralizing thermal dissipation and optimizing component operation.

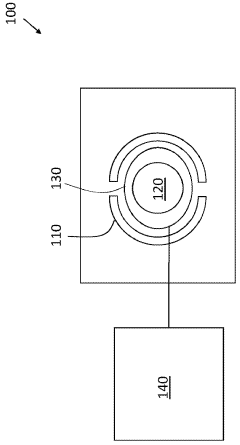

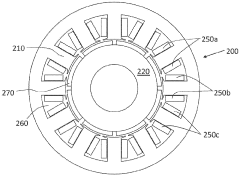

Electric motor having cryocooled armature LITZ windings

PatentWO2024110756A1

Innovation

- An electric motor with cryocooled Litz windings and a magnetic core, utilizing high-purity materials and cryogens like hydrogen, neon, or helium to achieve current densities over 25 A/mm², minimizing electrical losses and maximizing power output.

Aerospace Regulatory Framework for Cryogenic Systems

The aerospace industry operates under stringent regulatory frameworks that govern the implementation of cryogenic systems in flight hardware. These regulations are established by international aviation authorities such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and the International Civil Aviation Organization (ICAO), which collectively ensure safety, reliability, and performance standards across global aerospace operations.

Cryogenic systems in aerospace applications must comply with specific regulatory requirements outlined in standards like DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment) and MIL-STD-810 (Environmental Engineering Considerations and Laboratory Tests). These standards define the testing protocols for extreme temperature conditions, including cryogenic environments, ensuring electronic components maintain functionality at temperatures approaching absolute zero.

Material selection for cryogenic applications faces particular scrutiny under aerospace regulations. AS9100 quality management standards mandate rigorous material qualification processes, with special provisions for materials used in extreme temperature environments. Regulatory bodies require extensive documentation of material properties at cryogenic temperatures, including thermal expansion coefficients, embrittlement thresholds, and thermal conductivity characteristics.

Certification processes for cryogenic electronics in aerospace systems involve multi-phase testing regimes. These include thermal cycling between ambient and cryogenic temperatures, thermal shock testing, and long-duration exposure tests to verify system integrity. Regulatory frameworks typically require demonstration of Mean Time Between Failure (MTBF) metrics that exceed standard operational requirements by significant margins when cryogenic conditions are involved.

Safety regulations for cryogenic systems are particularly stringent, with emphasis on containment, pressure management, and emergency procedures. The Compressed Gas Association (CGA) guidelines, incorporated by reference in aerospace regulations, establish specific requirements for cryogenic fluid handling in aerospace applications. These include redundant safety systems, pressure relief mechanisms, and specialized insulation requirements to prevent catastrophic failures.

International transport of aerospace components with cryogenic capabilities must comply with dangerous goods regulations established by the International Air Transport Association (IATA). These regulations impose specific packaging, labeling, and documentation requirements for components designed to operate in or generate cryogenic conditions, adding complexity to global supply chain management for aerospace manufacturers.

Regulatory compliance documentation for cryogenic aerospace systems must include comprehensive risk assessments addressing both normal operations and failure modes. These assessments must demonstrate that cryogenic components maintain safety margins across the entire operational envelope, including during rapid temperature transitions that may occur during mission profiles.

Cryogenic systems in aerospace applications must comply with specific regulatory requirements outlined in standards like DO-160 (Environmental Conditions and Test Procedures for Airborne Equipment) and MIL-STD-810 (Environmental Engineering Considerations and Laboratory Tests). These standards define the testing protocols for extreme temperature conditions, including cryogenic environments, ensuring electronic components maintain functionality at temperatures approaching absolute zero.

Material selection for cryogenic applications faces particular scrutiny under aerospace regulations. AS9100 quality management standards mandate rigorous material qualification processes, with special provisions for materials used in extreme temperature environments. Regulatory bodies require extensive documentation of material properties at cryogenic temperatures, including thermal expansion coefficients, embrittlement thresholds, and thermal conductivity characteristics.

Certification processes for cryogenic electronics in aerospace systems involve multi-phase testing regimes. These include thermal cycling between ambient and cryogenic temperatures, thermal shock testing, and long-duration exposure tests to verify system integrity. Regulatory frameworks typically require demonstration of Mean Time Between Failure (MTBF) metrics that exceed standard operational requirements by significant margins when cryogenic conditions are involved.

Safety regulations for cryogenic systems are particularly stringent, with emphasis on containment, pressure management, and emergency procedures. The Compressed Gas Association (CGA) guidelines, incorporated by reference in aerospace regulations, establish specific requirements for cryogenic fluid handling in aerospace applications. These include redundant safety systems, pressure relief mechanisms, and specialized insulation requirements to prevent catastrophic failures.

International transport of aerospace components with cryogenic capabilities must comply with dangerous goods regulations established by the International Air Transport Association (IATA). These regulations impose specific packaging, labeling, and documentation requirements for components designed to operate in or generate cryogenic conditions, adding complexity to global supply chain management for aerospace manufacturers.

Regulatory compliance documentation for cryogenic aerospace systems must include comprehensive risk assessments addressing both normal operations and failure modes. These assessments must demonstrate that cryogenic components maintain safety margins across the entire operational envelope, including during rapid temperature transitions that may occur during mission profiles.

Space Qualification Standards for Cryogenic Components

Space qualification standards for cryogenic components in aerospace applications represent a critical framework ensuring reliability and performance under extreme conditions. These standards are primarily governed by organizations such as NASA, ESA, and military specifications including MIL-STD-883 and MIL-PRF-38534, which have established comprehensive testing protocols specifically addressing cryogenic environments.

The qualification process for cryogenic electronic components involves rigorous testing across multiple temperature cycles, typically ranging from ultra-low temperatures (below -150°C) to standard operating temperatures. Components must demonstrate consistent electrical performance, mechanical integrity, and thermal stability throughout these extreme temperature variations. Standards such as ECSS-Q-ST-70 (European Cooperation for Space Standardization) specifically address material outgassing concerns at cryogenic temperatures, which can significantly impact sensitive optical instruments and sensors in space environments.

Radiation hardness testing forms another crucial aspect of these standards, as cryogenic electronics in space applications must withstand cosmic radiation while operating at extremely low temperatures. The combined effects of radiation and cryogenic conditions create unique failure mechanisms that require specialized testing methodologies beyond conventional qualification procedures.

Hermetic sealing requirements become particularly stringent for cryogenic components, as thermal cycling between extreme temperatures can compromise traditional sealing methods. Standards specify helium leak testing under cryogenic conditions with leak rates typically not exceeding 1×10^-8 atm-cc/sec to ensure long-term reliability in vacuum environments.

Reliability demonstration testing for space-qualified cryogenic components typically requires extended operation at target temperatures, often exceeding 1000 hours, with comprehensive performance monitoring throughout. Statistical analysis of failure rates must demonstrate compliance with mission reliability requirements, which for critical space applications may demand failure rates below 10 FIT (failures in 10^9 hours).

Manufacturing process control standards for cryogenic components include specialized requirements for material selection, with particular emphasis on matching thermal expansion coefficients to prevent mechanical failures during temperature cycling. Specialized soldering and bonding techniques that maintain integrity at cryogenic temperatures are mandated, with standards specifying qualification procedures for these specialized processes.

Documentation requirements for space-qualified cryogenic components exceed typical aerospace standards, requiring comprehensive traceability of materials, processes, and test results throughout the supply chain. This enhanced documentation supports failure analysis capabilities and ensures consistent manufacturing quality for these highly specialized components.

The qualification process for cryogenic electronic components involves rigorous testing across multiple temperature cycles, typically ranging from ultra-low temperatures (below -150°C) to standard operating temperatures. Components must demonstrate consistent electrical performance, mechanical integrity, and thermal stability throughout these extreme temperature variations. Standards such as ECSS-Q-ST-70 (European Cooperation for Space Standardization) specifically address material outgassing concerns at cryogenic temperatures, which can significantly impact sensitive optical instruments and sensors in space environments.

Radiation hardness testing forms another crucial aspect of these standards, as cryogenic electronics in space applications must withstand cosmic radiation while operating at extremely low temperatures. The combined effects of radiation and cryogenic conditions create unique failure mechanisms that require specialized testing methodologies beyond conventional qualification procedures.

Hermetic sealing requirements become particularly stringent for cryogenic components, as thermal cycling between extreme temperatures can compromise traditional sealing methods. Standards specify helium leak testing under cryogenic conditions with leak rates typically not exceeding 1×10^-8 atm-cc/sec to ensure long-term reliability in vacuum environments.

Reliability demonstration testing for space-qualified cryogenic components typically requires extended operation at target temperatures, often exceeding 1000 hours, with comprehensive performance monitoring throughout. Statistical analysis of failure rates must demonstrate compliance with mission reliability requirements, which for critical space applications may demand failure rates below 10 FIT (failures in 10^9 hours).

Manufacturing process control standards for cryogenic components include specialized requirements for material selection, with particular emphasis on matching thermal expansion coefficients to prevent mechanical failures during temperature cycling. Specialized soldering and bonding techniques that maintain integrity at cryogenic temperatures are mandated, with standards specifying qualification procedures for these specialized processes.

Documentation requirements for space-qualified cryogenic components exceed typical aerospace standards, requiring comprehensive traceability of materials, processes, and test results throughout the supply chain. This enhanced documentation supports failure analysis capabilities and ensures consistent manufacturing quality for these highly specialized components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!