What Role Does Superconductivity Play in Cryogenic Electronics?

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superconductivity in Cryogenic Electronics: Background and Objectives

Superconductivity, a quantum mechanical phenomenon characterized by zero electrical resistance and the expulsion of magnetic fields, has been a cornerstone in the evolution of cryogenic electronics since its discovery by Heike Kamerlingh Onnes in 1911. The field has witnessed remarkable advancements over the past century, transitioning from fundamental scientific curiosity to practical applications in various technological domains. The trajectory of superconductivity research has been marked by significant milestones, including the development of high-temperature superconductors in the 1980s, which expanded the operational temperature range beyond liquid helium requirements.

The integration of superconductivity into electronic systems has created a distinct technological paradigm known as cryogenic electronics, which operates at temperatures significantly below ambient conditions. This symbiotic relationship has enabled unprecedented performance in computing, sensing, and communication systems. The historical progression reveals a consistent trend toward higher critical temperatures, improved material properties, and enhanced integration capabilities with conventional semiconductor technologies.

Current technological objectives in this field are multifaceted, focusing on overcoming the practical limitations of implementing superconducting systems. Primary goals include developing materials with higher critical temperatures to reduce cooling requirements, enhancing the energy efficiency of cryogenic cooling systems, and improving the reliability and scalability of superconducting electronic components. Additionally, there is significant emphasis on bridging the interface between room-temperature electronics and superconducting circuits, addressing the thermal management challenges inherent in hybrid systems.

The emergence of quantum computing has reinvigorated interest in superconducting electronics, as superconducting qubits represent one of the most promising platforms for quantum information processing. This application has established new technical objectives related to coherence time improvement, error correction, and scalable qubit architectures. Concurrently, traditional applications in medical imaging, particle detection, and precision measurement continue to drive innovation in superconducting sensor technologies.

Looking forward, the field is poised for transformative developments in materials science, with research focused on room-temperature superconductivity representing the ultimate goal. While theoretical models suggest this possibility, practical realization remains elusive. Intermediate objectives include the development of superconductors operational at nitrogen temperatures (77K) or above, which would dramatically reduce system complexity and operational costs. The convergence of superconductivity with emerging technologies such as neuromorphic computing and spintronics also presents exciting new research directions.

The technical objectives extend beyond pure performance metrics to include considerations of manufacturability, reliability, and economic viability. As superconducting electronics transition from specialized applications to more mainstream use cases, addressing these practical aspects becomes increasingly critical for widespread adoption and commercial success.

The integration of superconductivity into electronic systems has created a distinct technological paradigm known as cryogenic electronics, which operates at temperatures significantly below ambient conditions. This symbiotic relationship has enabled unprecedented performance in computing, sensing, and communication systems. The historical progression reveals a consistent trend toward higher critical temperatures, improved material properties, and enhanced integration capabilities with conventional semiconductor technologies.

Current technological objectives in this field are multifaceted, focusing on overcoming the practical limitations of implementing superconducting systems. Primary goals include developing materials with higher critical temperatures to reduce cooling requirements, enhancing the energy efficiency of cryogenic cooling systems, and improving the reliability and scalability of superconducting electronic components. Additionally, there is significant emphasis on bridging the interface between room-temperature electronics and superconducting circuits, addressing the thermal management challenges inherent in hybrid systems.

The emergence of quantum computing has reinvigorated interest in superconducting electronics, as superconducting qubits represent one of the most promising platforms for quantum information processing. This application has established new technical objectives related to coherence time improvement, error correction, and scalable qubit architectures. Concurrently, traditional applications in medical imaging, particle detection, and precision measurement continue to drive innovation in superconducting sensor technologies.

Looking forward, the field is poised for transformative developments in materials science, with research focused on room-temperature superconductivity representing the ultimate goal. While theoretical models suggest this possibility, practical realization remains elusive. Intermediate objectives include the development of superconductors operational at nitrogen temperatures (77K) or above, which would dramatically reduce system complexity and operational costs. The convergence of superconductivity with emerging technologies such as neuromorphic computing and spintronics also presents exciting new research directions.

The technical objectives extend beyond pure performance metrics to include considerations of manufacturability, reliability, and economic viability. As superconducting electronics transition from specialized applications to more mainstream use cases, addressing these practical aspects becomes increasingly critical for widespread adoption and commercial success.

Market Analysis for Cryogenic Electronic Applications

The cryogenic electronics market is experiencing significant growth driven by advancements in quantum computing, space exploration, and medical imaging technologies. Current market valuations place the global cryogenic electronics sector at approximately 7.5 billion USD, with projections indicating a compound annual growth rate of 8.2% through 2030. This growth trajectory is primarily fueled by increasing investments in quantum computing research and development, which requires superconducting materials operating at extremely low temperatures.

Demand segmentation reveals that research institutions and technology companies focused on quantum computing represent the largest market share at 42%, followed by healthcare applications at 27%, space and defense at 18%, and other industrial applications comprising the remaining 13%. Geographically, North America leads with 38% market share, followed by Europe at 31%, Asia-Pacific at 26%, and other regions at 5%.

The healthcare sector demonstrates particularly strong growth potential, with superconducting quantum interference devices (SQUIDs) revolutionizing magnetic resonance imaging (MRI) and magnetoencephalography (MEG) technologies. These applications benefit from the enhanced sensitivity and reduced noise offered by superconducting materials in cryogenic environments, enabling more precise diagnostics and research capabilities.

Quantum computing represents the most disruptive application area, with major technology companies including IBM, Google, and Microsoft making substantial investments in superconducting qubit technologies. The market for quantum computing hardware utilizing cryogenic electronics is expected to grow from 612 million USD in 2023 to over 3 billion USD by 2028, representing one of the fastest-growing segments within the broader cryogenic electronics landscape.

Key market challenges include the high operational costs associated with maintaining cryogenic temperatures, limited infrastructure for widespread deployment, and technical barriers to scaling superconducting systems. The cost of liquid helium, essential for achieving temperatures near absolute zero, has increased by 35% over the past five years, creating additional market pressures.

Customer adoption patterns indicate a transition from purely research-oriented applications toward more commercial implementations, particularly in financial services, pharmaceuticals, and materials science. This shift is supported by improving price-performance ratios as manufacturing processes mature and economies of scale begin to take effect.

Market forecasts suggest that breakthroughs in high-temperature superconductors could dramatically expand the addressable market by reducing cooling requirements and associated costs. Such advancements would potentially open new application areas in energy transmission, transportation, and consumer electronics, expanding the total addressable market by an estimated 65% by 2035.

Demand segmentation reveals that research institutions and technology companies focused on quantum computing represent the largest market share at 42%, followed by healthcare applications at 27%, space and defense at 18%, and other industrial applications comprising the remaining 13%. Geographically, North America leads with 38% market share, followed by Europe at 31%, Asia-Pacific at 26%, and other regions at 5%.

The healthcare sector demonstrates particularly strong growth potential, with superconducting quantum interference devices (SQUIDs) revolutionizing magnetic resonance imaging (MRI) and magnetoencephalography (MEG) technologies. These applications benefit from the enhanced sensitivity and reduced noise offered by superconducting materials in cryogenic environments, enabling more precise diagnostics and research capabilities.

Quantum computing represents the most disruptive application area, with major technology companies including IBM, Google, and Microsoft making substantial investments in superconducting qubit technologies. The market for quantum computing hardware utilizing cryogenic electronics is expected to grow from 612 million USD in 2023 to over 3 billion USD by 2028, representing one of the fastest-growing segments within the broader cryogenic electronics landscape.

Key market challenges include the high operational costs associated with maintaining cryogenic temperatures, limited infrastructure for widespread deployment, and technical barriers to scaling superconducting systems. The cost of liquid helium, essential for achieving temperatures near absolute zero, has increased by 35% over the past five years, creating additional market pressures.

Customer adoption patterns indicate a transition from purely research-oriented applications toward more commercial implementations, particularly in financial services, pharmaceuticals, and materials science. This shift is supported by improving price-performance ratios as manufacturing processes mature and economies of scale begin to take effect.

Market forecasts suggest that breakthroughs in high-temperature superconductors could dramatically expand the addressable market by reducing cooling requirements and associated costs. Such advancements would potentially open new application areas in energy transmission, transportation, and consumer electronics, expanding the total addressable market by an estimated 65% by 2035.

Current State and Technical Challenges in Superconducting Electronics

Superconducting electronics has witnessed significant advancements globally, with major research centers in the United States, Europe, Japan, and increasingly China making substantial contributions. The current state of the technology demonstrates remarkable achievements in both digital and analog applications, yet faces considerable challenges that limit widespread commercial adoption.

The fundamental advantage of superconducting electronics—near-zero electrical resistance at cryogenic temperatures—enables unprecedented energy efficiency and switching speeds. Current implementations include Josephson junction-based digital circuits capable of operating at frequencies exceeding 100 GHz, while consuming orders of magnitude less power than semiconductor alternatives. Rapid Single Flux Quantum (RSFQ) logic has evolved into energy-efficient variants such as ERSFQ and eSFQ, addressing earlier power distribution limitations.

Despite these advances, significant technical hurdles persist. The requirement for cryogenic cooling infrastructure represents perhaps the most formidable challenge, necessitating complex and energy-intensive refrigeration systems that offset many of the technology's inherent efficiency advantages. Current commercial cryocoolers remain bulky, expensive, and relatively inefficient, with typical coefficients of performance below 1% at 4K.

Integration density presents another critical limitation. While semiconductor technologies routinely achieve billions of transistors per chip, superconducting circuits typically contain thousands to tens of thousands of Josephson junctions, limiting computational capacity. This integration gap stems from manufacturing challenges including larger feature sizes (typically micron-scale versus nanometer-scale in advanced CMOS), lower yields, and less mature design tools.

Interface challenges between room temperature electronics and cryogenic superconducting circuits create additional bottlenecks. Current I/O solutions consume significant power and introduce latency, undermining system-level performance advantages. The limited availability of cryogenic memory solutions further complicates system architecture, as existing superconducting memory cells suffer from low density and challenging integration requirements.

Material science challenges also persist, with researchers seeking superconducting materials with higher critical temperatures to reduce cooling requirements. While high-temperature superconductors offer operation at more accessible temperatures (>77K), they present complex fabrication challenges and less ideal electronic properties for digital applications compared to low-temperature alternatives like niobium.

The economic landscape presents additional obstacles, with limited commercial infrastructure for manufacturing superconducting circuits. Most fabrication occurs in specialized research facilities rather than high-volume production environments, resulting in higher costs and limited accessibility for broader applications beyond niche markets like quantum computing control systems and specialized sensing applications.

The fundamental advantage of superconducting electronics—near-zero electrical resistance at cryogenic temperatures—enables unprecedented energy efficiency and switching speeds. Current implementations include Josephson junction-based digital circuits capable of operating at frequencies exceeding 100 GHz, while consuming orders of magnitude less power than semiconductor alternatives. Rapid Single Flux Quantum (RSFQ) logic has evolved into energy-efficient variants such as ERSFQ and eSFQ, addressing earlier power distribution limitations.

Despite these advances, significant technical hurdles persist. The requirement for cryogenic cooling infrastructure represents perhaps the most formidable challenge, necessitating complex and energy-intensive refrigeration systems that offset many of the technology's inherent efficiency advantages. Current commercial cryocoolers remain bulky, expensive, and relatively inefficient, with typical coefficients of performance below 1% at 4K.

Integration density presents another critical limitation. While semiconductor technologies routinely achieve billions of transistors per chip, superconducting circuits typically contain thousands to tens of thousands of Josephson junctions, limiting computational capacity. This integration gap stems from manufacturing challenges including larger feature sizes (typically micron-scale versus nanometer-scale in advanced CMOS), lower yields, and less mature design tools.

Interface challenges between room temperature electronics and cryogenic superconducting circuits create additional bottlenecks. Current I/O solutions consume significant power and introduce latency, undermining system-level performance advantages. The limited availability of cryogenic memory solutions further complicates system architecture, as existing superconducting memory cells suffer from low density and challenging integration requirements.

Material science challenges also persist, with researchers seeking superconducting materials with higher critical temperatures to reduce cooling requirements. While high-temperature superconductors offer operation at more accessible temperatures (>77K), they present complex fabrication challenges and less ideal electronic properties for digital applications compared to low-temperature alternatives like niobium.

The economic landscape presents additional obstacles, with limited commercial infrastructure for manufacturing superconducting circuits. Most fabrication occurs in specialized research facilities rather than high-volume production environments, resulting in higher costs and limited accessibility for broader applications beyond niche markets like quantum computing control systems and specialized sensing applications.

Mainstream Superconducting Circuit Implementations

01 High-temperature superconducting materials

Various materials exhibit superconductivity at relatively high temperatures, making them practical for commercial applications. These materials include certain ceramic compounds, cuprates, and iron-based superconductors. Research focuses on developing materials with higher critical temperatures to reduce cooling requirements and improve efficiency in power transmission, magnetic levitation, and other applications.- High-temperature superconducting materials: Various high-temperature superconducting materials have been developed to achieve superconductivity at relatively higher temperatures than conventional superconductors. These materials typically include specific compositions of copper oxides (cuprates), iron-based compounds, and other complex oxides that can maintain zero electrical resistance at temperatures above liquid nitrogen. Research focuses on improving critical temperature, current density, and magnetic field tolerance of these materials for practical applications.

- Superconducting magnetic devices and systems: Superconducting materials are utilized in various magnetic devices including magnets, magnetic resonance imaging (MRI) systems, and magnetic energy storage systems. These applications leverage the perfect diamagnetism and zero resistance properties of superconductors to generate strong magnetic fields with minimal energy loss. The designs incorporate specialized cooling systems and magnetic field management to maintain superconducting states during operation.

- Superconducting power transmission and electrical applications: Superconducting materials are implemented in power transmission systems, generators, motors, and other electrical applications to significantly reduce energy losses and increase efficiency. These systems utilize the zero resistance property of superconductors to carry large currents without generating heat, enabling more compact and powerful electrical devices. Special designs address challenges related to cooling requirements, mechanical stress, and maintaining superconductivity under varying operational conditions.

- Fabrication methods for superconducting materials and devices: Various fabrication techniques have been developed for producing superconducting materials and devices, including thin film deposition, wire and tape manufacturing, and bulk material synthesis. These methods focus on achieving optimal crystal structure, phase purity, and microstructural properties that enhance superconducting performance. Processing parameters are carefully controlled to maximize critical current density and mechanical properties while maintaining superconductivity under application conditions.

- Superconducting quantum devices and sensors: Superconducting materials are utilized in quantum computing devices, sensitive magnetic field detectors (SQUIDs), and other precision measurement instruments. These applications leverage quantum effects that occur in superconducting states, such as flux quantization and Josephson effects. The devices operate at extremely low temperatures and are designed to maintain quantum coherence while performing computational operations or sensing extremely small magnetic fields with unprecedented sensitivity.

02 Superconducting magnetic devices and systems

Superconducting materials are used to create powerful magnetic fields for various applications. These include magnetic resonance imaging (MRI) systems, magnetic levitation for transportation, particle accelerators, and energy storage systems. The absence of electrical resistance in superconductors allows for the generation of strong, stable magnetic fields with minimal energy loss, making these systems highly efficient.Expand Specific Solutions03 Superconducting power transmission and energy applications

Superconducting materials enable efficient power transmission with minimal energy loss. Applications include superconducting power cables, fault current limiters, transformers, and energy storage systems such as superconducting magnetic energy storage (SMES). These technologies offer significant advantages in grid stability, energy efficiency, and power density compared to conventional systems.Expand Specific Solutions04 Fabrication methods for superconducting devices

Various techniques are employed to fabricate superconducting materials and devices, including thin film deposition, wire and tape manufacturing, and bulk material processing. These methods focus on achieving optimal critical current density, mechanical properties, and long-term stability. Advanced fabrication techniques include chemical vapor deposition, pulsed laser deposition, and specialized heat treatment processes to enhance superconducting properties.Expand Specific Solutions05 Cooling systems for superconducting applications

Specialized cooling systems are essential for maintaining superconducting materials below their critical temperature. These include cryogenic cooling using liquid helium, liquid nitrogen, or mechanical cryocoolers. Advanced thermal management techniques focus on improving cooling efficiency, reducing operating costs, and enhancing the reliability of superconducting systems in practical applications.Expand Specific Solutions

Key Industry Players and Research Institutions

Superconductivity plays a critical role in cryogenic electronics, currently transitioning from research to commercial applications with an estimated market size of $2-3 billion annually. The technology landscape shows varying maturity levels across different applications. Industry leaders like IBM, Fujitsu, and American Superconductor are advancing commercial superconducting computing and power systems, while research institutions including MIT, Naval Research Laboratory, and Shanghai Superconductor Technology focus on fundamental breakthroughs. Specialized players such as SuperNode and Semiqon are developing niche applications in power transmission and quantum computing. The field is characterized by collaborative ecosystems between academic institutions, national laboratories, and commercial entities, with increasing investment in quantum computing applications driving market expansion.

American Superconductor Corp.

Technical Solution: American Superconductor (AMSC) has developed proprietary high-temperature superconductor (HTS) wire technology specifically designed for cryogenic electronics applications. Their Amperium® wire utilizes yttrium barium copper oxide (YBCO) thin film deposited on metal substrates, enabling operation at liquid nitrogen temperatures (77K) rather than requiring liquid helium cooling. This technology forms the foundation for their superconducting fault current limiters (SFCLs) and power cables that can operate with zero resistance when cooled below critical temperature. AMSC has implemented a manufacturing process that allows for kilometer-length production of consistent quality HTS wire with critical current densities exceeding 300 A/mm² in self-field at 77K. Their cryogenic systems integrate specialized cooling technology with superconducting components to create complete solutions for power transmission and distribution applications.

Strengths: Industry-leading manufacturing capability for long-length HTS wire; established commercial deployment experience; integrated cooling system expertise. Weaknesses: Higher operational costs compared to conventional electronics; requires sophisticated cryogenic infrastructure; limited to applications where performance benefits justify cooling complexity.

International Business Machines Corp.

Technical Solution: IBM has pioneered superconducting electronics through their development of Josephson junction-based quantum computing technology. Their approach utilizes aluminum-aluminum oxide-aluminum junctions fabricated on silicon substrates, operating at millikelvin temperatures (10-20 mK) achieved through dilution refrigeration systems. IBM's superconducting qubits leverage the quantum coherence properties of superconductors to maintain quantum states essential for quantum computation. The company has developed a comprehensive cryogenic architecture that includes custom control electronics, quantum-limited amplifiers, and specialized interconnects designed to minimize thermal loads. Their superconducting quantum processors feature 3D integration techniques that allow for increased qubit density while maintaining the ultra-low temperatures required for operation. IBM has demonstrated quantum processors with over 100 superconducting qubits and continues to advance the scalability of this technology through innovations in materials science and cryogenic engineering.

Strengths: World-class expertise in quantum computing implementations; advanced fabrication capabilities for complex superconducting circuits; integrated system design approach combining hardware and software. Weaknesses: Extremely low operating temperatures require sophisticated and expensive cooling infrastructure; scaling challenges for large qubit arrays; sensitivity to environmental noise and interference.

Critical Patents and Breakthroughs in Superconducting Materials

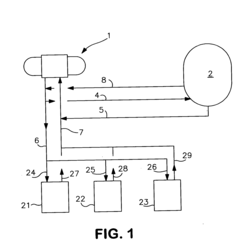

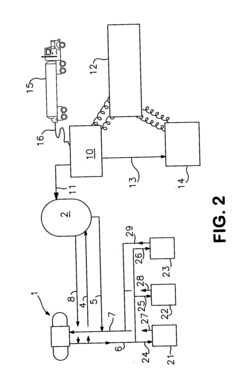

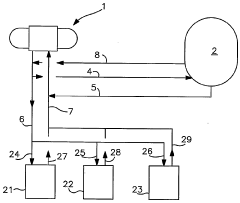

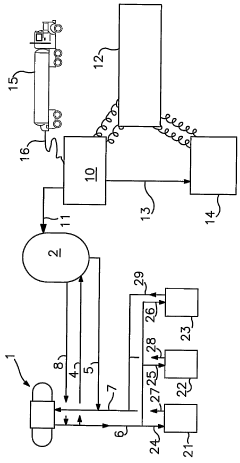

Cryogenic refrigeration system for superconducting devices

PatentInactiveUS20070028636A1

Innovation

- A method and apparatus that utilize a primary cryocooler to cool and subcool cryogenic liquid, which is then stored in a reserve container and used to provide indirect cooling to superconducting devices, ensuring the liquid remains in a subcooled state and preventing gas formation.

Refrigeration system for superconducting devices

PatentWO2007123561A2

Innovation

- A refrigeration system that uses a primary cryocooler to cool and subcool cryogenic liquid, which is then stored in a reserve container and used to provide cooling to superconducting devices, ensuring the liquid remains in a subcooled state and preventing gas formation.

Energy Efficiency and Cooling Infrastructure Requirements

Superconductivity in cryogenic electronics presents a significant paradox in terms of energy efficiency. While superconducting circuits operate with virtually zero electrical resistance, thereby eliminating power dissipation in signal transmission, the cooling infrastructure required to maintain superconducting temperatures represents a substantial energy investment. This energy trade-off forms the central consideration in implementing superconducting technology in practical electronic systems.

The cooling requirements for superconducting electronics vary based on the materials employed. High-temperature superconductors (HTS) operating at liquid nitrogen temperatures (77K) require approximately 15-20 watts of cooling power per watt of heat removed. In contrast, low-temperature superconductors functioning at liquid helium temperatures (4K) demand significantly higher cooling power ratios of 500-1000 watts per watt of heat dissipation.

Modern cryogenic cooling systems for electronics employ various technologies, including pulse tube refrigerators, Gifford-McMahon coolers, and dilution refrigerators. Recent advances in cryocooler efficiency have reduced the power requirements by 15-20% over the past decade, yet the fundamental thermodynamic limitations remain challenging. The coefficient of performance decreases dramatically as target temperatures approach absolute zero, creating an inherent efficiency barrier.

The physical infrastructure for cooling superconducting electronics requires substantial space allocation, often exceeding the footprint of the electronic components themselves by factors of 10-100. This spatial requirement presents significant integration challenges for compact applications and data centers, where space utilization directly impacts operational costs.

Energy consumption patterns in superconducting systems exhibit unique characteristics. While the electronic circuits themselves consume minimal power during operation, the continuous cooling load represents a constant baseline energy requirement regardless of computational workload. This contrasts sharply with conventional electronics, where power consumption scales more directly with processing activity.

Recent developments in cryogenic engineering have focused on recuperative cooling techniques and multi-stage systems that capture and reuse cooling capacity across temperature gradients. These innovations have improved overall system efficiency by 25-30% in laboratory settings, though commercial implementation remains limited by cost considerations and reliability concerns.

The economic viability of superconducting electronics ultimately depends on the application domain. For high-performance computing applications requiring extreme processing capabilities, the energy savings from reduced computational power may offset cooling costs. However, for more mainstream applications, the energy balance currently favors conventional semiconductor technologies despite their inherent resistive losses.

The cooling requirements for superconducting electronics vary based on the materials employed. High-temperature superconductors (HTS) operating at liquid nitrogen temperatures (77K) require approximately 15-20 watts of cooling power per watt of heat removed. In contrast, low-temperature superconductors functioning at liquid helium temperatures (4K) demand significantly higher cooling power ratios of 500-1000 watts per watt of heat dissipation.

Modern cryogenic cooling systems for electronics employ various technologies, including pulse tube refrigerators, Gifford-McMahon coolers, and dilution refrigerators. Recent advances in cryocooler efficiency have reduced the power requirements by 15-20% over the past decade, yet the fundamental thermodynamic limitations remain challenging. The coefficient of performance decreases dramatically as target temperatures approach absolute zero, creating an inherent efficiency barrier.

The physical infrastructure for cooling superconducting electronics requires substantial space allocation, often exceeding the footprint of the electronic components themselves by factors of 10-100. This spatial requirement presents significant integration challenges for compact applications and data centers, where space utilization directly impacts operational costs.

Energy consumption patterns in superconducting systems exhibit unique characteristics. While the electronic circuits themselves consume minimal power during operation, the continuous cooling load represents a constant baseline energy requirement regardless of computational workload. This contrasts sharply with conventional electronics, where power consumption scales more directly with processing activity.

Recent developments in cryogenic engineering have focused on recuperative cooling techniques and multi-stage systems that capture and reuse cooling capacity across temperature gradients. These innovations have improved overall system efficiency by 25-30% in laboratory settings, though commercial implementation remains limited by cost considerations and reliability concerns.

The economic viability of superconducting electronics ultimately depends on the application domain. For high-performance computing applications requiring extreme processing capabilities, the energy savings from reduced computational power may offset cooling costs. However, for more mainstream applications, the energy balance currently favors conventional semiconductor technologies despite their inherent resistive losses.

Standardization and Integration Challenges

The standardization and integration of superconducting technologies into cryogenic electronics systems present significant challenges that must be addressed for widespread commercial adoption. Currently, the field lacks unified standards for superconducting circuit design, fabrication processes, and testing methodologies, creating barriers to interoperability and scalability across different platforms and applications.

One major challenge is the absence of standardized interfaces between superconducting components and conventional room-temperature electronics. The significant temperature gradient between cryogenic environments (typically below 10K) and ambient conditions necessitates specialized interconnect technologies that can maintain signal integrity while minimizing thermal loading. Various proprietary solutions exist, but the lack of industry-wide standards hampers broader integration efforts.

Manufacturing standardization represents another critical hurdle. Superconducting materials and devices often require highly specialized fabrication processes with extremely tight tolerances. The absence of standardized manufacturing protocols leads to inconsistent device performance, yield issues, and challenges in scaling production. This variability significantly impacts the reliability and reproducibility of cryogenic electronic systems, particularly for complex applications like quantum computing.

System-level integration presents additional complexities. Cryogenic electronics systems typically incorporate multiple technologies—superconducting circuits, semiconductor devices, MEMS components, and optical interfaces—each with distinct operational requirements. Developing cohesive integration frameworks that accommodate these diverse elements while maintaining optimal performance remains challenging. The lack of standardized design tools and simulation environments specifically tailored for cryogenic superconducting systems further complicates integration efforts.

Power management and thermal engineering standards are particularly underdeveloped. Efficient heat dissipation and power delivery in cryogenic environments require specialized approaches that differ significantly from conventional electronics. Without standardized methodologies for thermal modeling and power distribution, designers must develop custom solutions for each application, increasing development time and costs.

Addressing these standardization and integration challenges requires coordinated efforts across industry, academia, and standards organizations. Several initiatives are emerging to develop reference architectures, standardized test procedures, and common interfaces for cryogenic superconducting systems. These efforts aim to create an ecosystem that facilitates innovation while ensuring compatibility and reliability across different implementations, ultimately accelerating the commercial viability of superconductivity-based cryogenic electronics.

One major challenge is the absence of standardized interfaces between superconducting components and conventional room-temperature electronics. The significant temperature gradient between cryogenic environments (typically below 10K) and ambient conditions necessitates specialized interconnect technologies that can maintain signal integrity while minimizing thermal loading. Various proprietary solutions exist, but the lack of industry-wide standards hampers broader integration efforts.

Manufacturing standardization represents another critical hurdle. Superconducting materials and devices often require highly specialized fabrication processes with extremely tight tolerances. The absence of standardized manufacturing protocols leads to inconsistent device performance, yield issues, and challenges in scaling production. This variability significantly impacts the reliability and reproducibility of cryogenic electronic systems, particularly for complex applications like quantum computing.

System-level integration presents additional complexities. Cryogenic electronics systems typically incorporate multiple technologies—superconducting circuits, semiconductor devices, MEMS components, and optical interfaces—each with distinct operational requirements. Developing cohesive integration frameworks that accommodate these diverse elements while maintaining optimal performance remains challenging. The lack of standardized design tools and simulation environments specifically tailored for cryogenic superconducting systems further complicates integration efforts.

Power management and thermal engineering standards are particularly underdeveloped. Efficient heat dissipation and power delivery in cryogenic environments require specialized approaches that differ significantly from conventional electronics. Without standardized methodologies for thermal modeling and power distribution, designers must develop custom solutions for each application, increasing development time and costs.

Addressing these standardization and integration challenges requires coordinated efforts across industry, academia, and standards organizations. Several initiatives are emerging to develop reference architectures, standardized test procedures, and common interfaces for cryogenic superconducting systems. These efforts aim to create an ecosystem that facilitates innovation while ensuring compatibility and reliability across different implementations, ultimately accelerating the commercial viability of superconductivity-based cryogenic electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!