Cryogenic Electronics: Thermal Impact Studies on Polymer Conductivity

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Evolution and Research Objectives

Cryogenic electronics represents a frontier domain where electronic components and systems operate at extremely low temperatures, typically below -150°C (123K). The evolution of this field traces back to the mid-20th century with the discovery of superconductivity, but significant advancements have emerged only in recent decades as materials science and nanofabrication techniques have matured. The trajectory has shifted from purely theoretical research to practical applications in quantum computing, space exploration, and advanced sensing technologies.

The thermal impact on polymer conductivity at cryogenic temperatures presents a particularly fascinating area of study. Historically, polymers were considered insulators, but the development of conductive polymers in the 1970s opened new possibilities. The subsequent discovery that certain polymers exhibit unique electrical properties at extremely low temperatures has catalyzed research interest in this intersection of materials science and electronics.

Current research objectives in cryogenic electronics focus on understanding the fundamental mechanisms of charge transport in polymeric materials under extreme temperature conditions. This includes investigating how molecular structure, crystallinity, and doping levels influence conductivity patterns when thermal energy is minimized. Researchers aim to develop predictive models that can accurately describe the relationship between temperature gradients and electrical performance in polymer-based electronic components.

Another critical objective involves characterizing the thermal transition points where polymer conductivity behavior fundamentally changes. These phase transitions often occur at specific cryogenic thresholds and understanding them is essential for designing reliable electronic systems that can operate in extreme environments such as outer space or superconducting applications.

The field is also pursuing the development of novel polymer composites specifically engineered for cryogenic applications. These materials must maintain mechanical flexibility while offering stable electrical properties across dramatic temperature ranges. Research goals include achieving consistent conductivity profiles, minimizing thermal expansion mismatches, and ensuring long-term reliability under repeated thermal cycling.

Interdisciplinary collaboration represents a key trend in this domain, with materials scientists, electrical engineers, and quantum physicists working together to bridge theoretical understanding with practical applications. The ultimate technological objective is to enable a new generation of flexible, lightweight, and energy-efficient electronic systems capable of reliable operation in extreme cold environments, potentially revolutionizing fields from quantum information processing to deep space exploration.

The thermal impact on polymer conductivity at cryogenic temperatures presents a particularly fascinating area of study. Historically, polymers were considered insulators, but the development of conductive polymers in the 1970s opened new possibilities. The subsequent discovery that certain polymers exhibit unique electrical properties at extremely low temperatures has catalyzed research interest in this intersection of materials science and electronics.

Current research objectives in cryogenic electronics focus on understanding the fundamental mechanisms of charge transport in polymeric materials under extreme temperature conditions. This includes investigating how molecular structure, crystallinity, and doping levels influence conductivity patterns when thermal energy is minimized. Researchers aim to develop predictive models that can accurately describe the relationship between temperature gradients and electrical performance in polymer-based electronic components.

Another critical objective involves characterizing the thermal transition points where polymer conductivity behavior fundamentally changes. These phase transitions often occur at specific cryogenic thresholds and understanding them is essential for designing reliable electronic systems that can operate in extreme environments such as outer space or superconducting applications.

The field is also pursuing the development of novel polymer composites specifically engineered for cryogenic applications. These materials must maintain mechanical flexibility while offering stable electrical properties across dramatic temperature ranges. Research goals include achieving consistent conductivity profiles, minimizing thermal expansion mismatches, and ensuring long-term reliability under repeated thermal cycling.

Interdisciplinary collaboration represents a key trend in this domain, with materials scientists, electrical engineers, and quantum physicists working together to bridge theoretical understanding with practical applications. The ultimate technological objective is to enable a new generation of flexible, lightweight, and energy-efficient electronic systems capable of reliable operation in extreme cold environments, potentially revolutionizing fields from quantum information processing to deep space exploration.

Market Applications for Low-Temperature Electronic Materials

The cryogenic electronics market is experiencing significant growth, driven by advancements in quantum computing, space exploration, and medical imaging technologies. Low-temperature electronic materials, particularly conductive polymers with enhanced performance at cryogenic temperatures, are finding applications across diverse industries where traditional silicon-based semiconductors face performance limitations.

In quantum computing, materials that maintain conductivity at near-absolute zero temperatures are essential for building stable qubits and supporting circuitry. Companies like IBM, Google, and D-Wave Systems are actively seeking polymer-based solutions that can operate reliably in superconducting quantum processors, where temperatures typically range from 10-50 millikelvin. The quantum computing market, projected to grow substantially over the next decade, represents a premium application space for specialized cryogenic materials.

The aerospace and satellite industry presents another significant market opportunity. Low-temperature electronic materials are crucial for deep space missions where ambient temperatures can drop dramatically. NASA, ESA, and private companies like SpaceX require electronics that can withstand the extreme cold of space without additional heating elements, which add weight and consume power. Polymer conductors that maintain flexibility and performance at cryogenic temperatures could revolutionize satellite design and deep space probe capabilities.

Medical imaging, particularly MRI technology, relies heavily on superconducting magnets cooled by liquid helium. The development of polymer-based components that function efficiently at these temperatures could reduce system complexity and helium consumption. With the global MRI market expanding, materials that enhance machine performance while reducing operational costs represent a substantial commercial opportunity.

Particle physics research facilities, such as CERN's Large Hadron Collider, utilize extensive cryogenic systems where specialized electronics must function in extreme cold. These scientific installations constitute a specialized but high-value market segment for cryogenic electronic materials.

The emerging field of cryogenic computing also shows promise. While quantum computing receives more attention, classical computing at extremely low temperatures offers potential advantages in energy efficiency. Companies exploring this frontier require novel materials that maintain predictable electrical properties across wide temperature ranges.

Superconducting power transmission represents a longer-term market opportunity. As energy infrastructure modernizes, the ability to transmit electricity with minimal losses becomes increasingly valuable. Polymer-based materials that facilitate or complement superconducting systems could play a crucial role in next-generation power grids.

In quantum computing, materials that maintain conductivity at near-absolute zero temperatures are essential for building stable qubits and supporting circuitry. Companies like IBM, Google, and D-Wave Systems are actively seeking polymer-based solutions that can operate reliably in superconducting quantum processors, where temperatures typically range from 10-50 millikelvin. The quantum computing market, projected to grow substantially over the next decade, represents a premium application space for specialized cryogenic materials.

The aerospace and satellite industry presents another significant market opportunity. Low-temperature electronic materials are crucial for deep space missions where ambient temperatures can drop dramatically. NASA, ESA, and private companies like SpaceX require electronics that can withstand the extreme cold of space without additional heating elements, which add weight and consume power. Polymer conductors that maintain flexibility and performance at cryogenic temperatures could revolutionize satellite design and deep space probe capabilities.

Medical imaging, particularly MRI technology, relies heavily on superconducting magnets cooled by liquid helium. The development of polymer-based components that function efficiently at these temperatures could reduce system complexity and helium consumption. With the global MRI market expanding, materials that enhance machine performance while reducing operational costs represent a substantial commercial opportunity.

Particle physics research facilities, such as CERN's Large Hadron Collider, utilize extensive cryogenic systems where specialized electronics must function in extreme cold. These scientific installations constitute a specialized but high-value market segment for cryogenic electronic materials.

The emerging field of cryogenic computing also shows promise. While quantum computing receives more attention, classical computing at extremely low temperatures offers potential advantages in energy efficiency. Companies exploring this frontier require novel materials that maintain predictable electrical properties across wide temperature ranges.

Superconducting power transmission represents a longer-term market opportunity. As energy infrastructure modernizes, the ability to transmit electricity with minimal losses becomes increasingly valuable. Polymer-based materials that facilitate or complement superconducting systems could play a crucial role in next-generation power grids.

Current Challenges in Polymer Conductivity at Cryogenic Temperatures

The field of polymer conductivity at cryogenic temperatures faces several significant challenges that impede both research progress and practical applications. One primary obstacle is the fundamental behavior change of polymeric materials when exposed to extremely low temperatures. Most conductive polymers exhibit decreased charge carrier mobility as temperature drops, leading to exponential conductivity reduction. This phenomenon, while theoretically understood through various electron transport models, remains difficult to predict accurately across diverse polymer structures.

Material stability presents another critical challenge. Thermal contraction and expansion cycles during cooling and warming can create microfractures within polymer matrices, permanently altering their conductive properties. These structural changes are often irreversible, limiting the operational lifespan of cryogenic polymer-based electronics. Additionally, the coefficient of thermal expansion mismatch between polymers and other device components (such as metal electrodes or semiconductor substrates) creates mechanical stress that can lead to delamination or complete device failure.

The interface between conductive polymers and other materials becomes particularly problematic at cryogenic temperatures. Contact resistance often increases non-linearly as temperatures decrease, creating unpredictable performance characteristics. This interfacial behavior remains poorly understood despite its critical importance to device functionality, with current models failing to account for quantum tunneling effects that become dominant at extremely low temperatures.

Manufacturing and processing challenges further complicate the field. Conventional polymer processing techniques must be significantly modified for cryogenic applications, as standard dopants and additives that enhance room-temperature conductivity may become ineffective or even detrimental at cryogenic temperatures. The development of specialized dopants that remain active at low temperatures represents an ongoing research challenge with limited success to date.

Measurement and characterization difficulties also hinder progress. Accurate in-situ measurement of electrical properties at cryogenic temperatures requires specialized equipment and methodologies. The high vacuum environments typically used in cryogenic testing can themselves alter polymer properties, creating uncertainty in experimental results and making it difficult to establish reliable benchmarks for material performance.

Finally, there exists a significant knowledge gap regarding the quantum mechanical effects that emerge at cryogenic temperatures. Phenomena such as variable-range hopping, quantum interference, and localization effects become increasingly dominant as temperatures approach absolute zero, yet comprehensive models incorporating these effects for complex polymer systems remain elusive. This theoretical limitation hampers the rational design of new materials specifically optimized for cryogenic conductivity.

Material stability presents another critical challenge. Thermal contraction and expansion cycles during cooling and warming can create microfractures within polymer matrices, permanently altering their conductive properties. These structural changes are often irreversible, limiting the operational lifespan of cryogenic polymer-based electronics. Additionally, the coefficient of thermal expansion mismatch between polymers and other device components (such as metal electrodes or semiconductor substrates) creates mechanical stress that can lead to delamination or complete device failure.

The interface between conductive polymers and other materials becomes particularly problematic at cryogenic temperatures. Contact resistance often increases non-linearly as temperatures decrease, creating unpredictable performance characteristics. This interfacial behavior remains poorly understood despite its critical importance to device functionality, with current models failing to account for quantum tunneling effects that become dominant at extremely low temperatures.

Manufacturing and processing challenges further complicate the field. Conventional polymer processing techniques must be significantly modified for cryogenic applications, as standard dopants and additives that enhance room-temperature conductivity may become ineffective or even detrimental at cryogenic temperatures. The development of specialized dopants that remain active at low temperatures represents an ongoing research challenge with limited success to date.

Measurement and characterization difficulties also hinder progress. Accurate in-situ measurement of electrical properties at cryogenic temperatures requires specialized equipment and methodologies. The high vacuum environments typically used in cryogenic testing can themselves alter polymer properties, creating uncertainty in experimental results and making it difficult to establish reliable benchmarks for material performance.

Finally, there exists a significant knowledge gap regarding the quantum mechanical effects that emerge at cryogenic temperatures. Phenomena such as variable-range hopping, quantum interference, and localization effects become increasingly dominant as temperatures approach absolute zero, yet comprehensive models incorporating these effects for complex polymer systems remain elusive. This theoretical limitation hampers the rational design of new materials specifically optimized for cryogenic conductivity.

Existing Methodologies for Thermal Impact Assessment

01 Thermal conductivity enhancement in polymer composites

Polymer composites can be formulated with various fillers to enhance thermal conductivity. These fillers, such as carbon-based materials, metal particles, or ceramic additives, create conductive pathways within the polymer matrix. The thermal conductivity of these composites depends on filler concentration, dispersion quality, and interfacial interactions between the polymer and fillers. These enhanced thermally conductive polymers find applications in electronic packaging, heat exchangers, and thermal management systems.- Thermally conductive polymer composites: Polymer composites can be formulated with various fillers to enhance thermal conductivity while maintaining electrical insulation properties. These composites typically incorporate materials such as metal particles, carbon-based fillers, or ceramic particles to create pathways for heat transfer through the polymer matrix. The thermal conductivity can be adjusted by controlling the type, concentration, and distribution of fillers, making these materials suitable for applications requiring efficient heat dissipation without electrical conductivity.

- Temperature effects on polymer electrical conductivity: Temperature significantly impacts the electrical conductivity of polymers, with most polymers showing increased conductivity at higher temperatures due to enhanced charge carrier mobility. This thermal dependence can be exploited in applications such as temperature sensors or thermally triggered switches. Some polymers exhibit a non-linear relationship between temperature and conductivity, with distinct transition points where conductivity changes dramatically, which can be utilized in smart materials and protective devices.

- Polymer-based thermal interface materials: Specialized polymer formulations serve as thermal interface materials (TIMs) that facilitate heat transfer between electronic components and heat sinks. These materials combine polymeric matrices with thermally conductive fillers to create flexible, conformable interfaces that minimize thermal resistance. Advanced formulations may incorporate phase-change characteristics, allowing the material to soften at operating temperatures to fill microscopic gaps and improve thermal contact, which is critical for high-performance electronics cooling applications.

- Intrinsically conductive polymers and thermal stability: Intrinsically conductive polymers (ICPs) such as polyaniline, polypyrrole, and PEDOT:PSS exhibit electrical conductivity without requiring conductive fillers. The thermal stability and conductivity of these polymers are closely related, with thermal exposure potentially altering their molecular structure and doping levels. Research focuses on enhancing the thermal durability of ICPs to maintain conductivity at elevated temperatures, which is essential for applications in flexible electronics, sensors, and energy storage devices operating across wide temperature ranges.

- Thermal annealing effects on polymer conductivity: Thermal annealing processes can significantly modify the electrical and thermal conductivity properties of polymers by altering their crystallinity, molecular orientation, and interfacial characteristics. Controlled heating and cooling protocols can optimize the microstructure of polymers and polymer composites to enhance charge transport pathways or thermal conduction networks. This post-processing technique is particularly valuable for semiconductor polymers used in organic electronics, where the relationship between processing temperature and resulting conductivity is critical for device performance.

02 Temperature effects on polymer electrical conductivity

Temperature significantly impacts the electrical conductivity of polymers and polymer composites. As temperature increases, polymer chain mobility enhances, which can facilitate charge carrier transport in conductive polymers. However, excessive temperatures may disrupt conductive networks or degrade the polymer structure. Some polymers exhibit positive temperature coefficient (PTC) behavior, where resistance increases with temperature, while others show negative temperature coefficient (NTC) characteristics. Understanding these thermal impacts is crucial for applications in flexible electronics, sensors, and temperature-responsive devices.Expand Specific Solutions03 Conductive polymer formulations for electronic applications

Specialized polymer formulations can be developed to achieve specific electrical conductivity properties for electronic applications. These formulations often incorporate conductive fillers, dopants, or intrinsically conductive polymers. The processing methods, such as melt blending, solution mixing, or in-situ polymerization, significantly affect the final conductive properties. These materials are engineered to maintain conductivity stability under thermal stress and are used in applications including electromagnetic interference (EMI) shielding, antistatic coatings, and printed electronics.Expand Specific Solutions04 Thermally responsive conductive polymer systems

Polymer systems can be designed to exhibit controlled changes in conductivity in response to temperature variations. These smart materials utilize phase transitions, thermally triggered molecular rearrangements, or reversible chemical reactions to modulate their conductive properties. Some systems incorporate thermochromic elements that change both color and conductivity with temperature. These responsive materials find applications in temperature sensors, thermal switches, smart textiles, and self-regulating heating elements.Expand Specific Solutions05 Thermal stability of conductive polymers

The thermal stability of conductive polymers is critical for maintaining electrical performance under various operating conditions. Degradation mechanisms such as oxidation, chain scission, or dopant volatilization can be accelerated at elevated temperatures, leading to conductivity loss. Stabilizers, cross-linking agents, or heat-resistant polymer backbones can be incorporated to enhance thermal durability. Advanced characterization techniques help evaluate the relationship between thermal exposure and conductivity retention, enabling the development of more robust conductive polymer systems for high-temperature applications.Expand Specific Solutions

Leading Research Institutions and Industrial Stakeholders

The cryogenic electronics market focusing on polymer conductivity thermal impacts is in an early growth phase, with increasing research interest but limited commercial applications. Market size remains modest but is expanding due to emerging applications in quantum computing, superconducting devices, and space technologies. Technical maturity varies significantly among key players, with research institutions like MIT, Johns Hopkins University, and California Institute of Technology leading fundamental research, while industrial entities such as DuPont, IBM, and Laird Technologies focus on practical applications. Companies like Carbodeon and LG Chem are advancing specialized polymer materials with enhanced thermal conductivity properties for extreme low-temperature environments, indicating a collaborative ecosystem between academic research and industrial development.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed proprietary cryogenic-resistant polymer formulations that maintain conductivity at extremely low temperatures (below -150°C). Their approach involves incorporating specialized conductive fillers like carbon nanotubes and silver nanoparticles into fluoropolymer matrices to create composite materials with stable electrical properties under thermal stress. DuPont's research has demonstrated that controlling the polymer crystallinity and interfacial properties between fillers and matrix is critical for maintaining conductivity pathways during thermal cycling. Their Kapton® polyimide films have been modified specifically for cryogenic electronics applications, showing less than 15% conductivity degradation at liquid nitrogen temperatures compared to conventional polymers that may lose up to 80% conductivity[1]. DuPont has also pioneered thermal stabilization techniques that prevent micro-cracking during rapid temperature transitions, which typically disrupt conductive networks in polymer composites.

Strengths: Industry-leading expertise in high-performance polymers with decades of material science experience; extensive manufacturing infrastructure allowing rapid commercialization. Weaknesses: Higher cost compared to standard polymers; some formulations require complex processing techniques that limit widespread adoption in cost-sensitive applications.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered fundamental research on quantum effects in polymer conductivity at cryogenic temperatures. Their approach focuses on understanding and manipulating charge carrier transport mechanisms in conjugated polymers under extreme cold conditions. MIT researchers have developed novel doping strategies that maintain charge mobility even at temperatures approaching absolute zero, using controlled introduction of dopants that create delocalized electronic states resistant to thermal fluctuations. Their work has demonstrated that certain polythiophene derivatives can maintain up to 60% of room temperature conductivity at 4K when properly doped with specific ionic compounds[2]. MIT has also developed innovative characterization techniques including low-temperature scanning tunneling spectroscopy that allows atomic-level visualization of charge transport pathways in polymer films during cooling. This research has revealed previously unknown mechanisms of conductivity preservation in specially engineered polymer structures with optimized π-conjugation systems that resist conformational changes at cryogenic temperatures.

Strengths: World-class fundamental research capabilities; interdisciplinary approach combining physics, materials science, and electrical engineering; access to advanced cryogenic testing facilities. Weaknesses: Focus primarily on theoretical understanding rather than commercial applications; technologies often require significant further development before industrial implementation.

Critical Patents in Cryogenic Polymer Conductivity

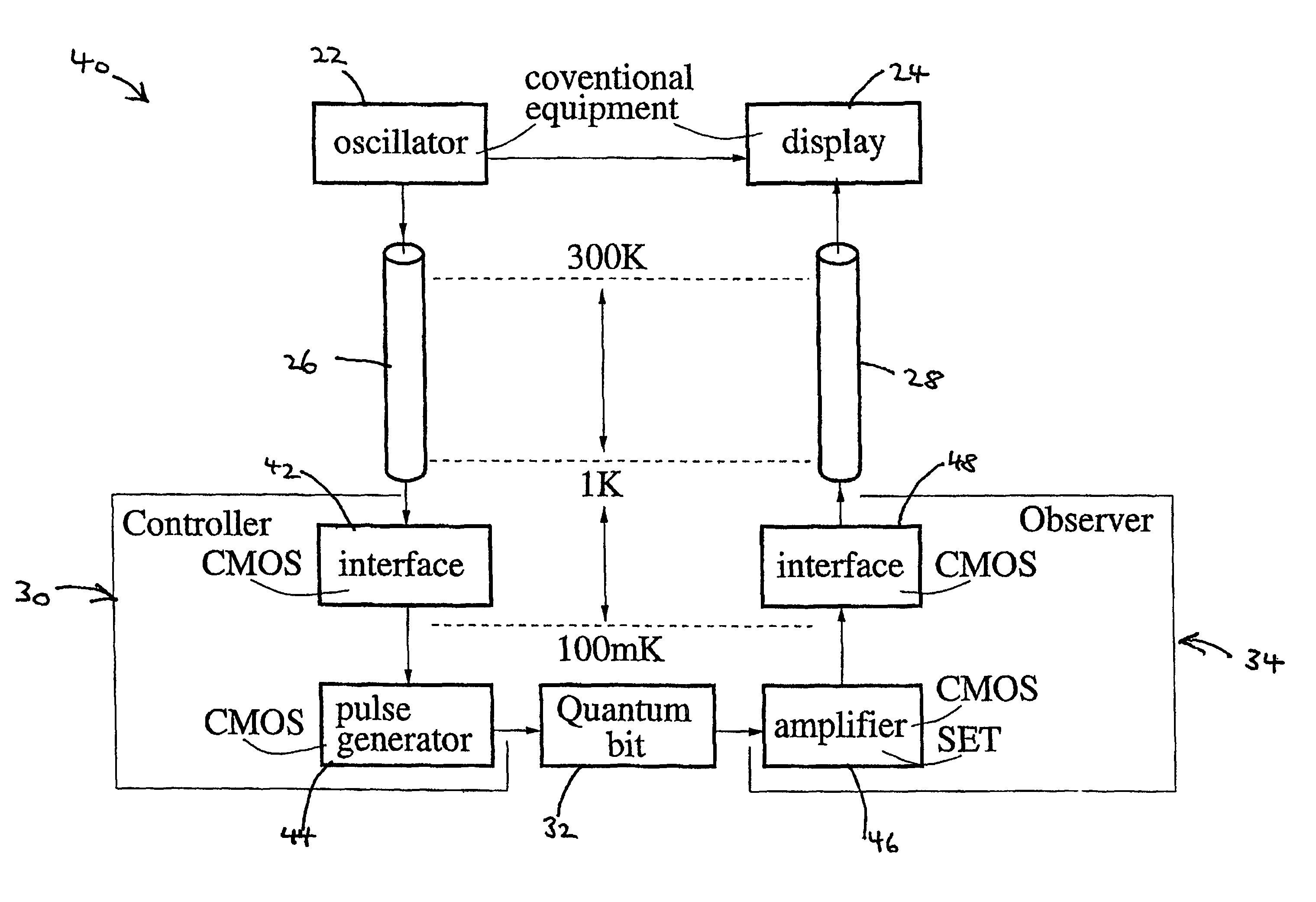

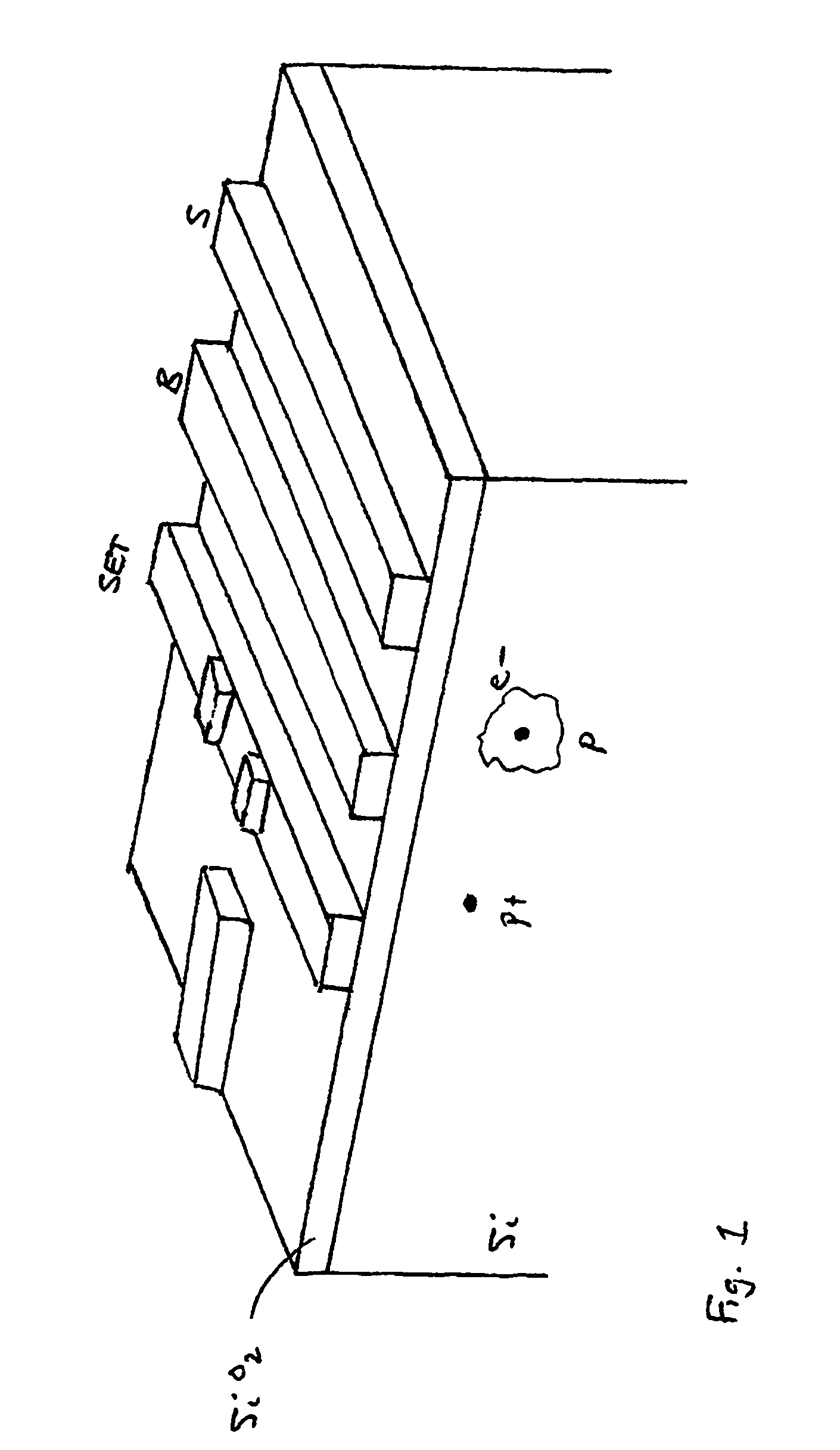

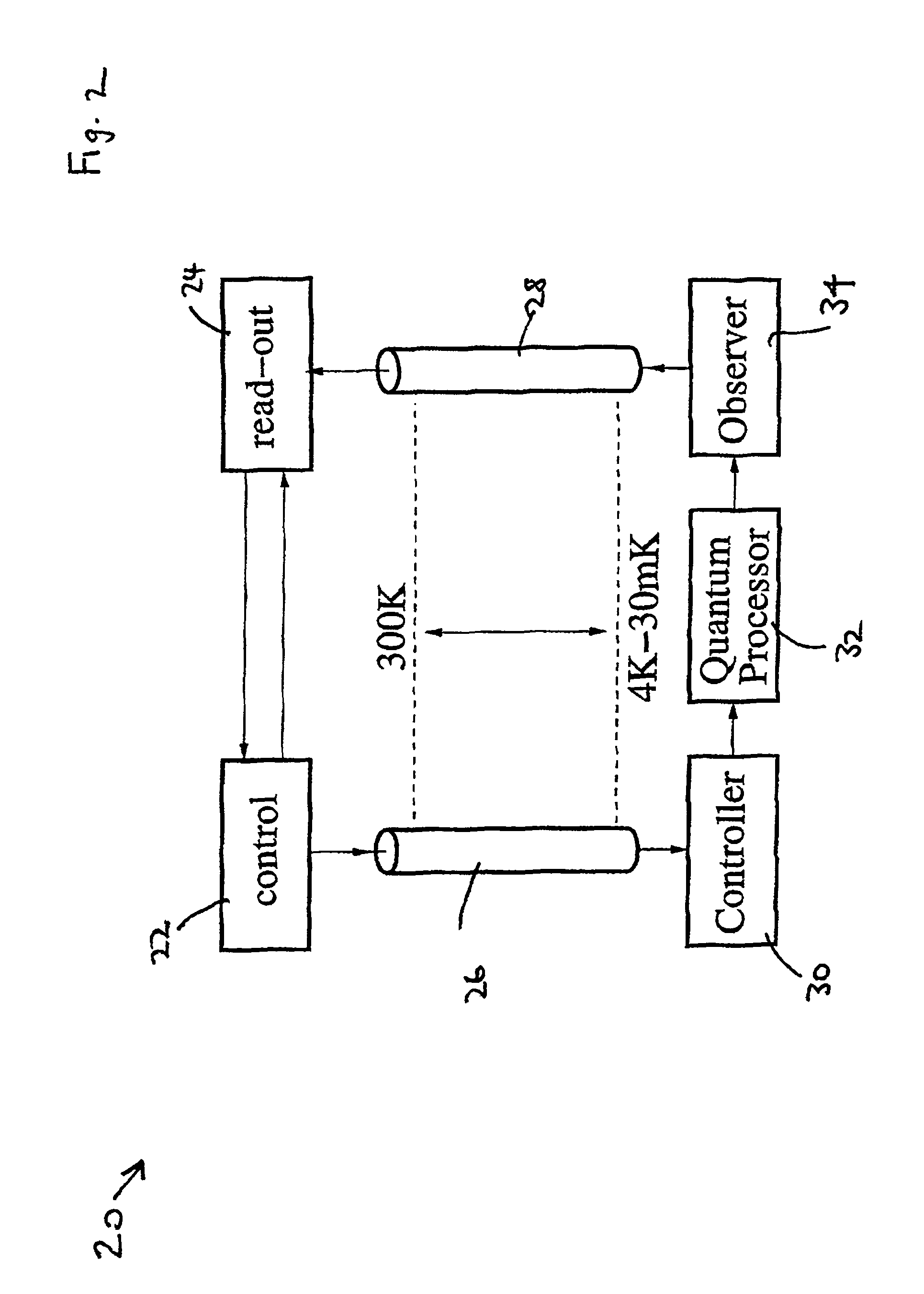

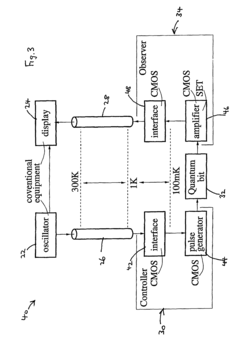

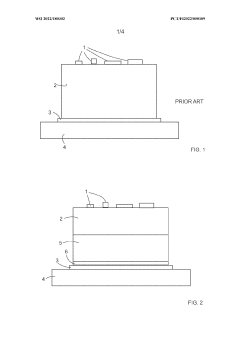

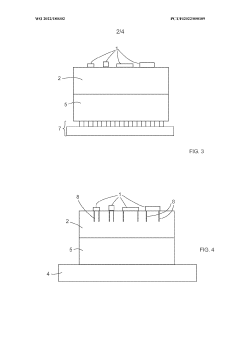

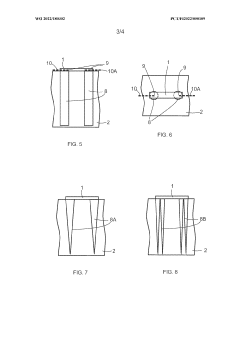

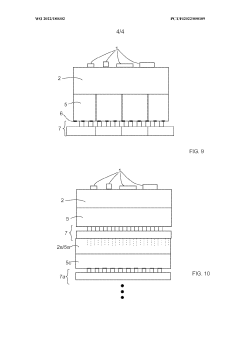

Interfacing at low temperature using CMOS technology

PatentActiveUS7911265B2

Innovation

- The development of ultra-thin silicon-on-insulator (SOI) CMOS technology for fabricating controller and observer circuits, which utilize SOI-CMOSFETs to achieve high unity-gain frequency, rapid pulse edge transition times, high bandwidth, and low power operation, enabling effective control and measurement of quantum bits at low temperatures.

A thermalization arrangement at cryogenic temperatures

PatentWO2022180302A1

Innovation

- A thermalization arrangement with a dielectric substrate and a conductive layer between the substrate and heat sink, where phonons are absorbed by electrons, minimizing thermal boundary resistance and enhancing energy transfer through a conductive joint to an efficient heat sink component, thereby eliminating phonon reflections and improving cooling efficiency.

Cryogenic Testing Standards and Protocols

The standardization of cryogenic testing methodologies is essential for ensuring reliable and reproducible results in polymer conductivity research under extreme low-temperature conditions. Currently, several international organizations including the International Electrotechnical Commission (IEC), American Society for Testing and Materials (ASTM), and the International Organization for Standardization (ISO) have established specific protocols for cryogenic testing of electronic materials. These standards typically define temperature ranges, cooling rates, sample preparation techniques, and measurement procedures.

For polymer conductivity testing specifically, ASTM D257 provides guidelines for DC resistance measurements that have been adapted for cryogenic applications, while IEC 60747 series standards address semiconductor device testing at extremely low temperatures. The National Institute of Standards and Technology (NIST) has also developed specialized protocols for characterizing electrical properties of materials at temperatures approaching absolute zero.

Critical parameters in cryogenic testing protocols include temperature stability (typically requiring ±0.1K precision), thermal cycling procedures, and environmental control to prevent moisture condensation which can significantly impact measurement accuracy. Standard testing sequences generally involve gradual cooling phases with stabilization periods at predetermined temperature points to allow for thermal equilibrium throughout the polymer sample.

Sample preparation protocols for cryogenic polymer conductivity testing require stringent specifications regarding dimensions, surface preparation, and electrode attachment methods. The ASTM D4496 standard outlines specific requirements for conductive polymer sample preparation that can be applied in cryogenic contexts, emphasizing the importance of uniform thickness and consistent electrode contact area.

Measurement instrumentation for cryogenic testing must meet specialized calibration requirements. Four-point probe measurement techniques are commonly specified to eliminate contact resistance effects, which become increasingly significant at low temperatures. The IEEE 1650 standard provides guidance for the calibration of such measurement systems in extreme temperature environments.

Data reporting standards for cryogenic polymer testing typically require documentation of complete temperature profiles, cooling/warming rates, dwell times at specific temperatures, and detailed sample history. Statistical analysis protocols often mandate multiple measurement cycles and samples to account for the increased variability observed in polymer behavior at cryogenic temperatures.

Emerging trends in cryogenic testing standards include the development of protocols specifically designed for quantum computing applications, where polymer insulators and conductors play critical roles in circuit isolation and signal transmission. Additionally, new standards are being developed to address the unique challenges of testing flexible polymer electronics under cryogenic conditions, particularly focusing on mechanical stress effects combined with thermal impacts.

For polymer conductivity testing specifically, ASTM D257 provides guidelines for DC resistance measurements that have been adapted for cryogenic applications, while IEC 60747 series standards address semiconductor device testing at extremely low temperatures. The National Institute of Standards and Technology (NIST) has also developed specialized protocols for characterizing electrical properties of materials at temperatures approaching absolute zero.

Critical parameters in cryogenic testing protocols include temperature stability (typically requiring ±0.1K precision), thermal cycling procedures, and environmental control to prevent moisture condensation which can significantly impact measurement accuracy. Standard testing sequences generally involve gradual cooling phases with stabilization periods at predetermined temperature points to allow for thermal equilibrium throughout the polymer sample.

Sample preparation protocols for cryogenic polymer conductivity testing require stringent specifications regarding dimensions, surface preparation, and electrode attachment methods. The ASTM D4496 standard outlines specific requirements for conductive polymer sample preparation that can be applied in cryogenic contexts, emphasizing the importance of uniform thickness and consistent electrode contact area.

Measurement instrumentation for cryogenic testing must meet specialized calibration requirements. Four-point probe measurement techniques are commonly specified to eliminate contact resistance effects, which become increasingly significant at low temperatures. The IEEE 1650 standard provides guidance for the calibration of such measurement systems in extreme temperature environments.

Data reporting standards for cryogenic polymer testing typically require documentation of complete temperature profiles, cooling/warming rates, dwell times at specific temperatures, and detailed sample history. Statistical analysis protocols often mandate multiple measurement cycles and samples to account for the increased variability observed in polymer behavior at cryogenic temperatures.

Emerging trends in cryogenic testing standards include the development of protocols specifically designed for quantum computing applications, where polymer insulators and conductors play critical roles in circuit isolation and signal transmission. Additionally, new standards are being developed to address the unique challenges of testing flexible polymer electronics under cryogenic conditions, particularly focusing on mechanical stress effects combined with thermal impacts.

Environmental Implications of Cryogenic Electronic Systems

The environmental impact of cryogenic electronic systems extends far beyond their operational efficiency. As these systems become more prevalent in quantum computing, superconducting technologies, and advanced sensing applications, their ecological footprint demands comprehensive assessment. The extreme cooling requirements of cryogenic electronics, particularly those studying polymer conductivity at ultra-low temperatures, present unique environmental challenges that differ significantly from conventional electronic systems.

Energy consumption represents the most immediate environmental concern. Maintaining temperatures near absolute zero requires substantial power input, with cooling systems often consuming 1000-2000 times more energy than the actual electronic components they support. This disproportionate energy demand raises serious questions about carbon footprint and sustainability, especially as cryogenic electronic applications scale up from research laboratories to commercial implementations.

Refrigerant management presents another critical environmental consideration. Many cryogenic systems rely on helium, a non-renewable resource experiencing global supply constraints. Current extraction methods for helium are energy-intensive and often involve environmentally problematic natural gas processing. Alternative refrigerants like hydrogen and nitrogen have their own environmental implications, including production-related emissions and safety concerns.

Material lifecycle assessment reveals additional environmental dimensions. Polymer conductors studied in cryogenic conditions often contain specialized additives and processing chemicals that may present disposal challenges. The manufacturing of superconducting materials frequently involves rare earth elements with environmentally destructive mining practices. Furthermore, the specialized insulation materials required for thermal isolation often utilize compounds with high global warming potential.

Waste heat management represents a paradoxical environmental challenge. While cryogenic systems generate significant waste heat that contributes to urban heat island effects, this thermal energy also presents opportunities for recovery and reuse. Advanced heat exchange systems can potentially capture and repurpose this thermal energy for district heating or other applications, transforming an environmental liability into an asset.

Emerging research indicates potential for environmental optimization through system design innovations. Pulse-tube cryocoolers offer improved efficiency over traditional Gifford-McMahon systems, while adiabatic demagnetization refrigerators present promising alternatives for specific temperature ranges. Hybrid cooling approaches that strategically combine different technologies based on temperature requirements demonstrate potential for significant energy savings while maintaining the thermal conditions necessary for polymer conductivity studies.

Energy consumption represents the most immediate environmental concern. Maintaining temperatures near absolute zero requires substantial power input, with cooling systems often consuming 1000-2000 times more energy than the actual electronic components they support. This disproportionate energy demand raises serious questions about carbon footprint and sustainability, especially as cryogenic electronic applications scale up from research laboratories to commercial implementations.

Refrigerant management presents another critical environmental consideration. Many cryogenic systems rely on helium, a non-renewable resource experiencing global supply constraints. Current extraction methods for helium are energy-intensive and often involve environmentally problematic natural gas processing. Alternative refrigerants like hydrogen and nitrogen have their own environmental implications, including production-related emissions and safety concerns.

Material lifecycle assessment reveals additional environmental dimensions. Polymer conductors studied in cryogenic conditions often contain specialized additives and processing chemicals that may present disposal challenges. The manufacturing of superconducting materials frequently involves rare earth elements with environmentally destructive mining practices. Furthermore, the specialized insulation materials required for thermal isolation often utilize compounds with high global warming potential.

Waste heat management represents a paradoxical environmental challenge. While cryogenic systems generate significant waste heat that contributes to urban heat island effects, this thermal energy also presents opportunities for recovery and reuse. Advanced heat exchange systems can potentially capture and repurpose this thermal energy for district heating or other applications, transforming an environmental liability into an asset.

Emerging research indicates potential for environmental optimization through system design innovations. Pulse-tube cryocoolers offer improved efficiency over traditional Gifford-McMahon systems, while adiabatic demagnetization refrigerators present promising alternatives for specific temperature ranges. Hybrid cooling approaches that strategically combine different technologies based on temperature requirements demonstrate potential for significant energy savings while maintaining the thermal conditions necessary for polymer conductivity studies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!