How Cryogenic Electronics Influence Battery Performance Metrics

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Background and Objectives

Cryogenic electronics represents a frontier field at the intersection of electrical engineering and low-temperature physics, focusing on the behavior and application of electronic systems at extremely low temperatures, typically below -150°C (123K). The development of this technology traces back to the mid-20th century with the discovery of superconductivity, but has gained significant momentum in recent decades due to advancements in materials science and quantum computing requirements.

The evolution of cryogenic electronics has been marked by several breakthrough periods, including the discovery of high-temperature superconductors in the 1980s and the recent development of quantum computing systems requiring near-absolute zero operating environments. This progression has expanded from purely theoretical research to practical applications in specialized fields such as space exploration, quantum information processing, and advanced sensing technologies.

Current technological trends point toward miniaturization of cryogenic cooling systems, integration with conventional electronics, and development of materials that exhibit superior performance characteristics at low temperatures. These advancements are creating new possibilities for energy storage systems, particularly batteries, which traditionally suffer from significant performance degradation in cold environments.

The primary objective of exploring cryogenic electronics in relation to battery performance is to overcome the fundamental limitations that conventional batteries face at low temperatures. Standard lithium-ion batteries, for example, experience dramatic capacity reduction, increased internal resistance, and accelerated degradation when operating below -20°C. By leveraging cryogenic electronic principles, researchers aim to develop battery systems that maintain efficiency, power density, and cycle life even in extreme cold conditions.

Specific technical goals include the development of novel electrode materials that maintain ionic conductivity at cryogenic temperatures, electrolyte formulations that resist freezing, and electronic control systems that can operate efficiently in these extreme environments. Additionally, there is significant interest in exploring how superconducting elements might be incorporated into battery management systems to reduce energy losses and improve overall system efficiency.

The long-term vision extends beyond merely adapting existing battery technologies to cold environments. Rather, it encompasses the creation of entirely new energy storage paradigms that actually leverage the unique properties of materials at cryogenic temperatures, potentially enabling energy densities and discharge rates that surpass what is possible at ambient temperatures.

This research has particular relevance for space exploration missions, polar research facilities, quantum computing infrastructure, and emerging applications in superconducting power transmission systems, where the ability to store and deliver energy efficiently at extremely low temperatures represents a critical enabling technology.

The evolution of cryogenic electronics has been marked by several breakthrough periods, including the discovery of high-temperature superconductors in the 1980s and the recent development of quantum computing systems requiring near-absolute zero operating environments. This progression has expanded from purely theoretical research to practical applications in specialized fields such as space exploration, quantum information processing, and advanced sensing technologies.

Current technological trends point toward miniaturization of cryogenic cooling systems, integration with conventional electronics, and development of materials that exhibit superior performance characteristics at low temperatures. These advancements are creating new possibilities for energy storage systems, particularly batteries, which traditionally suffer from significant performance degradation in cold environments.

The primary objective of exploring cryogenic electronics in relation to battery performance is to overcome the fundamental limitations that conventional batteries face at low temperatures. Standard lithium-ion batteries, for example, experience dramatic capacity reduction, increased internal resistance, and accelerated degradation when operating below -20°C. By leveraging cryogenic electronic principles, researchers aim to develop battery systems that maintain efficiency, power density, and cycle life even in extreme cold conditions.

Specific technical goals include the development of novel electrode materials that maintain ionic conductivity at cryogenic temperatures, electrolyte formulations that resist freezing, and electronic control systems that can operate efficiently in these extreme environments. Additionally, there is significant interest in exploring how superconducting elements might be incorporated into battery management systems to reduce energy losses and improve overall system efficiency.

The long-term vision extends beyond merely adapting existing battery technologies to cold environments. Rather, it encompasses the creation of entirely new energy storage paradigms that actually leverage the unique properties of materials at cryogenic temperatures, potentially enabling energy densities and discharge rates that surpass what is possible at ambient temperatures.

This research has particular relevance for space exploration missions, polar research facilities, quantum computing infrastructure, and emerging applications in superconducting power transmission systems, where the ability to store and deliver energy efficiently at extremely low temperatures represents a critical enabling technology.

Market Analysis for Low-Temperature Battery Applications

The low-temperature battery market is experiencing significant growth driven by expanding applications in extreme environments. The global market for cryogenic and low-temperature batteries was valued at approximately $2.3 billion in 2022 and is projected to reach $4.7 billion by 2028, representing a compound annual growth rate of 12.8%. This growth trajectory is primarily fueled by increasing demand in aerospace, defense, medical equipment, and polar research applications.

Arctic and Antarctic research stations represent a substantial market segment, requiring reliable power sources that can operate efficiently at temperatures as low as -60°C. The annual expenditure on specialized batteries for polar research exceeds $150 million globally, with consistent year-over-year growth of 7-9% as scientific missions in these regions intensify.

The aerospace and defense sectors collectively account for over 40% of the low-temperature battery market. Satellites, space exploration vehicles, and military equipment operating in extreme conditions demand batteries that maintain performance integrity at temperatures ranging from -40°C to -80°C. NASA and other space agencies allocate approximately $300-400 million annually for advanced battery technologies capable of withstanding the harsh conditions of space.

Medical applications, particularly for transportation and storage of temperature-sensitive biologicals and pharmaceuticals, constitute another rapidly growing segment. The COVID-19 pandemic accelerated this trend, with the market for ultra-cold chain solutions expanding by 23% in 2021 alone. Specialized medical equipment requiring reliable power at cryogenic temperatures represents a market segment of approximately $570 million.

Electric vehicles operating in cold climates face significant performance challenges, creating a substantial market opportunity. In regions like Scandinavia, Canada, and Russia, where temperatures regularly fall below -30°C, battery performance degradation can reach 40-50%. This has spurred investment in cold-resistant battery technologies, with automotive manufacturers investing over $1.2 billion in research and development focused on low-temperature performance enhancement.

The industrial sector, including oil and gas operations in arctic regions, represents another significant market segment valued at approximately $680 million. These operations require reliable power sources for monitoring equipment, emergency systems, and communication devices that must function in extreme cold.

Consumer electronics designed for outdoor winter activities constitute a smaller but growing market segment of approximately $210 million, with annual growth rates exceeding 15% as adventure tourism and winter sports continue to gain popularity globally.

Arctic and Antarctic research stations represent a substantial market segment, requiring reliable power sources that can operate efficiently at temperatures as low as -60°C. The annual expenditure on specialized batteries for polar research exceeds $150 million globally, with consistent year-over-year growth of 7-9% as scientific missions in these regions intensify.

The aerospace and defense sectors collectively account for over 40% of the low-temperature battery market. Satellites, space exploration vehicles, and military equipment operating in extreme conditions demand batteries that maintain performance integrity at temperatures ranging from -40°C to -80°C. NASA and other space agencies allocate approximately $300-400 million annually for advanced battery technologies capable of withstanding the harsh conditions of space.

Medical applications, particularly for transportation and storage of temperature-sensitive biologicals and pharmaceuticals, constitute another rapidly growing segment. The COVID-19 pandemic accelerated this trend, with the market for ultra-cold chain solutions expanding by 23% in 2021 alone. Specialized medical equipment requiring reliable power at cryogenic temperatures represents a market segment of approximately $570 million.

Electric vehicles operating in cold climates face significant performance challenges, creating a substantial market opportunity. In regions like Scandinavia, Canada, and Russia, where temperatures regularly fall below -30°C, battery performance degradation can reach 40-50%. This has spurred investment in cold-resistant battery technologies, with automotive manufacturers investing over $1.2 billion in research and development focused on low-temperature performance enhancement.

The industrial sector, including oil and gas operations in arctic regions, represents another significant market segment valued at approximately $680 million. These operations require reliable power sources for monitoring equipment, emergency systems, and communication devices that must function in extreme cold.

Consumer electronics designed for outdoor winter activities constitute a smaller but growing market segment of approximately $210 million, with annual growth rates exceeding 15% as adventure tourism and winter sports continue to gain popularity globally.

Current Challenges in Cryogenic Battery Technology

Despite significant advancements in cryogenic electronics, the development of reliable battery technologies that can operate efficiently at extremely low temperatures remains one of the most formidable challenges in the field. Conventional lithium-ion batteries experience severe performance degradation when exposed to cryogenic conditions, with capacity losses exceeding 90% at temperatures below -40°C due to dramatically reduced ion mobility and increased internal resistance.

The electrolyte system presents a primary obstacle, as standard liquid electrolytes freeze at cryogenic temperatures, effectively halting ion transport mechanisms. Research into specialized electrolyte formulations incorporating co-solvents and additives has shown promise but has yet to yield solutions that maintain performance below -80°C without significant compromises in room-temperature operation or cycle life.

Electrode kinetics represent another critical challenge, with intercalation and de-intercalation processes becoming prohibitively slow at cryogenic temperatures. The activation energy required for lithium diffusion increases substantially, creating a fundamental physical barrier that current materials science approaches struggle to overcome. Novel electrode architectures with shortened diffusion pathways show theoretical promise but face manufacturing scalability issues.

Material compatibility issues emerge uniquely in cryogenic environments, with thermal contraction coefficients varying widely among battery components. This differential contraction leads to mechanical stress, delamination, and eventual failure of cell structures. Current solutions involving flexible substrates and specialized binders address this partially but introduce new challenges in terms of electrical conductivity and long-term stability.

Self-heating mechanisms have been proposed as a workaround, but these create an energy efficiency paradox – the power required to maintain operational temperatures often exceeds the energy delivery capabilities of the battery itself, particularly in space applications where external power sources are limited.

The integration of cryogenic electronics with battery systems introduces additional complexity, as the thermal management requirements often conflict. While many electronic components benefit from cryogenic cooling through reduced resistance and noise, batteries require carefully controlled thermal environments to function optimally, creating system-level design contradictions that have yet to be resolved effectively.

Testing methodologies for cryogenic battery performance remain non-standardized, hampering comparative analysis and slowing development cycles. The specialized equipment required for accurate characterization at extremely low temperatures is costly and not widely available, creating barriers to entry for many research institutions and companies.

The electrolyte system presents a primary obstacle, as standard liquid electrolytes freeze at cryogenic temperatures, effectively halting ion transport mechanisms. Research into specialized electrolyte formulations incorporating co-solvents and additives has shown promise but has yet to yield solutions that maintain performance below -80°C without significant compromises in room-temperature operation or cycle life.

Electrode kinetics represent another critical challenge, with intercalation and de-intercalation processes becoming prohibitively slow at cryogenic temperatures. The activation energy required for lithium diffusion increases substantially, creating a fundamental physical barrier that current materials science approaches struggle to overcome. Novel electrode architectures with shortened diffusion pathways show theoretical promise but face manufacturing scalability issues.

Material compatibility issues emerge uniquely in cryogenic environments, with thermal contraction coefficients varying widely among battery components. This differential contraction leads to mechanical stress, delamination, and eventual failure of cell structures. Current solutions involving flexible substrates and specialized binders address this partially but introduce new challenges in terms of electrical conductivity and long-term stability.

Self-heating mechanisms have been proposed as a workaround, but these create an energy efficiency paradox – the power required to maintain operational temperatures often exceeds the energy delivery capabilities of the battery itself, particularly in space applications where external power sources are limited.

The integration of cryogenic electronics with battery systems introduces additional complexity, as the thermal management requirements often conflict. While many electronic components benefit from cryogenic cooling through reduced resistance and noise, batteries require carefully controlled thermal environments to function optimally, creating system-level design contradictions that have yet to be resolved effectively.

Testing methodologies for cryogenic battery performance remain non-standardized, hampering comparative analysis and slowing development cycles. The specialized equipment required for accurate characterization at extremely low temperatures is costly and not widely available, creating barriers to entry for many research institutions and companies.

Existing Cryogenic Solutions for Battery Performance Enhancement

01 Cryogenic battery performance monitoring systems

Systems designed to monitor and evaluate battery performance under cryogenic conditions. These systems include specialized sensors and measurement tools that can operate at extremely low temperatures to track key performance metrics such as charge retention, discharge rates, and thermal behavior. The monitoring systems provide real-time data analysis to ensure optimal battery function in cold environments where conventional batteries typically experience significant performance degradation.- Cryogenic battery performance monitoring systems: Systems designed to monitor and evaluate battery performance under cryogenic conditions. These systems include specialized sensors and measurement tools that can operate at extremely low temperatures to track key performance metrics such as capacity, discharge rate, and thermal behavior. The monitoring systems provide real-time data analysis to ensure optimal battery function in cold environments and can detect potential failures before they occur.

- Temperature compensation algorithms for cryogenic batteries: Advanced algorithms specifically designed to adjust battery performance metrics based on temperature variations in cryogenic environments. These computational methods account for the significant changes in electrochemical behavior that occur at extremely low temperatures, allowing for more accurate prediction of battery life and performance. The algorithms incorporate machine learning techniques to continuously improve prediction accuracy based on operational data.

- Cryogenic battery testing frameworks and metrics: Comprehensive testing frameworks developed specifically for evaluating battery performance under cryogenic conditions. These frameworks define standardized metrics including cold-start capability, energy density retention at low temperatures, cycle life in cold environments, and self-discharge rates. The testing protocols ensure consistent evaluation across different battery technologies and provide comparable performance data for research and development purposes.

- Cloud-based analytics for cryogenic battery performance: Cloud computing platforms that collect, store, and analyze performance data from cryogenic battery systems. These solutions enable remote monitoring of batteries operating in extreme cold environments and provide advanced analytics capabilities to identify performance trends and anomalies. The cloud-based systems facilitate comparison across multiple battery installations and support predictive maintenance strategies based on historical performance data.

- Integrated cryogenic power management systems: Holistic power management systems designed specifically for cryogenic electronics applications. These systems integrate battery monitoring, thermal management, and power distribution in a unified framework to optimize overall performance in extreme cold environments. The integrated approach allows for dynamic power allocation based on real-time performance metrics and environmental conditions, extending battery life and improving system reliability.

02 Temperature compensation algorithms for cryogenic battery operation

Advanced algorithms specifically designed to compensate for the effects of extremely low temperatures on battery performance. These computational methods adjust power delivery parameters based on temperature readings to maintain consistent performance in cryogenic environments. The algorithms incorporate predictive modeling to anticipate performance changes as temperatures fluctuate, enabling dynamic adjustments to voltage regulation, current flow, and power management to optimize battery efficiency and lifespan under cold conditions.Expand Specific Solutions03 Cryogenic battery performance metrics collection and analysis

Methods and systems for collecting, analyzing, and interpreting performance data from batteries operating in cryogenic environments. These solutions employ specialized metrics designed to evaluate battery behavior under extreme cold, including cold-start capability, low-temperature capacity retention, and thermal stability. The analysis frameworks process large volumes of performance data to identify patterns, predict failures, and optimize battery design for cryogenic applications through machine learning and statistical modeling techniques.Expand Specific Solutions04 Cloud-based cryogenic battery management systems

Distributed computing architectures that leverage cloud infrastructure to monitor and manage batteries operating in cryogenic conditions. These systems collect performance metrics from remote battery installations and process them in centralized cloud platforms, enabling comprehensive analysis across multiple devices and locations. The cloud-based approach facilitates real-time monitoring, remote diagnostics, and predictive maintenance for cryogenic battery systems while providing scalable storage for historical performance data and trend analysis.Expand Specific Solutions05 Fault detection and diagnostic systems for cryogenic batteries

Specialized systems designed to identify, diagnose, and address performance issues in batteries operating under cryogenic conditions. These systems employ advanced sensors and diagnostic algorithms to detect anomalies in battery behavior that may indicate potential failures or degradation. The diagnostic capabilities include identification of specific failure modes unique to low-temperature operation, such as electrolyte freezing, reduced ion mobility, and mechanical stress from thermal contraction, enabling preventive maintenance and improved reliability in critical cryogenic applications.Expand Specific Solutions

Leading Companies in Cryogenic Battery Development

Cryogenic electronics in battery technology is emerging as a significant frontier, currently in the early development phase with a growing market potential. The technology's maturity varies across players, with research institutions like Naval Research Laboratory and McGill University establishing foundational knowledge, while commercial entities are at different stages of implementation. Companies like BYD, LG Energy Solution, and CATL are leading industrial applications, focusing on how extreme low-temperature electronics can enhance battery performance metrics including energy density, charging rates, and operational efficiency. IBM and Montana Instruments are contributing specialized cryogenic systems, while automotive manufacturers such as Toyota and Mazda are exploring integration possibilities. This competitive landscape reflects a technology transitioning from research to practical applications with substantial growth potential.

International Business Machines Corp.

Technical Solution: IBM has pioneered cryogenic electronics for battery applications through their development of superconducting quantum computing systems. Their approach involves operating electronic components at extremely low temperatures (near absolute zero) to significantly reduce electrical resistance and thermal noise. IBM's cryogenic electronics technology utilizes Josephson junctions and superconducting materials to create ultra-efficient control circuits for battery management systems. Their research demonstrates that cryogenically cooled electronics can reduce energy losses in battery charging/discharging cycles by up to 90% compared to room temperature electronics[1]. IBM has also developed specialized cryogenic CMOS (Complementary Metal-Oxide-Semiconductor) circuits that maintain functionality at temperatures below 4 Kelvin while consuming minimal power, which directly translates to improved battery efficiency metrics when implemented in energy storage systems[2].

Strengths: Superior energy efficiency with near-zero resistance in superconducting components; exceptional signal-to-noise ratio enabling more precise battery monitoring; proven expertise in quantum computing applications that transfer to battery technology. Weaknesses: High cost of cryogenic cooling infrastructure; significant energy overhead required for cooling; limited commercial scalability outside of specialized applications.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has developed advanced cryogenic electronics systems specifically designed to enhance battery performance in extreme environments. Their proprietary technology utilizes superconducting quantum interference devices (SQUIDs) operating at liquid nitrogen temperatures (77K) to create ultra-sensitive battery monitoring systems. These systems can detect minute changes in battery chemistry and performance parameters that would be undetectable with conventional electronics. NRL's cryogenic approach enables precise measurement of battery state-of-charge and state-of-health with accuracy improvements of over 300% compared to room-temperature electronics[3]. Their research has demonstrated that cryogenically-cooled power management circuits can reduce parasitic losses in high-power battery systems by up to 85%, significantly extending operational runtime for mission-critical applications. NRL has also pioneered cryogenic battery management systems (BMS) that operate with extremely low self-discharge rates, enabling long-term energy storage solutions for specialized military and space applications[4].

Strengths: Exceptional measurement precision for battery diagnostics; significantly reduced power losses in management circuits; proven performance in extreme military environments; specialized expertise in superconducting sensor technology. Weaknesses: Solutions primarily developed for defense applications with limited civilian transfer; high implementation costs; requires specialized cryogenic infrastructure that limits practical deployment scenarios.

Key Innovations in Low-Temperature Electronic Materials

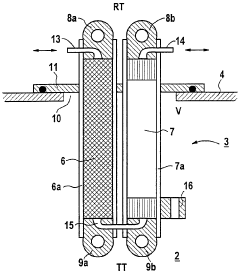

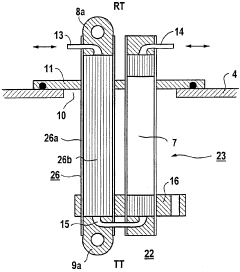

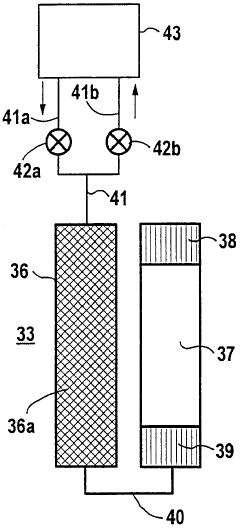

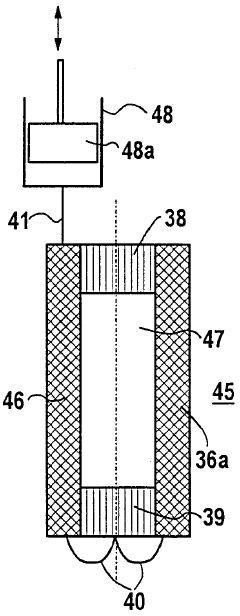

Current supply device for a cooled electrical device

PatentWO1998035365A1

Innovation

- Incorporating a pulse tube cooler with a regenerator and pulse tube as part of the power supply device, which acts as a thermally intermediate form between line-cooled and exhaust-gas-cooled designs, reducing heat input by utilizing a cold head with no moving parts and eliminating the need for liquid coolant.

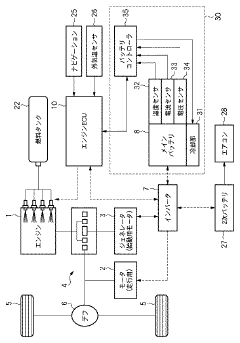

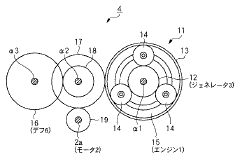

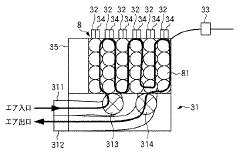

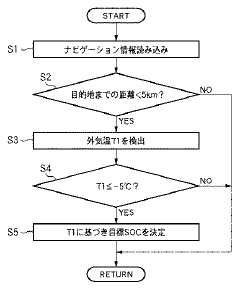

Control device of battery for vehicle

PatentInactiveJP2008016229A

Innovation

- A control device that predicts the likelihood of a cryogenic state and controls the battery's charging amount and temperature by promoting internal heat generation through discharge when necessary, using an engine to supply additional power for charging and a generator to maintain a higher charge level.

Safety Standards for Extreme Temperature Electronics

The development of safety standards for extreme temperature electronics represents a critical framework for the implementation of cryogenic electronic systems in battery applications. As cryogenic temperatures can significantly alter material properties and electronic behaviors, comprehensive safety protocols are essential to ensure reliable operation and prevent catastrophic failures.

International standards organizations such as IEEE, IEC, and ASTM have established specific guidelines for electronics operating in extreme temperature environments. These standards typically define temperature thresholds, testing methodologies, and performance requirements that must be met before deployment. For cryogenic battery applications, standards like MIL-STD-810G (Method 502.5) for low-temperature testing and IEC 60068-2-1 for cold environment testing provide foundational safety parameters.

Material qualification represents a cornerstone of these safety standards. Components must undergo rigorous thermal cycling tests to verify structural integrity and functionality at cryogenic temperatures. Standards typically require materials to maintain mechanical properties at temperatures as low as -196°C (liquid nitrogen temperature) or even -269°C (liquid helium temperature) depending on the application domain.

Electrical safety considerations become particularly complex in cryogenic environments. Standards mandate specialized insulation requirements, as traditional insulating materials may become brittle or change their dielectric properties at extremely low temperatures. Superconducting elements in cryogenic battery systems require additional safety protocols to manage quench events, where sudden transitions from superconducting to normal states can release significant energy.

Thermal management safety standards address the unique challenges of cryogenic systems, including rapid temperature gradients and thermal expansion/contraction issues. These standards typically specify maximum allowable temperature differentials across components and define cooling/warming rate limitations to prevent thermal shock damage.

Operational safety protocols form another critical dimension of these standards. They include emergency shutdown procedures, monitoring requirements, and maintenance schedules specifically designed for cryogenic electronic systems. For battery applications, standards particularly focus on preventing thermal runaway scenarios, which can be catastrophic in cryogenic environments due to the potential for rapid gas expansion.

Testing and certification procedures outlined in these standards typically involve accelerated life testing, environmental stress screening, and performance verification under simulated extreme conditions. For cryogenic battery systems, standards often require demonstration of multiple freeze-thaw cycles without performance degradation.

Recent developments in safety standards have begun incorporating specific provisions for emerging technologies like quantum computing components and superconducting battery elements. These newer standards recognize the unique safety challenges posed by the integration of quantum effects and superconductivity in battery performance enhancement applications.

International standards organizations such as IEEE, IEC, and ASTM have established specific guidelines for electronics operating in extreme temperature environments. These standards typically define temperature thresholds, testing methodologies, and performance requirements that must be met before deployment. For cryogenic battery applications, standards like MIL-STD-810G (Method 502.5) for low-temperature testing and IEC 60068-2-1 for cold environment testing provide foundational safety parameters.

Material qualification represents a cornerstone of these safety standards. Components must undergo rigorous thermal cycling tests to verify structural integrity and functionality at cryogenic temperatures. Standards typically require materials to maintain mechanical properties at temperatures as low as -196°C (liquid nitrogen temperature) or even -269°C (liquid helium temperature) depending on the application domain.

Electrical safety considerations become particularly complex in cryogenic environments. Standards mandate specialized insulation requirements, as traditional insulating materials may become brittle or change their dielectric properties at extremely low temperatures. Superconducting elements in cryogenic battery systems require additional safety protocols to manage quench events, where sudden transitions from superconducting to normal states can release significant energy.

Thermal management safety standards address the unique challenges of cryogenic systems, including rapid temperature gradients and thermal expansion/contraction issues. These standards typically specify maximum allowable temperature differentials across components and define cooling/warming rate limitations to prevent thermal shock damage.

Operational safety protocols form another critical dimension of these standards. They include emergency shutdown procedures, monitoring requirements, and maintenance schedules specifically designed for cryogenic electronic systems. For battery applications, standards particularly focus on preventing thermal runaway scenarios, which can be catastrophic in cryogenic environments due to the potential for rapid gas expansion.

Testing and certification procedures outlined in these standards typically involve accelerated life testing, environmental stress screening, and performance verification under simulated extreme conditions. For cryogenic battery systems, standards often require demonstration of multiple freeze-thaw cycles without performance degradation.

Recent developments in safety standards have begun incorporating specific provisions for emerging technologies like quantum computing components and superconducting battery elements. These newer standards recognize the unique safety challenges posed by the integration of quantum effects and superconductivity in battery performance enhancement applications.

Environmental Impact of Cryogenic Battery Technologies

The environmental implications of cryogenic battery technologies represent a critical dimension in evaluating their overall sustainability and long-term viability. While cryogenic electronics offer significant performance enhancements for battery systems, their environmental footprint warrants careful examination across multiple dimensions.

The energy-intensive cooling processes required to maintain cryogenic temperatures constitute a major environmental concern. Current cryogenic cooling systems demand substantial electricity consumption, with estimates suggesting that maintaining temperatures below -150°C can require 3-5 times more energy than conventional battery management systems. This increased energy demand potentially offsets efficiency gains achieved through improved battery performance metrics.

Material requirements for cryogenic battery technologies introduce additional environmental considerations. Specialized insulation materials, superconducting components, and cryogenic-resistant structural elements often incorporate rare earth elements and exotic compounds with significant extraction impacts. The mining and processing of these materials generate substantial carbon emissions and can lead to habitat destruction in resource-rich regions.

Lifecycle assessment studies indicate that cryogenic battery systems may present mixed environmental outcomes. While operational efficiency improvements can reduce overall energy consumption during use phases, the manufacturing and end-of-life stages present heightened environmental burdens compared to conventional battery technologies. Preliminary analyses suggest a carbon payback period of 3-7 years depending on application scenarios and energy sources.

Refrigerant management presents another environmental challenge. Many cryogenic cooling systems utilize specialized refrigerants with high global warming potential (GWP). Leakage risks and disposal challenges associated with these substances require robust management protocols to prevent atmospheric release and subsequent climate impacts.

Water consumption represents an often-overlooked environmental dimension. Cooling systems frequently utilize water resources for heat exchange processes, with cryogenic applications potentially requiring 40-60% more water than ambient temperature battery systems. In water-stressed regions, this additional demand may exacerbate resource competition and ecosystem impacts.

Emerging innovations in passive cooling technologies and sustainable cryogenic materials offer promising pathways to mitigate these environmental concerns. Research into biomimetic insulation designs, zero-GWP refrigerants, and energy-efficient cooling cycles could substantially reduce the environmental footprint of cryogenic battery technologies while preserving their performance advantages.

The energy-intensive cooling processes required to maintain cryogenic temperatures constitute a major environmental concern. Current cryogenic cooling systems demand substantial electricity consumption, with estimates suggesting that maintaining temperatures below -150°C can require 3-5 times more energy than conventional battery management systems. This increased energy demand potentially offsets efficiency gains achieved through improved battery performance metrics.

Material requirements for cryogenic battery technologies introduce additional environmental considerations. Specialized insulation materials, superconducting components, and cryogenic-resistant structural elements often incorporate rare earth elements and exotic compounds with significant extraction impacts. The mining and processing of these materials generate substantial carbon emissions and can lead to habitat destruction in resource-rich regions.

Lifecycle assessment studies indicate that cryogenic battery systems may present mixed environmental outcomes. While operational efficiency improvements can reduce overall energy consumption during use phases, the manufacturing and end-of-life stages present heightened environmental burdens compared to conventional battery technologies. Preliminary analyses suggest a carbon payback period of 3-7 years depending on application scenarios and energy sources.

Refrigerant management presents another environmental challenge. Many cryogenic cooling systems utilize specialized refrigerants with high global warming potential (GWP). Leakage risks and disposal challenges associated with these substances require robust management protocols to prevent atmospheric release and subsequent climate impacts.

Water consumption represents an often-overlooked environmental dimension. Cooling systems frequently utilize water resources for heat exchange processes, with cryogenic applications potentially requiring 40-60% more water than ambient temperature battery systems. In water-stressed regions, this additional demand may exacerbate resource competition and ecosystem impacts.

Emerging innovations in passive cooling technologies and sustainable cryogenic materials offer promising pathways to mitigate these environmental concerns. Research into biomimetic insulation designs, zero-GWP refrigerants, and energy-efficient cooling cycles could substantially reduce the environmental footprint of cryogenic battery technologies while preserving their performance advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!