Cryogenic Electronics Regulation: Key Challenges and Opportunities

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Background and Objectives

Cryogenic electronics represents a specialized field of electronic engineering that focuses on the design, development, and operation of electronic systems at extremely low temperatures, typically below 123K (-150°C). The evolution of this technology dates back to the mid-20th century, with significant advancements occurring in parallel with developments in superconductivity research. Initially driven by space exploration and quantum computing requirements, cryogenic electronics has expanded into various applications including medical imaging, particle physics, and advanced computing systems.

The technological trajectory of cryogenic electronics has been marked by progressive improvements in material science, particularly in superconducting materials and semiconductor behavior at ultra-low temperatures. Silicon-based devices, which dominate conventional electronics, exhibit significantly different characteristics at cryogenic temperatures, necessitating specialized design approaches and novel materials. Recent years have witnessed accelerated development in this field, propelled by quantum computing's growing prominence and the need for more energy-efficient computing solutions.

The primary objectives of cryogenic electronics regulation research are multifaceted. First, to establish comprehensive understanding of electronic component behavior under extreme temperature conditions, enabling reliable operation in cryogenic environments. Second, to develop standardized testing methodologies and performance metrics specifically tailored for cryogenic electronic systems, addressing the current lack of industry-wide standards. Third, to create efficient thermal management solutions that minimize the energy requirements for maintaining cryogenic conditions while ensuring stable electronic performance.

Additionally, research aims to identify and mitigate reliability challenges unique to cryogenic operations, including thermal cycling effects, material degradation, and interconnect failures. The development of specialized integrated circuits designed explicitly for cryogenic operation represents another critical objective, potentially revolutionizing quantum computing architectures and space-based electronic systems.

From a regulatory perspective, the field seeks to establish safety protocols and operational guidelines for cryogenic electronic systems, particularly as these technologies transition from research laboratories to commercial applications. This includes addressing potential environmental impacts of cryogenic cooling systems and ensuring compliance with existing electronic equipment regulations while acknowledging the unique characteristics of cryogenic operation.

The convergence of quantum computing demands, space exploration requirements, and the pursuit of more energy-efficient computing solutions has positioned cryogenic electronics as a critical enabling technology for next-generation systems. Understanding the fundamental physics of electronic behavior at ultra-low temperatures remains central to advancing this field, with significant implications for future technological capabilities across multiple industries.

The technological trajectory of cryogenic electronics has been marked by progressive improvements in material science, particularly in superconducting materials and semiconductor behavior at ultra-low temperatures. Silicon-based devices, which dominate conventional electronics, exhibit significantly different characteristics at cryogenic temperatures, necessitating specialized design approaches and novel materials. Recent years have witnessed accelerated development in this field, propelled by quantum computing's growing prominence and the need for more energy-efficient computing solutions.

The primary objectives of cryogenic electronics regulation research are multifaceted. First, to establish comprehensive understanding of electronic component behavior under extreme temperature conditions, enabling reliable operation in cryogenic environments. Second, to develop standardized testing methodologies and performance metrics specifically tailored for cryogenic electronic systems, addressing the current lack of industry-wide standards. Third, to create efficient thermal management solutions that minimize the energy requirements for maintaining cryogenic conditions while ensuring stable electronic performance.

Additionally, research aims to identify and mitigate reliability challenges unique to cryogenic operations, including thermal cycling effects, material degradation, and interconnect failures. The development of specialized integrated circuits designed explicitly for cryogenic operation represents another critical objective, potentially revolutionizing quantum computing architectures and space-based electronic systems.

From a regulatory perspective, the field seeks to establish safety protocols and operational guidelines for cryogenic electronic systems, particularly as these technologies transition from research laboratories to commercial applications. This includes addressing potential environmental impacts of cryogenic cooling systems and ensuring compliance with existing electronic equipment regulations while acknowledging the unique characteristics of cryogenic operation.

The convergence of quantum computing demands, space exploration requirements, and the pursuit of more energy-efficient computing solutions has positioned cryogenic electronics as a critical enabling technology for next-generation systems. Understanding the fundamental physics of electronic behavior at ultra-low temperatures remains central to advancing this field, with significant implications for future technological capabilities across multiple industries.

Market Analysis for Cryogenic Electronic Systems

The global market for cryogenic electronic systems is experiencing significant growth, driven primarily by advancements in quantum computing, medical imaging technologies, and space exploration. Current market valuations indicate that the cryogenic electronics sector reached approximately $4.2 billion in 2022, with projections suggesting a compound annual growth rate (CAGR) of 8.3% through 2030, potentially reaching $8.7 billion by the end of the forecast period.

Quantum computing represents the largest application segment, accounting for nearly 38% of the total market share. This dominance stems from the fundamental requirement for near-absolute zero temperatures to maintain quantum coherence in quantum bits (qubits). Major technology corporations including IBM, Google, and Intel have substantially increased their investments in quantum computing infrastructure, with collective industry investments exceeding $1.5 billion in 2022 alone.

Medical imaging, particularly Magnetic Resonance Imaging (MRI) systems, constitutes the second-largest market segment at approximately 27% market share. The demand for higher-resolution imaging capabilities in healthcare facilities worldwide continues to drive the need for superconducting magnets that operate at cryogenic temperatures. The healthcare sector's adoption of advanced diagnostic tools has created a steady demand pattern with relatively predictable growth trajectories.

Geographically, North America leads the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (23%). The United States maintains its position as the single largest national market due to substantial government funding in quantum research and advanced healthcare infrastructure. However, China is demonstrating the fastest growth rate at 12.7% annually, fueled by aggressive national initiatives in quantum technologies and semiconductor development.

From a supply chain perspective, the market faces significant challenges related to specialized materials and components required for cryogenic operation. The limited number of suppliers capable of producing cryocoolers, specialized insulators, and superconducting materials creates potential bottlenecks in production scaling. This supply constraint has contributed to premium pricing structures throughout the industry, with gross margins averaging 38-45% for specialized component manufacturers.

Customer segmentation reveals three primary buyer categories: research institutions (41%), government/defense agencies (32%), and commercial enterprises (27%). The research segment demonstrates the most price sensitivity, while government contracts typically prioritize performance specifications over cost considerations. Commercial adoption is accelerating, particularly in financial services and pharmaceutical sectors seeking competitive advantages through quantum computing applications.

Quantum computing represents the largest application segment, accounting for nearly 38% of the total market share. This dominance stems from the fundamental requirement for near-absolute zero temperatures to maintain quantum coherence in quantum bits (qubits). Major technology corporations including IBM, Google, and Intel have substantially increased their investments in quantum computing infrastructure, with collective industry investments exceeding $1.5 billion in 2022 alone.

Medical imaging, particularly Magnetic Resonance Imaging (MRI) systems, constitutes the second-largest market segment at approximately 27% market share. The demand for higher-resolution imaging capabilities in healthcare facilities worldwide continues to drive the need for superconducting magnets that operate at cryogenic temperatures. The healthcare sector's adoption of advanced diagnostic tools has created a steady demand pattern with relatively predictable growth trajectories.

Geographically, North America leads the market with approximately 42% share, followed by Europe (28%) and Asia-Pacific (23%). The United States maintains its position as the single largest national market due to substantial government funding in quantum research and advanced healthcare infrastructure. However, China is demonstrating the fastest growth rate at 12.7% annually, fueled by aggressive national initiatives in quantum technologies and semiconductor development.

From a supply chain perspective, the market faces significant challenges related to specialized materials and components required for cryogenic operation. The limited number of suppliers capable of producing cryocoolers, specialized insulators, and superconducting materials creates potential bottlenecks in production scaling. This supply constraint has contributed to premium pricing structures throughout the industry, with gross margins averaging 38-45% for specialized component manufacturers.

Customer segmentation reveals three primary buyer categories: research institutions (41%), government/defense agencies (32%), and commercial enterprises (27%). The research segment demonstrates the most price sensitivity, while government contracts typically prioritize performance specifications over cost considerations. Commercial adoption is accelerating, particularly in financial services and pharmaceutical sectors seeking competitive advantages through quantum computing applications.

Technical Challenges and Global Development Status

Cryogenic electronics regulation faces significant technical challenges that have hindered widespread adoption despite its promising applications in quantum computing, space exploration, and medical imaging. The primary obstacle remains thermal management, as maintaining stable ultra-low temperatures (below 4K) requires sophisticated cooling systems that consume substantial energy and occupy considerable physical space. Current cryostats and dilution refrigerators, while effective, remain bulky and expensive, limiting deployment in commercial applications.

Material limitations present another critical challenge. Standard semiconductor materials exhibit altered electrical properties at cryogenic temperatures, necessitating specialized design considerations. Silicon-based devices experience carrier freeze-out, while conventional interconnect materials may become brittle or exhibit altered conductivity profiles. Research into superconducting materials shows promise but faces manufacturing scalability issues.

Power regulation at cryogenic temperatures introduces unique complications. Conventional voltage regulators and power management circuits designed for room temperature operation exhibit significant performance degradation when cooled. The trade-off between placing regulation components at room temperature (requiring long interconnects) versus cryogenic integration remains unresolved in many applications.

Globally, cryogenic electronics development shows distinct regional patterns. North America leads in quantum computing applications, with companies like IBM, Google, and Intel investing heavily in superconducting qubit technologies. The European Union has established strong research networks focused on cryogenic CMOS development, particularly through initiatives at TU Delft and CEA-Leti. Japan maintains expertise in superconducting electronics, while China has rapidly expanded investment in both quantum technologies and cryogenic computing systems.

Standardization remains underdeveloped, with limited consensus on testing protocols, performance metrics, and interface specifications for cryogenic electronic systems. This fragmentation impedes interoperability and slows commercial adoption. Recent efforts by IEEE and the Quantum Economic Development Consortium represent initial steps toward establishing industry standards.

Manufacturing infrastructure presents another bottleneck, as specialized fabrication facilities for cryogenic electronics remain limited. Most production relies on modified conventional semiconductor processes rather than purpose-built manufacturing lines. This approach introduces yield and reliability challenges that increase costs and limit production volumes.

Despite these challenges, recent breakthroughs in cryogenic CMOS, superconducting digital logic, and integrated cooling technologies suggest accelerating development. The convergence of quantum computing demands and space exploration requirements has catalyzed increased investment, potentially addressing key technical barriers within the next decade.

Material limitations present another critical challenge. Standard semiconductor materials exhibit altered electrical properties at cryogenic temperatures, necessitating specialized design considerations. Silicon-based devices experience carrier freeze-out, while conventional interconnect materials may become brittle or exhibit altered conductivity profiles. Research into superconducting materials shows promise but faces manufacturing scalability issues.

Power regulation at cryogenic temperatures introduces unique complications. Conventional voltage regulators and power management circuits designed for room temperature operation exhibit significant performance degradation when cooled. The trade-off between placing regulation components at room temperature (requiring long interconnects) versus cryogenic integration remains unresolved in many applications.

Globally, cryogenic electronics development shows distinct regional patterns. North America leads in quantum computing applications, with companies like IBM, Google, and Intel investing heavily in superconducting qubit technologies. The European Union has established strong research networks focused on cryogenic CMOS development, particularly through initiatives at TU Delft and CEA-Leti. Japan maintains expertise in superconducting electronics, while China has rapidly expanded investment in both quantum technologies and cryogenic computing systems.

Standardization remains underdeveloped, with limited consensus on testing protocols, performance metrics, and interface specifications for cryogenic electronic systems. This fragmentation impedes interoperability and slows commercial adoption. Recent efforts by IEEE and the Quantum Economic Development Consortium represent initial steps toward establishing industry standards.

Manufacturing infrastructure presents another bottleneck, as specialized fabrication facilities for cryogenic electronics remain limited. Most production relies on modified conventional semiconductor processes rather than purpose-built manufacturing lines. This approach introduces yield and reliability challenges that increase costs and limit production volumes.

Despite these challenges, recent breakthroughs in cryogenic CMOS, superconducting digital logic, and integrated cooling technologies suggest accelerating development. The convergence of quantum computing demands and space exploration requirements has catalyzed increased investment, potentially addressing key technical barriers within the next decade.

Current Regulatory Solutions for Cryogenic Electronics

01 Cryogenic cooling systems for electronic components

Specialized cooling systems designed to maintain electronic components at cryogenic temperatures for optimal performance. These systems include regulated cooling mechanisms that control temperature stability, prevent thermal fluctuations, and ensure proper operation of sensitive electronic devices in extreme cold environments. The cooling systems incorporate various refrigeration cycles and thermal management techniques to achieve and maintain the required low temperatures.- Cryogenic cooling systems for electronic components: Specialized cooling systems designed to maintain electronic components at cryogenic temperatures for optimal performance. These systems include regulated cooling mechanisms that control temperature stability, prevent thermal fluctuations, and ensure proper operation of sensitive electronic devices in extreme cold environments. The cooling systems incorporate various refrigeration cycles and thermal management techniques to achieve and maintain the required low temperatures.

- Thermal regulation for superconducting electronics: Regulatory systems specifically designed for superconducting electronic components that require precise temperature control at cryogenic levels. These systems monitor and adjust cooling parameters to maintain superconducting states, prevent quenching, and ensure stable operation. The regulation mechanisms include feedback control systems, temperature sensors, and specialized algorithms that respond to thermal load variations while maintaining the required operating conditions for superconducting circuits.

- Cryogenic electronic enclosures and shielding: Specialized enclosures and shielding systems designed to protect cryogenic electronic components from electromagnetic interference, thermal radiation, and mechanical stress. These enclosures incorporate regulated vacuum insulation, multi-layer radiation shields, and vibration isolation to maintain stable operating environments. The designs include considerations for thermal expansion/contraction, material compatibility at low temperatures, and access for maintenance while maintaining thermal integrity.

- Power management for cryogenic electronic systems: Power regulation and distribution systems specifically designed for electronics operating at cryogenic temperatures. These systems address the unique challenges of power delivery to cold electronics, including thermal loading, impedance changes, and component behavior variations at extreme temperatures. The power management solutions incorporate specialized voltage regulators, current limiters, and thermal isolation techniques to maintain stable power while minimizing heat introduction to the cryogenic environment.

- Testing and calibration standards for cryogenic electronics: Regulatory frameworks and methodologies for testing, validating, and calibrating electronic systems operating at cryogenic temperatures. These standards ensure consistent performance, reliability, and safety of cryogenic electronic components across various applications. The testing protocols include procedures for thermal cycling, performance verification at various temperature points, and long-term stability assessment, along with calibration techniques that account for the unique behavior of electronic components in extreme cold environments.

02 Thermal regulation for superconducting electronics

Regulatory mechanisms specifically designed for superconducting electronic devices that operate at cryogenic temperatures. These systems monitor and control the thermal environment to maintain superconducting states, prevent quenching, and ensure stable operation. The regulation includes precise temperature control, thermal isolation techniques, and specialized cooling interfaces that accommodate the unique requirements of superconducting materials and circuits.Expand Specific Solutions03 Cryogenic electronic packaging and shielding

Specialized packaging solutions for cryogenic electronic components that provide thermal isolation, electromagnetic shielding, and mechanical stability at extremely low temperatures. These packaging technologies incorporate materials and designs that maintain their properties and functionality in cryogenic environments while protecting sensitive electronics from thermal gradients, electromagnetic interference, and mechanical stress caused by thermal contraction.Expand Specific Solutions04 Regulatory standards for cryogenic electronic systems

Frameworks and standards governing the design, testing, and operation of electronic systems in cryogenic environments. These regulations address safety requirements, performance specifications, reliability standards, and certification processes for electronics operating at extremely low temperatures. The standards ensure consistent performance, interoperability, and safety across different cryogenic electronic applications in research, medical, aerospace, and industrial settings.Expand Specific Solutions05 Cryogenic temperature sensing and control systems

Advanced sensing and control technologies specifically designed for monitoring and regulating cryogenic environments for electronic applications. These systems incorporate specialized sensors that function accurately at extremely low temperatures, feedback control mechanisms, and precision regulation algorithms to maintain stable operating conditions. The control systems provide real-time monitoring, automated adjustment capabilities, and safety features to protect sensitive electronic components.Expand Specific Solutions

Leading Organizations in Cryogenic Electronics Field

The cryogenic electronics regulation landscape is evolving rapidly, currently positioned at an early growth stage with significant expansion potential. The global market is projected to grow substantially as quantum computing and superconducting technologies gain traction. Technologically, the field shows varying maturity levels across applications, with companies like IBM, Microsoft, and Northrop Grumman leading commercial development while research institutions such as MIT, Naval Research Laboratory, and McGill University drive fundamental innovations. Specialized players including Sumitomo Cryogenics, kiutra GmbH, and QDevil are advancing purpose-built cryogenic solutions. The competitive environment features strategic collaborations between technology giants and specialized cryogenic experts to overcome the significant technical challenges of operating electronics at ultra-low temperatures.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has developed advanced cryogenic electronics regulation systems primarily for aerospace and defense applications. Their technology centers on radiation-hardened, ultra-low-power cryogenic control electronics capable of operating in extreme environments. Their approach includes specialized SiGe BiCMOS technology optimized for cryogenic temperatures, which maintains functionality down to 4K while consuming minimal power. Northrop's cryogenic electronics incorporate custom voltage reference circuits that maintain stability across wide temperature ranges (300K to 4K) with drift characteristics below 1ppm/°C. For defense applications, they've engineered electromagnetic interference (EMI) shielding techniques specific to cryogenic environments, where traditional shielding materials may fail. Their systems feature proprietary thermal isolation techniques that minimize heat leakage between temperature stages, critical for maintaining cryogenic conditions in space-based applications where cooling resources are limited. Northrop has also pioneered specialized testing methodologies for cryogenic electronics that verify performance under combined environmental stresses.

Strengths: Exceptional reliability in extreme environments; radiation-hardened designs suitable for space applications; extensive experience with military-grade requirements for cryogenic systems. Weaknesses: Solutions often highly specialized for defense applications with limited commercial transferability; high development and production costs; systems typically optimized for specific mission requirements rather than general-purpose applications.

kiutra GmbH

Technical Solution: kiutra has developed innovative magnetic cooling technology for cryogenic electronics regulation that represents a significant departure from conventional approaches. Their system utilizes the magnetocaloric effect to achieve cooling without mechanical compressors or cryogenic fluids, dramatically reducing system complexity and maintenance requirements. kiutra's technology enables continuous cooling operation down to 2K through a cascade of magnetic refrigeration stages, each optimized for specific temperature ranges. Their approach incorporates specialized magnetic materials with carefully engineered phase transitions that maximize cooling efficiency at different temperature points. For electronics regulation, they've developed integrated thermal management systems that provide precise temperature control (±0.01K stability) while minimizing electromagnetic interference with sensitive electronics. Their solution includes proprietary control algorithms that dynamically adjust cooling power based on the thermal load from operating electronics, maintaining optimal conditions while minimizing energy consumption. kiutra's systems feature modular designs that allow for customization based on specific application requirements, from quantum computing to superconducting electronics testing.

Strengths: Innovative magnetic cooling technology eliminates need for cryogenic fluids; lower maintenance requirements compared to conventional cryostats; vibration-free operation beneficial for sensitive electronics. Weaknesses: Limited cooling power compared to some conventional systems; relatively new technology with less established reliability data; higher initial cost compared to some traditional cooling approaches.

Critical Patents and Research in Cryogenic Regulation

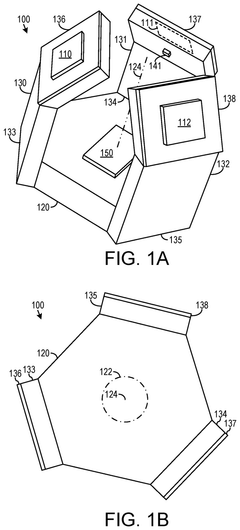

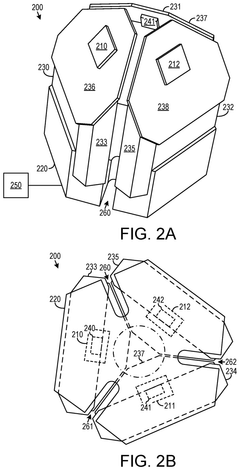

Platform for Precise Thermal Regulation of Cryogenic Electronic Circuits

PatentPendingUS20240302455A1

Innovation

- A platform for precise thermal regulation of cryogenic electronic circuits, featuring a cold distribution plate coupled with a cryogenic cooler, cold blades supporting the circuits, and heaters controlled by a thermal regulator to maintain uniform temperature, ensuring accurate signal detection.

Cryogenic system for cooling a consumer having a time-variable heat load

PatentInactiveEP2411745A1

Innovation

- A cryogenic system with a multivariable regulator that controls pressure in supply and discharge ducts using a mathematical model accounting for coupling between pressures, allowing dynamic operation without significant structural modifications, utilizing controlled valves and a control device to generate signals based on measured and setpoint values.

Standardization Frameworks for Cryogenic Electronics

The development of standardization frameworks for cryogenic electronics represents a critical foundation for the advancement and commercial viability of this emerging technology. Currently, the field lacks comprehensive standards, creating significant barriers to interoperability, reliability assessment, and market growth. Existing electronic standards cannot be directly applied to cryogenic environments due to the fundamental differences in material properties and device behaviors at ultra-low temperatures.

Several international organizations have begun preliminary efforts to establish cryogenic electronics standards. The IEEE Cryogenic Electronics Working Group has initiated the development of testing protocols for superconducting circuits, while the International Electrotechnical Commission (IEC) has formed a technical committee focused on defining operational parameters for cryogenic semiconductor devices. These efforts, though promising, remain fragmented and insufficient for industry-wide adoption.

Key areas requiring standardization include thermal management interfaces, signal integrity specifications, and reliability metrics specific to cryogenic operations. The thermal gradient management between room temperature and cryogenic environments presents unique challenges that necessitate standardized approaches for thermal interfaces and heat load calculations. Without these standards, system integration becomes exceptionally difficult across different manufacturer platforms.

Performance characterization represents another critical standardization need. Current testing methodologies vary significantly between research institutions and companies, making performance comparisons nearly impossible. Standardized benchmarking protocols would enable meaningful evaluation of different cryogenic electronic solutions and accelerate technology maturation through healthy competition.

Reliability assessment frameworks constitute perhaps the most urgent standardization requirement. The unique failure mechanisms at cryogenic temperatures—including thermal cycling stress, superconducting state stability, and radiation sensitivity—require specialized testing protocols. Industry stakeholders have identified the need for accelerated life testing standards that can realistically predict long-term performance in cryogenic environments.

The path toward comprehensive standardization will likely require a phased approach. Initial efforts should focus on measurement and testing standards to establish a common language for performance evaluation. This foundation can then support the development of interface standards, followed by reliability and safety frameworks. Collaborative industry-academia partnerships will be essential to this process, with government agencies potentially serving as neutral facilitators.

Successful standardization efforts will significantly reduce development costs, accelerate innovation cycles, and ultimately enable broader commercial adoption of cryogenic electronics across quantum computing, space exploration, and medical imaging applications.

Several international organizations have begun preliminary efforts to establish cryogenic electronics standards. The IEEE Cryogenic Electronics Working Group has initiated the development of testing protocols for superconducting circuits, while the International Electrotechnical Commission (IEC) has formed a technical committee focused on defining operational parameters for cryogenic semiconductor devices. These efforts, though promising, remain fragmented and insufficient for industry-wide adoption.

Key areas requiring standardization include thermal management interfaces, signal integrity specifications, and reliability metrics specific to cryogenic operations. The thermal gradient management between room temperature and cryogenic environments presents unique challenges that necessitate standardized approaches for thermal interfaces and heat load calculations. Without these standards, system integration becomes exceptionally difficult across different manufacturer platforms.

Performance characterization represents another critical standardization need. Current testing methodologies vary significantly between research institutions and companies, making performance comparisons nearly impossible. Standardized benchmarking protocols would enable meaningful evaluation of different cryogenic electronic solutions and accelerate technology maturation through healthy competition.

Reliability assessment frameworks constitute perhaps the most urgent standardization requirement. The unique failure mechanisms at cryogenic temperatures—including thermal cycling stress, superconducting state stability, and radiation sensitivity—require specialized testing protocols. Industry stakeholders have identified the need for accelerated life testing standards that can realistically predict long-term performance in cryogenic environments.

The path toward comprehensive standardization will likely require a phased approach. Initial efforts should focus on measurement and testing standards to establish a common language for performance evaluation. This foundation can then support the development of interface standards, followed by reliability and safety frameworks. Collaborative industry-academia partnerships will be essential to this process, with government agencies potentially serving as neutral facilitators.

Successful standardization efforts will significantly reduce development costs, accelerate innovation cycles, and ultimately enable broader commercial adoption of cryogenic electronics across quantum computing, space exploration, and medical imaging applications.

Environmental Impact and Sustainability Considerations

The environmental footprint of cryogenic electronics represents a significant consideration in the broader adoption of this technology. Cooling systems required for maintaining superconducting states typically consume substantial energy, with traditional cryogenic cooling methods demanding between 500-1000 watts of power to remove just 1 watt of heat at temperatures approaching absolute zero. This energy-intensive process contributes to considerable carbon emissions when powered by non-renewable sources.

Recent advancements in cooling efficiency have shown promising developments. Pulse tube cryocoolers and magnetic refrigeration techniques have demonstrated up to 30% improvement in energy efficiency compared to conventional Gifford-McMahon refrigerators. These innovations are gradually reducing the environmental burden associated with cryogenic operations, though significant challenges remain.

Material considerations also present environmental concerns. Many superconducting materials contain rare earth elements or potentially toxic compounds that require careful handling throughout their lifecycle. The extraction and processing of these materials often involve environmentally damaging mining practices and chemical processes that generate hazardous waste. Developing alternative materials with reduced environmental impact represents a critical research direction.

Lifecycle assessment studies indicate that despite high operational energy demands, cryogenic electronics may offer net environmental benefits in specific applications. For instance, in high-performance computing, the energy efficiency gains from superconducting processors can potentially offset the cooling costs over extended operational periods, particularly when integrated with renewable energy sources.

Water usage presents another environmental consideration, as cooling systems often require substantial water resources for heat exchange processes. Closed-loop cooling systems and dry cooling technologies are being explored to minimize water consumption, though these solutions often come with efficiency trade-offs that must be carefully balanced.

The sustainability profile of cryogenic electronics is further complicated by end-of-life considerations. Recycling and proper disposal of specialized materials and components remain underdeveloped areas, with limited infrastructure currently available for processing these advanced technological components. Designing for disassembly and material recovery represents an emerging focus area for sustainable cryogenic electronics development.

Regulatory frameworks addressing the environmental aspects of cryogenic technologies are still evolving. Forward-thinking companies are proactively implementing sustainability measures, including renewable energy integration for cooling operations, material substitution strategies, and comprehensive lifecycle management approaches to minimize environmental impact while maximizing the technological benefits of cryogenic electronics.

Recent advancements in cooling efficiency have shown promising developments. Pulse tube cryocoolers and magnetic refrigeration techniques have demonstrated up to 30% improvement in energy efficiency compared to conventional Gifford-McMahon refrigerators. These innovations are gradually reducing the environmental burden associated with cryogenic operations, though significant challenges remain.

Material considerations also present environmental concerns. Many superconducting materials contain rare earth elements or potentially toxic compounds that require careful handling throughout their lifecycle. The extraction and processing of these materials often involve environmentally damaging mining practices and chemical processes that generate hazardous waste. Developing alternative materials with reduced environmental impact represents a critical research direction.

Lifecycle assessment studies indicate that despite high operational energy demands, cryogenic electronics may offer net environmental benefits in specific applications. For instance, in high-performance computing, the energy efficiency gains from superconducting processors can potentially offset the cooling costs over extended operational periods, particularly when integrated with renewable energy sources.

Water usage presents another environmental consideration, as cooling systems often require substantial water resources for heat exchange processes. Closed-loop cooling systems and dry cooling technologies are being explored to minimize water consumption, though these solutions often come with efficiency trade-offs that must be carefully balanced.

The sustainability profile of cryogenic electronics is further complicated by end-of-life considerations. Recycling and proper disposal of specialized materials and components remain underdeveloped areas, with limited infrastructure currently available for processing these advanced technological components. Designing for disassembly and material recovery represents an emerging focus area for sustainable cryogenic electronics development.

Regulatory frameworks addressing the environmental aspects of cryogenic technologies are still evolving. Forward-thinking companies are proactively implementing sustainability measures, including renewable energy integration for cooling operations, material substitution strategies, and comprehensive lifecycle management approaches to minimize environmental impact while maximizing the technological benefits of cryogenic electronics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!