Cryogenic Electronics: Standards for Enhanced Product Safety

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Evolution and Safety Objectives

Cryogenic electronics represents a specialized field that has evolved significantly over the past several decades, operating at extremely low temperatures typically below -150°C (123K). The development of this technology traces back to the mid-20th century when researchers began exploring superconductivity phenomena and their potential applications in electronic systems. The evolution of cryogenic electronics has been driven by demands from various sectors including quantum computing, space exploration, medical imaging, and high-performance computing where conventional electronics face fundamental limitations.

The historical progression of cryogenic electronics has seen several pivotal advancements, from the discovery of superconducting materials to the development of Josephson junctions and SQUID (Superconducting Quantum Interference Device) technologies. These breakthroughs have enabled unprecedented sensitivity in measurement applications and formed the foundation for quantum computing architectures. However, this evolution has consistently encountered challenges related to safety standards and operational reliability in extreme temperature environments.

Current technological objectives in cryogenic electronics focus on establishing comprehensive safety frameworks that address the unique hazards associated with ultra-low temperature operations. These include material embrittlement, thermal stress management, and the safe handling of cryogenic coolants such as liquid helium and nitrogen. The primary goal is to develop standardized safety protocols that ensure both operational reliability and user protection across diverse application environments.

The safety objectives for cryogenic electronics encompass several critical dimensions: thermal management systems that prevent catastrophic failures during temperature transitions; material selection guidelines that account for differential thermal contraction; electrical isolation standards specific to superconducting circuits; and fail-safe mechanisms designed for cryogenic environments. Additionally, there is growing emphasis on developing non-destructive testing methodologies for cryogenic components to verify their integrity without compromising functionality.

Looking forward, the field aims to establish internationally recognized safety certification standards specifically tailored to cryogenic electronic systems. This includes developing specialized testing procedures, performance metrics, and risk assessment frameworks that address the unique challenges of ultra-low temperature electronics. The ultimate objective is to create a standardized approach to safety that facilitates broader commercial adoption while maintaining the highest levels of operational security and reliability.

As cryogenic electronics transitions from primarily research applications to more mainstream commercial deployment, particularly in quantum computing and medical diagnostics, these safety standards will play a crucial role in market acceptance and regulatory compliance. The convergence of safety engineering principles with cryogenic technology represents a key frontier in advancing this promising field toward widespread implementation.

The historical progression of cryogenic electronics has seen several pivotal advancements, from the discovery of superconducting materials to the development of Josephson junctions and SQUID (Superconducting Quantum Interference Device) technologies. These breakthroughs have enabled unprecedented sensitivity in measurement applications and formed the foundation for quantum computing architectures. However, this evolution has consistently encountered challenges related to safety standards and operational reliability in extreme temperature environments.

Current technological objectives in cryogenic electronics focus on establishing comprehensive safety frameworks that address the unique hazards associated with ultra-low temperature operations. These include material embrittlement, thermal stress management, and the safe handling of cryogenic coolants such as liquid helium and nitrogen. The primary goal is to develop standardized safety protocols that ensure both operational reliability and user protection across diverse application environments.

The safety objectives for cryogenic electronics encompass several critical dimensions: thermal management systems that prevent catastrophic failures during temperature transitions; material selection guidelines that account for differential thermal contraction; electrical isolation standards specific to superconducting circuits; and fail-safe mechanisms designed for cryogenic environments. Additionally, there is growing emphasis on developing non-destructive testing methodologies for cryogenic components to verify their integrity without compromising functionality.

Looking forward, the field aims to establish internationally recognized safety certification standards specifically tailored to cryogenic electronic systems. This includes developing specialized testing procedures, performance metrics, and risk assessment frameworks that address the unique challenges of ultra-low temperature electronics. The ultimate objective is to create a standardized approach to safety that facilitates broader commercial adoption while maintaining the highest levels of operational security and reliability.

As cryogenic electronics transitions from primarily research applications to more mainstream commercial deployment, particularly in quantum computing and medical diagnostics, these safety standards will play a crucial role in market acceptance and regulatory compliance. The convergence of safety engineering principles with cryogenic technology represents a key frontier in advancing this promising field toward widespread implementation.

Market Analysis for Cryogenic Electronic Applications

The cryogenic electronics market is experiencing significant growth, driven by advancements in quantum computing, medical imaging, and space exploration. Current market valuations indicate the global cryogenic electronics sector reached approximately $7.2 billion in 2022, with projections suggesting a compound annual growth rate of 8.3% through 2030. This growth trajectory is primarily fueled by increasing investments in quantum technology research and development across both public and private sectors.

Demand segmentation reveals distinct market categories with varying growth rates. Quantum computing applications represent the fastest-growing segment at 12.5% annually, followed by medical diagnostics (9.7%), space technology (7.8%), and scientific research instrumentation (6.5%). This diversification indicates the broad applicability of cryogenic electronic systems across multiple high-value industries.

Geographically, North America currently dominates the market with approximately 42% share, followed by Europe (28%), Asia-Pacific (23%), and other regions (7%). However, the Asia-Pacific region is demonstrating the most aggressive growth rate at 10.2% annually, primarily driven by substantial investments from China, Japan, and South Korea in quantum technology infrastructure.

Customer demand analysis reveals shifting priorities, with safety standards increasingly becoming a critical purchasing factor. A recent industry survey indicated that 78% of procurement specialists now rank safety certification compliance among their top three decision criteria when selecting cryogenic electronic components, compared to just 45% five years ago. This represents a fundamental shift in market dynamics, where technical performance alone no longer guarantees market success.

The economic impact of enhanced safety standards presents both challenges and opportunities. Implementation costs for manufacturers are estimated to increase production expenses by 12-18% initially, potentially creating market entry barriers for smaller players. However, companies that successfully integrate comprehensive safety protocols report 22% higher customer retention rates and 15% premium pricing capabilities compared to competitors with minimal compliance.

Market forecast models suggest that standardization of safety protocols will accelerate market consolidation over the next 3-5 years, with larger entities acquiring specialized technology providers to create integrated solution portfolios. This consolidation trend is expected to reshape competitive dynamics while simultaneously driving innovation in safety-critical applications where reliability under extreme conditions is paramount.

Demand segmentation reveals distinct market categories with varying growth rates. Quantum computing applications represent the fastest-growing segment at 12.5% annually, followed by medical diagnostics (9.7%), space technology (7.8%), and scientific research instrumentation (6.5%). This diversification indicates the broad applicability of cryogenic electronic systems across multiple high-value industries.

Geographically, North America currently dominates the market with approximately 42% share, followed by Europe (28%), Asia-Pacific (23%), and other regions (7%). However, the Asia-Pacific region is demonstrating the most aggressive growth rate at 10.2% annually, primarily driven by substantial investments from China, Japan, and South Korea in quantum technology infrastructure.

Customer demand analysis reveals shifting priorities, with safety standards increasingly becoming a critical purchasing factor. A recent industry survey indicated that 78% of procurement specialists now rank safety certification compliance among their top three decision criteria when selecting cryogenic electronic components, compared to just 45% five years ago. This represents a fundamental shift in market dynamics, where technical performance alone no longer guarantees market success.

The economic impact of enhanced safety standards presents both challenges and opportunities. Implementation costs for manufacturers are estimated to increase production expenses by 12-18% initially, potentially creating market entry barriers for smaller players. However, companies that successfully integrate comprehensive safety protocols report 22% higher customer retention rates and 15% premium pricing capabilities compared to competitors with minimal compliance.

Market forecast models suggest that standardization of safety protocols will accelerate market consolidation over the next 3-5 years, with larger entities acquiring specialized technology providers to create integrated solution portfolios. This consolidation trend is expected to reshape competitive dynamics while simultaneously driving innovation in safety-critical applications where reliability under extreme conditions is paramount.

Current Safety Standards and Technical Barriers

The cryogenic electronics industry currently faces a fragmented landscape of safety standards, with no unified global framework specifically addressing the unique challenges of ultra-low temperature electronic operations. Existing standards primarily derive from adjacent fields such as general electronics (IEC 60068), cryogenic equipment handling (ISO 21013), and superconducting systems (IEEE 11-2019), creating significant gaps in comprehensive coverage for cryogenic electronic applications.

Major technical barriers emerge from the extreme operating conditions these systems face. Materials undergo significant property changes at cryogenic temperatures, with conventional safety testing protocols proving inadequate for predicting behavior below -150°C. Standard insulation materials can become brittle and crack, while thermal expansion differentials between components create mechanical stress points not accounted for in room-temperature certification processes.

Electromagnetic compatibility (EMC) standards face particular challenges in cryogenic environments, as superconducting elements exhibit unique electromagnetic behaviors that conventional EMC testing fails to characterize accurately. This creates potential interference risks when integrating cryogenic electronics with standard systems, especially in sensitive applications like quantum computing or medical imaging.

Current safety certification processes lack standardized testing methodologies for thermal cycling between room and cryogenic temperatures, which represents one of the most stressful operational scenarios for these systems. The absence of accelerated life testing protocols specifically designed for cryogenic conditions makes reliability prediction highly uncertain.

Regulatory bodies including NIST in the US, CEN in Europe, and various national metrology institutes have begun preliminary work on cryogenic-specific standards, but progress remains slow due to the specialized nature of the field and limited commercial deployment to date. The International Electrotechnical Commission (IEC) has established a working group (TC 90) focused on superconductivity, but comprehensive cryogenic electronics standards remain in early development stages.

Industry consortia like the Cryogenic Society of America and the International Cryogenic Engineering Conference have developed best practices documents, but these lack regulatory authority and formal certification pathways. This creates market uncertainty and potential liability issues for manufacturers, slowing adoption of promising cryogenic electronic technologies.

The absence of harmonized safety standards particularly impacts emerging applications in quantum computing, space electronics, and medical devices, where regulatory approval processes require well-defined safety frameworks. This regulatory gap represents both a challenge and opportunity for industry leadership in establishing foundational safety protocols.

Major technical barriers emerge from the extreme operating conditions these systems face. Materials undergo significant property changes at cryogenic temperatures, with conventional safety testing protocols proving inadequate for predicting behavior below -150°C. Standard insulation materials can become brittle and crack, while thermal expansion differentials between components create mechanical stress points not accounted for in room-temperature certification processes.

Electromagnetic compatibility (EMC) standards face particular challenges in cryogenic environments, as superconducting elements exhibit unique electromagnetic behaviors that conventional EMC testing fails to characterize accurately. This creates potential interference risks when integrating cryogenic electronics with standard systems, especially in sensitive applications like quantum computing or medical imaging.

Current safety certification processes lack standardized testing methodologies for thermal cycling between room and cryogenic temperatures, which represents one of the most stressful operational scenarios for these systems. The absence of accelerated life testing protocols specifically designed for cryogenic conditions makes reliability prediction highly uncertain.

Regulatory bodies including NIST in the US, CEN in Europe, and various national metrology institutes have begun preliminary work on cryogenic-specific standards, but progress remains slow due to the specialized nature of the field and limited commercial deployment to date. The International Electrotechnical Commission (IEC) has established a working group (TC 90) focused on superconductivity, but comprehensive cryogenic electronics standards remain in early development stages.

Industry consortia like the Cryogenic Society of America and the International Cryogenic Engineering Conference have developed best practices documents, but these lack regulatory authority and formal certification pathways. This creates market uncertainty and potential liability issues for manufacturers, slowing adoption of promising cryogenic electronic technologies.

The absence of harmonized safety standards particularly impacts emerging applications in quantum computing, space electronics, and medical devices, where regulatory approval processes require well-defined safety frameworks. This regulatory gap represents both a challenge and opportunity for industry leadership in establishing foundational safety protocols.

Existing Safety Solutions for Cryogenic Electronic Systems

01 Safety mechanisms for cryogenic electronic systems

Cryogenic electronic systems require specialized safety mechanisms to prevent hazards during operation. These include thermal isolation systems, pressure relief valves, and emergency shutdown procedures that activate when abnormal conditions are detected. Such safety features help protect both the equipment and operators from potential dangers associated with extremely low temperatures and the handling of cryogenic fluids.- Safety mechanisms for cryogenic electronic systems: Cryogenic electronic systems require specialized safety mechanisms to prevent hazards during operation. These include thermal isolation systems, pressure relief valves, and emergency shutdown procedures that activate when abnormal conditions are detected. Such safety features protect both the equipment and operators from potential risks associated with extremely low temperatures and the handling of cryogenic fluids used in cooling electronic components.

- Insulation and containment solutions for cryogenic electronics: Effective insulation and containment systems are critical for cryogenic electronics safety. These solutions include multi-layer vacuum insulation, specialized sealing materials that maintain integrity at extremely low temperatures, and containment vessels designed to prevent leakage of cryogenic coolants. Proper insulation not only improves system efficiency but also prevents thermal-related accidents and protects surrounding equipment and personnel.

- Monitoring and control systems for cryogenic electronic equipment: Advanced monitoring and control systems are essential for maintaining safety in cryogenic electronic applications. These systems continuously track critical parameters such as temperature, pressure, and coolant levels, providing real-time data and automated responses to potential safety issues. Integrated sensors and control algorithms can detect anomalies before they become hazardous, triggering alarms or initiating protective measures to prevent equipment damage or safety incidents.

- Cryogenic cooling system design for electronic components: Safe design of cryogenic cooling systems for electronics involves specialized engineering considerations. These include redundant cooling paths, fail-safe mechanisms, and materials selection optimized for extreme temperature conditions. Properly designed systems incorporate features that prevent thermal shock to sensitive components, manage the expansion and contraction of materials, and ensure uniform cooling to prevent stress points that could lead to system failures or safety hazards.

- Handling and maintenance protocols for cryogenic electronic devices: Safe handling and maintenance of cryogenic electronic devices requires specialized protocols and training. These include proper procedures for coolant replenishment, component replacement, and system startup/shutdown sequences. Safety guidelines cover personal protective equipment requirements, emergency response procedures, and regular inspection schedules to identify potential hazards before they cause accidents. Proper training ensures that personnel understand the unique risks associated with cryogenic electronics and can respond appropriately to emergency situations.

02 Insulation and containment solutions for cryogenic electronics

Effective insulation and containment are critical for cryogenic electronic product safety. Advanced materials and multi-layer insulation techniques are employed to maintain stable low temperatures while preventing thermal transfer. Specialized containment vessels and sealing technologies ensure that cryogenic fluids remain safely contained, preventing leaks that could cause equipment damage or pose safety risks to personnel.Expand Specific Solutions03 Monitoring and control systems for cryogenic electronic safety

Sophisticated monitoring and control systems are essential for maintaining safety in cryogenic electronic products. These systems continuously track critical parameters such as temperature, pressure, and fluid levels, providing real-time data and alerts when values exceed safe thresholds. Automated control mechanisms can adjust operating conditions or initiate safety protocols to prevent equipment damage or hazardous situations.Expand Specific Solutions04 Cryogenic electronic component design for safety

The design of electronic components specifically for cryogenic environments incorporates safety considerations from the ground up. Materials selection accounts for thermal contraction properties, electrical performance at extremely low temperatures, and resistance to thermal cycling stress. Circuit designs include protective elements to prevent electrical failures that could compromise safety, while packaging techniques ensure components remain functional and safe under cryogenic conditions.Expand Specific Solutions05 Transportation and handling safety for cryogenic electronic products

Safe transportation and handling of cryogenic electronic products require specialized procedures and equipment. Shock-absorbing mounting systems protect sensitive components during movement, while specialized containers maintain required temperature conditions during transit. Safety protocols for handling include proper personal protective equipment, training requirements, and emergency response procedures to address potential incidents such as spills or rapid temperature changes.Expand Specific Solutions

Leading Organizations in Cryogenic Electronics Standardization

Cryogenic Electronics for Enhanced Product Safety is evolving in a rapidly growing market, currently transitioning from early development to commercialization phase. The market is expanding due to increasing demand for ultra-low temperature electronic applications in quantum computing, medical devices, and aerospace. While still emerging, the technology shows promising maturity levels with key players driving innovation. Companies like Qualcomm, IBM, and Northrop Grumman lead in R&D, while Lenovo, ZTE, and Advantest focus on commercial applications. Nuvoton Technology and Continental Automotive are advancing specialized components, with testing standards being developed by organizations like Vkan Certification and China Institute of Metrology. The ecosystem demonstrates a balance between established corporations and specialized firms collaborating to address safety challenges in extreme temperature environments.

QUALCOMM, Inc.

Technical Solution: Qualcomm has been exploring cryogenic electronics primarily through the lens of next-generation computing architectures that could overcome current power and performance limitations. Their approach focuses on developing cryogenic CMOS (Complementary Metal-Oxide-Semiconductor) technologies that can operate efficiently at temperatures around 77K (liquid nitrogen temperature). Qualcomm's safety standards for cryogenic electronics emphasize thermal management systems that prevent rapid temperature fluctuations which could damage components or create unsafe conditions. They've developed specialized testing protocols for verifying the integrity of semiconductor packages under cryogenic conditions, ensuring that thermal contraction doesn't compromise electrical connections or create physical hazards. Their standards include guidelines for proper insulation and venting of cryogenic systems to prevent condensation buildup that could lead to electrical shorts or component degradation. Qualcomm has also invested in developing specialized ESD (Electrostatic Discharge) protection circuits that remain effective at cryogenic temperatures, addressing the unique challenges of managing static electricity in ultra-cold environments.

Strengths: Extensive semiconductor manufacturing expertise provides advantages in scaling cryogenic technologies; strong industry partnerships facilitate broader adoption of safety standards. Weaknesses: Less experience with ultra-low temperature systems (below 4K) compared to quantum computing specialists; primary focus on mobile applications may limit applicability to other domains.

Northrop Grumman Systems Corp.

Technical Solution: Northrop Grumman has developed advanced cryogenic electronics systems primarily for aerospace, defense, and space applications where extreme reliability is critical. Their technology focuses on radiation-hardened superconducting electronics that operate at temperatures approaching absolute zero. Their safety standards incorporate triple-redundant monitoring systems for cryogenic cooling infrastructure, with particular emphasis on preventing single-point failures. Northrop's approach includes specialized packaging techniques that maintain hermeticity under extreme thermal cycling, preventing contamination that could compromise safety. They've pioneered the use of superconducting quantum interference devices (SQUIDs) with integrated safety monitoring capabilities that can detect minute electromagnetic anomalies before they become hazardous. Their cryogenic electronics incorporate self-diagnostic capabilities that continuously monitor operational parameters and can initiate controlled shutdown procedures when safety thresholds are exceeded. Northrop's standards also address the unique challenges of maintaining safety during power transitions between room temperature and cryogenic states.

Strengths: Military-grade reliability testing protocols ensure exceptional durability; extensive experience with space-qualified hardware provides valuable insights for extreme environments. Weaknesses: Solutions are often customized for specific applications rather than standardized; high security requirements around defense applications limit knowledge sharing with broader industry.

Key Patents and Research in Cryogenic Safety Technology

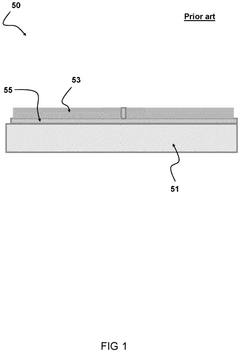

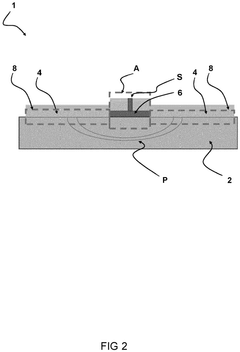

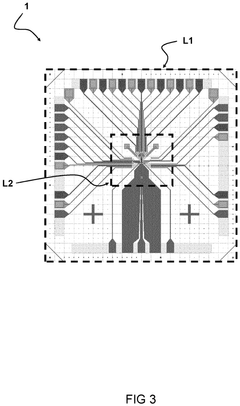

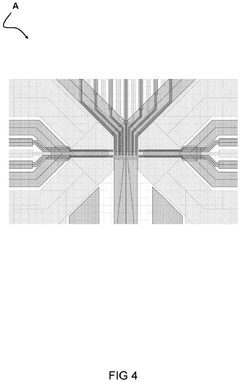

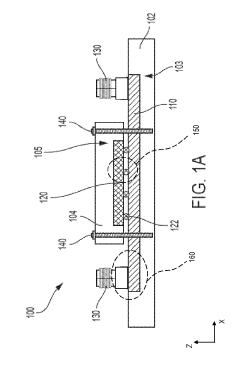

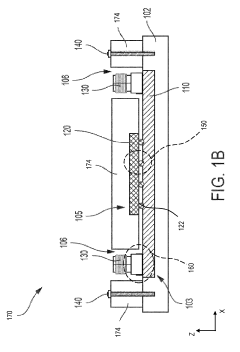

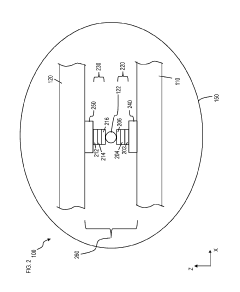

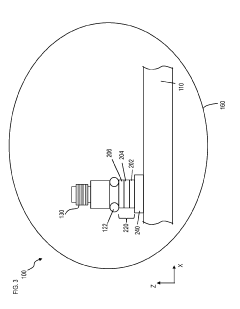

A semiconductor processing device, a method of manufacturing thereof, and a quantum computing unit

PatentPendingEP4465357A1

Innovation

- A cryogenic semiconductor processing device with a dielectric layer partially removed between the gate electrode layer and the semiconductor substrate, allowing direct contact at room temperature for controlled ESD discharge, and leveraging temperature-dependent semiconductor properties for insulation at cryogenic temperatures.

Bump bonded cryogenic chip carrier

PatentActiveUS20190103541A1

Innovation

- A system utilizing thin films with superconducting regions connected by low ohmic solder material with a melting point above 700 degrees Celsius, eliminating the need for intermediary connection mechanisms like wire bonds, and enabling direct electrical and thermal conduction between substrates.

Risk Assessment Methodologies for Extreme-Temperature Electronics

Risk assessment for cryogenic electronics requires specialized methodologies that account for the unique challenges posed by extreme temperature environments. Traditional risk assessment frameworks often fail to adequately address the specific failure modes and safety concerns that emerge when electronic components operate at temperatures approaching absolute zero.

The primary risk assessment approach for cryogenic electronics involves systematic identification of thermal stress points through multi-physics modeling. These models must integrate electrical performance parameters with thermodynamic behaviors across temperature gradients ranging from ambient to below 4 Kelvin. Simulation tools such as COMSOL Multiphysics and ANSYS have been adapted specifically for cryogenic applications, allowing engineers to predict potential failure points before physical prototyping.

Material degradation analysis forms another critical component of risk assessment. At cryogenic temperatures, conventional materials exhibit dramatically altered properties, including increased brittleness, thermal contraction mismatches, and modified electrical conductivity. Assessment methodologies must incorporate comprehensive materials characterization data across the entire operating temperature range, with particular attention to transition points where sudden property changes occur.

Accelerated life testing protocols have been developed specifically for cryogenic electronics, involving rapid thermal cycling between extreme temperature points. These methodologies help identify weaknesses in component integrity, solder joint reliability, and package hermeticity that might not manifest under standard testing conditions. Statistical models derived from these tests enable more accurate mean-time-between-failure (MTBF) predictions for cryogenic applications.

Fault tree analysis (FTA) and Failure Mode and Effects Analysis (FMEA) frameworks have been modified to incorporate cryogenic-specific failure mechanisms. These adaptations include additional consideration for superconducting state transitions, trapped magnetic flux, and quantum tunneling effects that become prominent at ultra-low temperatures. The modified frameworks assign higher risk priorities to failure modes unique to cryogenic operation.

Electromagnetic interference (EMI) assessment methodologies require significant adaptation for cryogenic electronics, particularly for superconducting circuits. The extremely low noise floor and high sensitivity of these systems necessitate specialized EMI testing chambers capable of operating at cryogenic temperatures while providing accurate electromagnetic field measurements.

Safety certification standards for cryogenic electronics have emerged from these specialized risk assessment methodologies. Organizations including the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established working groups focused on developing standardized risk assessment protocols specifically for extreme-temperature electronic systems, ensuring consistent safety evaluation across the industry.

The primary risk assessment approach for cryogenic electronics involves systematic identification of thermal stress points through multi-physics modeling. These models must integrate electrical performance parameters with thermodynamic behaviors across temperature gradients ranging from ambient to below 4 Kelvin. Simulation tools such as COMSOL Multiphysics and ANSYS have been adapted specifically for cryogenic applications, allowing engineers to predict potential failure points before physical prototyping.

Material degradation analysis forms another critical component of risk assessment. At cryogenic temperatures, conventional materials exhibit dramatically altered properties, including increased brittleness, thermal contraction mismatches, and modified electrical conductivity. Assessment methodologies must incorporate comprehensive materials characterization data across the entire operating temperature range, with particular attention to transition points where sudden property changes occur.

Accelerated life testing protocols have been developed specifically for cryogenic electronics, involving rapid thermal cycling between extreme temperature points. These methodologies help identify weaknesses in component integrity, solder joint reliability, and package hermeticity that might not manifest under standard testing conditions. Statistical models derived from these tests enable more accurate mean-time-between-failure (MTBF) predictions for cryogenic applications.

Fault tree analysis (FTA) and Failure Mode and Effects Analysis (FMEA) frameworks have been modified to incorporate cryogenic-specific failure mechanisms. These adaptations include additional consideration for superconducting state transitions, trapped magnetic flux, and quantum tunneling effects that become prominent at ultra-low temperatures. The modified frameworks assign higher risk priorities to failure modes unique to cryogenic operation.

Electromagnetic interference (EMI) assessment methodologies require significant adaptation for cryogenic electronics, particularly for superconducting circuits. The extremely low noise floor and high sensitivity of these systems necessitate specialized EMI testing chambers capable of operating at cryogenic temperatures while providing accurate electromagnetic field measurements.

Safety certification standards for cryogenic electronics have emerged from these specialized risk assessment methodologies. Organizations including the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) have established working groups focused on developing standardized risk assessment protocols specifically for extreme-temperature electronic systems, ensuring consistent safety evaluation across the industry.

International Regulatory Framework for Cryogenic Systems

The global landscape for cryogenic electronics regulation is characterized by a complex network of standards that vary significantly across regions. The International Electrotechnical Commission (IEC) has established foundational standards through IEC 60747 for semiconductor devices and IEC 61340 for electrostatic discharge protection, which provide baseline requirements for cryogenic electronic systems. These standards address operational safety parameters including thermal management, electrical isolation, and material compatibility at extremely low temperatures.

In the United States, regulatory oversight is primarily managed through the Department of Energy's Cryogenic Safety Standard (DOE-STD-1029) and the National Institute of Standards and Technology's guidelines for cryogenic equipment. The Food and Drug Administration also maintains specific requirements for medical devices utilizing cryogenic electronics, particularly for MRI systems and cryosurgery equipment, through 21 CFR Part 820.

The European Union has implemented more comprehensive frameworks through the Pressure Equipment Directive (2014/68/EU) and Low Voltage Directive (2014/35/EU), which explicitly address cryogenic applications. Additionally, the European Committee for Standardization (CEN) has developed EN 13458 specifically for cryogenic vessels, which includes provisions for associated electronic control systems.

In Asia, Japan's High Pressure Gas Safety Act and China's GB 150 pressure vessel code incorporate specific provisions for cryogenic electronics safety. These regulations are particularly relevant for superconducting applications and quantum computing hardware that operate at near-absolute zero temperatures.

International harmonization efforts are being led by organizations such as the International Cryogenic Engineering Conference (ICEC) and the Cryogenic Society of America, which work to develop consensus-based best practices. These organizations have been instrumental in addressing emerging challenges related to quench detection systems, persistent current switches, and cryocooler control electronics.

Recent regulatory developments have focused on addressing the unique safety challenges of quantum computing systems, which require extensive cryogenic infrastructure. The IEEE Quantum Initiative has begun developing standards specifically for quantum cryogenic interfaces, while ISO Technical Committee 86 is expanding its scope to include cryogenic electronic components used in industrial refrigeration systems.

Compliance with these diverse regulatory frameworks presents significant challenges for manufacturers operating in global markets, necessitating comprehensive understanding of regional variations and certification requirements. The trend toward international harmonization is gaining momentum, though complete standardization remains a distant goal in this rapidly evolving technological domain.

In the United States, regulatory oversight is primarily managed through the Department of Energy's Cryogenic Safety Standard (DOE-STD-1029) and the National Institute of Standards and Technology's guidelines for cryogenic equipment. The Food and Drug Administration also maintains specific requirements for medical devices utilizing cryogenic electronics, particularly for MRI systems and cryosurgery equipment, through 21 CFR Part 820.

The European Union has implemented more comprehensive frameworks through the Pressure Equipment Directive (2014/68/EU) and Low Voltage Directive (2014/35/EU), which explicitly address cryogenic applications. Additionally, the European Committee for Standardization (CEN) has developed EN 13458 specifically for cryogenic vessels, which includes provisions for associated electronic control systems.

In Asia, Japan's High Pressure Gas Safety Act and China's GB 150 pressure vessel code incorporate specific provisions for cryogenic electronics safety. These regulations are particularly relevant for superconducting applications and quantum computing hardware that operate at near-absolute zero temperatures.

International harmonization efforts are being led by organizations such as the International Cryogenic Engineering Conference (ICEC) and the Cryogenic Society of America, which work to develop consensus-based best practices. These organizations have been instrumental in addressing emerging challenges related to quench detection systems, persistent current switches, and cryocooler control electronics.

Recent regulatory developments have focused on addressing the unique safety challenges of quantum computing systems, which require extensive cryogenic infrastructure. The IEEE Quantum Initiative has begun developing standards specifically for quantum cryogenic interfaces, while ISO Technical Committee 86 is expanding its scope to include cryogenic electronic components used in industrial refrigeration systems.

Compliance with these diverse regulatory frameworks presents significant challenges for manufacturers operating in global markets, necessitating comprehensive understanding of regional variations and certification requirements. The trend toward international harmonization is gaining momentum, though complete standardization remains a distant goal in this rapidly evolving technological domain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!