Comparison of Cryogenic Electronics vs Traditional Electronics Performance

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Background and Objectives

Cryogenic electronics represents a frontier technology domain that operates electronic devices and circuits at extremely low temperatures, typically below 123K (-150°C). The field emerged in the mid-20th century alongside advancements in cryogenic cooling technologies, but has gained significant momentum in recent decades due to its potential applications in quantum computing, space exploration, and high-performance computing systems.

The evolution of cryogenic electronics has been closely tied to developments in superconductivity research, beginning with the discovery of superconductivity in mercury at 4.2K by Heike Kamerlingh Onnes in 1911. Major technological breakthroughs occurred in the 1960s with the development of Josephson junctions and SQUID (Superconducting Quantum Interference Device) technologies, followed by high-temperature superconductors in the 1980s that expanded practical application possibilities.

Current technological trends point toward integration of cryogenic electronics with quantum information processing systems, development of more energy-efficient cryogenic cooling solutions, and creation of hybrid systems that leverage both conventional and cryogenic electronic components. The field is experiencing accelerated growth due to substantial investments in quantum computing infrastructure globally.

The primary objective of cryogenic electronics research is to harness the unique physical properties that emerge at ultra-low temperatures, including superconductivity, reduced thermal noise, and enhanced carrier mobility, to create electronic systems with performance capabilities that fundamentally surpass traditional room-temperature electronics.

Specific technical goals include developing cryogenic electronic components with improved energy efficiency, as cryogenic cooling itself requires significant power; creating reliable interfaces between room-temperature and cryogenic systems; extending operational lifetimes of cryogenic components; and miniaturizing cryogenic cooling systems to enable more practical applications.

Additionally, researchers aim to establish standardized design methodologies and simulation tools specifically for cryogenic electronic circuits, as traditional electronic design automation tools are optimized for room-temperature operation and often fail to accurately model cryogenic behavior.

The comparison between cryogenic and traditional electronics performance represents a critical research focus, with cryogenic systems demonstrating superior characteristics in terms of signal-to-noise ratio, switching speed, and power consumption under specific conditions. However, these advantages must be weighed against the substantial infrastructure requirements and operational complexities associated with maintaining cryogenic temperatures.

As quantum computing and other advanced technologies continue to develop, cryogenic electronics stands at a pivotal juncture where theoretical performance advantages must be translated into practical, scalable systems that can deliver transformative capabilities across multiple industries and scientific disciplines.

The evolution of cryogenic electronics has been closely tied to developments in superconductivity research, beginning with the discovery of superconductivity in mercury at 4.2K by Heike Kamerlingh Onnes in 1911. Major technological breakthroughs occurred in the 1960s with the development of Josephson junctions and SQUID (Superconducting Quantum Interference Device) technologies, followed by high-temperature superconductors in the 1980s that expanded practical application possibilities.

Current technological trends point toward integration of cryogenic electronics with quantum information processing systems, development of more energy-efficient cryogenic cooling solutions, and creation of hybrid systems that leverage both conventional and cryogenic electronic components. The field is experiencing accelerated growth due to substantial investments in quantum computing infrastructure globally.

The primary objective of cryogenic electronics research is to harness the unique physical properties that emerge at ultra-low temperatures, including superconductivity, reduced thermal noise, and enhanced carrier mobility, to create electronic systems with performance capabilities that fundamentally surpass traditional room-temperature electronics.

Specific technical goals include developing cryogenic electronic components with improved energy efficiency, as cryogenic cooling itself requires significant power; creating reliable interfaces between room-temperature and cryogenic systems; extending operational lifetimes of cryogenic components; and miniaturizing cryogenic cooling systems to enable more practical applications.

Additionally, researchers aim to establish standardized design methodologies and simulation tools specifically for cryogenic electronic circuits, as traditional electronic design automation tools are optimized for room-temperature operation and often fail to accurately model cryogenic behavior.

The comparison between cryogenic and traditional electronics performance represents a critical research focus, with cryogenic systems demonstrating superior characteristics in terms of signal-to-noise ratio, switching speed, and power consumption under specific conditions. However, these advantages must be weighed against the substantial infrastructure requirements and operational complexities associated with maintaining cryogenic temperatures.

As quantum computing and other advanced technologies continue to develop, cryogenic electronics stands at a pivotal juncture where theoretical performance advantages must be translated into practical, scalable systems that can deliver transformative capabilities across multiple industries and scientific disciplines.

Market Analysis for Cryogenic Electronic Applications

The cryogenic electronics market is experiencing significant growth driven by advancements in quantum computing, space exploration, and scientific research applications. Current market valuations indicate the global cryogenic electronics sector reached approximately $2.3 billion in 2022, with projections suggesting a compound annual growth rate of 8.7% through 2030. This growth trajectory is primarily fueled by substantial investments in quantum computing research, with major technology corporations and governments allocating billions to develop quantum technologies that rely heavily on cryogenic electronic components.

Market segmentation reveals distinct application sectors for cryogenic electronics. Quantum computing represents the largest market share at roughly 42%, followed by scientific research instrumentation at 28%, space and defense applications at 18%, and medical imaging systems at 12%. The quantum computing segment is expected to maintain the highest growth rate due to increasing commercial interest in quantum advantage for complex computational problems.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%), Asia-Pacific (24%), and other regions (9%). The United States and China are engaged in aggressive investment strategies to achieve quantum supremacy, creating significant market opportunities for cryogenic electronic suppliers. The European market is characterized by strong research institutions and government-backed quantum initiatives, particularly in Germany, France, and the Netherlands.

Key demand drivers include the exponential growth in data processing requirements that conventional electronics cannot efficiently address, increasing need for ultra-sensitive detection systems in scientific and medical applications, and the expanding space exploration sector requiring electronics that can function in extreme environments. The superior performance characteristics of cryogenic electronics—including dramatically reduced power consumption, minimal thermal noise, and enhanced signal integrity—create compelling value propositions across these applications.

Market challenges include the high infrastructure costs associated with cryogenic cooling systems, limited manufacturing scalability of specialized components, and the nascent supply chain for cryogenic electronic materials. The cost-benefit analysis remains challenging for many potential commercial applications, restricting broader market penetration beyond research and specialized high-value applications.

Customer segments show distinct purchasing patterns, with government research laboratories and academic institutions focusing on performance regardless of cost, while commercial entities increasingly seek more cost-effective solutions that balance performance with operational practicality. This dichotomy is driving innovation in more accessible cryogenic electronic systems that can operate at relatively higher temperatures (10-20K versus sub-1K), potentially expanding the addressable market significantly in the coming decade.

Market segmentation reveals distinct application sectors for cryogenic electronics. Quantum computing represents the largest market share at roughly 42%, followed by scientific research instrumentation at 28%, space and defense applications at 18%, and medical imaging systems at 12%. The quantum computing segment is expected to maintain the highest growth rate due to increasing commercial interest in quantum advantage for complex computational problems.

Geographically, North America leads the market with approximately 38% share, followed by Europe (29%), Asia-Pacific (24%), and other regions (9%). The United States and China are engaged in aggressive investment strategies to achieve quantum supremacy, creating significant market opportunities for cryogenic electronic suppliers. The European market is characterized by strong research institutions and government-backed quantum initiatives, particularly in Germany, France, and the Netherlands.

Key demand drivers include the exponential growth in data processing requirements that conventional electronics cannot efficiently address, increasing need for ultra-sensitive detection systems in scientific and medical applications, and the expanding space exploration sector requiring electronics that can function in extreme environments. The superior performance characteristics of cryogenic electronics—including dramatically reduced power consumption, minimal thermal noise, and enhanced signal integrity—create compelling value propositions across these applications.

Market challenges include the high infrastructure costs associated with cryogenic cooling systems, limited manufacturing scalability of specialized components, and the nascent supply chain for cryogenic electronic materials. The cost-benefit analysis remains challenging for many potential commercial applications, restricting broader market penetration beyond research and specialized high-value applications.

Customer segments show distinct purchasing patterns, with government research laboratories and academic institutions focusing on performance regardless of cost, while commercial entities increasingly seek more cost-effective solutions that balance performance with operational practicality. This dichotomy is driving innovation in more accessible cryogenic electronic systems that can operate at relatively higher temperatures (10-20K versus sub-1K), potentially expanding the addressable market significantly in the coming decade.

Current State and Challenges in Cryogenic Electronics

Cryogenic electronics represents a frontier in semiconductor technology, operating at extremely low temperatures typically below 10 Kelvin. The global landscape of cryogenic electronics development shows significant advancements in recent years, with major research institutions in the United States, Europe, and Asia making substantial contributions. The current state of this technology is characterized by promising laboratory demonstrations but limited commercial deployment due to several persistent challenges.

The fundamental physics of semiconductor behavior changes dramatically at cryogenic temperatures, creating both opportunities and obstacles. While electron mobility increases and thermal noise decreases at these temperatures, new phenomena such as carrier freeze-out and hot electron effects emerge, requiring novel design approaches. Current cryogenic electronic systems demonstrate superior performance metrics in terms of signal-to-noise ratio and power efficiency compared to their room-temperature counterparts, with improvements of up to two orders of magnitude in certain applications.

Material constraints represent a significant challenge, as conventional semiconductor materials exhibit different properties at cryogenic temperatures. Silicon-based technologies show limited functionality below certain temperatures, while specialized materials like silicon-germanium (SiGe) and indium phosphide (InP) demonstrate better performance but present manufacturing complexities. The integration of these materials into established fabrication processes remains problematic, often requiring custom manufacturing approaches that limit scalability.

Thermal management presents another critical challenge. The interface between cryogenic components and room-temperature systems creates substantial heat gradients that must be carefully managed. Current cooling technologies, primarily based on liquid helium or mechanical cryocoolers, are bulky, energy-intensive, and costly to operate continuously. The energy efficiency of these cooling systems significantly impacts the overall system performance, often negating some of the theoretical advantages of cryogenic operation.

Reliability and operational stability of cryogenic electronics remain inconsistent across different implementations. Thermal cycling between room temperature and cryogenic conditions induces mechanical stress that can lead to premature component failure. Current mean-time-between-failure metrics for cryogenic systems lag behind conventional electronics by a significant margin, limiting their practical application in mission-critical systems.

The economic viability of cryogenic electronics represents perhaps the most significant barrier to widespread adoption. The high costs associated with specialized materials, custom fabrication processes, and cooling infrastructure result in systems that are orders of magnitude more expensive than conventional alternatives. This cost differential restricts current applications primarily to high-value niches such as quantum computing, space exploration, and certain scientific instrumentation where performance requirements justify the expense.

The fundamental physics of semiconductor behavior changes dramatically at cryogenic temperatures, creating both opportunities and obstacles. While electron mobility increases and thermal noise decreases at these temperatures, new phenomena such as carrier freeze-out and hot electron effects emerge, requiring novel design approaches. Current cryogenic electronic systems demonstrate superior performance metrics in terms of signal-to-noise ratio and power efficiency compared to their room-temperature counterparts, with improvements of up to two orders of magnitude in certain applications.

Material constraints represent a significant challenge, as conventional semiconductor materials exhibit different properties at cryogenic temperatures. Silicon-based technologies show limited functionality below certain temperatures, while specialized materials like silicon-germanium (SiGe) and indium phosphide (InP) demonstrate better performance but present manufacturing complexities. The integration of these materials into established fabrication processes remains problematic, often requiring custom manufacturing approaches that limit scalability.

Thermal management presents another critical challenge. The interface between cryogenic components and room-temperature systems creates substantial heat gradients that must be carefully managed. Current cooling technologies, primarily based on liquid helium or mechanical cryocoolers, are bulky, energy-intensive, and costly to operate continuously. The energy efficiency of these cooling systems significantly impacts the overall system performance, often negating some of the theoretical advantages of cryogenic operation.

Reliability and operational stability of cryogenic electronics remain inconsistent across different implementations. Thermal cycling between room temperature and cryogenic conditions induces mechanical stress that can lead to premature component failure. Current mean-time-between-failure metrics for cryogenic systems lag behind conventional electronics by a significant margin, limiting their practical application in mission-critical systems.

The economic viability of cryogenic electronics represents perhaps the most significant barrier to widespread adoption. The high costs associated with specialized materials, custom fabrication processes, and cooling infrastructure result in systems that are orders of magnitude more expensive than conventional alternatives. This cost differential restricts current applications primarily to high-value niches such as quantum computing, space exploration, and certain scientific instrumentation where performance requirements justify the expense.

Technical Solutions Comparison Between Cryogenic and Traditional Electronics

01 Cryogenic electronic systems and performance advantages

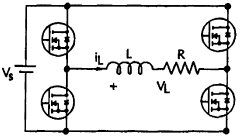

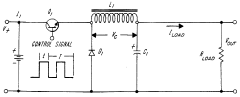

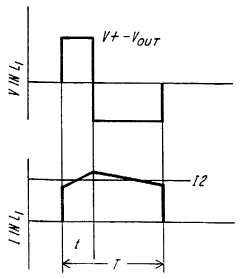

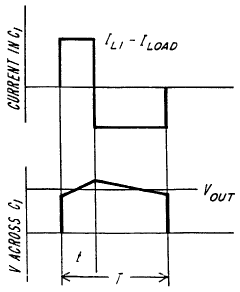

Cryogenic electronics operate at extremely low temperatures, offering significant performance advantages over traditional electronics. These systems demonstrate improved conductivity, reduced electrical resistance, and enhanced signal-to-noise ratios. The low-temperature environment enables superconductivity in certain materials, allowing for faster processing speeds and reduced power consumption. Cryogenic electronic systems are particularly valuable in applications requiring high precision and sensitivity.- Performance characteristics of cryogenic electronics: Cryogenic electronics demonstrate superior performance characteristics compared to traditional electronics when operated at extremely low temperatures. These systems exhibit reduced electrical resistance, lower noise levels, and increased signal-to-noise ratios, enabling higher sensitivity in detection applications. The superconducting properties that emerge at cryogenic temperatures allow for faster switching speeds and significantly reduced power consumption, making them ideal for specialized applications requiring exceptional performance metrics.

- Cooling systems for cryogenic electronics: Specialized cooling systems are essential for maintaining the ultra-low temperatures required by cryogenic electronic components. These systems employ various refrigeration techniques including liquid helium, liquid nitrogen, or mechanical cryocoolers to achieve and maintain temperatures near absolute zero. Advanced thermal management solutions incorporate multi-stage cooling processes, vacuum insulation, and specialized materials to minimize heat transfer and maintain stable operating conditions for sensitive cryogenic circuits and components.

- Applications of cryogenic electronics: Cryogenic electronics find applications in specialized fields requiring extreme sensitivity or performance. These include quantum computing systems where superconducting qubits operate at near absolute zero temperatures, space exploration equipment designed to function in the cold vacuum of space, advanced scientific instrumentation for particle physics research, and medical imaging systems like SQUID-based magnetoencephalography. The unique properties of materials at cryogenic temperatures enable capabilities impossible with traditional room-temperature electronics, despite the additional complexity and cost of the required cooling infrastructure.

- Thermal management challenges in electronics: Thermal management presents significant challenges in both cryogenic and traditional electronic systems. While traditional electronics struggle with heat dissipation to prevent performance degradation and component failure, cryogenic systems face the opposite challenge of maintaining extremely low temperatures while minimizing thermal interference. Advanced thermal interface materials, heat sinks, and specialized cooling solutions are developed to address these challenges. Effective thermal management is critical for reliability, performance stability, and longevity of electronic systems across temperature ranges.

- Material considerations for extreme temperature electronics: Material selection is crucial for electronics operating at extreme temperatures. Cryogenic electronics require materials that maintain or improve their electrical properties at ultra-low temperatures, such as certain superconductors, specialized semiconductors, and low-thermal-expansion alloys. Traditional electronics typically use silicon-based semiconductors optimized for room temperature operation. Advanced packaging materials, interconnects, and substrate technologies are developed to accommodate the different thermal expansion coefficients and mechanical stresses experienced across wide temperature ranges, ensuring reliable operation in their respective operating environments.

02 Cooling systems for electronic components

Various cooling technologies have been developed to maintain electronic components at cryogenic temperatures. These include liquid nitrogen/helium cooling systems, pulse tube cryocoolers, and specialized heat exchangers. Efficient thermal management is critical for maintaining stable operating conditions and preventing thermal cycling damage. Advanced insulation materials and vacuum chambers are often employed to minimize heat transfer from the ambient environment, ensuring consistent performance of cryogenic electronic systems.Expand Specific Solutions03 Material considerations for cryogenic electronics

Special materials are required for electronic components operating at cryogenic temperatures. Conventional semiconductor materials often exhibit different electrical properties at extremely low temperatures, necessitating specialized design approaches. Superconducting materials, specialized alloys, and modified semiconductor compositions are employed to ensure reliable operation. Material selection must account for thermal expansion coefficients, mechanical strength at low temperatures, and consistent electrical performance across wide temperature ranges.Expand Specific Solutions04 Applications of cryogenic electronics

Cryogenic electronics find applications in quantum computing, space exploration, medical imaging, and scientific research. Quantum computers utilize superconducting circuits operating at near absolute zero to maintain quantum coherence. Space missions employ cryogenically cooled sensors for improved sensitivity in astronomical observations. Medical applications include superconducting quantum interference devices (SQUIDs) for magnetoencephalography and magnetic resonance imaging. High-energy physics experiments also benefit from the enhanced sensitivity and reduced noise of cryogenic detection systems.Expand Specific Solutions05 Integration challenges between cryogenic and traditional electronics

Integrating cryogenic and room-temperature electronics presents significant engineering challenges. Interface designs must accommodate the extreme temperature gradients between different operating environments. Signal integrity must be maintained across temperature boundaries, often requiring specialized interconnects and buffer circuits. Power delivery to cryogenic components demands careful thermal management to prevent unwanted heating. Packaging solutions must address thermal expansion mismatches while providing adequate thermal isolation between temperature zones.Expand Specific Solutions

Leading Companies and Research Institutions in Cryogenic Electronics

The cryogenic electronics market is in an early growth phase, characterized by significant research activity but limited commercial deployment. Market size remains relatively small but is expanding rapidly due to quantum computing applications, with projections suggesting substantial growth over the next decade. Technologically, cryogenic electronics offers superior performance in power efficiency and speed compared to traditional electronics, though challenges in scalability and integration persist. Leading players include specialized companies like Hypres and kiutra GmbH focusing exclusively on superconducting technologies, alongside major corporations such as IBM, Northrop Grumman, and Siemens investing in research capabilities. Academic institutions including MIT, McGill University, and Tsinghua University are driving fundamental research, while government laboratories like Naval Research Laboratory and Japan Science & Technology Agency provide critical infrastructure support.

International Business Machines Corp.

Technical Solution: IBM has pioneered cryogenic electronics through their superconducting quantum computing initiatives. Their technical approach involves operating superconducting qubits at temperatures near absolute zero (10-15 millikelvin), utilizing Josephson junctions as the fundamental building blocks. IBM has developed specialized cryogenic control electronics that can function at extremely low temperatures, reducing signal latency and thermal noise compared to room-temperature control systems. Their cryogenic infrastructure includes dilution refrigerators with multi-stage cooling and custom-designed cryogenic amplifiers that maintain quantum coherence. IBM's roadmap includes developing more integrated cryogenic control systems that can scale with increasing qubit counts, potentially reducing the complexity of current implementations that require room-temperature electronics connected via specialized cabling.

Strengths: Superior signal-to-noise ratio in quantum operations; significantly reduced thermal noise; enhanced quantum coherence times; lower power dissipation. Weaknesses: Extremely high cooling costs; complex infrastructure requirements; limited scalability due to cooling constraints; specialized manufacturing processes required for cryogenic compatibility.

Cryotech Co., Ltd.

Technical Solution: Cryotech has developed specialized cryogenic electronics focused on superconducting sensors and readout systems. Their technical approach centers on developing Superconducting Quantum Interference Devices (SQUIDs) that operate at liquid helium temperatures (4K) or with high-temperature superconductors at liquid nitrogen temperatures (77K). Cryotech's systems integrate custom cryogenic amplifiers with ultra-low noise characteristics, achieving noise levels below 1 pA/√Hz. Their technology includes specialized cryogenic packaging solutions that maintain thermal isolation while providing necessary electrical connections between room temperature and cryogenic environments. Cryotech has pioneered techniques for multiplexing multiple superconducting sensors, allowing for scalable arrays of detectors with minimal thermal load on the cooling system. Their systems find applications in medical imaging (magnetoencephalography), geophysical exploration, and fundamental physics research.

Strengths: Unparalleled sensitivity for magnetic field detection; extremely low noise floor; ability to detect signals impossible with conventional electronics; energy efficient operation. Weaknesses: Requires continuous cryogenic cooling infrastructure; limited commercial applications outside specialized fields; higher maintenance requirements; complex calibration procedures.

Key Patents and Breakthroughs in Cryogenic Electronics

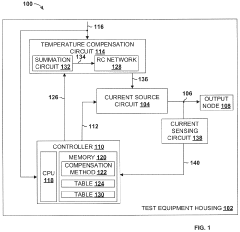

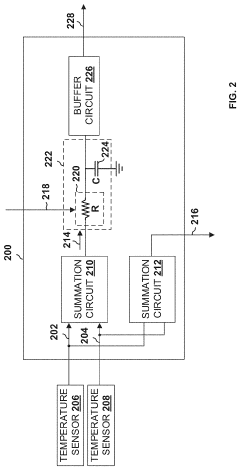

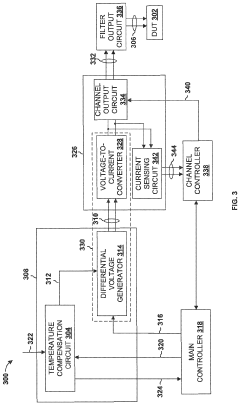

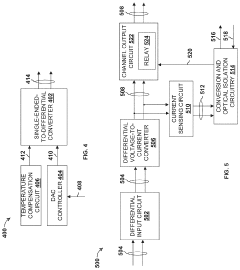

Temperature compensated current source for cryogenic electronic testing

PatentActiveUS11789065B1

Innovation

- A system with a controller that receives temperature signals, identifies thermal saturation time, and generates a time constant adjustment signal to delay temperature compensation, adjusting the RC network's time constant to match the thermal saturation time, thereby compensating for temperature effects on current sources at a later stage when current drift occurs.

Cryogenic electronics power supply

PatentInactiveAU707457B2

Innovation

- Embedding high-temperature superconducting inductors in a cryogenically cooled environment, along with other components, to reduce component stress and improve performance, allowing for higher power output with reduced size and cost, by operating at frequencies above 500 Hertz and using cryogenic cooling to achieve superconductivity.

Energy Efficiency and Thermal Management Considerations

Energy efficiency represents a critical differentiator between cryogenic and traditional electronics, with profound implications for system design and operational costs. Cryogenic electronics operate at extremely low temperatures, typically below 10 Kelvin, which fundamentally alters their power consumption profile. While traditional electronics face increasing power density challenges as transistor sizes shrink according to Moore's Law, cryogenic systems demonstrate significantly reduced leakage currents and lower resistive losses, potentially offering orders of magnitude improvement in energy efficiency for certain applications.

The thermal management requirements for these technologies present stark contrasts. Traditional electronics rely on conventional cooling methods such as heat sinks, fans, and liquid cooling systems, which typically consume 30-50% of total data center energy. These systems struggle to keep pace with increasing power densities in advanced computing architectures, leading to thermal throttling and performance limitations.

Cryogenic electronics, conversely, require sophisticated cooling infrastructure including cryostats, dilution refrigerators, or liquid helium systems. The energy cost of maintaining cryogenic temperatures presents a significant overhead—approximately 1000 watts of cooling power may be required for each watt dissipated at deep cryogenic temperatures. This cooling penalty creates a complex efficiency equation that must be carefully evaluated for each application scenario.

The energy balance calculation must consider both static and dynamic power consumption. In traditional CMOS electronics, dynamic power scales with frequency and voltage squared, while static leakage grows exponentially with decreasing transistor dimensions. Cryogenic operation dramatically reduces this static component, potentially enabling higher clock frequencies without thermal constraints.

Recent advances in cryogenic cooling technologies, including pulse tube cryocoolers and magnetic refrigeration, have improved cooling efficiency by 15-20% over the past decade. However, the fundamental thermodynamic limits of removing heat from low-temperature environments remain challenging, with theoretical minimum energy requirements defined by Carnot efficiency.

For quantum computing applications, the energy trade-off becomes particularly nuanced. While the quantum processing elements may consume minimal power, the surrounding control electronics and refrigeration systems dominate the energy budget. Hybrid approaches that strategically position only critical components at cryogenic temperatures while maintaining support systems at higher temperatures offer promising compromises.

The environmental impact of these technologies must also be considered in comprehensive energy assessments. Traditional electronics contribute significantly to global carbon emissions through both operational energy consumption and manufacturing processes, while cryogenic systems may have smaller deployment footprints but higher embodied energy costs in specialized cooling infrastructure.

The thermal management requirements for these technologies present stark contrasts. Traditional electronics rely on conventional cooling methods such as heat sinks, fans, and liquid cooling systems, which typically consume 30-50% of total data center energy. These systems struggle to keep pace with increasing power densities in advanced computing architectures, leading to thermal throttling and performance limitations.

Cryogenic electronics, conversely, require sophisticated cooling infrastructure including cryostats, dilution refrigerators, or liquid helium systems. The energy cost of maintaining cryogenic temperatures presents a significant overhead—approximately 1000 watts of cooling power may be required for each watt dissipated at deep cryogenic temperatures. This cooling penalty creates a complex efficiency equation that must be carefully evaluated for each application scenario.

The energy balance calculation must consider both static and dynamic power consumption. In traditional CMOS electronics, dynamic power scales with frequency and voltage squared, while static leakage grows exponentially with decreasing transistor dimensions. Cryogenic operation dramatically reduces this static component, potentially enabling higher clock frequencies without thermal constraints.

Recent advances in cryogenic cooling technologies, including pulse tube cryocoolers and magnetic refrigeration, have improved cooling efficiency by 15-20% over the past decade. However, the fundamental thermodynamic limits of removing heat from low-temperature environments remain challenging, with theoretical minimum energy requirements defined by Carnot efficiency.

For quantum computing applications, the energy trade-off becomes particularly nuanced. While the quantum processing elements may consume minimal power, the surrounding control electronics and refrigeration systems dominate the energy budget. Hybrid approaches that strategically position only critical components at cryogenic temperatures while maintaining support systems at higher temperatures offer promising compromises.

The environmental impact of these technologies must also be considered in comprehensive energy assessments. Traditional electronics contribute significantly to global carbon emissions through both operational energy consumption and manufacturing processes, while cryogenic systems may have smaller deployment footprints but higher embodied energy costs in specialized cooling infrastructure.

Quantum Computing Integration Potential

The integration of cryogenic electronics with quantum computing systems represents a frontier of technological convergence with extraordinary potential. Quantum computers fundamentally require ultra-low temperature environments to maintain quantum coherence, typically operating at millikelvin temperatures. This necessity creates a natural synergy with cryogenic electronics, which can operate directly within these extreme environments.

Traditional electronics face significant performance degradation when placed in quantum computing environments, exhibiting increased power consumption, reduced switching speeds, and signal integrity issues. Conversely, cryogenic electronics demonstrate enhanced carrier mobility, reduced leakage currents, and improved energy efficiency at these temperatures, making them ideal companions for quantum processors.

The implementation of cryogenic control electronics in close proximity to quantum bits (qubits) substantially reduces signal latency and noise - two critical factors limiting quantum computing performance. Current research indicates that integrating cryogenic CMOS, superconducting electronics, or single-flux quantum (SFQ) circuits directly with quantum processors could enable scaling beyond the current limitations of room-temperature control systems.

Several pioneering experiments have demonstrated that cryogenic electronics can reduce the interconnect complexity that currently plagues quantum systems. By placing control and readout circuits within the cryogenic environment, researchers have achieved up to 10x improvements in qubit readout fidelity and significant reductions in thermal noise contribution.

The material properties of semiconductors at cryogenic temperatures also offer unique advantages for quantum integration. Silicon-based cryogenic electronics exhibit dramatically reduced phonon scattering, while superconducting materials eliminate resistive losses entirely, enabling circuit designs that would be impossible with traditional electronics operating at room temperature.

Looking forward, the co-development of specialized cryogenic electronic interfaces and quantum processors represents a promising path toward practical quantum advantage. Industry projections suggest that purpose-built cryogenic control systems could enable quantum computers to scale beyond 1,000 logical qubits - a critical threshold for many practical applications.

The economic implications of this integration extend beyond quantum computing itself, potentially revolutionizing fields like materials science, cryptography, and pharmaceutical development. As cryogenic electronic manufacturing techniques mature, the cost-performance ratio continues to improve, gradually removing one of the major barriers to widespread quantum computing adoption.

Traditional electronics face significant performance degradation when placed in quantum computing environments, exhibiting increased power consumption, reduced switching speeds, and signal integrity issues. Conversely, cryogenic electronics demonstrate enhanced carrier mobility, reduced leakage currents, and improved energy efficiency at these temperatures, making them ideal companions for quantum processors.

The implementation of cryogenic control electronics in close proximity to quantum bits (qubits) substantially reduces signal latency and noise - two critical factors limiting quantum computing performance. Current research indicates that integrating cryogenic CMOS, superconducting electronics, or single-flux quantum (SFQ) circuits directly with quantum processors could enable scaling beyond the current limitations of room-temperature control systems.

Several pioneering experiments have demonstrated that cryogenic electronics can reduce the interconnect complexity that currently plagues quantum systems. By placing control and readout circuits within the cryogenic environment, researchers have achieved up to 10x improvements in qubit readout fidelity and significant reductions in thermal noise contribution.

The material properties of semiconductors at cryogenic temperatures also offer unique advantages for quantum integration. Silicon-based cryogenic electronics exhibit dramatically reduced phonon scattering, while superconducting materials eliminate resistive losses entirely, enabling circuit designs that would be impossible with traditional electronics operating at room temperature.

Looking forward, the co-development of specialized cryogenic electronic interfaces and quantum processors represents a promising path toward practical quantum advantage. Industry projections suggest that purpose-built cryogenic control systems could enable quantum computers to scale beyond 1,000 logical qubits - a critical threshold for many practical applications.

The economic implications of this integration extend beyond quantum computing itself, potentially revolutionizing fields like materials science, cryptography, and pharmaceutical development. As cryogenic electronic manufacturing techniques mature, the cost-performance ratio continues to improve, gradually removing one of the major barriers to widespread quantum computing adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!