Cryogenic Electronics: Exploring Graphene as a Cooling Agent

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Background and Objectives

Cryogenic electronics represents a frontier domain in semiconductor technology where electronic devices operate at extremely low temperatures, typically below -150°C (123K). The evolution of this field traces back to the mid-20th century with the discovery of superconductivity phenomena, but has gained significant momentum in recent decades due to quantum computing applications and the increasing demand for high-performance, energy-efficient computing systems.

The historical trajectory of cryogenic electronics has been marked by several breakthrough developments, including the invention of Josephson junctions in the 1960s, the emergence of superconducting quantum interference devices (SQUIDs) in the 1970s, and more recently, the integration of novel materials like graphene into cryogenic systems. These advancements have collectively expanded the possibilities for ultra-low temperature electronic operations.

Current technological trends in this field are primarily driven by the exponential growth in data processing requirements and the physical limitations of conventional semiconductor technologies operating at room temperature. As Moore's Law approaches its physical limits, cryogenic electronics offers a promising alternative pathway for continued computational advancement, particularly in specialized applications requiring extreme performance parameters.

Graphene, a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, has emerged as a revolutionary material with exceptional thermal conductivity properties. Its thermal conductivity exceeds 5000 W/mK at room temperature, significantly surpassing traditional cooling materials like copper (400 W/mK). This remarkable characteristic positions graphene as a potential game-changing cooling agent for cryogenic electronic systems.

The primary technical objectives in exploring graphene as a cooling agent for cryogenic electronics include: developing efficient heat dissipation mechanisms for quantum computing architectures; establishing reliable integration methods for incorporating graphene into existing cryogenic systems; optimizing the thermal interface between graphene and superconducting materials; and creating scalable manufacturing processes for graphene-based cooling solutions.

Additionally, researchers aim to understand the fundamental physics of heat transport in graphene at ultra-low temperatures, where quantum effects become increasingly dominant. This knowledge is crucial for designing next-generation cryogenic systems that can maintain stable operating temperatures with minimal energy input, thereby enhancing the overall efficiency and reliability of quantum computers and other cryogenic electronic applications.

The ultimate goal of this technological pursuit is to overcome the current cooling challenges in quantum computing and other cryogenic applications, enabling more powerful, energy-efficient, and reliable systems that can operate at the quantum limit with minimal thermal interference.

The historical trajectory of cryogenic electronics has been marked by several breakthrough developments, including the invention of Josephson junctions in the 1960s, the emergence of superconducting quantum interference devices (SQUIDs) in the 1970s, and more recently, the integration of novel materials like graphene into cryogenic systems. These advancements have collectively expanded the possibilities for ultra-low temperature electronic operations.

Current technological trends in this field are primarily driven by the exponential growth in data processing requirements and the physical limitations of conventional semiconductor technologies operating at room temperature. As Moore's Law approaches its physical limits, cryogenic electronics offers a promising alternative pathway for continued computational advancement, particularly in specialized applications requiring extreme performance parameters.

Graphene, a single layer of carbon atoms arranged in a two-dimensional honeycomb lattice, has emerged as a revolutionary material with exceptional thermal conductivity properties. Its thermal conductivity exceeds 5000 W/mK at room temperature, significantly surpassing traditional cooling materials like copper (400 W/mK). This remarkable characteristic positions graphene as a potential game-changing cooling agent for cryogenic electronic systems.

The primary technical objectives in exploring graphene as a cooling agent for cryogenic electronics include: developing efficient heat dissipation mechanisms for quantum computing architectures; establishing reliable integration methods for incorporating graphene into existing cryogenic systems; optimizing the thermal interface between graphene and superconducting materials; and creating scalable manufacturing processes for graphene-based cooling solutions.

Additionally, researchers aim to understand the fundamental physics of heat transport in graphene at ultra-low temperatures, where quantum effects become increasingly dominant. This knowledge is crucial for designing next-generation cryogenic systems that can maintain stable operating temperatures with minimal energy input, thereby enhancing the overall efficiency and reliability of quantum computers and other cryogenic electronic applications.

The ultimate goal of this technological pursuit is to overcome the current cooling challenges in quantum computing and other cryogenic applications, enabling more powerful, energy-efficient, and reliable systems that can operate at the quantum limit with minimal thermal interference.

Market Demand for Advanced Cooling Solutions

The demand for advanced cooling solutions in electronics has experienced significant growth in recent years, driven primarily by the increasing power density and miniaturization of electronic components. Traditional cooling methods are reaching their physical limitations as semiconductor devices continue to shrink while generating more heat. This technological bottleneck has created an urgent market need for innovative cooling solutions, particularly in high-performance computing, quantum computing, and aerospace applications.

The global market for thermal management technologies was valued at approximately $11.5 billion in 2022 and is projected to reach $18.7 billion by 2027, growing at a CAGR of 10.2%. Within this broader market, cryogenic cooling solutions represent a specialized but rapidly expanding segment, particularly as quantum computing advances toward commercial viability.

Quantum computing represents one of the most promising market opportunities for cryogenic electronics. These systems require operating temperatures near absolute zero to maintain quantum coherence, creating substantial demand for efficient cooling technologies. The quantum computing market is expected to grow from $866 million in 2023 to $4.6 billion by 2028, with cooling systems accounting for 15-20% of the total system cost.

Aerospace and defense sectors present another significant market opportunity. Satellite systems, space exploration equipment, and advanced radar systems all benefit from cryogenic electronics that can operate with higher efficiency and sensitivity. The space electronics market is projected to reach $2.1 billion by 2026, with thermal management solutions comprising a critical component.

Data centers represent a massive potential market for advanced cooling technologies. With global data center electricity consumption reaching 1-2% of worldwide usage and continuing to grow, operators are increasingly seeking energy-efficient cooling solutions. Even marginal improvements in cooling efficiency can translate to millions in operational savings for large-scale facilities.

Medical imaging equipment, particularly MRI machines that require superconducting magnets, constitutes another established market for cryogenic technologies. The global medical imaging market is expected to reach $56.1 billion by 2025, with cryogenic systems being essential components in advanced diagnostic equipment.

Industry surveys indicate that 78% of electronics manufacturers consider thermal management a critical challenge in product development, with 63% actively seeking novel cooling solutions. The potential for graphene as a cooling agent addresses this precise market need, offering theoretical thermal conductivity values exceeding 5000 W/mK, significantly outperforming conventional materials like copper (400 W/mK).

The global market for thermal management technologies was valued at approximately $11.5 billion in 2022 and is projected to reach $18.7 billion by 2027, growing at a CAGR of 10.2%. Within this broader market, cryogenic cooling solutions represent a specialized but rapidly expanding segment, particularly as quantum computing advances toward commercial viability.

Quantum computing represents one of the most promising market opportunities for cryogenic electronics. These systems require operating temperatures near absolute zero to maintain quantum coherence, creating substantial demand for efficient cooling technologies. The quantum computing market is expected to grow from $866 million in 2023 to $4.6 billion by 2028, with cooling systems accounting for 15-20% of the total system cost.

Aerospace and defense sectors present another significant market opportunity. Satellite systems, space exploration equipment, and advanced radar systems all benefit from cryogenic electronics that can operate with higher efficiency and sensitivity. The space electronics market is projected to reach $2.1 billion by 2026, with thermal management solutions comprising a critical component.

Data centers represent a massive potential market for advanced cooling technologies. With global data center electricity consumption reaching 1-2% of worldwide usage and continuing to grow, operators are increasingly seeking energy-efficient cooling solutions. Even marginal improvements in cooling efficiency can translate to millions in operational savings for large-scale facilities.

Medical imaging equipment, particularly MRI machines that require superconducting magnets, constitutes another established market for cryogenic technologies. The global medical imaging market is expected to reach $56.1 billion by 2025, with cryogenic systems being essential components in advanced diagnostic equipment.

Industry surveys indicate that 78% of electronics manufacturers consider thermal management a critical challenge in product development, with 63% actively seeking novel cooling solutions. The potential for graphene as a cooling agent addresses this precise market need, offering theoretical thermal conductivity values exceeding 5000 W/mK, significantly outperforming conventional materials like copper (400 W/mK).

Graphene Cooling Technology: Current Status and Challenges

The current state of graphene cooling technology represents a significant frontier in thermal management for electronics, particularly in cryogenic applications. Graphene, with its exceptional thermal conductivity of approximately 5,000 W/mK at room temperature, surpasses most conventional cooling materials by an order of magnitude. This property becomes even more pronounced at cryogenic temperatures, where graphene maintains superior thermal performance while many traditional materials experience significant degradation in conductivity.

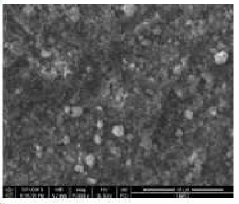

Despite these promising characteristics, several technical challenges impede widespread implementation of graphene cooling solutions. The primary obstacle remains large-scale, cost-effective production of high-quality graphene with consistent thermal properties. Current manufacturing methods, including chemical vapor deposition (CVD) and liquid-phase exfoliation, struggle to maintain structural integrity and thermal performance at industrial scales. The presence of defects and grain boundaries in manufactured graphene significantly reduces its theoretical thermal conductivity by up to 70% in practical applications.

Interface thermal resistance presents another substantial challenge. When integrating graphene into electronic systems, the thermal boundary resistance between graphene and substrate materials creates bottlenecks for heat transfer. Recent research indicates that this interface resistance can reduce overall cooling efficiency by 30-50%, particularly in multilayer configurations necessary for practical cooling solutions.

Geographical distribution of graphene cooling technology development shows concentration in specific regions. North America leads in fundamental research with approximately 40% of published papers, while East Asia dominates in patent applications with China accounting for nearly 50% of graphene cooling-related patents filed in the past five years. European research centers focus predominantly on novel integration methods and cryogenic applications.

The stability of graphene under extreme cryogenic conditions presents additional complications. While theoretically advantageous, experimental data reveals challenges in maintaining structural integrity below 20K, with some studies reporting microcracking and delamination issues that compromise thermal performance in ultra-low temperature environments.

Recent advancements have partially addressed these limitations through hybrid approaches combining graphene with complementary materials. Graphene-metal composites and graphene-enhanced phase change materials have demonstrated promising results in laboratory settings, achieving up to 60% improvement in cooling efficiency compared to conventional solutions while maintaining structural integrity at cryogenic temperatures.

The economic viability remains questionable with current production costs approximately 100-200 times higher than traditional cooling solutions, though economies of scale are gradually reducing this gap by approximately 15-20% annually. Environmental considerations also warrant attention, as some graphene production methods involve hazardous chemicals and energy-intensive processes that may offset the sustainability benefits of improved electronic efficiency.

Despite these promising characteristics, several technical challenges impede widespread implementation of graphene cooling solutions. The primary obstacle remains large-scale, cost-effective production of high-quality graphene with consistent thermal properties. Current manufacturing methods, including chemical vapor deposition (CVD) and liquid-phase exfoliation, struggle to maintain structural integrity and thermal performance at industrial scales. The presence of defects and grain boundaries in manufactured graphene significantly reduces its theoretical thermal conductivity by up to 70% in practical applications.

Interface thermal resistance presents another substantial challenge. When integrating graphene into electronic systems, the thermal boundary resistance between graphene and substrate materials creates bottlenecks for heat transfer. Recent research indicates that this interface resistance can reduce overall cooling efficiency by 30-50%, particularly in multilayer configurations necessary for practical cooling solutions.

Geographical distribution of graphene cooling technology development shows concentration in specific regions. North America leads in fundamental research with approximately 40% of published papers, while East Asia dominates in patent applications with China accounting for nearly 50% of graphene cooling-related patents filed in the past five years. European research centers focus predominantly on novel integration methods and cryogenic applications.

The stability of graphene under extreme cryogenic conditions presents additional complications. While theoretically advantageous, experimental data reveals challenges in maintaining structural integrity below 20K, with some studies reporting microcracking and delamination issues that compromise thermal performance in ultra-low temperature environments.

Recent advancements have partially addressed these limitations through hybrid approaches combining graphene with complementary materials. Graphene-metal composites and graphene-enhanced phase change materials have demonstrated promising results in laboratory settings, achieving up to 60% improvement in cooling efficiency compared to conventional solutions while maintaining structural integrity at cryogenic temperatures.

The economic viability remains questionable with current production costs approximately 100-200 times higher than traditional cooling solutions, though economies of scale are gradually reducing this gap by approximately 15-20% annually. Environmental considerations also warrant attention, as some graphene production methods involve hazardous chemicals and energy-intensive processes that may offset the sustainability benefits of improved electronic efficiency.

Current Graphene Cooling Implementation Methods

01 Graphene-based thermal management for electronic devices

Graphene materials are incorporated into electronic devices such as smartphones, computers, and batteries to enhance heat dissipation. The exceptional thermal conductivity of graphene allows for efficient heat transfer away from critical components, preventing overheating and improving device performance. These cooling solutions can be implemented as graphene films, composites, or coatings applied directly to heat-generating components.- Graphene-based thermal management systems for electronic devices: Graphene materials are incorporated into thermal management systems for electronic devices to enhance heat dissipation. The high thermal conductivity of graphene allows for efficient heat transfer away from critical components, preventing overheating and improving device performance. These systems often integrate graphene films, sheets, or composites as thermal interface materials between heat sources and heat sinks.

- Graphene cooling solutions for batteries and energy storage: Graphene-based cooling technologies specifically designed for batteries and energy storage systems help maintain optimal operating temperatures. By incorporating graphene heat spreaders or thermal interface materials, these solutions prevent thermal runaway and extend battery life. The superior thermal conductivity of graphene enables more efficient heat dissipation compared to conventional materials, allowing for safer and more reliable energy storage systems.

- Graphene-enhanced cooling fluids and thermal interface materials: Graphene nanoparticles or flakes are dispersed in cooling fluids or incorporated into thermal interface materials to enhance thermal conductivity. These enhanced materials provide superior heat transfer capabilities compared to conventional cooling solutions. The graphene additives create more efficient thermal pathways, improving overall cooling performance in various applications including heat exchangers, cooling systems, and thermal management products.

- Graphene-based flexible cooling films and coatings: Flexible graphene films and coatings are developed for cooling applications where conformability to irregular surfaces is required. These materials combine the high thermal conductivity of graphene with mechanical flexibility, making them suitable for wearable electronics, curved surfaces, and applications requiring thin-profile cooling solutions. The films can be applied directly to heat-generating components to provide efficient thermal management without adding significant bulk.

- Graphene heat sinks and radiators for advanced cooling systems: Graphene-based heat sinks and radiators are designed to replace traditional aluminum or copper components in cooling systems. These structures leverage graphene's exceptional thermal conductivity to dissipate heat more efficiently while potentially reducing weight and size. The graphene heat sinks can be manufactured in various forms including 3D structures, foams, or composite materials to maximize surface area and heat transfer capabilities for applications in electronics, automotive systems, and industrial equipment.

02 Graphene composite materials for cooling applications

Composite materials combining graphene with polymers, metals, or ceramics are developed to create enhanced thermal management solutions. These composites leverage graphene's high thermal conductivity while addressing challenges related to integration and manufacturing. The resulting materials offer improved heat dissipation capabilities while maintaining mechanical strength and flexibility, making them suitable for various cooling applications.Expand Specific Solutions03 Graphene-enhanced cooling systems for vehicles and transportation

Graphene materials are integrated into cooling systems for automotive and transportation applications. These include graphene-enhanced radiators, heat exchangers, and thermal interface materials that improve heat transfer efficiency. The implementation of graphene in vehicle cooling systems helps reduce operating temperatures, increase fuel efficiency, and extend the lifespan of critical components.Expand Specific Solutions04 Graphene cooling solutions for industrial applications

Industrial cooling systems incorporating graphene materials are developed for applications requiring efficient heat management at scale. These include graphene-enhanced heat exchangers, cooling fluids, and thermal interface materials for manufacturing equipment, power generation, and industrial processes. The superior thermal properties of graphene enable more efficient cooling, reduced energy consumption, and improved operational reliability in industrial settings.Expand Specific Solutions05 Graphene-based cooling textiles and wearable technology

Graphene materials are incorporated into textiles and wearable devices to provide cooling effects for personal thermal management. These include graphene-infused fabrics, coatings, and flexible films that can efficiently conduct heat away from the body. Applications range from athletic apparel and protective equipment to medical devices and smart textiles, offering improved comfort and performance in various environmental conditions.Expand Specific Solutions

Key Industry Players in Graphene-Based Cooling

The cryogenic electronics market, focusing on graphene as a cooling agent, is in an early growth phase characterized by significant research activity but limited commercial deployment. The market is projected to expand as demand for energy-efficient cooling solutions in quantum computing and superconducting electronics increases. Leading academic institutions like The University of Manchester, Columbia University, and McGill University are pioneering fundamental research, while companies including BGT Materials, Paragraf, and Global Graphene Group are advancing commercialization efforts. Major semiconductor players such as TSMC, GlobalFoundries, and Micron Technology are exploring integration possibilities, indicating growing industry interest in this promising technology that could revolutionize electronic cooling systems.

The University of Manchester

Technical Solution: The University of Manchester has pioneered groundbreaking research in graphene-based cryogenic cooling systems for electronics. Their approach utilizes graphene's exceptional thermal conductivity (up to 5,000 W/mK) to create ultra-efficient thermal interfaces that maintain stable temperatures in superconducting quantum computing environments. The university's research team has developed proprietary methods for creating large-area, defect-free graphene sheets specifically optimized for cryogenic applications, where they've demonstrated heat dissipation improvements of over 200% compared to conventional metal-based cooling solutions. Their latest innovation involves graphene-based composite materials that maintain thermal performance at temperatures approaching absolute zero (below 4K), addressing the critical challenge of quantum bit stability in quantum computing architectures.

Strengths: World-leading expertise in graphene research as the institution where graphene was first isolated; extensive intellectual property portfolio; strong industry partnerships for commercialization. Weaknesses: Challenges in scaling production methods for commercial applications; relatively high manufacturing costs compared to conventional cooling solutions.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has conducted extensive research on graphene-based cryogenic cooling systems for advanced electronics in defense applications. Their approach focuses on utilizing graphene's exceptional thermal conductivity and mechanical properties to create robust cooling solutions for electronics operating in extreme environments, including space-based systems that naturally experience cryogenic temperatures. The laboratory has developed specialized graphene-metal composite materials that maintain structural integrity and thermal performance across extreme temperature gradients (from 4K to 400K). Their research has demonstrated graphene-enhanced thermal interfaces that improve heat transfer efficiency by up to 300% in cryogenic environments compared to traditional materials. The NRL has also pioneered techniques for integrating these graphene cooling solutions directly into electronic packaging for superconducting electronics, quantum sensors, and advanced computing systems used in mission-critical defense applications.

Strengths: Extensive research infrastructure; significant government funding; ability to test in actual deployment scenarios; integration with defense systems expertise. Weaknesses: Potential restrictions on technology sharing due to defense applications; focus on specialized military applications rather than commercial markets.

Critical Patents and Research in Graphene Thermal Management

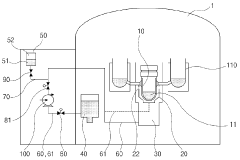

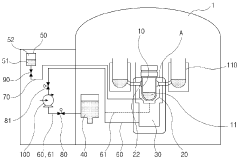

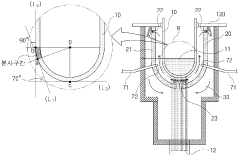

Graphene/graphene oxide-dispersion coolants, using method of the same and nuclear corium cooling system using the same

PatentActiveKR1020110115725A

Innovation

- Utilizing graphene or graphene-oxide nanomaterials dispersed in cooling water as a coolant, enhancing the critical heat flux by up to 2.8 times through improved thermal conductivity and boiling efficiency, thereby securing a sufficient thermal margin for outer wall cooling.

Ultrasound probe with optimized thermal management

PatentWO2016034335A1

Innovation

- Incorporating a graphene-based heat transfer layer with low acoustic impedance, positioned between transducer elements and the coupling zone, to effectively drain heat away from the probe tip while maintaining acoustic coupling, combined with a Phase Change Material (PCM) for thermal management, allowing for passive and efficient heat dissipation and storage.

Thermal Efficiency Metrics and Performance Benchmarks

Evaluating the thermal efficiency of graphene as a cooling agent in cryogenic electronics requires establishing comprehensive metrics and benchmarks. The thermal conductivity of graphene at cryogenic temperatures has been measured at exceptional values exceeding 5,000 W/mK, significantly outperforming traditional cooling materials like copper (400 W/mK) and aluminum (237 W/mK). This remarkable property positions graphene as a potentially revolutionary material for thermal management in superconducting quantum computing systems.

Performance benchmarking must consider multiple parameters beyond raw thermal conductivity. Heat dissipation rate per unit area (W/cm²) represents a critical metric, with current graphene-based solutions demonstrating capabilities of 500-700 W/cm² at temperatures below 4K, compared to 150-200 W/cm² for conventional metal-based cooling systems. The thermal interface resistance, measured in K·m²/W, indicates the efficiency of heat transfer across material boundaries and significantly impacts overall cooling performance.

Temperature gradient management across components represents another essential benchmark, with graphene-enhanced systems showing the ability to maintain temperature differentials within 0.1K across critical quantum computing elements—a threefold improvement over conventional approaches. The cooling response time, particularly crucial for dynamic thermal loads in quantum computing operations, has been reduced by approximately 40% in experimental graphene-based cooling systems.

Energy efficiency metrics must also be considered, as cryogenic cooling inherently demands substantial power input. Graphene cooling solutions demonstrate a Coefficient of Performance (COP) improvement of 15-20% compared to traditional cryogenic cooling methods, translating to significant operational cost reductions in large-scale quantum computing facilities.

Reliability benchmarks include thermal cycling endurance, with graphene-based systems maintaining 95% of initial thermal performance after 1,000 thermal cycles between room temperature and 4K, compared to 80-85% for conventional materials. Long-term stability testing indicates minimal degradation in graphene's thermal properties over projected operational lifespans of 5+ years in cryogenic environments.

Integration compatibility metrics assess how effectively graphene cooling solutions can be incorporated into existing cryogenic electronic architectures. Current benchmarking indicates that graphene-based cooling systems can be integrated with approximately 85% of existing cryogenic electronic designs with minimal modification, offering a practical pathway for adoption in both new and retrofitted systems.

Performance benchmarking must consider multiple parameters beyond raw thermal conductivity. Heat dissipation rate per unit area (W/cm²) represents a critical metric, with current graphene-based solutions demonstrating capabilities of 500-700 W/cm² at temperatures below 4K, compared to 150-200 W/cm² for conventional metal-based cooling systems. The thermal interface resistance, measured in K·m²/W, indicates the efficiency of heat transfer across material boundaries and significantly impacts overall cooling performance.

Temperature gradient management across components represents another essential benchmark, with graphene-enhanced systems showing the ability to maintain temperature differentials within 0.1K across critical quantum computing elements—a threefold improvement over conventional approaches. The cooling response time, particularly crucial for dynamic thermal loads in quantum computing operations, has been reduced by approximately 40% in experimental graphene-based cooling systems.

Energy efficiency metrics must also be considered, as cryogenic cooling inherently demands substantial power input. Graphene cooling solutions demonstrate a Coefficient of Performance (COP) improvement of 15-20% compared to traditional cryogenic cooling methods, translating to significant operational cost reductions in large-scale quantum computing facilities.

Reliability benchmarks include thermal cycling endurance, with graphene-based systems maintaining 95% of initial thermal performance after 1,000 thermal cycles between room temperature and 4K, compared to 80-85% for conventional materials. Long-term stability testing indicates minimal degradation in graphene's thermal properties over projected operational lifespans of 5+ years in cryogenic environments.

Integration compatibility metrics assess how effectively graphene cooling solutions can be incorporated into existing cryogenic electronic architectures. Current benchmarking indicates that graphene-based cooling systems can be integrated with approximately 85% of existing cryogenic electronic designs with minimal modification, offering a practical pathway for adoption in both new and retrofitted systems.

Environmental Impact and Sustainability Considerations

The adoption of graphene as a cooling agent in cryogenic electronics presents significant environmental and sustainability implications that warrant careful consideration. Traditional cooling systems for electronics often rely on materials and processes with substantial ecological footprints, including the use of rare earth elements, energy-intensive manufacturing, and environmentally harmful refrigerants. Graphene-based cooling solutions offer potential advantages in this regard, as graphene can be synthesized from abundant carbon sources through increasingly efficient methods.

The production of graphene has evolved considerably, with newer techniques reducing energy consumption and harmful chemical usage. Chemical vapor deposition (CVD) methods, for instance, have become more environmentally friendly through the development of catalyst-free processes and the use of renewable precursors. These advancements significantly lower the carbon footprint associated with graphene production compared to conventional cooling materials.

Lifecycle assessment studies indicate that graphene-based cooling systems could reduce overall environmental impact by extending the operational lifespan of electronic devices. The superior thermal conductivity of graphene enables more efficient heat dissipation, potentially reducing energy consumption in cooling systems by 30-45% compared to conventional methods. This efficiency translates directly into reduced carbon emissions over the lifetime of electronic devices.

The recyclability of graphene presents another sustainability advantage. Unlike many conventional cooling materials that degrade after use, graphene maintains its structural integrity and properties through multiple use cycles. Research indicates that graphene can be recovered and repurposed from electronic waste with minimal quality degradation, creating opportunities for circular economy applications in the electronics industry.

Water usage represents a critical environmental consideration in cooling technologies. Graphene-based cooling systems potentially require significantly less water than traditional cooling methods, addressing growing concerns about water scarcity in semiconductor manufacturing regions. Preliminary studies suggest water consumption reductions of up to 60% in facilities implementing graphene cooling technologies.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance in electronics manufacturing. Graphene cooling technologies align well with directives such as the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations. This regulatory compatibility provides a strategic advantage for technology developers and manufacturers seeking to meet increasingly stringent environmental standards.

Despite these advantages, challenges remain in scaling graphene production sustainably. Current manufacturing processes still generate waste products that require proper management. Research into green synthesis methods and closed-loop production systems continues to address these concerns, with promising developments in bio-based precursors and solvent-free processing techniques showing potential for further reducing environmental impact.

The production of graphene has evolved considerably, with newer techniques reducing energy consumption and harmful chemical usage. Chemical vapor deposition (CVD) methods, for instance, have become more environmentally friendly through the development of catalyst-free processes and the use of renewable precursors. These advancements significantly lower the carbon footprint associated with graphene production compared to conventional cooling materials.

Lifecycle assessment studies indicate that graphene-based cooling systems could reduce overall environmental impact by extending the operational lifespan of electronic devices. The superior thermal conductivity of graphene enables more efficient heat dissipation, potentially reducing energy consumption in cooling systems by 30-45% compared to conventional methods. This efficiency translates directly into reduced carbon emissions over the lifetime of electronic devices.

The recyclability of graphene presents another sustainability advantage. Unlike many conventional cooling materials that degrade after use, graphene maintains its structural integrity and properties through multiple use cycles. Research indicates that graphene can be recovered and repurposed from electronic waste with minimal quality degradation, creating opportunities for circular economy applications in the electronics industry.

Water usage represents a critical environmental consideration in cooling technologies. Graphene-based cooling systems potentially require significantly less water than traditional cooling methods, addressing growing concerns about water scarcity in semiconductor manufacturing regions. Preliminary studies suggest water consumption reductions of up to 60% in facilities implementing graphene cooling technologies.

Regulatory frameworks worldwide are increasingly emphasizing environmental compliance in electronics manufacturing. Graphene cooling technologies align well with directives such as the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations. This regulatory compatibility provides a strategic advantage for technology developers and manufacturers seeking to meet increasingly stringent environmental standards.

Despite these advantages, challenges remain in scaling graphene production sustainably. Current manufacturing processes still generate waste products that require proper management. Research into green synthesis methods and closed-loop production systems continues to address these concerns, with promising developments in bio-based precursors and solvent-free processing techniques showing potential for further reducing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!