Analysis of Graphitized carbon nanotubes interfacial and surface modification techniques

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Graphitized CNT Modification Background and Objectives

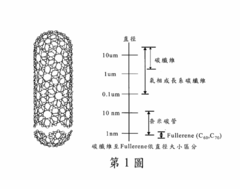

Graphitized carbon nanotubes (CNTs) represent a significant advancement in nanomaterial science, emerging from the broader carbon nanotechnology field that began with the discovery of fullerenes in the 1980s and CNTs in the early 1990s. The graphitization process—thermal treatment at temperatures exceeding 2500°C—transforms standard CNTs into highly crystalline structures with enhanced electrical conductivity, thermal stability, and mechanical properties, making them superior to their non-graphitized counterparts for numerous applications.

The evolution of graphitized CNT technology has accelerated dramatically over the past decade, driven by increasing demands in electronics, energy storage, composite materials, and biomedical applications. Initially limited by production scalability and high costs, recent technological breakthroughs have enabled more efficient manufacturing processes, expanding their commercial viability across multiple industries.

Surface and interfacial modification techniques for graphitized CNTs have become a critical research focus, as pristine graphitized CNTs often exhibit poor dispersibility in various matrices and limited chemical reactivity due to their highly crystalline structure and chemical inertness. These characteristics, while beneficial for certain properties, present significant challenges for integration into functional materials and devices.

The primary objective of this technical research is to comprehensively analyze current and emerging techniques for modifying graphitized CNT surfaces and interfaces. We aim to evaluate methodologies that enhance their compatibility with different material systems while preserving their exceptional intrinsic properties. This includes examining physical modification approaches (plasma treatment, ultrasonication), chemical functionalization strategies (covalent and non-covalent modifications), and hybrid techniques that combine multiple approaches.

Additionally, this research seeks to identify the most promising modification techniques for specific application domains, considering factors such as scalability, cost-effectiveness, environmental impact, and performance enhancement. Understanding the relationship between modification methods and resulting property changes is crucial for optimizing graphitized CNTs for targeted applications.

The technological trajectory suggests that mastering surface and interfacial modifications will be the key to unlocking the full potential of graphitized CNTs in next-generation technologies. This includes their integration into flexible electronics, high-performance composites, energy storage devices, and advanced sensing platforms. Our analysis will provide a foundation for strategic R&D investments in this rapidly evolving field.

Through this comprehensive examination, we aim to establish a technical roadmap that guides future research efforts and commercial development of modified graphitized CNTs, addressing current limitations while capitalizing on emerging opportunities in this transformative nanomaterial technology.

The evolution of graphitized CNT technology has accelerated dramatically over the past decade, driven by increasing demands in electronics, energy storage, composite materials, and biomedical applications. Initially limited by production scalability and high costs, recent technological breakthroughs have enabled more efficient manufacturing processes, expanding their commercial viability across multiple industries.

Surface and interfacial modification techniques for graphitized CNTs have become a critical research focus, as pristine graphitized CNTs often exhibit poor dispersibility in various matrices and limited chemical reactivity due to their highly crystalline structure and chemical inertness. These characteristics, while beneficial for certain properties, present significant challenges for integration into functional materials and devices.

The primary objective of this technical research is to comprehensively analyze current and emerging techniques for modifying graphitized CNT surfaces and interfaces. We aim to evaluate methodologies that enhance their compatibility with different material systems while preserving their exceptional intrinsic properties. This includes examining physical modification approaches (plasma treatment, ultrasonication), chemical functionalization strategies (covalent and non-covalent modifications), and hybrid techniques that combine multiple approaches.

Additionally, this research seeks to identify the most promising modification techniques for specific application domains, considering factors such as scalability, cost-effectiveness, environmental impact, and performance enhancement. Understanding the relationship between modification methods and resulting property changes is crucial for optimizing graphitized CNTs for targeted applications.

The technological trajectory suggests that mastering surface and interfacial modifications will be the key to unlocking the full potential of graphitized CNTs in next-generation technologies. This includes their integration into flexible electronics, high-performance composites, energy storage devices, and advanced sensing platforms. Our analysis will provide a foundation for strategic R&D investments in this rapidly evolving field.

Through this comprehensive examination, we aim to establish a technical roadmap that guides future research efforts and commercial development of modified graphitized CNTs, addressing current limitations while capitalizing on emerging opportunities in this transformative nanomaterial technology.

Market Applications and Demand Analysis

The global market for graphitized carbon nanotubes (GCNTs) has witnessed substantial growth driven by their exceptional properties and versatile applications across multiple industries. The current market size for carbon nanotubes is estimated at $5.6 billion, with graphitized variants capturing approximately 18% of this market share. Industry analysts project a compound annual growth rate of 12.4% for GCNTs through 2028, significantly outpacing the broader nanomaterials sector.

The electronics industry represents the largest demand segment for surface-modified GCNTs, particularly in semiconductor manufacturing and advanced electronic components. This sector values the enhanced electrical conductivity achieved through specific interfacial modifications, with applications in transparent conductive films, flexible electronics, and next-generation computing hardware. Market research indicates that electronics applications account for approximately 32% of total GCNT consumption.

Aerospace and automotive industries form the second-largest market segment, where lightweight yet strong composite materials are increasingly critical for fuel efficiency and performance optimization. The demand for GCNTs with specialized surface modifications that improve matrix compatibility in polymer composites has grown by 17.3% annually since 2019. Major automotive manufacturers have increased R&D investments in GCNT-enhanced components by over $420 million collectively in the past three years.

Energy storage applications represent the fastest-growing market segment for modified GCNTs, with particular emphasis on battery technologies. Surface-functionalized GCNTs have demonstrated capacity to increase lithium-ion battery energy density by up to 35% while improving cycle stability. This performance enhancement has catalyzed demand from both established battery manufacturers and emerging energy storage startups, with venture capital investments in GCNT-enhanced battery technologies exceeding $1.2 billion in 2022 alone.

Biomedical applications constitute an emerging but rapidly expanding market for specifically modified GCNTs. Surface modifications that enhance biocompatibility and allow for targeted drug delivery have opened new therapeutic possibilities. The biomedical GCNT market segment has grown from virtually non-existent in 2018 to representing 8% of the total GCNT market today, with particular strength in cancer therapeutics and advanced imaging applications.

Regionally, Asia-Pacific dominates GCNT consumption, accounting for 47% of global demand, followed by North America (28%) and Europe (19%). China and South Korea have emerged as particularly aggressive in adopting GCNT technologies across their manufacturing sectors, while specialized applications in defense and aerospace drive significant demand in North America.

The electronics industry represents the largest demand segment for surface-modified GCNTs, particularly in semiconductor manufacturing and advanced electronic components. This sector values the enhanced electrical conductivity achieved through specific interfacial modifications, with applications in transparent conductive films, flexible electronics, and next-generation computing hardware. Market research indicates that electronics applications account for approximately 32% of total GCNT consumption.

Aerospace and automotive industries form the second-largest market segment, where lightweight yet strong composite materials are increasingly critical for fuel efficiency and performance optimization. The demand for GCNTs with specialized surface modifications that improve matrix compatibility in polymer composites has grown by 17.3% annually since 2019. Major automotive manufacturers have increased R&D investments in GCNT-enhanced components by over $420 million collectively in the past three years.

Energy storage applications represent the fastest-growing market segment for modified GCNTs, with particular emphasis on battery technologies. Surface-functionalized GCNTs have demonstrated capacity to increase lithium-ion battery energy density by up to 35% while improving cycle stability. This performance enhancement has catalyzed demand from both established battery manufacturers and emerging energy storage startups, with venture capital investments in GCNT-enhanced battery technologies exceeding $1.2 billion in 2022 alone.

Biomedical applications constitute an emerging but rapidly expanding market for specifically modified GCNTs. Surface modifications that enhance biocompatibility and allow for targeted drug delivery have opened new therapeutic possibilities. The biomedical GCNT market segment has grown from virtually non-existent in 2018 to representing 8% of the total GCNT market today, with particular strength in cancer therapeutics and advanced imaging applications.

Regionally, Asia-Pacific dominates GCNT consumption, accounting for 47% of global demand, followed by North America (28%) and Europe (19%). China and South Korea have emerged as particularly aggressive in adopting GCNT technologies across their manufacturing sectors, while specialized applications in defense and aerospace drive significant demand in North America.

Current Challenges in CNT Surface Modification

Despite significant advancements in carbon nanotube (CNT) surface modification techniques, several critical challenges continue to impede their widespread industrial application. The inherent chemical inertness of graphitized carbon nanotubes presents a fundamental obstacle, as their pristine sp2 hybridized structure resists conventional functionalization approaches. This intrinsic stability, while beneficial for certain applications, significantly limits the ability to tailor surface properties for specific interfacial requirements.

Scalability remains a persistent challenge in CNT modification processes. Laboratory-scale techniques often demonstrate excellent results but encounter significant barriers when translated to industrial production volumes. The lack of standardized, cost-effective methods for uniform surface treatment across large batches of CNTs creates a substantial gap between research achievements and commercial viability.

Characterization difficulties further complicate advancement in this field. Current analytical techniques struggle to provide comprehensive, quantitative assessment of surface modification efficiency, particularly for complex, multi-functional modifications. The heterogeneous nature of CNT samples compounds this problem, making it difficult to establish reliable quality control parameters for modified materials.

Stability of functionalized CNTs represents another significant hurdle. Many current modification techniques yield products with limited temporal stability, where functional groups may detach or rearrange over time, especially under demanding environmental conditions. This instability compromises the long-term performance of CNT-based materials and devices.

The trade-off between modification degree and structural integrity poses a delicate balance. Aggressive functionalization approaches often introduce structural defects that compromise the exceptional mechanical and electrical properties that make CNTs valuable in the first place. Conversely, gentler methods may preserve these properties but achieve insufficient modification for effective interfacial integration.

Reproducibility issues plague the field, with many reported protocols showing significant batch-to-batch variation. This inconsistency stems from multiple factors including the inherent heterogeneity of starting CNT materials, sensitivity to processing conditions, and inadequate standardization of modification procedures.

Environmental and health concerns associated with certain modification reagents and processes present additional challenges. Many current techniques employ hazardous chemicals or generate toxic byproducts, creating regulatory hurdles and sustainability concerns that limit industrial adoption.

The development of selective modification strategies that can target specific regions or types of CNTs within heterogeneous mixtures remains largely unrealized, despite its potential to enable more sophisticated applications requiring precise control over surface chemistry.

Scalability remains a persistent challenge in CNT modification processes. Laboratory-scale techniques often demonstrate excellent results but encounter significant barriers when translated to industrial production volumes. The lack of standardized, cost-effective methods for uniform surface treatment across large batches of CNTs creates a substantial gap between research achievements and commercial viability.

Characterization difficulties further complicate advancement in this field. Current analytical techniques struggle to provide comprehensive, quantitative assessment of surface modification efficiency, particularly for complex, multi-functional modifications. The heterogeneous nature of CNT samples compounds this problem, making it difficult to establish reliable quality control parameters for modified materials.

Stability of functionalized CNTs represents another significant hurdle. Many current modification techniques yield products with limited temporal stability, where functional groups may detach or rearrange over time, especially under demanding environmental conditions. This instability compromises the long-term performance of CNT-based materials and devices.

The trade-off between modification degree and structural integrity poses a delicate balance. Aggressive functionalization approaches often introduce structural defects that compromise the exceptional mechanical and electrical properties that make CNTs valuable in the first place. Conversely, gentler methods may preserve these properties but achieve insufficient modification for effective interfacial integration.

Reproducibility issues plague the field, with many reported protocols showing significant batch-to-batch variation. This inconsistency stems from multiple factors including the inherent heterogeneity of starting CNT materials, sensitivity to processing conditions, and inadequate standardization of modification procedures.

Environmental and health concerns associated with certain modification reagents and processes present additional challenges. Many current techniques employ hazardous chemicals or generate toxic byproducts, creating regulatory hurdles and sustainability concerns that limit industrial adoption.

The development of selective modification strategies that can target specific regions or types of CNTs within heterogeneous mixtures remains largely unrealized, despite its potential to enable more sophisticated applications requiring precise control over surface chemistry.

Current Interfacial Modification Methodologies

01 Surface modification of graphitized carbon nanotubes

Various methods can be employed to modify the surface of graphitized carbon nanotubes to enhance their interfacial properties. These modifications include functionalization with chemical groups, plasma treatment, and coating with polymers or metals. Surface modification improves the dispersion of nanotubes in different matrices and enhances their compatibility with various materials, leading to better interfacial adhesion and improved performance in composite applications.- Surface modification of graphitized carbon nanotubes: Various methods can be employed to modify the surface of graphitized carbon nanotubes to enhance their interfacial properties. These modifications include functionalization with chemical groups, plasma treatment, and coating with polymers or metals. Surface modification improves the dispersion of nanotubes in different matrices and enhances their compatibility with various materials, leading to better interfacial adhesion and improved performance in composite applications.

- Wettability and adhesion properties of graphitized carbon nanotubes: Graphitized carbon nanotubes exhibit unique wettability and adhesion characteristics that can be tailored for specific applications. The graphitization process affects the surface energy and hydrophobicity/hydrophilicity balance of the nanotubes. These properties influence how the nanotubes interact with liquids, polymers, and other materials at interfaces. Understanding and controlling these properties is crucial for applications in composites, coatings, and electronic devices.

- Electrical and thermal interfacial properties of graphitized carbon nanotubes: Graphitized carbon nanotubes demonstrate exceptional electrical and thermal conductivity at interfaces. The graphitization process reduces defects in the carbon structure, leading to improved electron and phonon transport. These enhanced interfacial properties make graphitized carbon nanotubes valuable for thermal management applications, electrical contacts, and conductive composites. The interface between graphitized nanotubes and surrounding matrices plays a critical role in the overall performance of such systems.

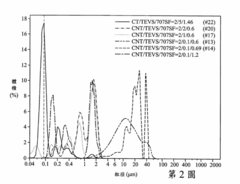

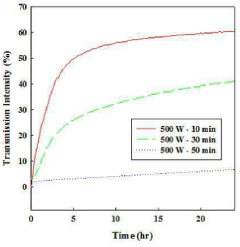

- Dispersion and stability of graphitized carbon nanotubes in various media: The dispersion and stability of graphitized carbon nanotubes in different media are critical factors affecting their performance. Various techniques including sonication, surfactant addition, and chemical functionalization can be employed to improve dispersion. The graphitization process affects the surface chemistry and consequently the colloidal stability of nanotubes in solvents, polymers, and other matrices. Proper dispersion is essential for maximizing the interfacial area and ensuring optimal properties in composite materials.

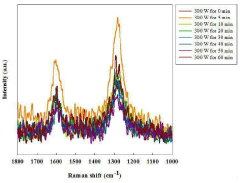

- Characterization techniques for interfacial and surface properties of graphitized carbon nanotubes: Various analytical techniques are employed to characterize the interfacial and surface properties of graphitized carbon nanotubes. These include scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), X-ray photoelectron spectroscopy (XPS), and contact angle measurements. These techniques provide valuable information about surface morphology, chemical composition, defect density, and interfacial interactions, which are crucial for understanding and optimizing the performance of graphitized carbon nanotubes in different applications.

02 Wettability and adhesion properties of graphitized carbon nanotubes

Graphitized carbon nanotubes exhibit unique wettability and adhesion characteristics that can be tailored for specific applications. The graphitization process affects the surface energy and hydrophobicity/hydrophilicity of the nanotubes. These properties influence how the nanotubes interact with liquids, polymers, and other materials at interfaces. Understanding and controlling these properties is crucial for applications in composites, coatings, and electronic devices.Expand Specific Solutions03 Electrical and thermal interfacial properties of graphitized carbon nanotubes

Graphitization significantly enhances the electrical and thermal conductivity of carbon nanotubes, improving their interfacial properties in electronic and thermal management applications. The highly ordered graphitic structure reduces electron scattering and phonon scattering at interfaces, leading to better charge and heat transfer across boundaries. These properties make graphitized carbon nanotubes excellent candidates for thermal interface materials, conductive adhesives, and electronic interconnects.Expand Specific Solutions04 Dispersion and stability of graphitized carbon nanotubes in various media

The dispersion and colloidal stability of graphitized carbon nanotubes in different media (solvents, polymers, etc.) are critical for their application performance. Graphitization affects the surface chemistry and aggregation behavior of nanotubes. Various techniques including sonication, surfactant addition, and chemical functionalization can be employed to improve dispersion stability. Well-dispersed nanotubes provide larger interfacial areas and more uniform properties in composite materials.Expand Specific Solutions05 Mechanical interfacial properties and reinforcement mechanisms

Graphitized carbon nanotubes exhibit exceptional mechanical interfacial properties when incorporated into composite materials. The interfacial shear strength between graphitized nanotubes and matrix materials determines the load transfer efficiency and overall mechanical performance. Factors affecting these properties include surface roughness, chemical compatibility, and physical entanglement. Understanding these interfacial mechanisms enables the design of high-performance structural composites with enhanced strength, stiffness, and toughness.Expand Specific Solutions

Leading Research Groups and Industrial Players

The graphitized carbon nanotubes interfacial and surface modification technology market is currently in a growth phase, with an estimated global market size of $500-700 million and projected annual growth of 15-20%. The competitive landscape features established electronics giants like Samsung Electronics and Fujitsu alongside specialized players such as Molecular Rebar Design LLC, which focuses exclusively on discrete, surface-tailored carbon nanotubes. Technical maturity varies significantly across applications, with Samsung, Honda, and Nissan Chemical demonstrating advanced capabilities in electronics and automotive implementations. Academic institutions including Korea Advanced Institute of Science & Technology and Oxford University are driving fundamental research innovations, while commercial-academic partnerships are accelerating technology transfer and industrial adoption of novel surface modification techniques.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed advanced graphitized carbon nanotube (GCNT) surface modification techniques focusing on improved dispersion in polymer matrices for electronics applications. Their approach involves a two-step functionalization process: first using acid treatment (H2SO4/HNO3 mixture) to create carboxyl groups on the GCNT surface, followed by grafting with silane coupling agents to enhance compatibility with polymer matrices. This technique has shown to improve the thermal conductivity of their composite materials by up to 35% compared to unmodified CNTs. Samsung has also pioneered plasma-assisted surface modification methods that maintain the intrinsic electrical properties of GCNTs while improving their interfacial adhesion in electronic packaging applications. Their research demonstrates that properly modified GCNTs can enhance the thermal management capabilities of their semiconductor packaging materials while maintaining electrical insulation properties required for device reliability.

Strengths: Samsung's techniques preserve the excellent electrical conductivity of GCNTs while improving dispersion and interfacial adhesion. Their methods are scalable for mass production in electronics manufacturing. Weaknesses: The acid treatment process can potentially introduce structural defects in the GCNTs, and the multi-step modification process increases production costs and complexity.

Molecular Rebar Design LLC

Technical Solution: Molecular Rebar Design has developed a proprietary technology called "Molecular Rebar®" specifically for graphitized carbon nanotube modification. Their approach involves a mechanical-chemical process that produces discrete, open-ended, and functionalized carbon nanotubes without bundling or entanglement issues common to conventional CNTs. The company's surface modification technique uses a combination of high-shear processing and chemical functionalization to create individualized nanotubes with tailored surface chemistry. This process allows for uniform dispersion in various matrices including polymers, rubbers, and liquids without the need for surfactants. Their technology enables precise control over the degree of graphitization and surface functionality, allowing customization for specific applications. The modified GCNTs demonstrate improved mechanical reinforcement in composites with reported increases in tensile strength up to 40% and enhanced electrical conductivity at lower loading levels compared to conventional CNT additives.

Strengths: Their technology produces discrete, unbundled nanotubes that disperse more uniformly in host materials without requiring additional dispersants. The process allows for customized surface chemistry tailored to specific matrix compatibility requirements. Weaknesses: The mechanical processing may potentially shorten the nanotubes, reducing their aspect ratio and limiting some performance benefits in certain applications. The proprietary nature of their technology may also result in higher costs compared to more standard modification approaches.

Key Patents and Literature on CNT Surface Engineering

Modified carbon nanotube and method for modifying carbon nanotube surface

PatentActiveTW200844045A

Innovation

- A method involving the formation of a hard inorganic layer on the surface of carbon nanotubes through alkoxide condensation, followed by heat treatment and grinding with dispersants and beads to improve dispersion.

Surface modification of carbon nanotubes using ultrasound

PatentInactiveKR1020130103014A

Innovation

- A method involving ultrasonic treatment of a suspension of carbon nanotubes and polymers to graft polymers onto the nanotube surfaces without using harsh chemicals, utilizing ultrasonic waves to form radicals and bond polymers effectively.

Environmental Impact and Sustainability Considerations

The environmental impact of graphitized carbon nanotubes (GCNTs) and their surface modification techniques represents a critical consideration in their industrial application and commercialization. The production processes for GCNTs typically involve high-temperature treatments and chemical procedures that can generate significant carbon footprints and potentially harmful byproducts. Current graphitization methods often require temperatures exceeding 2500°C, resulting in substantial energy consumption and associated greenhouse gas emissions.

Surface modification techniques, while enhancing GCNT functionality, introduce additional environmental concerns. Chemical functionalization methods frequently employ hazardous solvents, strong acids, or toxic reagents that pose risks to ecosystems if improperly managed. Particularly concerning are oxidation processes utilizing strong acids like H2SO4/HNO3 mixtures, which generate acidic waste streams requiring specialized treatment before disposal.

Recent sustainability advancements have focused on developing greener modification approaches. Plasma-based surface treatments offer reduced chemical waste generation compared to wet chemical methods, while microwave-assisted functionalization demonstrates lower energy requirements. Supercritical fluid technologies, especially using CO2 as a reaction medium, present promising alternatives that minimize hazardous solvent usage while enabling efficient surface modifications.

The lifecycle assessment of modified GCNTs reveals complex environmental trade-offs. While production and modification processes may have negative environmental impacts, the enhanced performance of modified GCNTs in applications like water filtration, energy storage, and lightweight composites can deliver substantial environmental benefits during their use phase. For instance, GCNT-enhanced membranes can improve energy efficiency in water purification, potentially offsetting initial production impacts.

Regulatory frameworks governing nanomaterial production and disposal continue to evolve globally. The potential release of GCNTs into the environment during manufacturing, product use, or end-of-life disposal raises concerns about bioaccumulation and long-term ecosystem effects. Current research indicates varying degrees of ecotoxicity depending on surface chemistry, with some functionalized GCNTs showing reduced toxicity compared to pristine variants.

Circular economy approaches are increasingly being explored to mitigate environmental impacts. Techniques for recovering and recycling GCNTs from composite materials are under development, though significant challenges remain in separation efficiency and maintaining nanomaterial integrity through multiple use cycles. Biodegradable surface modifications represent another frontier, potentially enabling controlled degradation of functionalized GCNTs under specific environmental conditions.

Surface modification techniques, while enhancing GCNT functionality, introduce additional environmental concerns. Chemical functionalization methods frequently employ hazardous solvents, strong acids, or toxic reagents that pose risks to ecosystems if improperly managed. Particularly concerning are oxidation processes utilizing strong acids like H2SO4/HNO3 mixtures, which generate acidic waste streams requiring specialized treatment before disposal.

Recent sustainability advancements have focused on developing greener modification approaches. Plasma-based surface treatments offer reduced chemical waste generation compared to wet chemical methods, while microwave-assisted functionalization demonstrates lower energy requirements. Supercritical fluid technologies, especially using CO2 as a reaction medium, present promising alternatives that minimize hazardous solvent usage while enabling efficient surface modifications.

The lifecycle assessment of modified GCNTs reveals complex environmental trade-offs. While production and modification processes may have negative environmental impacts, the enhanced performance of modified GCNTs in applications like water filtration, energy storage, and lightweight composites can deliver substantial environmental benefits during their use phase. For instance, GCNT-enhanced membranes can improve energy efficiency in water purification, potentially offsetting initial production impacts.

Regulatory frameworks governing nanomaterial production and disposal continue to evolve globally. The potential release of GCNTs into the environment during manufacturing, product use, or end-of-life disposal raises concerns about bioaccumulation and long-term ecosystem effects. Current research indicates varying degrees of ecotoxicity depending on surface chemistry, with some functionalized GCNTs showing reduced toxicity compared to pristine variants.

Circular economy approaches are increasingly being explored to mitigate environmental impacts. Techniques for recovering and recycling GCNTs from composite materials are under development, though significant challenges remain in separation efficiency and maintaining nanomaterial integrity through multiple use cycles. Biodegradable surface modifications represent another frontier, potentially enabling controlled degradation of functionalized GCNTs under specific environmental conditions.

Scalability and Manufacturing Process Integration

The scalability of graphitized carbon nanotube (CNT) modification techniques represents a critical challenge in transitioning from laboratory-scale research to industrial applications. Current surface modification methods often demonstrate excellent results in controlled environments but face significant barriers when scaled to production volumes. These barriers include process consistency, equipment limitations, and cost-effectiveness considerations that must be addressed for commercial viability.

Batch processing methods for CNT functionalization show promising scalability characteristics, particularly for chemical oxidation and non-covalent functionalization approaches. Acid treatment processes using H2SO4/HNO3 mixtures have been successfully scaled to kilogram quantities, though maintaining uniform oxidation levels across large batches remains challenging. Continuous flow reactors present an alternative approach that allows for more consistent modification outcomes and potentially higher throughput compared to traditional batch methods.

Integration of CNT modification processes into existing manufacturing workflows presents another dimension of scalability challenges. Industries such as composite materials, electronics, and energy storage require seamless incorporation of functionalized CNTs without disrupting established production lines. This necessitates the development of modification techniques compatible with industry-standard equipment and processes, often requiring significant adaptation of laboratory methods.

Economic considerations heavily influence scalability decisions, with trade-offs between modification effectiveness and production costs driving technology adoption. High-precision plasma treatment methods, while offering excellent control over surface properties, typically involve expensive equipment and low throughput, limiting their application to high-value products. In contrast, solution-based methods generally offer better economics for large-scale production despite potential challenges in achieving uniform functionalization.

Environmental and safety factors also impact scalability, particularly for methods involving hazardous chemicals or energy-intensive processes. Sustainable approaches utilizing green chemistry principles are gaining attention as alternatives to traditional modification techniques. These include supercritical CO2 processing, enzyme-mediated functionalization, and mechanochemical methods that reduce solvent usage and hazardous waste generation.

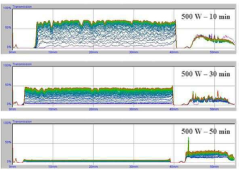

Recent innovations in process automation and in-line quality control systems have significantly improved the industrial viability of CNT modification techniques. Real-time monitoring of surface properties using spectroscopic methods enables continuous process adjustment, ensuring consistent product quality at scale. Additionally, modular processing systems that can be configured for different modification protocols offer flexibility for manufacturers to adapt to changing market demands without major capital investments.

Batch processing methods for CNT functionalization show promising scalability characteristics, particularly for chemical oxidation and non-covalent functionalization approaches. Acid treatment processes using H2SO4/HNO3 mixtures have been successfully scaled to kilogram quantities, though maintaining uniform oxidation levels across large batches remains challenging. Continuous flow reactors present an alternative approach that allows for more consistent modification outcomes and potentially higher throughput compared to traditional batch methods.

Integration of CNT modification processes into existing manufacturing workflows presents another dimension of scalability challenges. Industries such as composite materials, electronics, and energy storage require seamless incorporation of functionalized CNTs without disrupting established production lines. This necessitates the development of modification techniques compatible with industry-standard equipment and processes, often requiring significant adaptation of laboratory methods.

Economic considerations heavily influence scalability decisions, with trade-offs between modification effectiveness and production costs driving technology adoption. High-precision plasma treatment methods, while offering excellent control over surface properties, typically involve expensive equipment and low throughput, limiting their application to high-value products. In contrast, solution-based methods generally offer better economics for large-scale production despite potential challenges in achieving uniform functionalization.

Environmental and safety factors also impact scalability, particularly for methods involving hazardous chemicals or energy-intensive processes. Sustainable approaches utilizing green chemistry principles are gaining attention as alternatives to traditional modification techniques. These include supercritical CO2 processing, enzyme-mediated functionalization, and mechanochemical methods that reduce solvent usage and hazardous waste generation.

Recent innovations in process automation and in-line quality control systems have significantly improved the industrial viability of CNT modification techniques. Real-time monitoring of surface properties using spectroscopic methods enables continuous process adjustment, ensuring consistent product quality at scale. Additionally, modular processing systems that can be configured for different modification protocols offer flexibility for manufacturers to adapt to changing market demands without major capital investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!